Method for preparing boron-doped graphene through electrochemical stripping of double graphite electrodes

A graphite electrode and electrochemical technology, applied in the field of boron-doped graphene prepared by electrochemical exfoliation of double graphite electrodes, to achieve low cost, reduce cost, and avoid high toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

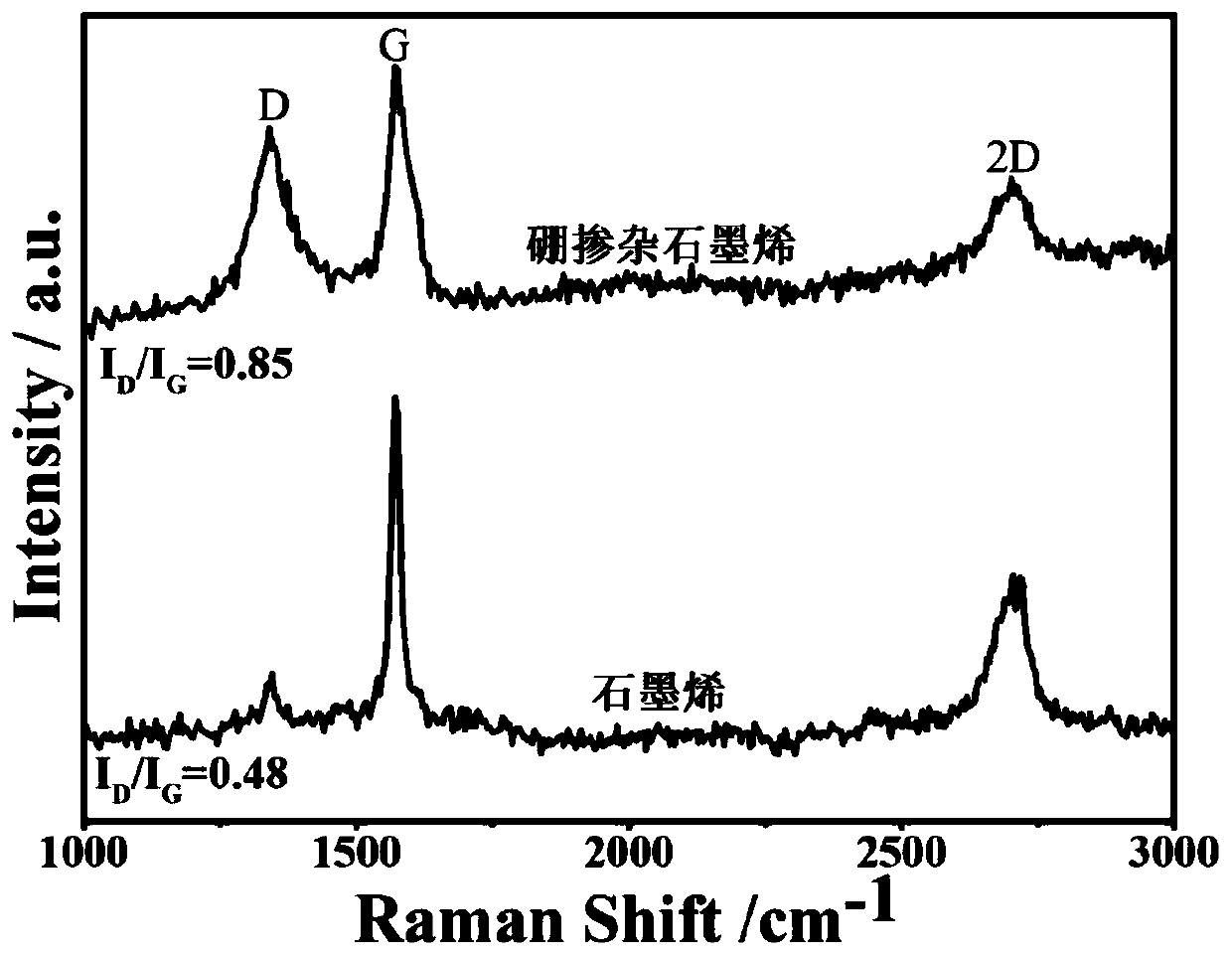

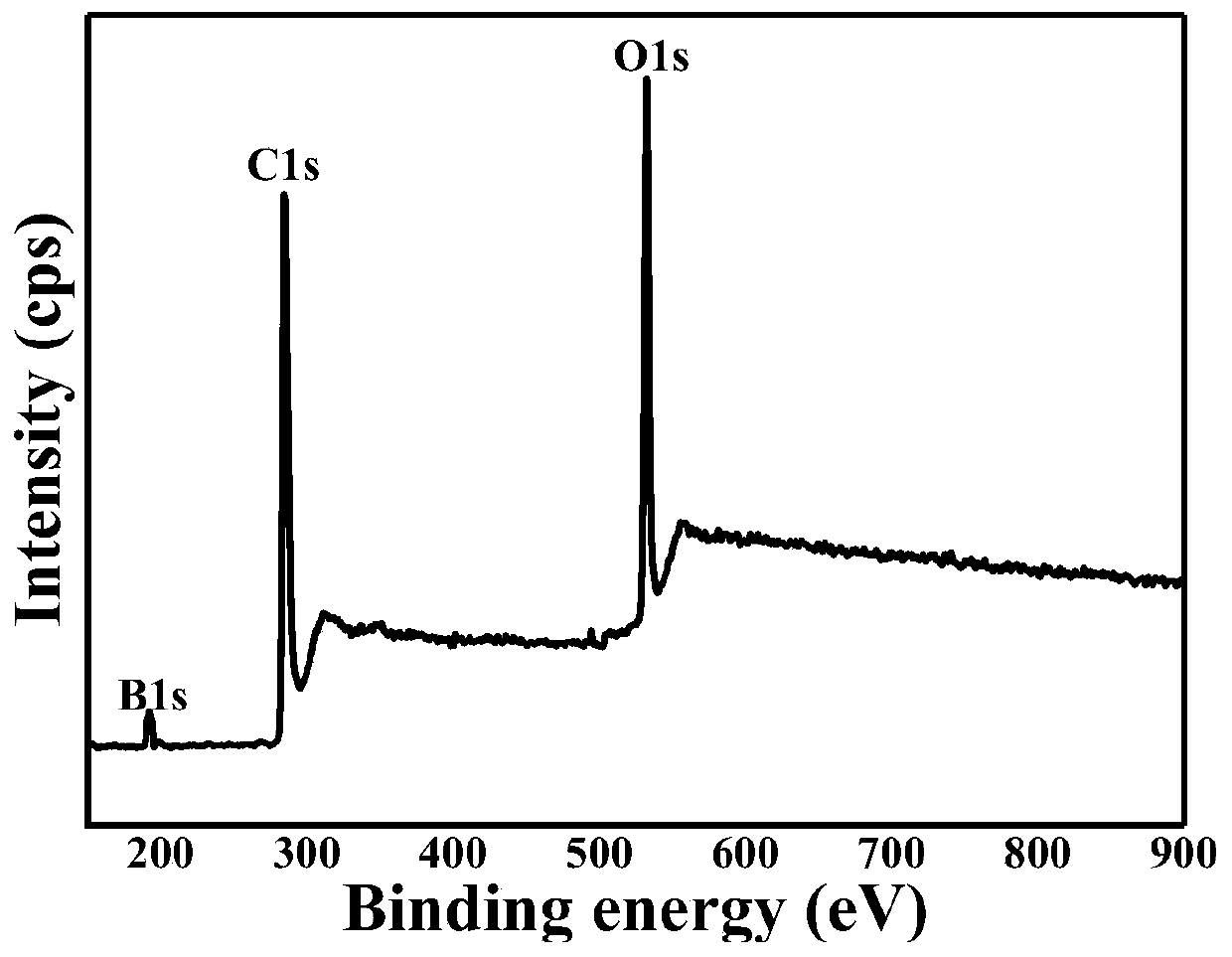

[0048] Please refer to figure 1 and image 3 , figure 1 For the Raman diagram of boron-doped graphene prepared by electrochemical exfoliation of dual graphite electrodes in Example 1 of the present invention, image 3 The boron-doped graphene X-ray photoelectron spectroscopy (XPS) diagram prepared for electrochemical exfoliation of double graphite electrodes in Example 1 of the present invention.

[0049] In this embodiment, 0.1 mol / L sodium borohydride was used and dissolved in 300 mL of deionized water to form an electrolyte solution.

[0050] Then put a graphite foil electrode with a length of 5cm, a width of 6cm, and a thickness of 0.2mm into the electrolyte, connect to a 10V AC power supply, and change the positive and negative poles of the power supply every 30s until the reaction of the two-electrode graphite electrode ends. It takes about 2 hours in this example.

[0051] Then use absolute ethanol and deionized water to carry out multiple re-washing, for example, w...

Embodiment 2

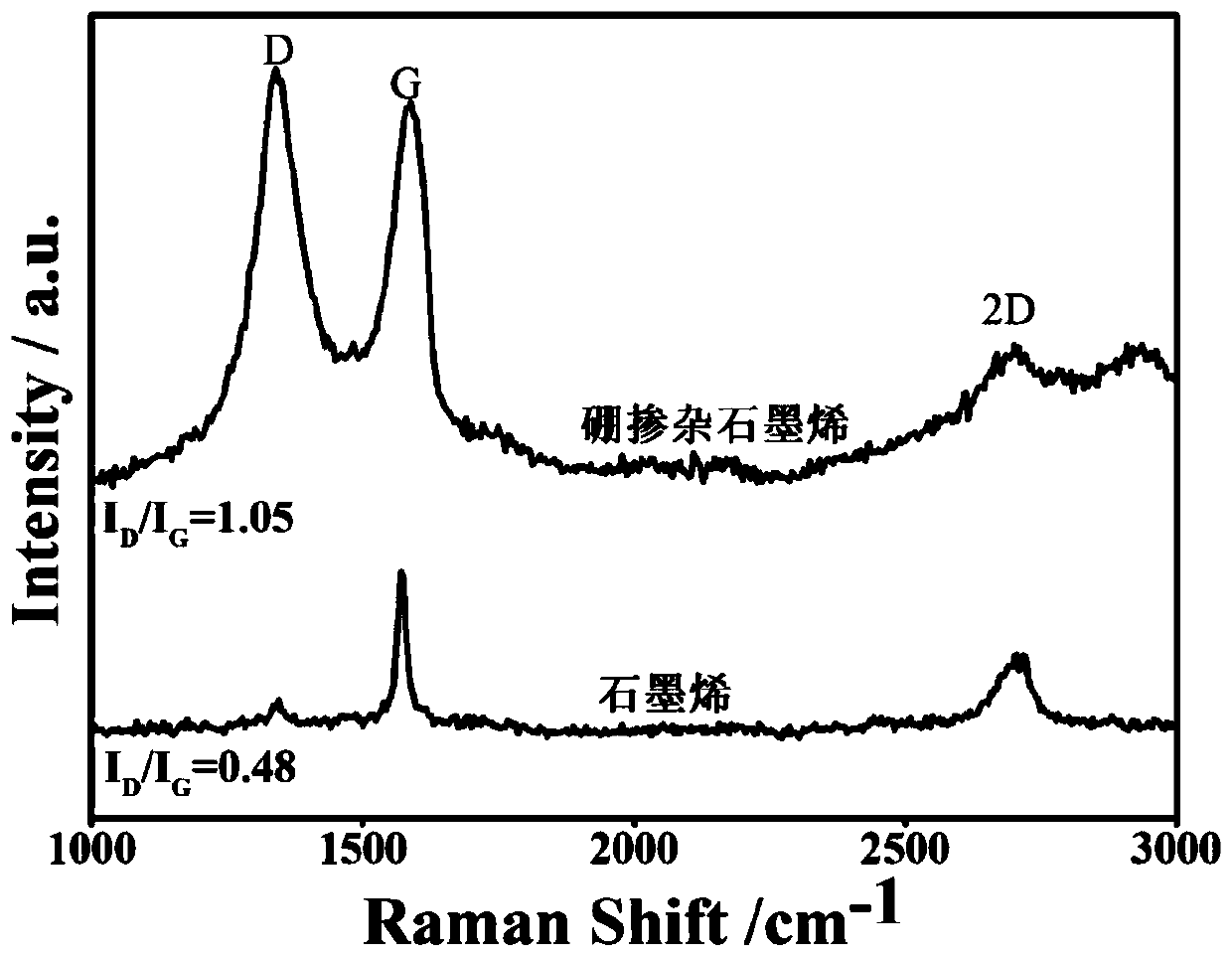

[0056] Please refer to figure 2 and Figure 4 , figure 2 For the Raman diagram of boron-doped graphene prepared by electrochemical exfoliation of dual graphite electrodes in Example 1 of the present invention, Figure 4 The boron-doped graphene X-ray photoelectron spectroscopy (XPS) diagram prepared for electrochemical exfoliation of double graphite electrodes in Example 1 of the present invention.

[0057] In this embodiment, 0.1 mol / L sodium borohydride was used and dissolved in 300 mL of deionized water to form an electrolyte solution.

[0058] Then put a graphite foil electrode with a length of 5cm, a width of 6cm, and a thickness of 0.2mm into the electrolyte, connect to a 10V AC power supply, and change the positive and negative poles of the power supply every 30s until the reaction of the two-electrode graphite electrode ends. It takes about 2 hours in this example.

[0059] Then use absolute ethanol and deionized water to carry out multiple re-washing, for exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com