Device and method for extracting krypton and xenon in liquid oxygen through low-temperature rectification

A low-temperature rectification and extraction technology, which is applied in the field of krypton and xenon gas in the extraction of liquid oxygen by cryogenic rectification, can solve the problems of high risk of hydrocarbon air separation units, achieve high recovery rate and wide application range , Increase the effect of added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

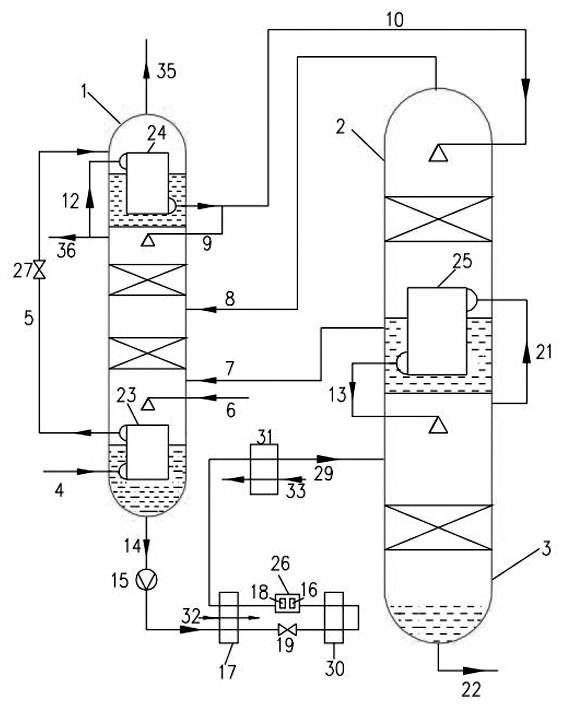

[0031] at 3000 Nm 3 / h liquid oxygen production as an example. 3000 Nm 3 / h Raw material liquid oxygen contains 100ppm Krypton, 30ppm Xenon, 100ppm C n h m (hydrocarbons), introduced into the tower at the position of 5 theoretical stages above the bottom of the primary concentration tower 1 for rectification. The theoretical stage of the primary concentration tower 1 is 12. Most of the high-boiling point krypton, xenon and hydrocarbons condense and flow down to the bottom of the primary concentration tower 1, and the low-boiling point oxygen, argon and a small amount of krypton and xenon evaporate from the downstream liquid and reach the top of the tower, where they are condensed by liquid nitrogen The latter part is used as the spray liquid of the primary concentration tower 1, and a part is sent to the secondary concentration tower 2. The oxygen and argon with low boiling point are volatilized from the downstream liquid, and the krypton and xenon with high boiling point a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com