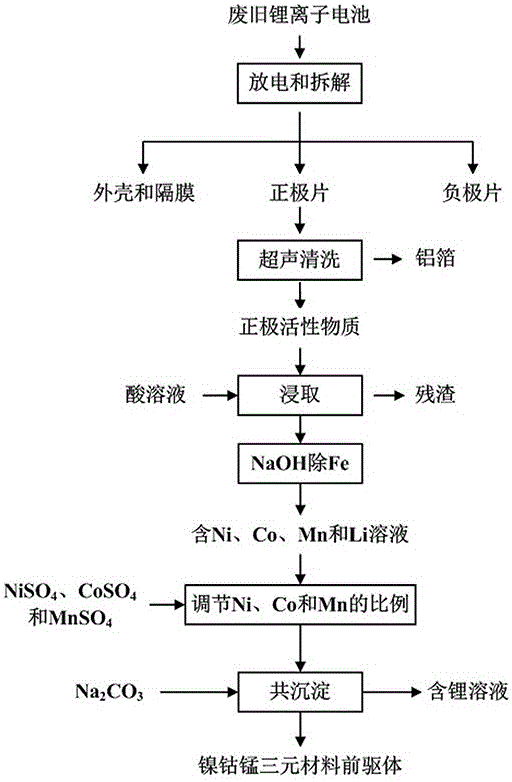

Method for preparing nickel-cobalt-manganese ternary material precursor from waste lithium ion battery

A technology for lithium-ion batteries and ternary materials, applied in the field of preparing nickel-cobalt-manganese ternary material precursors, can solve problems such as high separation costs, environmental hazards, and complex processes, and achieve simplified impurity removal processes, increased value, and simplified recycling The effect of craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

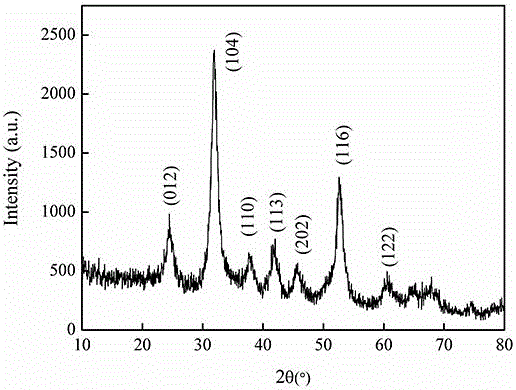

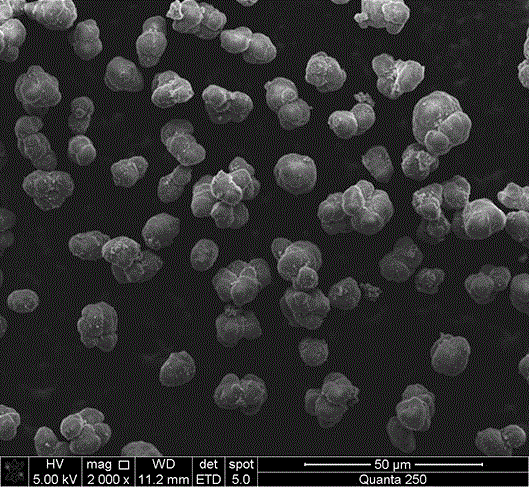

[0028] (1) Discharge the used lithium-ion battery fully, physically disassemble and remove the casing, and take out the positive electrode; (2) Put the positive electrode into the ultrasonic cleaning machine, control the temperature at 60°C, ultrasonically clean for 30 minutes, and recycle the separated aluminum foil directly (3) dissolving the positive electrode active material obtained in step (2) in 1mol / L sulfuric acid solution; (4) adding 1mol / L sodium hydroxide to the leaching solution to adjust the pH of the solution to 4, and filtering to remove ferric hydroxide; (5) Measure the metal ion content in the solution, add nickel sulfate, cobalt sulfate and manganese sulfate to adjust the molar ratio of nickel, cobalt and manganese to 1:1:1, and the total concentration is 2mol / L; (6) Add 2mol / L carbonic acid The sodium solution produces a precipitate, which is filtered, washed, and dried to obtain a nickel-cobalt-manganese ternary material precursor. The XRD pattern of the o...

Embodiment 2

[0030] (1) Discharge the used lithium-ion battery fully, physically disassemble and remove the casing, and take out the positive electrode sheet; (2) Put the positive electrode sheet into the ultrasonic cleaning machine, control the temperature at 70°C, and ultrasonically clean for 90 minutes, and the separated aluminum foil is directly recycled (3) Dissolving the positive electrode active material obtained in step (2) in 0.5mol / L hydrochloric acid solution; (4) Adding 1mol / L sodium hydroxide to the leaching solution to adjust the pH of the solution to 4, and filtering to remove ferric hydroxide ; (5) Measure the metal ion content in the solution, add nickel chloride, cobalt chloride and manganese chloride to adjust the molar ratio of nickel, cobalt and manganese to 5:2:3, and the total concentration is 2mol / L; (6) add 2mol / L sodium carbonate solution, a precipitate is generated, and the precipitate is filtered, washed, and dried to obtain a nickel-cobalt-manganese ternary mate...

Embodiment 3

[0032] (1) Fully discharge the used lithium-ion battery, physically disassemble and remove the casing, and take out the positive electrode; (2) Put the positive electrode in an ultrasonic cleaning machine, control the temperature at 50°C, ultrasonically clean for 60 minutes, and recycle the aluminum foil obtained directly (3) dissolving the positive electrode active material obtained in step (2) in 2mol / L nitric acid solution; (4) adding 1mol / L sodium hydroxide to the leaching solution to adjust the pH of the solution to 4, and filtering to remove ferric hydroxide; (5) Measure the metal ion content in the solution, add nickel nitrate, cobalt nitrate and manganese nitrate to adjust the molar ratio of nickel, cobalt and manganese to 2:1:2, and the total concentration is 2mol / L; (6) Add 2mol / L carbonic acid The sodium solution produces a precipitate, which is filtered, washed, and dried to obtain a nickel-cobalt-manganese ternary material precursor. The phase of the product obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com