Method for extracting and separating tungsten from molybdate solution

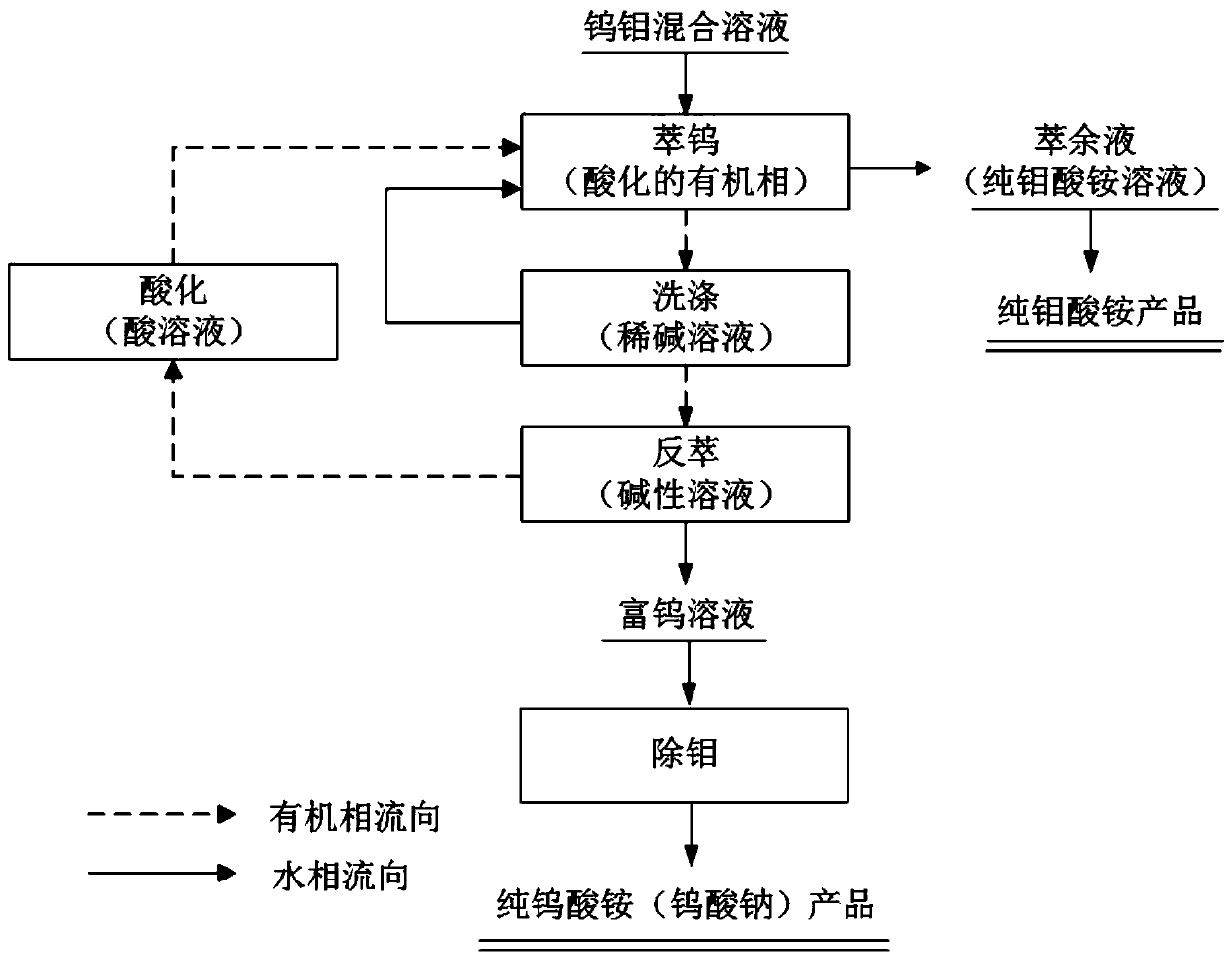

A molybdate and solution technology is applied in the field of extraction and separation of tungsten, which can solve the problems of difficulty in separation and removal of tungsten and high separation cost, and achieve the effects of reducing the amount of co-extraction, improving the separation effect, and simplifying the synthesis process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Feed liquid: ammonium molybdate solution containing tungsten, WO 3 27.95g / L, Mo 28.45g / L, WO 3 / Mo=0.982, pH value is 8.01.

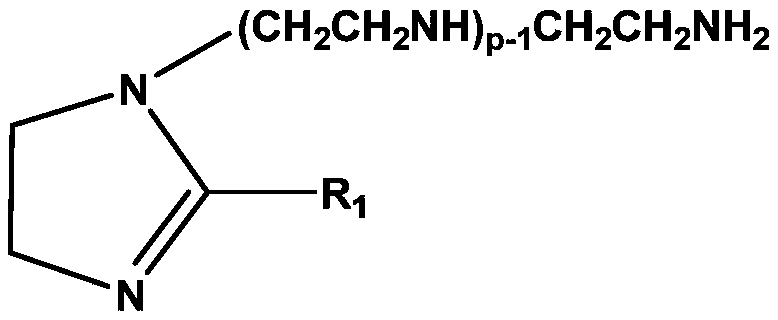

[0044] Organic phase: 5% volume of mixed amine extractant + 65% volume of sulfonated kerosene + 30% volume of isooctyl alcohol, subjected to 0.20mol / L H 2 SO 4 acidification.

[0045] The acidification time is 30min, the acidification ratio is O / A=1:1 (V / V), the extraction ratio is O / A (the volume ratio of the acidified organic phase to the solid liquid)=1:1, and the temperature is 25°C. The equilibration time is 10min. The results are as follows: the raffinate (raffinate aqueous phase) contains WO 3 12.24g / L, Mo 27.01g / L, tungsten extraction rate 56%, molybdenum extraction rate 4.75%, tungsten-molybdenum separation coefficient β WO3 / Mo =25.77.

Embodiment 2

[0047] Feed liquid: ammonium molybdate solution containing tungsten, WO 3 21.77g / L, Mo 20.96g / L, WO 3 / Mo=1.04, pH value is 7.4.

[0048] Organic phase: 5% volume of mixed amine extractant + 55% volume of sulfonated kerosene + 40% volume of isooctyl alcohol, with 0.05mol / L H before extraction 2 SO 4 The organic phase is acidified according to O / A=1 / 1 (volume ratio of organic phase to acid) (acidified organic phase is obtained).

[0049] Acidifying agent (for acidifying the organic phase and the organic phase after stripping): 0.05mol / L H 2 SO 4 aqueous solution

[0050] Extraction agent: 0.2mol / L NH 3 ·H 2 O aqueous solution

[0051] Stripping agent: 3.0mol / LNH 3 ·H 2 O aqueous solution

[0052] Operation: first heat the feed liquid to volatilize and deammoniate (or directly use H 2 SO 4 ) the pH value of the seasoning liquid is reduced to 7.4, and it is used as the feed liquid for extraction and removal of tungsten after cooling to room temperature.

[0053] Th...

Embodiment 3

[0057] Feed liquid: sodium molybdate solution containing tungsten, WO 3 38.85g / L, Mo 60.35g / L, WO 3 / Mo=0.644, pH value is 8.5.

[0058] Organic phase: the sulfonated kerosene of the isooctyl alcohol+50% volume of the mixed amines extraction agent+40% volume of 10% volume, before the extraction with the HCl of 1.4mol / L to organic phase by comparison O / A=1 / 1 for acidification.

[0059] Extraction agent: 0.25mol / L NaOH aqueous solution

[0060] Stripping agent: 2.0mol / L NaOH aqueous solution

[0061] The feed liquid and the acidified organic phase are subjected to multi-stage countercurrent extraction. During the countercurrent extraction process, tungsten is enriched in the loaded organic phase (extraction layer), and molybdenum is enriched in the raffinate aqueous phase; the loaded organic phase is extracted and washed. The stripping agent is subjected to multi-stage countercurrent stripping to obtain a tungsten-rich stripping liquid. The organic phase after back-extrac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com