Construction waste recycling and crushing equipment and using method thereof

A technology for construction waste and processing equipment, applied in grain processing, chemical instruments and methods, magnetic separation, etc., can solve the problems of reducing the service life of processing equipment, machine jams, and limited quality of finished products, achieving long service life and scientific and reasonable structure , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

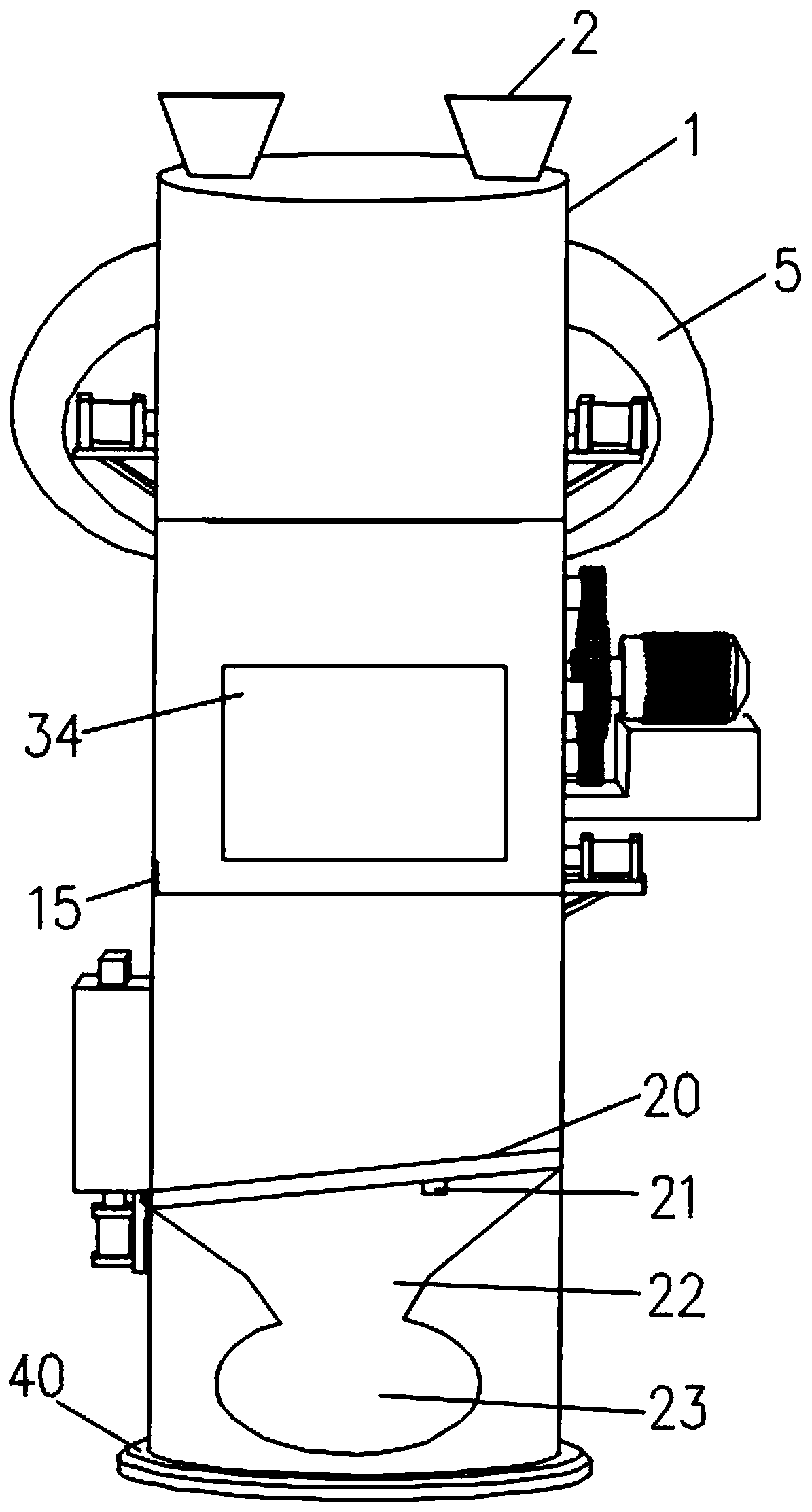

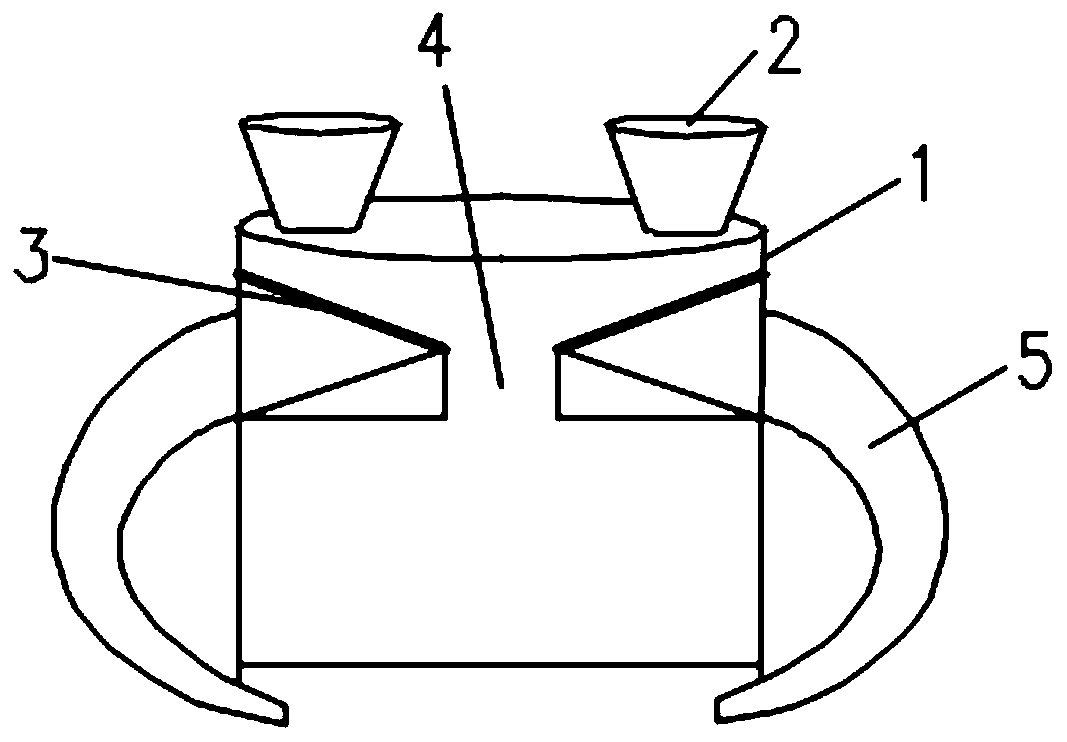

[0051] as attached figure 1 As shown, a kind of construction waste recycling and crushing processing equipment includes a cabinet 1, a feeding device, a crushing device, an impurity removal device and a collection box 23; The box 23 is arranged at the lower end of the cabinet 1 , the crushing device and the impurity removal device are arranged in the cabinet 1 , and the lower end of the cabinet 1 is provided with a base 40 .

[0052] Preferably, the inner wall of the chassis 1 is provided with a sound insulation board, which plays a certain role in sound insulation and avoids noise pollution.

[0053] It should be noted that the chassis 1 may also be of any structure such as a square tube, a rectangular tube, or the like.

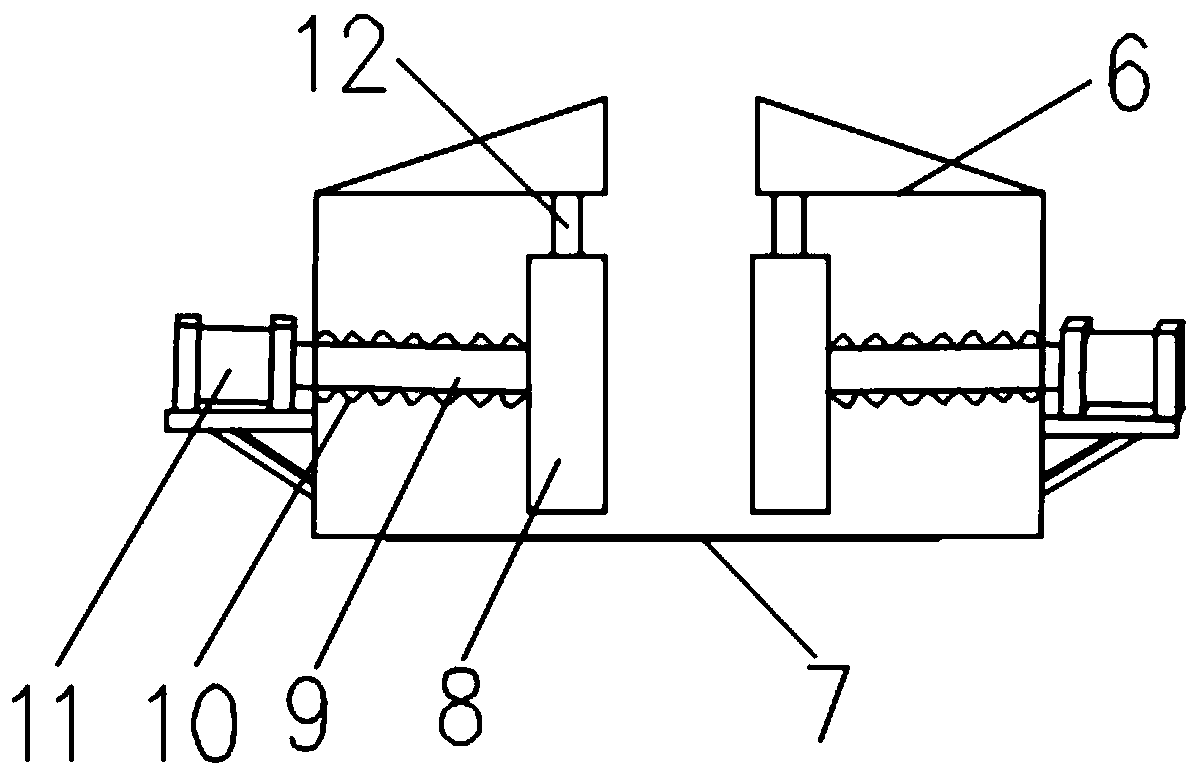

[0054] The crushing device includes a first crushing device and a second crushing device, the first crushing device is arranged at the lower end of the feeding device, the impurity removal device is arranged at the lower end of the first crushing device, a...

Embodiment 2

[0084] Based on the above-mentioned embodiment 1, the similarities will not be repeated, and the difference is that, as attached Image 6 As shown, the circulation processing device is installed on the outer wall of the cabinet 1, and the circulation processing device also includes a return channel 24, a pushing plate 25, a third telescopic rod 26, a third cylinder 27, and a discharge baffle 28. Feed sensor, discharge sensor and material circulation controller 31, the upper and lower ends of the return channel 24 are closed structures, and the pushing plate 25 is arranged in the return channel 24 and moves up and down , one end of the third telescopic rod 26 is connected to the pushing plate 25, and the other end is connected to the third cylinder 27; The lower end is located on the chassis 1.

[0085] The discharge sensor is arranged in the return channel 24, and is located on the outer wall of the cabinet 1 at the upper end of the discharge port 29; the feed sensor is arran...

Embodiment 3

[0091] Based on the above embodiments, a method for using construction waste recycling and crushing processing equipment includes the following steps:

[0092] S1. Construction waste enters from the hopper 2 and is filtered by the filter screen 3. The large-sized material enters the first crushing device from the discharge port 4, and the small-sized material enters the discharge channel 5 through the sieve hole on the filter screen 3, and passes through the lower Material channel 5 enters the impurity removal device;

[0093] S2. After the large-sized material enters the first crushing device, it is squeezed and crushed by the extrusion crushing device. The crushed material is processed through the screen 7, and the small-sized material passes through the screen 7 and enters the impurity removal device. The large-sized material continues Processed by extrusion crushing device;

[0094] S3. The material processed in steps S1 and S2 enters the impurity removal device, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com