Boiler smoke waste heat utilization and white smoke removal integrated system

A boiler flue gas and flue gas waste heat technology, which is applied to lighting and heating equipment, indirect carbon dioxide emission reduction, steam engine installations, etc., can solve the problem of high energy consumption for boiler exhaust smoke removal, and achieve reduced investment, system investment, and system simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

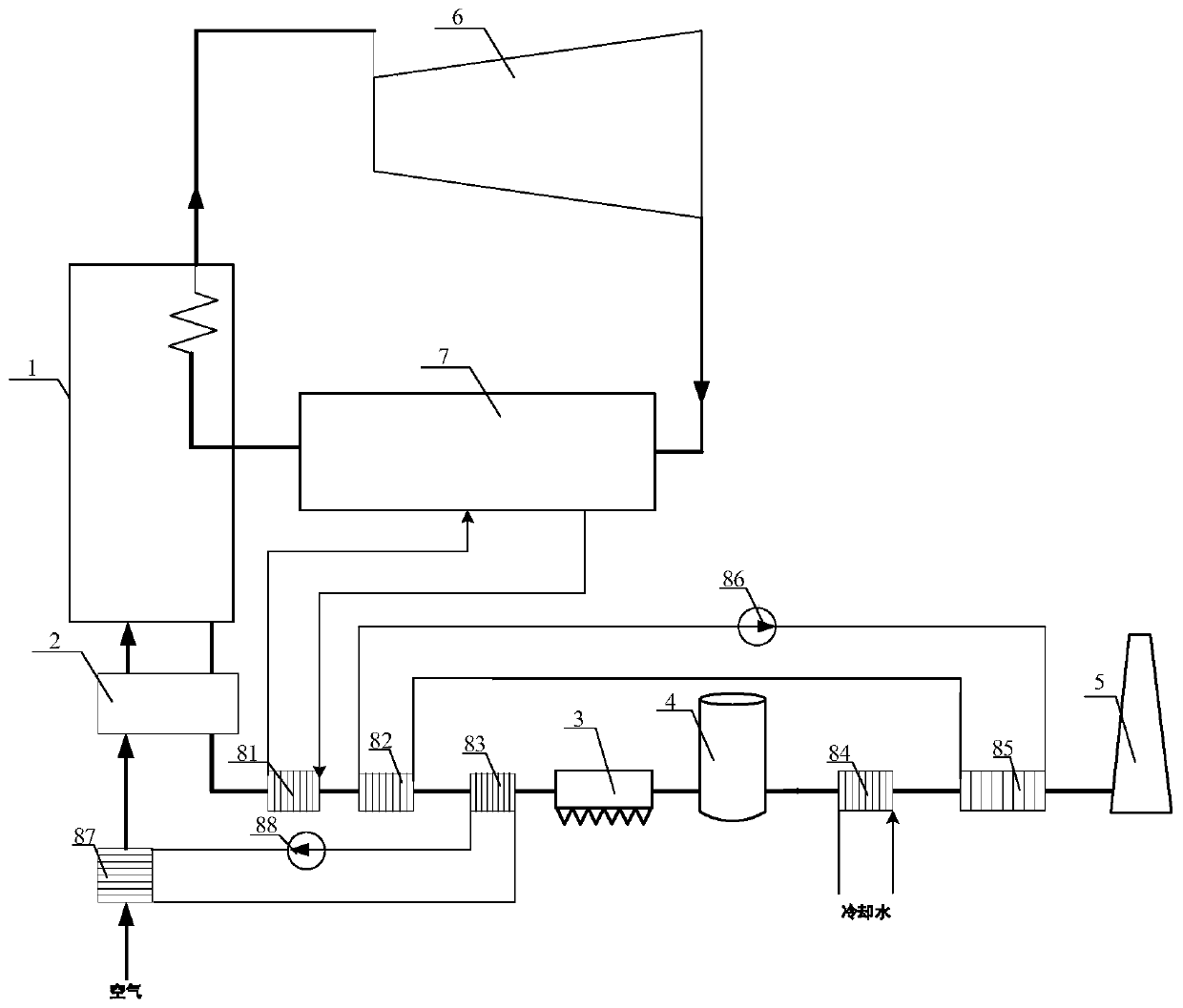

[0017] Attached below figure 1 To further describe the present invention, it should be understood that the content described here is only used to illustrate and explain the present invention, not to limit the present invention.

[0018] The present invention is based on the basic principle of "temperature matching and cascade utilization", coupling the flue gas de-whitening system with the flue gas waste heat utilization system, and realizes the cascade utilization of energy through the coupling of material flow and energy flow between the systems. Matching the temperature difference effectively reduces the system investment, thus realizing the coordinated work of system energy saving and whitening.

[0019] A coal-fired power station boiler flue gas waste heat utilization and de-whitening integrated system, which includes a conventional coal-fired power generation system. The conventional coal-fired power generation system consists of a boiler (1), an air preheater (2), and a dust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com