Plated tower

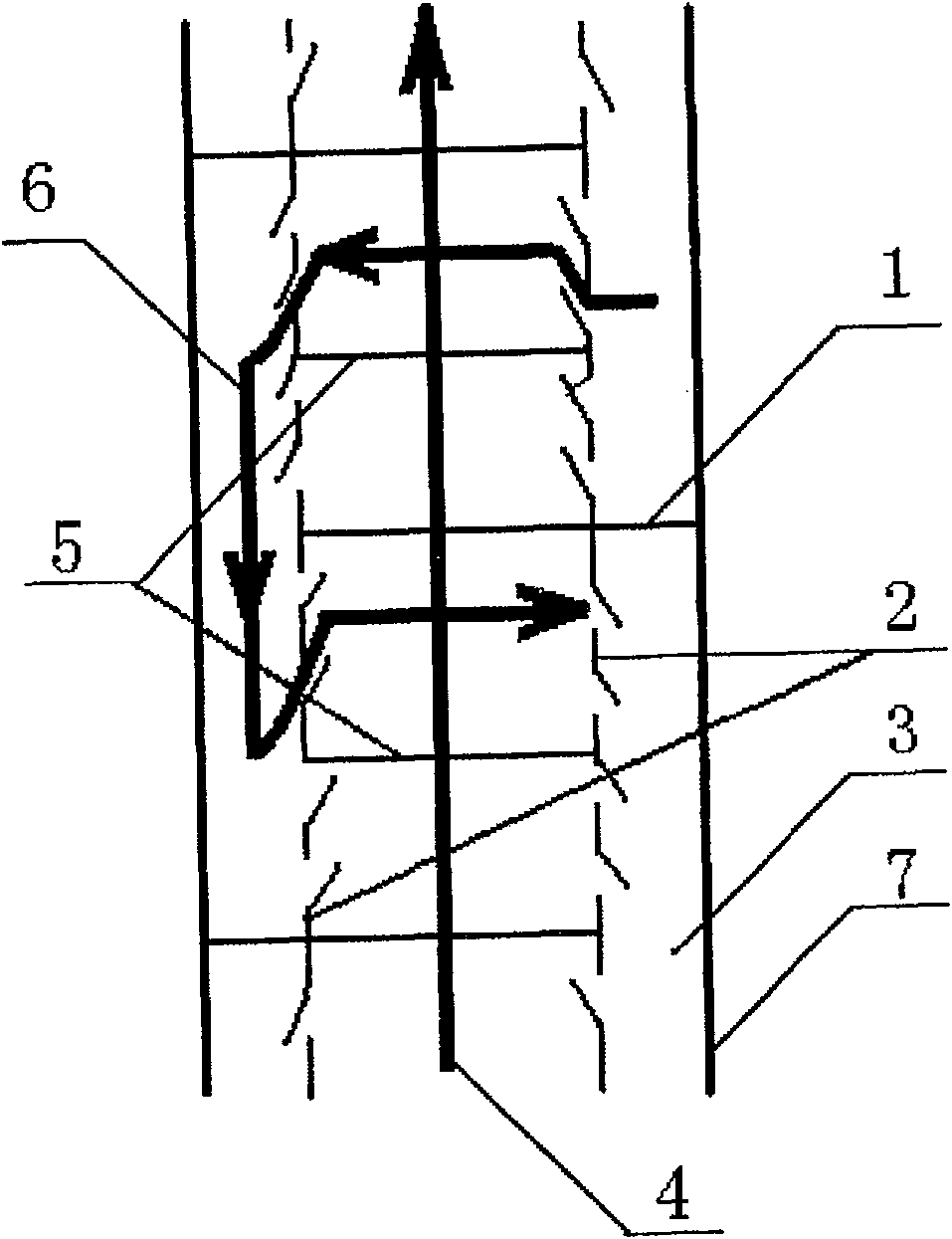

A plate tower, a new type of technology, applied in the field of chemical production equipment, plate tower, can solve the problems of small contact area, short contact time, low heat transfer, mass transfer efficiency, etc., to increase the opening area, increase the opening rate, The effect of improving the gas flow capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] In the laboratory, a common sieve tray is used to separate the ethanol-water mixed solution. The inner diameter of the rectification tower is 80 mm, 12 trays are installed in the tower, and the tray spacing is 50 mm. The feed contains 63% ethanol (mass percentage, the same below), the reflux ratio is 3, and it is operated at normal pressure. After stabilization, it is measured that the top distillate contains 90% ethanol and the bottom residue contains 5% ethanol.

[0019] The new type plate tower described in the present invention is used instead. Ordinary sieve plates are installed in the tower, the number of plates is reduced to 10, the area of the plate opening area is increased by 10%, the distance between the plates is reduced to 40 mm, the downcomer plate is provided with rectangular guide holes, and the opening rate is 20%. , The effective height of the tower (tray spacing × number of trays) is reduced from the original 600 mm to 400 mm. After stabilization, it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com