Method for simultaneously recycling and preparing carbon-based metal sulfide negative electrode material from waste nickel-cobalt-manganese lithium ion battery positive electrode material and waste cobalt-manganese lithium ion battery negative electrode material

A nickel-cobalt-manganese-lithium-ion battery technology, which is applied in the field of waste lithium-ion battery recycling and reuse, can solve the problems of complex process, long process, and little attention to lithium-ion battery material graphite, etc. The method is simple, the recycling process is reduced, The effect of excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Take 3G waste graphite, 17 g of used nickel-manganese three-dimensional powder and 10 g of sublimation sulfur to the ball mill, placed in a ball mill, ground 18 h, ground 18 h, resulting in uniform mixing powder material.

[0024] (2) Take 5G powder into small porcelain, and placed it in the middle of the tube furnace tube, in Ar / h 2 Under the atmosphere, heated at a temperature rise rate of 5 ° C / min to 700 ° C for 2 h.

[0025] (3) The obtained composite is placed in a beaker while adding 600 ml of deionized water, extracting Li, after 30 min under ultrasound conditions, filtered, filter cake drying in an oven at 120 ° C to obtain a carbon group The sulfide composite can be used directly for the sodium ion battery negative electrode material.

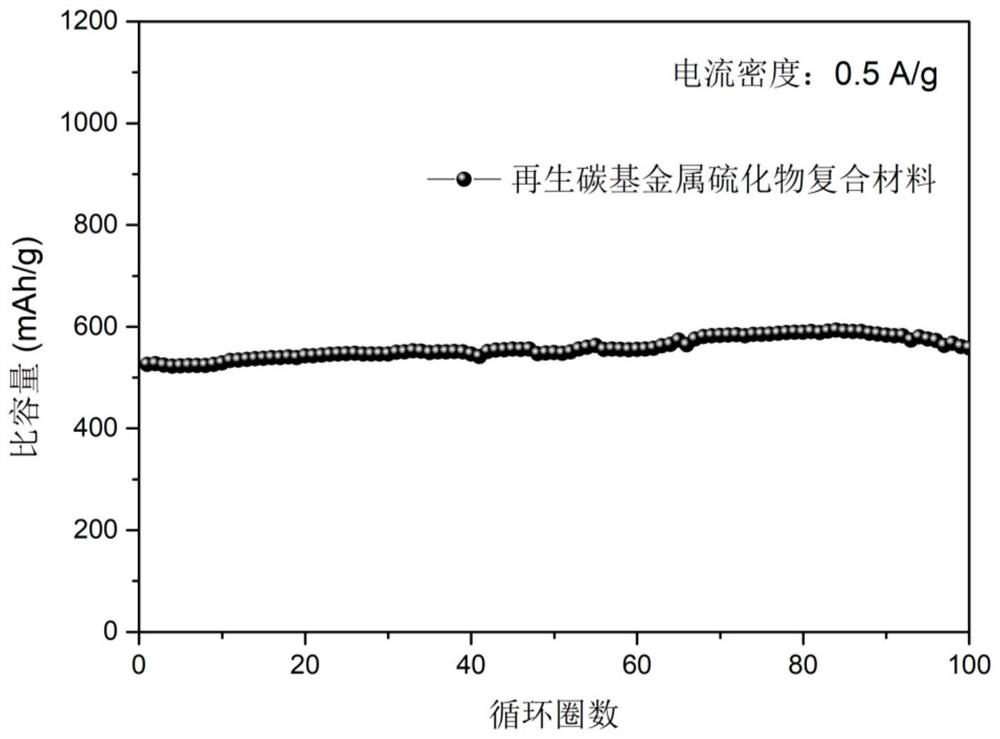

[0026] (4) Electrochemical properties test at room temperature conditions. The results show that( figure 1 ), At 0.5a / g, after 100 laps, the specific capacity is 558.3mAh / g, exhibiting high specific capacity and good cy...

Embodiment 2

[0028] (1) Take 3G waste graphite, 17g used nickel-watenganese ternary positive electrode powder and 20 g of sublimation sulfur to the ball mill, placed in a ball mill, and ground 8 h, ground 8 h, to obtain a uniform mixed powder material.

[0029] (2) Take 5 g of powder into small porcelain, and placed it in the intermediate portion of the tubular furnace tube, under the AR atmosphere, the temperature rise rate of 5 ° C / min is heated to 600 ° C, maintained for 2 h.

[0030] (3) Put the obtained composite material into the beaker while adding 300 ml of deionized water, extracting Li, after 30 min under ultrasound conditions, filtered, filter cake drying in an oven at 120 ° C to obtain a carbon group The sulfide composite is directly used in the sodium ion battery negative electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com