Method for preparing carbon fiber powder

A carbon fiber powder and fiber powder technology are applied in the field of carbon fiber powder preparation, which can solve the problems of low production efficiency and high energy consumption, and achieve the effects of simple preparation process and reduced dust pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

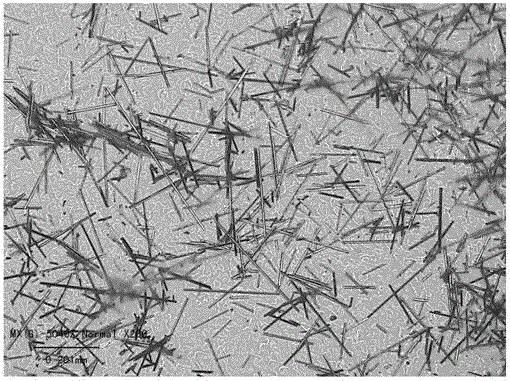

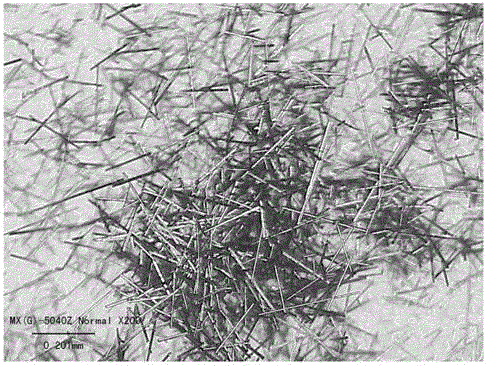

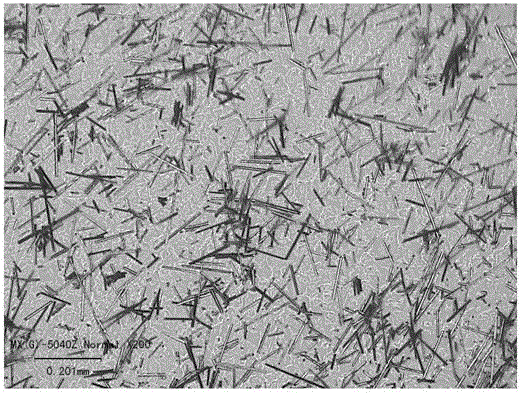

Image

Examples

Embodiment 1

[0038] On an intermeshing twin-screw extruder with a screw diameter of 27mm and an aspect ratio L / D=36:1 (Micro27 type from Leistritz, Germany), the temperature of the barrel is set at 220°C in ten sections from the feed port to the discharge port. °C, 230 °C, 240 °C, 250 °C, 255 °C, 260 °C, 260 °C, 260 °C, 250 °C, 240 °C, after the temperature reaches the set temperature and stabilizes, turn on the twin-screw main engine, so that the speed of the twin-screw is 180 rpm , add the dried SMA resin continuously from the feed port with a rate of 4.0kg / h with a loss-in-weight feeder, and the continuous carbon fiber (SIGRAFILC30) of 2 strands of 50K is opened from the middle part of the twin-screw extruder (the fifth section of the barrel) ) is introduced, and the extruded strip is water-cooled, air-dried, and pelletized to obtain a blended pellet of carbon fiber powder / SMA resin.

[0039] Weigh 10g of the above-mentioned blended pellets in a glass beaker and add 200ml butanone to diss...

Embodiment 2

[0041] On an intermeshing twin-screw extruder with a screw diameter of 27mm and an aspect ratio L / D=36:1 (Micro27 type from Leistritz, Germany), the temperature of the barrel is set at 220°C in ten sections from the feed port to the discharge port. °C, 230 °C, 240 °C, 250 °C, 255 °C, 265 °C, 270 °C, 270 °C, 265 °C, 260 °C, after the temperature reaches the set temperature and stabilizes, turn on the twin-screw main engine, so that the speed of the twin-screw is 170 rpm , add the dried PC resin continuously from the feeding port with a rate of 4.0kg / h with a loss-in-weight feeder, and the continuous carbon fiber (SIGRAFILC30) of 3 strands of 50K is opened from the middle of the twin-screw extruder (the fifth section of the barrel) ) is introduced, and the extruded strip is water-cooled, air-dried, and pelletized to obtain the blended pellets of carbon fiber powder / PC resin.

[0042] Weigh 10g of the above-mentioned blended pellets in a glass beaker and add 200ml of dichlorometh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com