Method for efficient production of high-purity oxygen and high-purity nitrogen

A high-purity oxygen and high-purity nitrogen technology, applied in refrigeration and liquefaction, lighting and heating equipment, liquefaction and other directions, can solve the problems of limiting the production of high-purity liquid oxygen and low extraction rate, achieving product safety and reliability, and improving safety. , the effect of wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

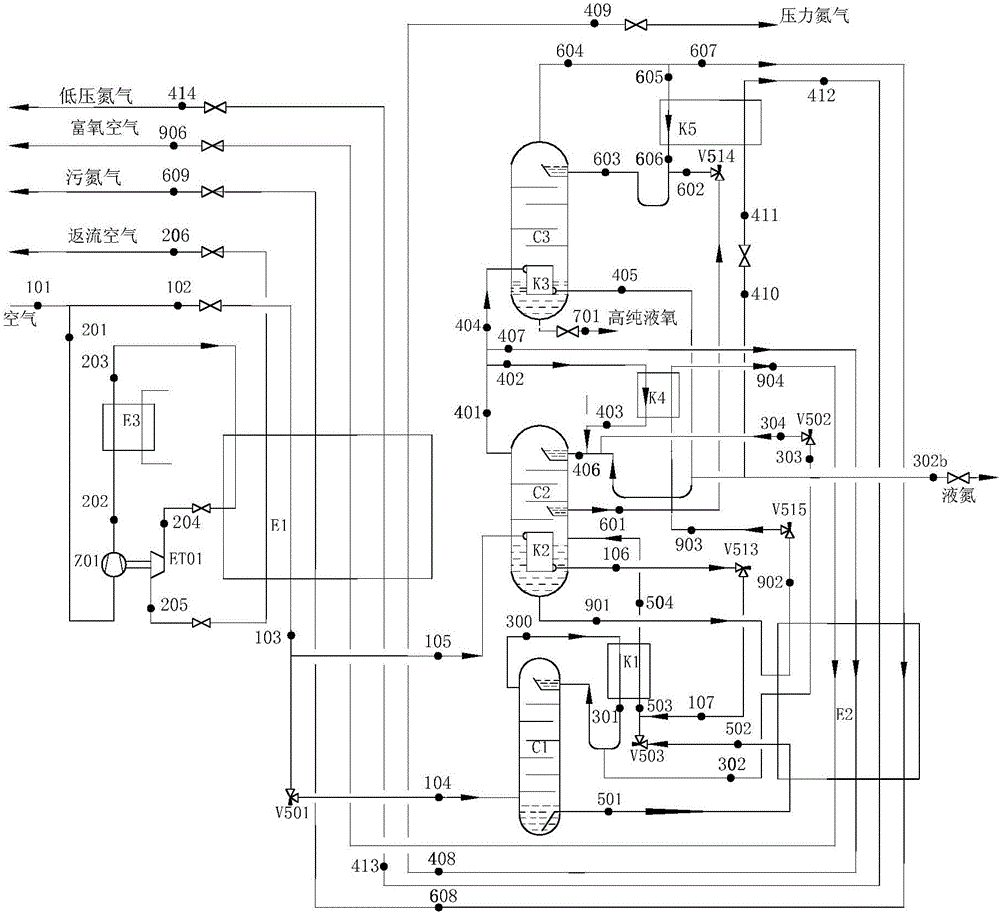

[0058] use as figure 1 The process flow method shown produces high-purity oxygen and high-purity nitrogen:

[0059] Purified and dried air 101 (3350NM 3 / h, 0.96MPa) is merged with the backflow air 206, and the air total flow after the described purification and drying after the merger is 7750NM 3 / h, and before being cooled to saturation in the main heat exchanger E1 of the fractionating column, it is divided into two streams:

[0060] One of them 102 directly enters the main heat exchanger E1 of the fractionation tower;

[0061] One of the other 201 (4400NM 3 / h, 0.96MPa) enters the turbo expander ET01 booster end Z01 to pressurize to 1.32MPa to obtain 202, then cools to 40°C through the water cooler E3, and then enters the main heat exchanger E1 of the fractionation tower to cool to -122°C , extract 204 from the middle of the main heat exchanger, and enter the turbo expander ET01 to expand to 0.025MPa to obtain 205, then return to the main heat exchanger E1 of the fracti...

Embodiment 2

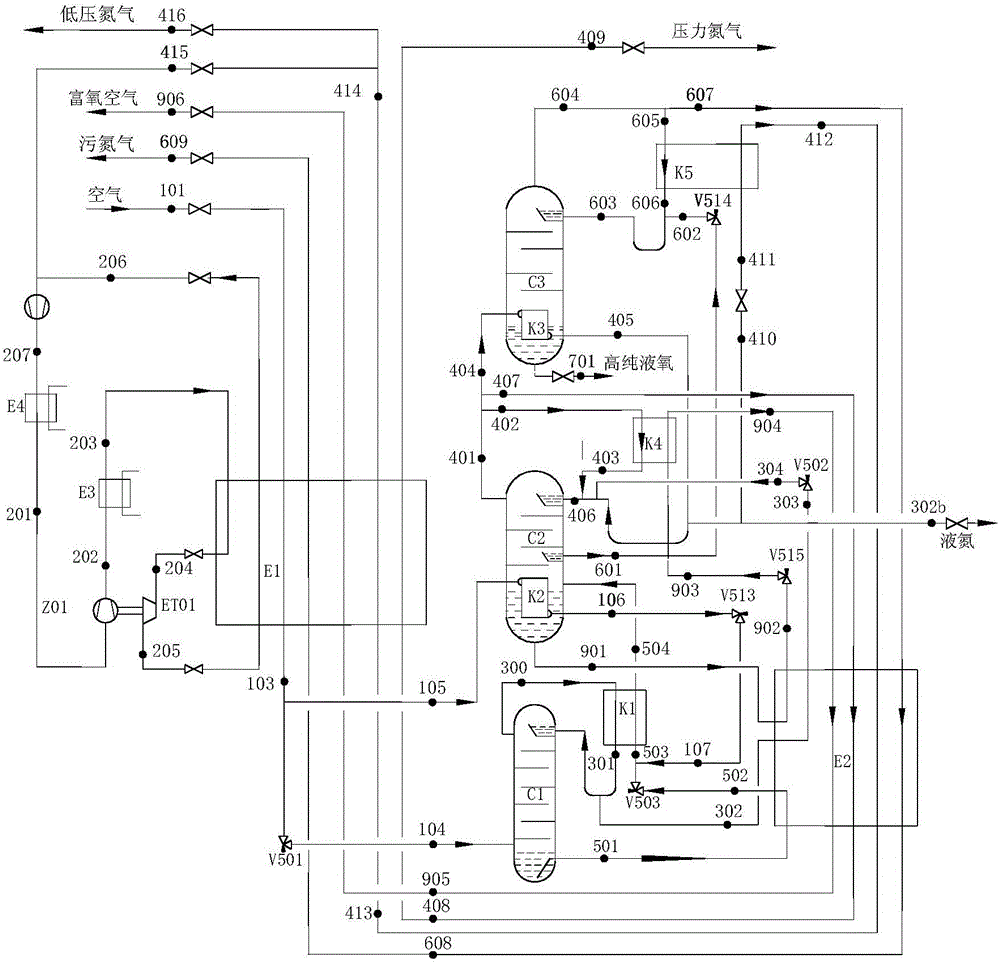

[0070] use as figure 2 The process flow method shown produces high-purity oxygen and high-purity nitrogen:

[0071] Purified and dried air 101 (3350NM 3 / h, 0.96MPa) is cooled to saturated state 103 in fractionation column main heat exchanger E1, a part of saturated air 104 (2950NM 3 / h) into the high-pressure rectification tower C1 tower kettle, separated into high-pressure nitrogen 300 and oxygen-enriched liquid air 501 in the high-pressure rectification tower C1; another part of saturated air 105 (400NM 3 / h) Enter the medium-pressure rectification tower reboiler K2 to condense into liquid air 106, and the liquid air 106 is mixed with the oxygen-enriched liquid air 501 in the high-pressure tower kettle to 503, and enter the high-pressure rectification tower condensing evaporator K1 to evaporate into a gaseous state 504, and then enter the medium-pressure rectification tower tower kettle; the nitrogen 404 separated by the high-pressure rectification tower C1 is sent to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com