Method for preparing synthesis gas by co-processing waste printed circuit board and organic waste liquid

A technology of organic waste liquid and co-processing, applied in the direction of manufacturing combustible gas, gasification process, granular/powdered fuel gasification, etc., can solve the problem of poor debromination effect, low recovery value of non-metallic parts, and difficult utilization of liquid products and other issues, to achieve the effect of saving clean water resources, high resource utilization efficiency, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

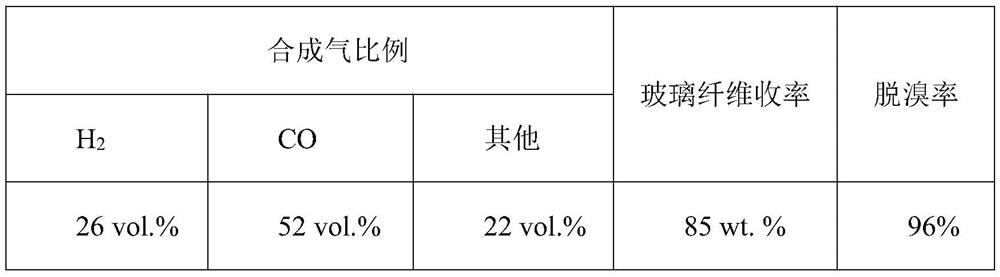

[0024] The waste printed circuit board is mechanically removed and the electronic components are crushed to obtain fine crushed material with a particle size of 2 Mainly clean syngas. The final dry-based syngas ratio, glass fiber recovery rate and debromination rate are shown in Table 1.

[0025] Table 1

[0026]

Embodiment 2

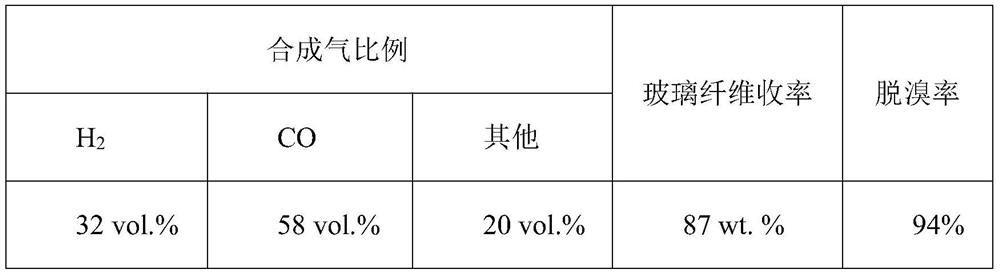

[0032] The waste printed circuit board is mechanically removed and the electronic components are crushed to obtain fine crushed material with a particle size of 2 Mainly clean syngas. The final dry-based syngas ratio, glass fiber recovery rate and debromination rate are shown in Table 3.

[0033] table 3

[0034]

Embodiment 3

[0036]The waste printed circuit boards are mechanically removed and the electronic components are crushed to obtain fine crushed materials with a particle size of 2 Mainly clean syngas. The final dry-based synthesis gas ratio, glass fiber recovery rate and debromination rate are shown in Table 4.

[0037] Table 4

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com