Low-cost, efficient and continuous tea saponin extraction process

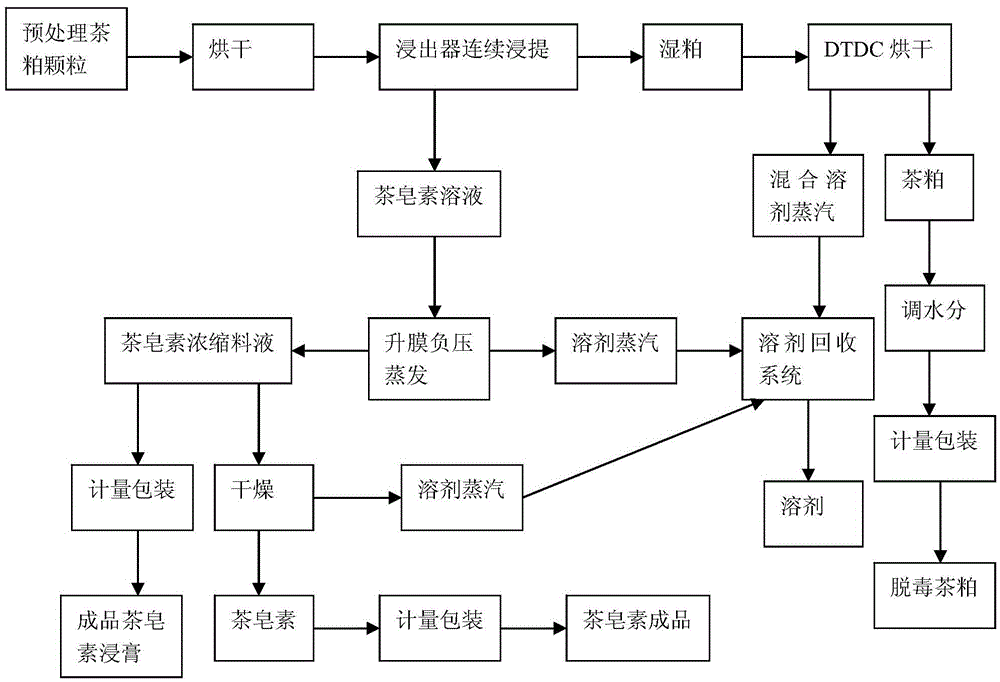

An extraction process and technology of tea saponin, which is applied in the field of high-efficiency and continuous extraction process of low-cost tea saponin, can solve the problems of reducing extraction effect and extraction efficiency, difficulty in large-scale application, high production cost, etc., and achieve material-liquid separation The effect and efficiency are high, the processing process is easy to scale up, and the large-scale application has broad prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Dry the pretreated camellia oleifera meal with a particle diameter greater than 1.5 mm and less than 5 mm, and adjust the water content to 9; the tea meal after adjusting the water content enters the extractor for continuous extraction of medium and high material layers, and adjusts the material level of the extractor For medium and high material level, spray solvent into the material according to the ratio of material:solvent = 1:10, and control the feeding and discharging time of the extractor at 150 minutes; the wet meal after extraction is dried in a DTDC multi-layer dryer, and then dried There are two layers in the machine pre-stripping section, no lower than three layers in the drying section, the gas phase temperature is 98°C, and at the same time, superheated steam is passed through the bottom layer for distillation. The water content is adjusted to about 12%, and it is feed-grade tea dregs after metering and packaging. The tea saponin mixed solution ...

Embodiment 2

[0018] Example 2: Dry the pretreated camellia oleifera meal with a particle diameter greater than 1.5mm and less than 5mm, and adjust the moisture to 7%; the tea meal after adjusting the moisture enters the extractor for continuous extraction of medium and high material layers, and adjusts the extractor material. The level is medium-high material level, spray solvent into the material according to the amount of material: solvent = 1:15, and the time of feeding and discharging the extractor is controlled at 90 minutes; the wet meal after extraction is dried in a DTDC multi-layer dryer, and then dried. There are two layers in the pre-detachment section of the dryer, and the drying section is not lower than three layers. The gas phase temperature is 90°C. At the same time, superheated steam is introduced from the bottom layer for distillation. The temperature of the superheated steam is not lower than 140°C, and the temperature of the bottom layer of the dryer is 110°C; The moistu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com