Method and device for producing pressure high-purity nitrogen and high-purity oxygen

A high-purity oxygen and high-purity nitrogen technology, applied in the field of gas production methods and devices, can solve the problems of expensive catalysts, long process routes, and large investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

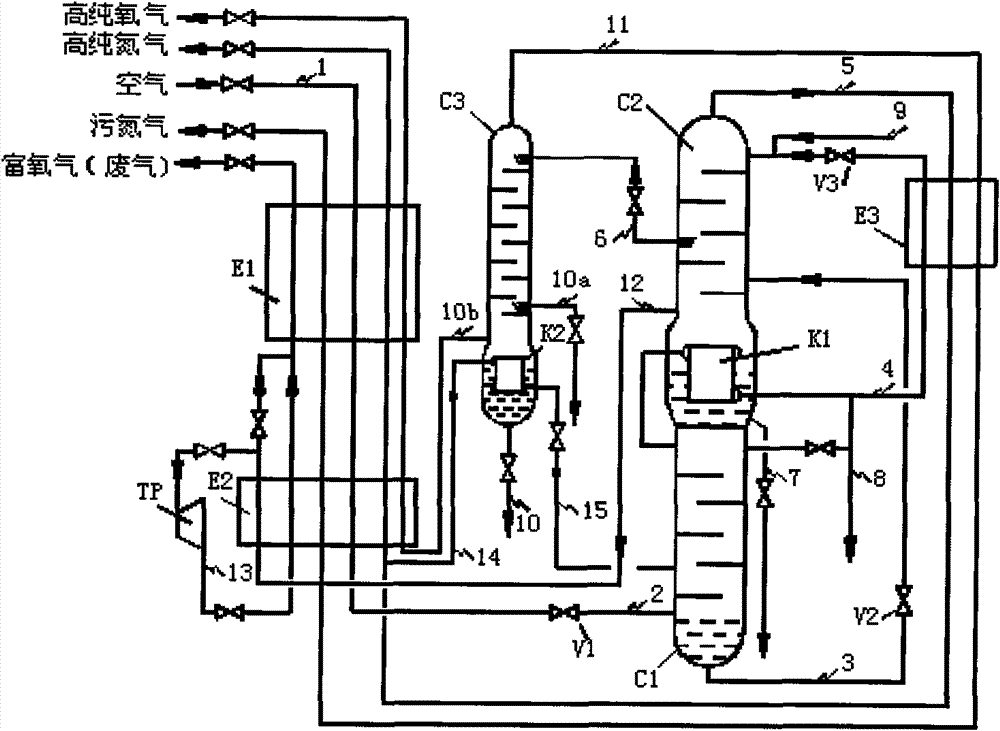

[0029] A device for producing pressurized high-purity nitrogen and high-purity oxygen, its structure is as follows figure 1 As shown, the purified air is compressed, and the purified compressed air is cooled in the air pre-cooling system, and after entering the molecular sieve purification system to remove carbon dioxide and moisture, the purified compressed air 1 enters the fractionation tower cold box in the main heat exchanger The upper section E1 and the lower section E2 heat exchange and cool down to a saturated state, and enter the high-pressure rectification tower C1 through the throttle valve V1, and part of the compressed air extracted from the lower section E2 of the main heat exchanger is used as the heat source 14 entering the reboiler of the oxygen rectification tower. Oxygen rectification tower reboiler K2, compressed air is liquefied into oxygen rectification tower reboiler condensate 15, this oxygen rectification tower reboiler condensate 15 is liquid air, enter...

Embodiment 2

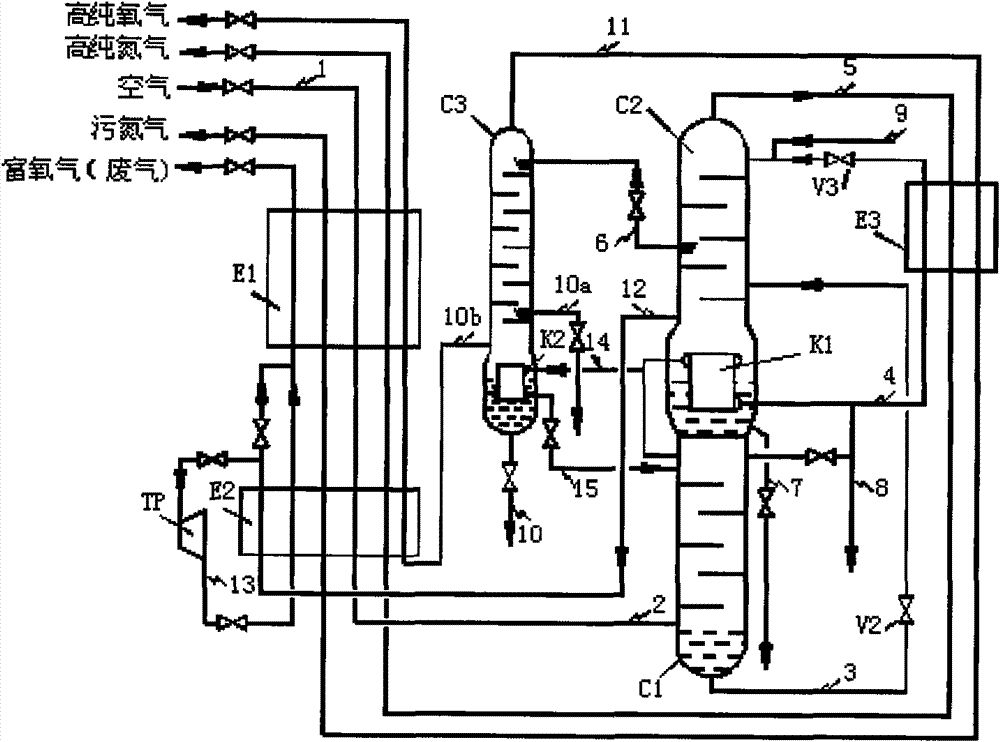

[0036] A method and device for producing pressurized high-purity nitrogen and high-purity oxygen, the structure of which is as follows figure 2 As shown, the difference from Example 1 is that the heat source entering the oxygen rectification tower reboiler K2 is the nitrogen separated by the high-pressure rectification tower C1, and the nitrogen is liquefied into the oxygen rectification tower reboiler condensate 15, and the condensate It is liquid nitrogen, and the liquid nitrogen is refluxed to the top of the high-pressure rectification tower C1 as the reflux liquid of the high-pressure rectification tower. The position of the reboiler K2 of the oxygen rectification tower should be higher than that of the feed port of the liquid nitrogen to overcome the resistance of the nitrogen pipeline.

Embodiment 3

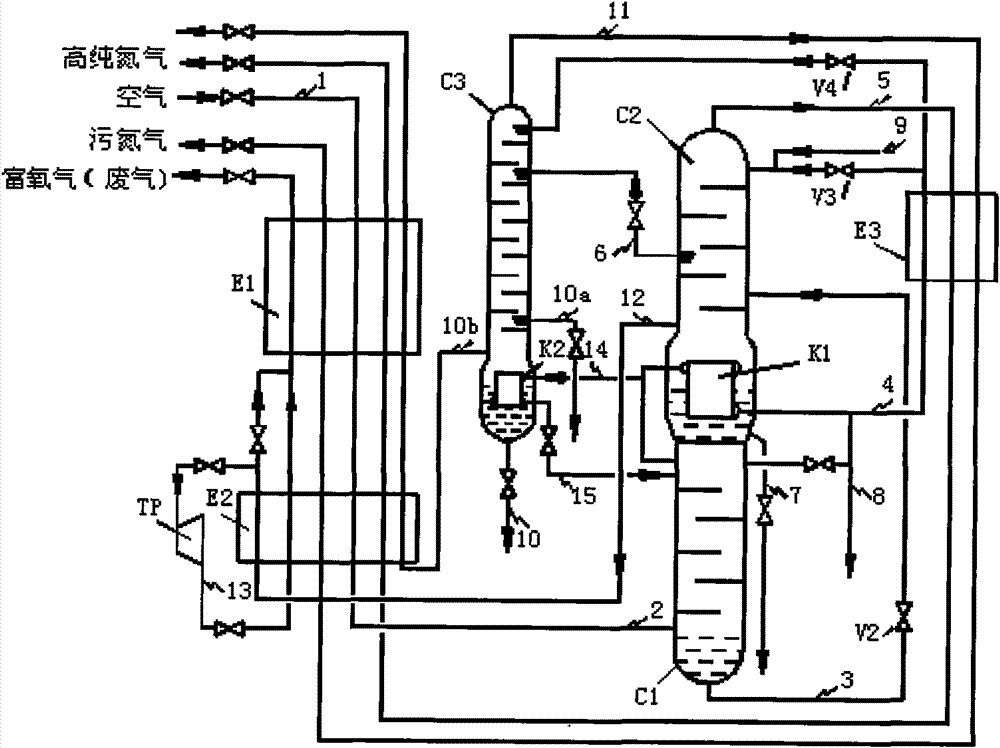

[0038] A device for producing pressurized high-purity nitrogen and high-purity oxygen, its structure is as follows image 3 As shown, the difference from Example 2 is that the liquid nitrogen 4 of the high-pressure rectification tower is divided into two strands before entering the throttle valve V3, and one strand enters the top of the medium-pressure rectification tower C2 after being depressurized in the throttle valve V3 as a medium pressure The reflux liquid of the rectification tower C2, the other stream is decompressed in the throttle valve V4 and enters the top of the oxygen rectification tower C3 as the reflux liquid of the oxygen rectification tower C3. The oxygen liquid 6 enters below the C3 liquid nitrogen inlet of the oxygen rectification tower after being depressurized by the throttle valve. In this way, the extraction rate of high-purity nitrogen under pressure is appropriately reduced to increase the extraction rate of high-purity oxygen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com