Fluid-bed reactor for oxido-reduction sintering of high calcium magnesium titanium slag

A fluidized bed reactor, high calcium and magnesium technology, applied in fluidized bed furnaces, process efficiency improvement, lighting and heating equipment, etc. In order to improve the solid phase residence time distribution, prolong the residence time and shorten the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

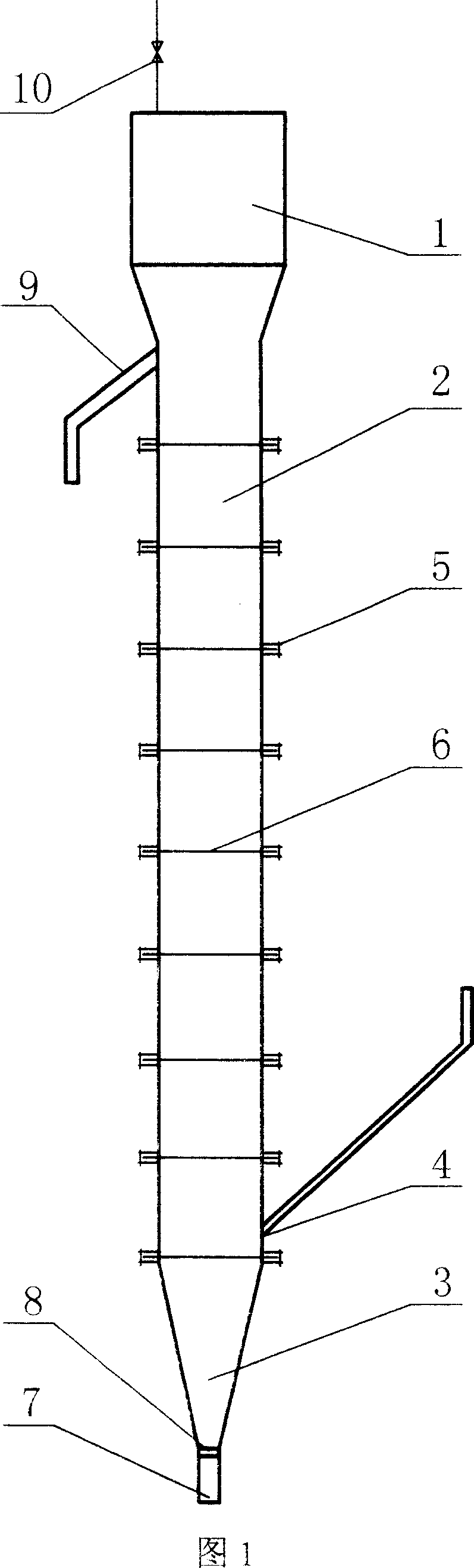

[0037] See Figure 1. A fluidized bed reactor with a height of 1800mm and an inner diameter of 86mm for oxidation-reduction roasting high-calcium-magnesium-titanium slag, which mainly consists of a cylindrical column material settling section 1, a cylindrical column material reaction section 2 and a conical The cylinder gas preheating section 3 constitutes.

[0038] The top of a cylindrical column material reaction section 2 is in the shape of a bell mouth, a cylindrical column material settling section 1 is connected to the top of the bell mouth column, and a cylindrical column material settling section 1 is connected at the bottom of the cylindrical column material reaction section. In the conical column gas preheating section 3, in the cylindrical column material reaction section 2, a plurality of baffle plates 6 with holes are fixed on the cylindrical column material reaction section by a plurality of flanges 5 On the wall, the aperture of the baffle plate 6 with holes is ...

Embodiment 2

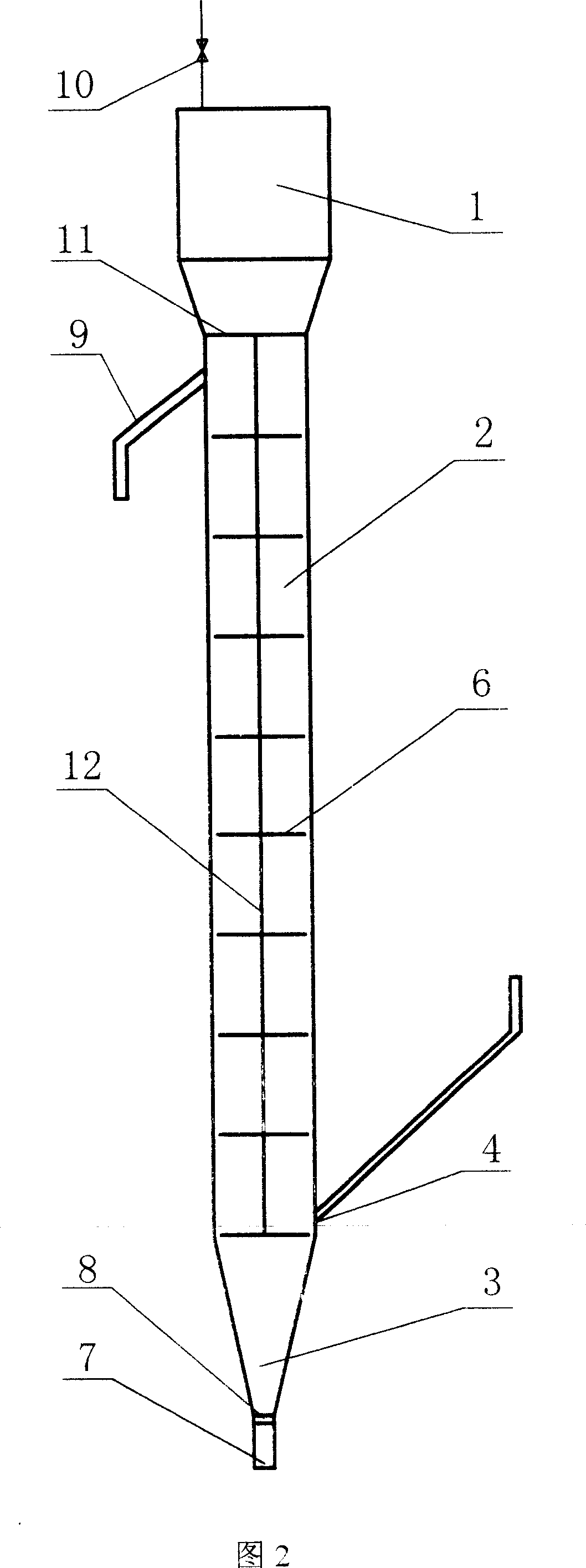

[0043] See Figure 2. A fluidized bed reactor with a height of 1500mm and an inner diameter of 86mm for oxidation-reduction roasting high-calcium-magnesium-titanium slag, which mainly consists of a cylindrical column material settling section 1, a cylindrical column material reaction section 2 and a conical The cylinder gas preheating section 3 constitutes.

[0044] The top of a cylindrical column material reaction section 2 is in the shape of a bell mouth, and a cylindrical column material settling section 1 is connected to the top of the bell mouth column, and a cylindrical column material reaction section is connected to a bottom end of the cylindrical column material reaction section. In the conical column gas preheating section 3, three pipe columns 12 are installed in the cylindrical column material reaction section 2, and they are distributed in an equilateral triangle. The pipe columns 12 are fixed on the fixing frame 11, and the fixing frame is fixed On the main body ...

Embodiment 3

[0052] See Figure 2. A fluidized-bed reactor with a height of 1800mm and an inner diameter of 100mm for oxidation-reduction roasting high-calcium-magnesium-titanium slag, which mainly consists of a cylindrical column material settling section 1, a cylindrical column material reaction section 2 and a conical The cylinder gas preheating section 3 constitutes.

[0053] The top of a cylindrical column material reaction section 2 is in the shape of a bell mouth, and a cylindrical column material settling section 1 is connected to the top of the bell mouth column, and a cylindrical column material reaction section is connected to a bottom end of the cylindrical column material reaction section. In the conical column gas preheating section 3, three pipe columns 12 are installed in the cylindrical column material reaction section 2, and they are distributed in an equilateral triangle. The pipe columns 12 are fixed on the fixing frame 11, and the fixing frame is fixed On the main body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com