Conductive graphene film and self-assembly preparation method thereof

A conductive graphite and self-assembly technology, applied in the field of conductive graphene film and its self-assembly preparation, can solve the problems of easy damage to the structure, easy reduction of strength, etc., and achieve the effects of tailorable shape, easy operation, and easy process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Preparation of graphene powder material

[0022] The preparation reference document of graphene powder material (1.Mcallister M J, Lio J L, Adamson D H, et al.Singlesheet functionalized graphene by oxidation and thermal expansion of graphite[J].Chemistry ofMaterials, 2007,19 (18): 4396- 4404.) (2. Yang Quanhong et al., High electrochemical capacity graphene oxide and its low-temperature preparation method and application, Chinese patent, application number: 200810151807.X). Wherein document 1 is a high-temperature preparation method of graphene, and document 2 is a low-temperature preparation method of graphene.

[0023] 2) Preparation of graphene oxide solution

[0024] The preparation of graphene oxide solution refers to the literature (Chen C M, Yang Q H, Yang Y G, et al.Self-assembled free-standing graphite oxide membrane[J].Adv.Mater., 2009, DOI: 10.1002 / adma.200803726.) this In addition to the water used in the literature, the graphene oxide solution solvent ...

Embodiment 2

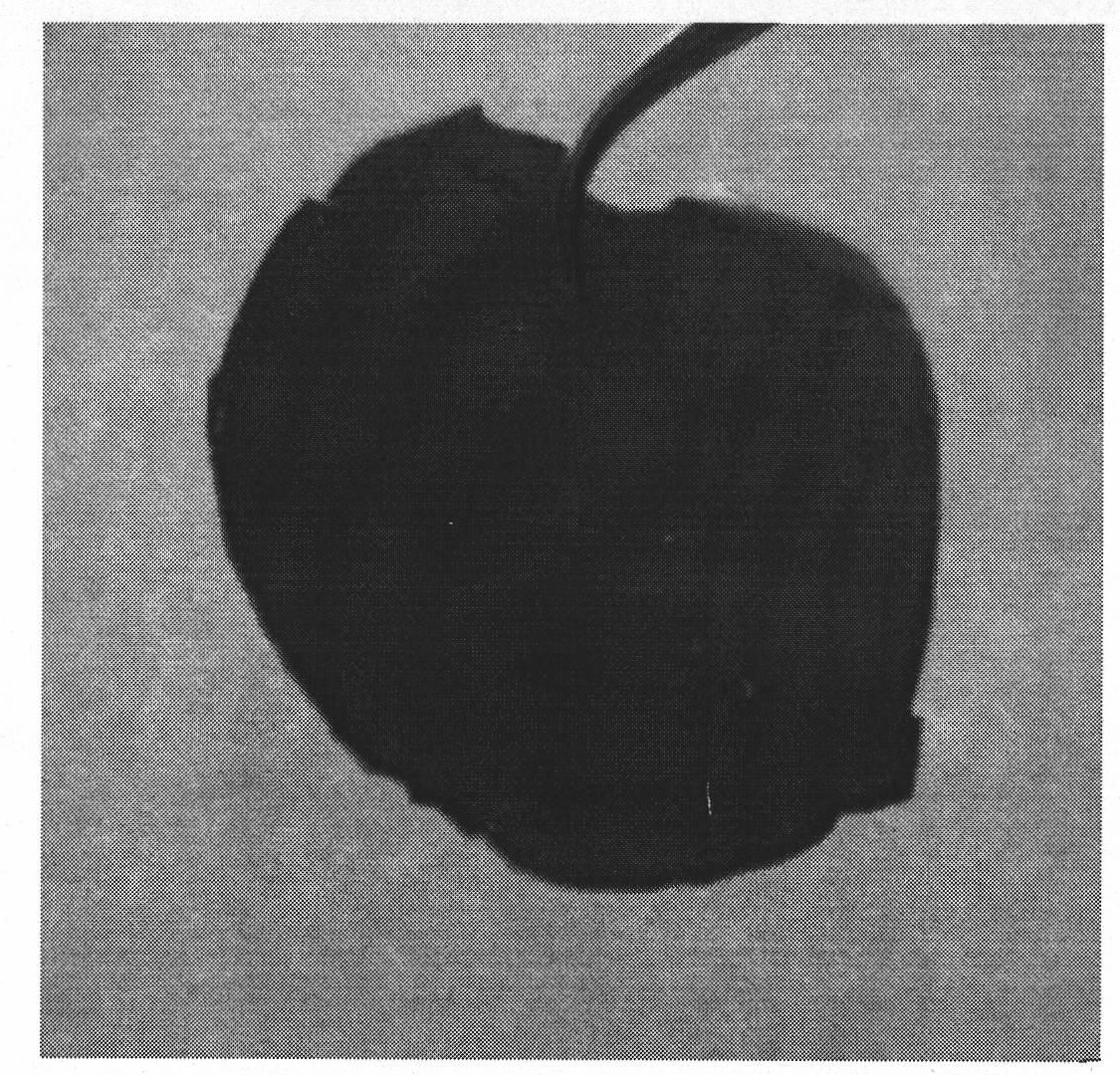

[0026] Embodiment 2: take by weighing 20mg according to the graphene powdery material prepared by low temperature method in embodiment 1 and 0.1mg (GT) 20 Put the single-stranded DNA into a 50ml beaker, add 30ml of water, and ultrasonically disperse in an ice-water bath for 1 hour, with an ultrasonic power of 120W, to obtain a well-dispersed graphene aqueous solution. Then move this well-dispersed graphene aqueous solution into a 50°C water bath and keep it for 45 minutes to form a uniform graphene film on the liquid surface. Remove the graphene film on the liquid surface and dry it at room temperature for 12 hours to obtain unsupported graphene membrane. Using four probes to measure the sheet resistance of this graphene film is 1Ω / sq, the thickness of this film is 30μm, and the area is 12cm 2 , as shown in 2 of 1.

Embodiment 3

[0027] Embodiment 3: take by weighing 100mg graphene powder material and 10mg sodium lignosulfonate prepared according to the low temperature method in Example 1 and put it into a 100mL beaker, add 50mL water, ultrasonically disperse 30min in an ice-water bath, ultrasonic power 300W, obtain Well-dispersed graphene aqueous solution. Weigh 20 mL of a 15 mg / ml graphene oxide aqueous solution that has been ultrasonicated for 3 hours and add it to the graphene aqueous solution, and mix evenly by ultrasonication. Finally, move this well-dispersed graphene aqueous solution into a 70°C water bath and keep it for 10 minutes. A uniform graphene film can be formed on the liquid surface. The graphene film on the liquid surface is removed and dried at room temperature for 12 hours to obtain an unsupported graphene membrane. Using four probes to measure the sheet resistance of this graphene film is 5900Ω / sq, the thickness of this film is 0.5μm, and the area is 19cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com