Method for recycling tungsten and vanadium from waste SCR denitration catalyst

A denitrification catalyst and extraction agent technology, which is applied in the field of catalyst recovery, can solve the problems of toxic gas pollution, release of toxic gas, and secondary pollution of the environment, and achieve the effects of strong operability, efficient recovery, and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Leaching of W and V

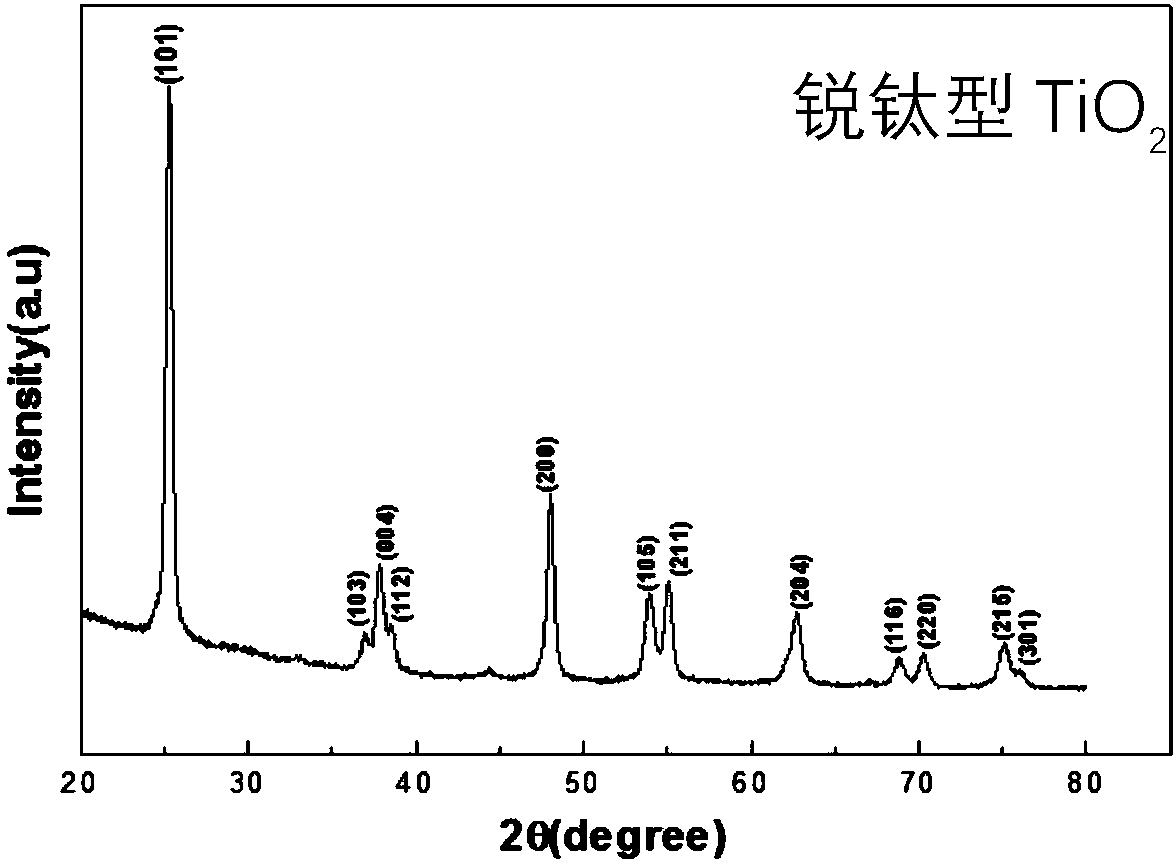

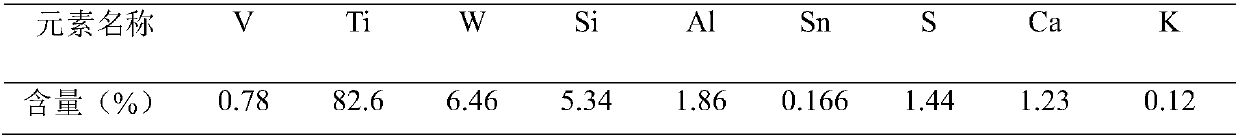

[0027] Take the waste SCR denitrification catalyst (the main component is V 2 o 5 -WO 3 / TiO 2 , the specific components are shown in Table 1), and the deactivated SCR denitrification catalyst is blown with clean and dry compressed air to remove the fly ash deposited on the surface of the catalyst, ground into powder in the grinding body, and then sieved with a 100-mesh standard sieve, Then the catalyst was dried at 85°C for 6h.

[0028] Table 1: Elemental composition list of spent SCR catalysts

[0029]

[0030] Use 8% sodium hydroxide solution to leach 5g of the dried and cooled catalyst powder, control the liquid-solid ratio to 5:1, the leaching temperature is 150°C, and the leaching time is 3h. The mixed solution is placed in a high-pressure reactor and stirred at a speed of 300 r / min, and a mixed leached slurry is obtained after leaching.

[0031] Then the mixed solution was suction-filtered, and the pore size of the filter membran...

Embodiment 2

[0039] 1) Leaching of W and V

[0040] Use the sodium hydroxide solution that concentration is 8%, the powder 5g of catalyst (same as embodiment 1) after oven dry, cooling is leached, and leaching process adopts the mode of high-pressure leaching, and mixed solution is placed in autoclave and with rotating speed Stir at 400r / min, control the liquid-solid ratio to 10:1, the leaching temperature is 190°C, and the leaching time is 3h. Then the mixed solution was suction-filtered, and the pore size of the filter membrane used in the suction-filtration process was 0.45 μm to obtain a leaching solution containing V and W and constant volume of 100ml, and the leaching rates of W and V were calculated to be 97.46% and 88.6% respectively.

[0041] 2) Extraction and purification of W and V in the leachate

[0042] Adjust the pH of the leachate obtained in step (2) to 5.5 with hydrochloric acid;

[0043] Take 30ml of the above leachate in a separatory funnel, add a solution diluted wit...

Embodiment 3

[0049] 1) Leaching of W and V

[0050] Use the sodium hydroxide solution that concentration is 8%, leaching is carried out with catalyst (same as embodiment 1) powder 5g after drying, cooling, and the leaching process adopts the mode of high-pressure leaching, and mixed solution is placed in autoclave and with rotating speed 500r / Stir for 1 min, control the liquid-solid ratio to 10:1, the leaching temperature is 250°C, and the leaching time is 6 hours. Then the mixed solution was suction-filtered, and the pore size of the filter membrane used in the suction-filtration process was 0.45 μm to obtain a leaching solution containing V and W and to a constant volume of 100ml. The calculated leaching rates of W and V were 97.80% and 87.5% respectively.

[0051] 2) Extraction and purification of W and V in the leachate

[0052] Adjust the pH of the obtained leachate to 5.5 with hydrochloric acid;

[0053] Take 30ml of the above leachate in a separatory funnel, add a solution dilute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com