Method for preparing polyvinylidene fluoride affinity membrane using amino acid as ligand

A polyvinylidene fluoride and amino acid technology, which is applied in the preparation method of peptides, chemical instruments and methods, membrane technology, etc., to achieve the effect of simple and convenient process, high adsorption efficiency, and meeting the needs of clinical applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

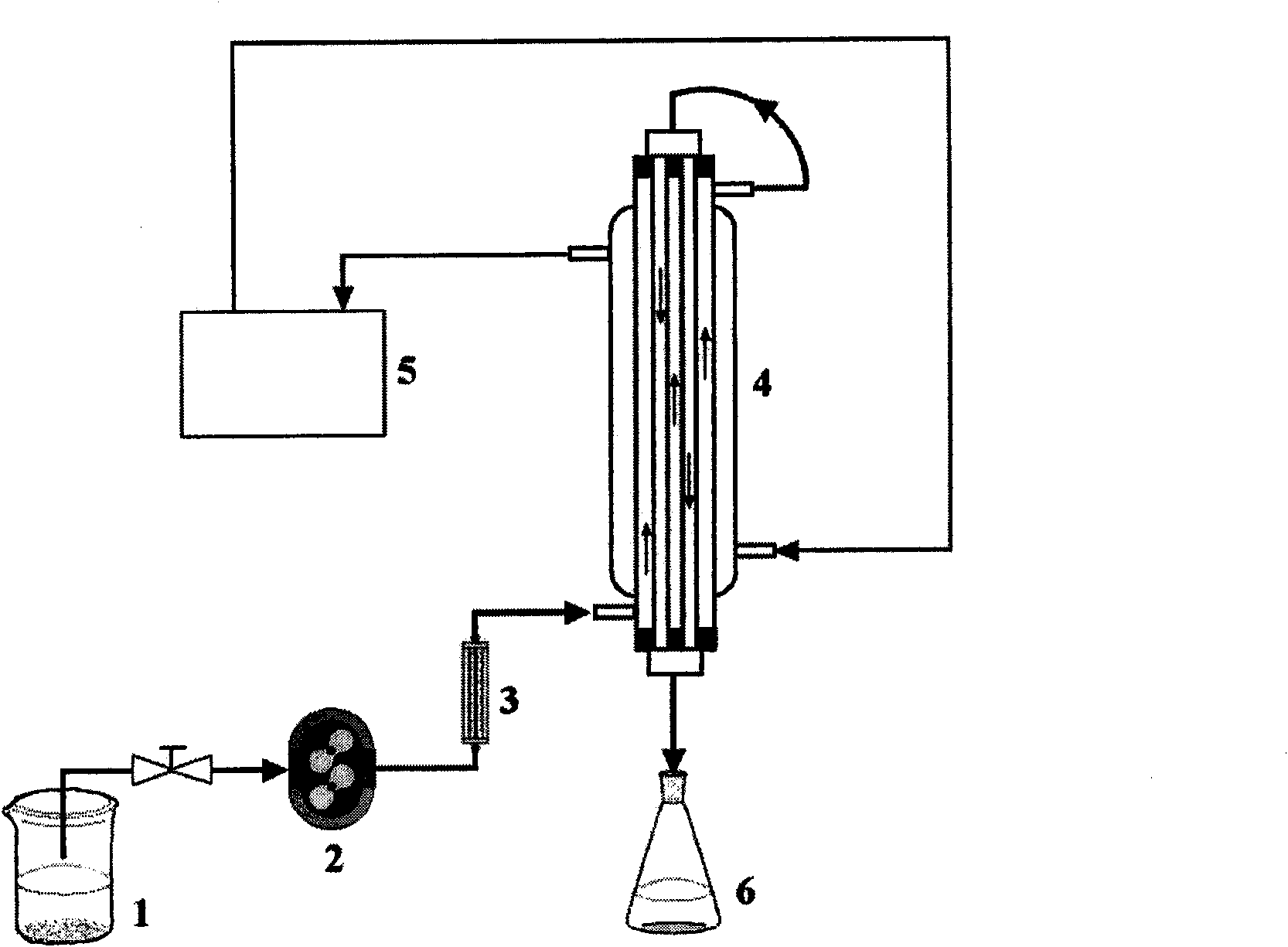

Method used

Image

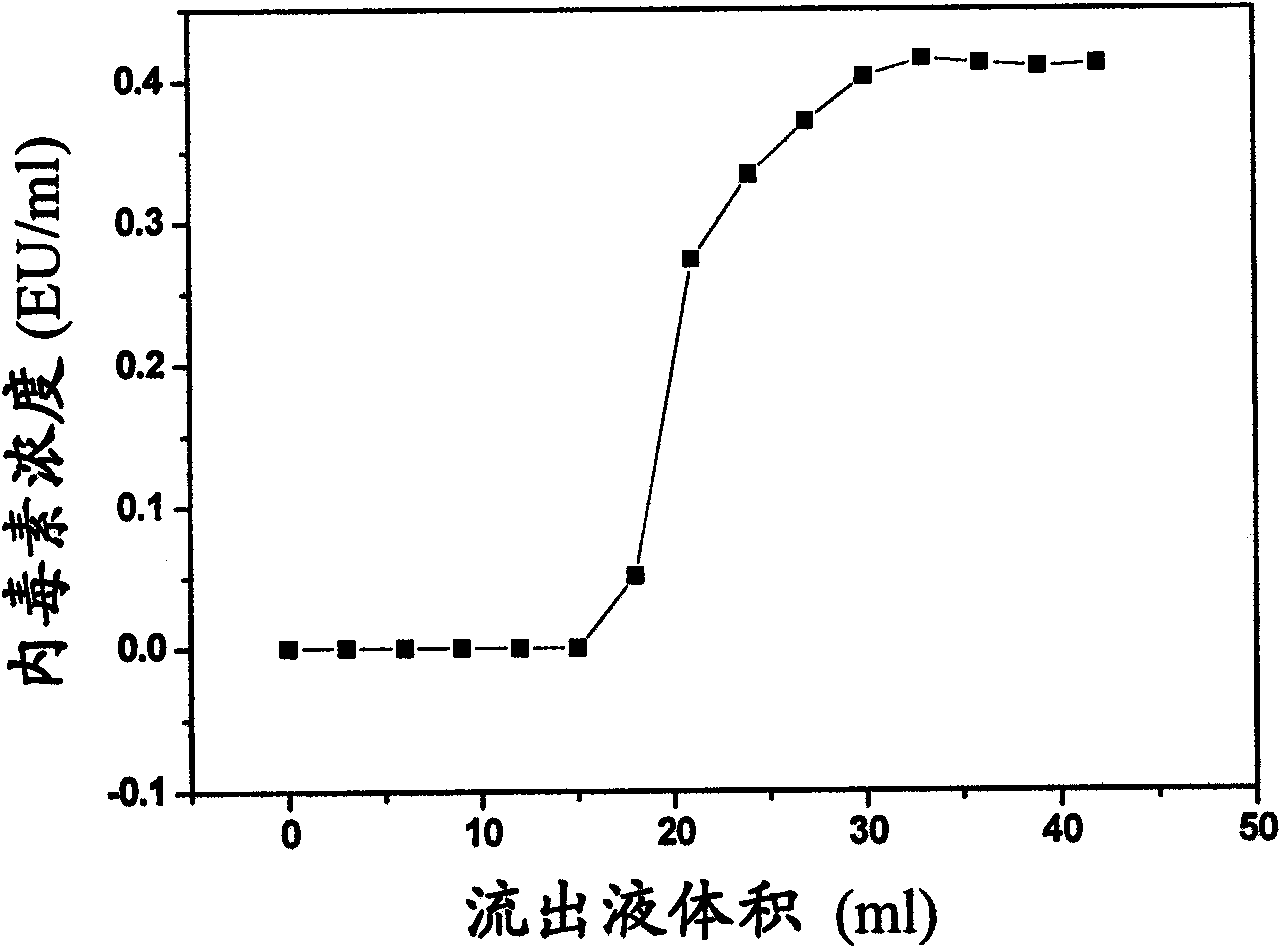

Examples

Embodiment 1

[0039] 1) Rinse the PVDF hollow fiber membrane with 30% ethanol for 30 minutes, and soak it in deionized water for 1 hour to wash away impurities on the surface of the membrane.

[0040] 2) Add 40g / l of KMnO 4 and 3mol / l KOH mixed solution at 80°C with a constant flow pump into the PVDF hollow fiber membrane module to react for 30min, and then with 60g / l H 2 SO 4 and 60g / l NaHSO 3 The mixture is restored.

[0041] 3) The membrane after reduction treatment was treated with a mixture of 1 mol / l NaOH and 10 g / l HEC at 90° C. for 15 min to increase the hydrophilicity of the membrane surface. Place it in a constant temperature hot air drying oven at 90°C and dry it with 0.5mol / l Na 2 CO 3 The solution was washed at 90°C for 10 min to wash off the unreacted HEC on the surface of the PVDF membrane.

[0042] 4) The hydrophilically modified membrane was activated at 60° C. with a mixture of epichlorohydrin (ECH): 1 mol / l NaOH with a volume ratio of 1:4, and washed with deionized ...

Embodiment 2

[0050] 1) Rinse the PVDF hollow fiber membrane with 30% ethanol for 40 minutes, and soak it in deionized water for 1 hour to wash away impurities on the surface of the membrane.

[0051] 2) Add 50g / l of KMnO 4 and 3mol / l KOH mixed solution at 60°C with a constant flow pump into the PVDF hollow fiber membrane module to react for 30min, and then with 60g / l H 2 SO 4 and 60g / l NaHSO 3 The mixture is restored.

[0052] 3) The membrane after reduction treatment was treated with a mixed solution of 1.5 mol / l NaOH and 15 g / l HEC at 80° C. for 10 min to increase the hydrophilicity of the membrane surface. Place it in a constant temperature hot air drying oven at 80°C and dry it with 0.5mol / l Na 2 CO 3 The solution was washed at 80°C for 10 min to wash off the unreacted HEC on the surface of the PVDF membrane.

[0053] 4) The hydrophilized modified membrane was activated with a mixture of epichlorohydrin (ECH): 1 mol / l NaOH with a volume ratio of 1:3 at 50° C., and washed with dei...

Embodiment 3

[0061] Step 1-6 is the same as embodiment 1

[0062] 7) React with 3g / l asparagine solution (0.2mol / l phosphate buffer with pH 7.2 as solvent) at 45°C for 24h to obtain polyvinylidene fluoride grafted with asparagine ligand membrane.

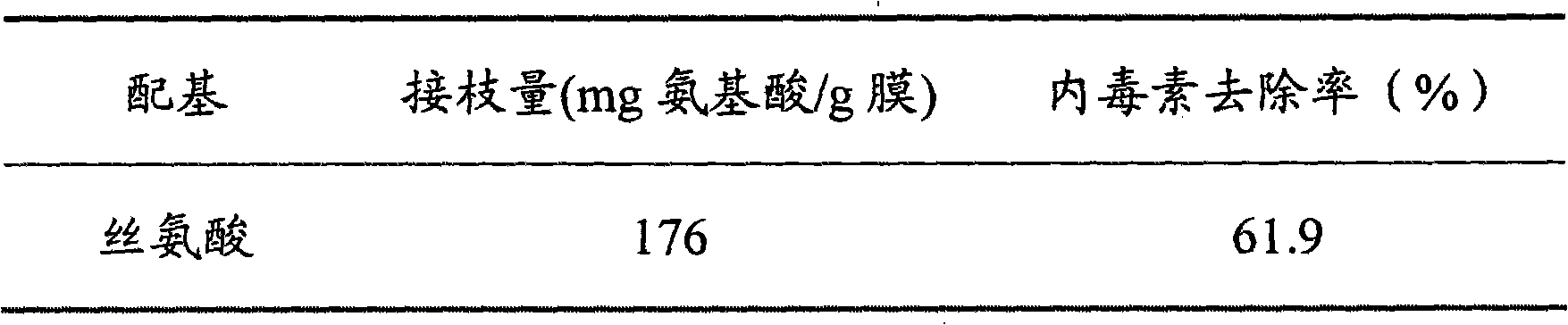

[0063] The experimental procedure for the removal of endotoxin in plasma by the polyvinylidene fluoride affinity membrane with asparagine ligand is the same as that in Example 1, and the graft density and endotoxin removal efficiency of the ligand are shown in Table 3.

[0064] The performance of the prepared affinity membrane of table 3 embodiment 3

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| grafting amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com