Particulate water absorber comprising water-absorbing resin as main component and process for manufacturing same

A manufacturing method and granular technology, applied in chemical instruments and methods, absorbent pads, other chemical processes, etc., can solve problems such as deterioration, liquid permeability, gel strength reduction, urine leakage from paper diapers, gel stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0082] (2-1) Preparation process of monomer aqueous solution

[0083] This step is a step of preparing an aqueous solution (hereinafter referred to as "monomer aqueous solution") containing acrylic acid (salt) as a main component. In addition, this "main component" has the same meaning as the content described in (1-2) "polyacrylic acid (salt)". In addition, instead of the monomer aqueous solution, a monomer slurry liquid may be used as long as the water absorbing performance is not lowered, but for convenience, the monomer aqueous solution will be described below.

[0084] (acrylic acid)

[0085] In the present invention, acrylic acid is used as a monomer from the viewpoint of effects, but such acrylic acid usually contains trace components such as polymerization inhibitors and impurities.

[0086] As the above-mentioned polymerization inhibitor, preferably phenols, more preferably methoxyphenols, and even more preferably p-methoxyphenols, from the effect of inhibiting poly...

Embodiment

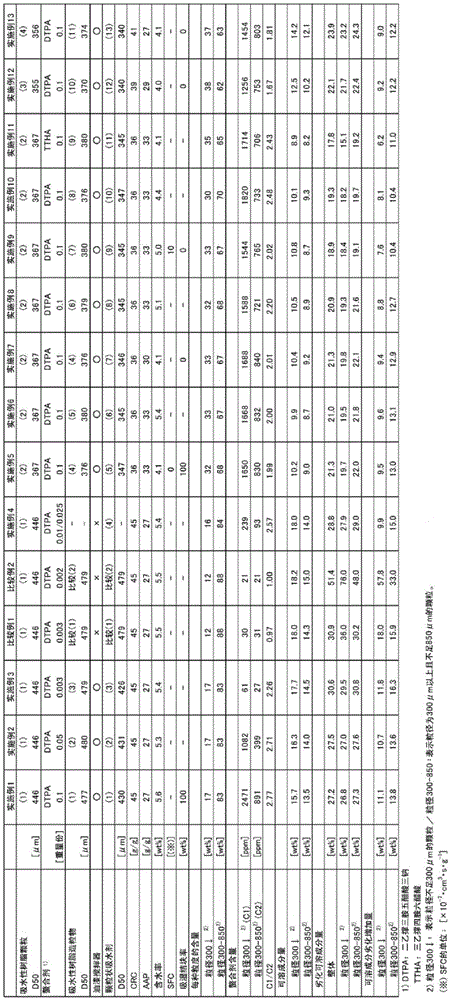

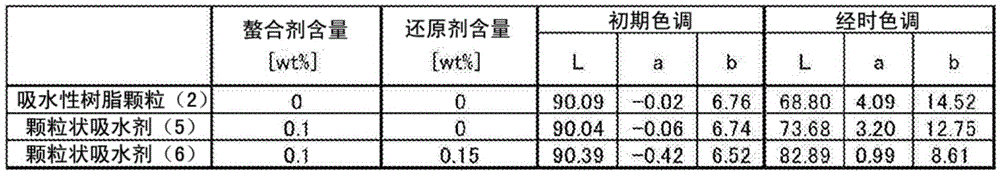

[0307] The present invention will be described in more detail with reference to the following examples, but the present invention is not to be construed as limited thereto, and examples obtained by appropriately combining the technical means disclosed in the respective examples are also included in the scope of the present invention.

[0308] It should be noted that, the electrical equipment (including the physical property measurement of the water absorbing agent) used in the production examples, examples and comparative examples used a power supply of 200V or 100V unless otherwise specified. In addition, each physical property of the water absorbing agent of this invention was measured under the conditions of room temperature (20-25 degreeC), and a relative humidity of 50%RH, unless otherwise specified.

[0309] [Measurement of Physical Properties of Particulate Water Absorbent]

[0310] The methods for measuring the physical properties of the particulate water-absorbing age...

manufacture example 1

[0402] In 5500 g of sodium acrylate aqueous solution (monomer concentration: 38 wt%) obtained by neutralizing acrylic acid containing 70 ppm of p-methoxyphenol with an aqueous sodium hydroxide solution and having a neutralization rate of 75 mol% (monomer concentration: 38 wt%) 2.5 g of polyethylene glycol diacrylate (average molecular weight: 523) was used as the monomer aqueous solution (1).

[0403] Next, the above-mentioned monomer aqueous solution (1) was put into a reactor formed by capping a double-arm jacketed stainless-steel kneader having an inner volume of 10 L and having two Σ-shaped blades while maintaining the liquid temperature at At 30°C, nitrogen was blown into the reactor to replace the inside of the system with nitrogen.

[0404] Next, while stirring the monomer aqueous solution (1), 14.2 g of a 20 wt % sodium persulfate aqueous solution and 2.4 g of a 1 wt % aqueous solution of L-ascorbic acid were added as polymerization initiators, respectively, and the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com