Method for performing modification of chitosan or derivative thereof on surface of medical polyurethane material

A polyurethane material, chitosan technology, applied in the field of modification of chitosan or its derivatives, can solve problems such as insoluble in aqueous solution, poor mechanical processing performance, etc., and achieve the effect of easy control of reaction conditions, high difficulty and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Graft chitosan on the surface of medical polyurethane material, and use Jones reagent for surface oxidation treatment

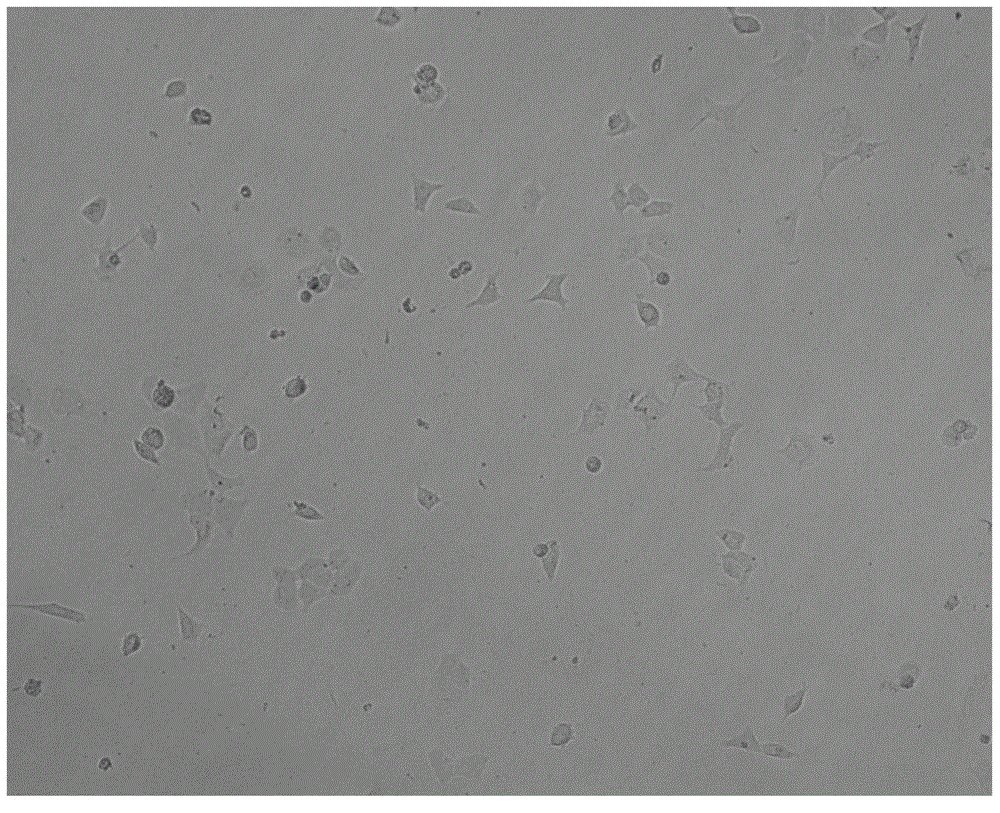

[0036] Measure 30ml of Jones reagent, put the washed and dried 0.5g (2cm*2cm) polyurethane film material into Jones reagent for 4h reaction. After the reaction was completed, the polyurethane film material was taken out and washed for 10 minutes, then placed in a 3 wt % carbodiimide solution for 8 hours, washed and dried. Prepare 50ml chitosan solution of 5wt% in a three-necked flask, put it into an oil bath with a temperature of 55° C., and under magnetic stirring, firstly add polyurethane film material into the reaction system, and pass into nitrogen protection. 1 ml of acrylic acid solution with a concentration of 95 wt% was slowly dropped into the reaction system with a dropper. The reaction time is 8h. After the grafting reaction, wash in hot water at about 60°C for 8 hours, change the water every 2 hours, and then ultrasonically clean with etha...

Embodiment 2

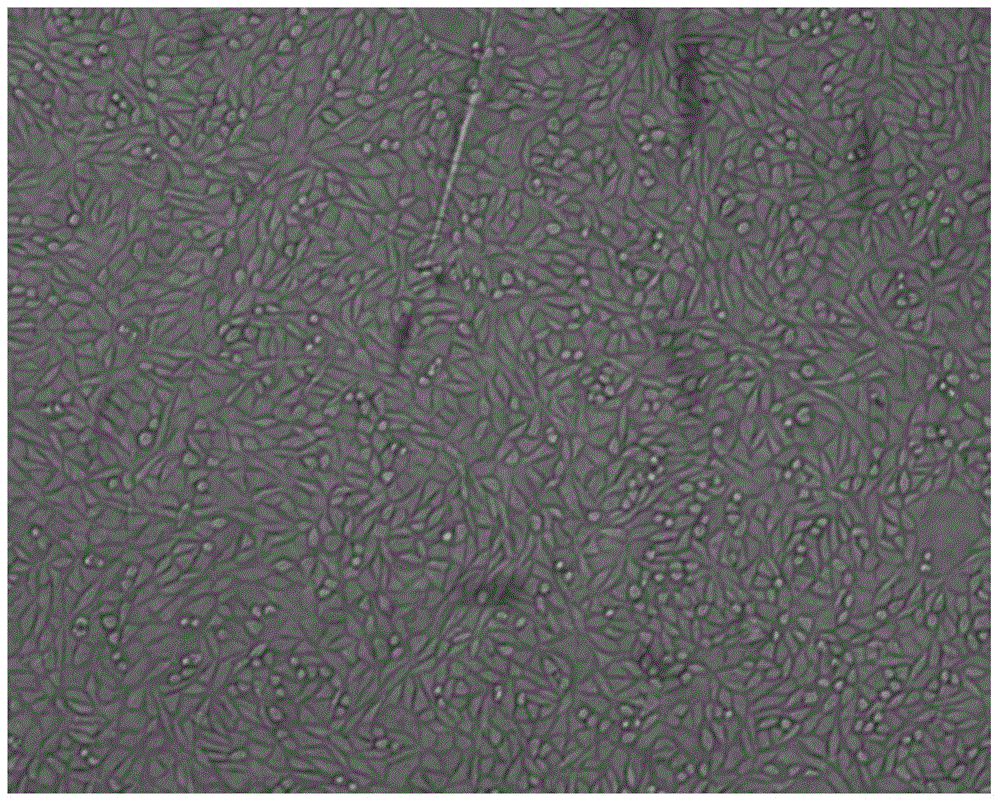

[0039] Grafting carboxymethyl chitosan on the surface of medical polyurethane material, and using Jones reagent for surface oxidation treatment

[0040] Measure 50ml of Jones reagent, put the cleaned and dried polyurethane catheter material with a length of 4cm in Jones reagent for 2h. After the reaction was completed, the polyurethane conduit material was taken out and cleaned for 20 minutes, then placed in a 2 wt % carbodiimide solution for 7 hours, washed and dried. Prepare 50ml carboxymethyl chitosan solution of 8wt% in a three-necked flask, put it into an oil bath at a temperature of 55° C., and under magnetic stirring, firstly add the polyurethane catheter material into the reaction system, and pass it into the nitrogen protection. 1 ml of acrylic acid solution with a concentration of 95 wt% was slowly dropped into the reaction system with a dropper. The reaction time is 8h. After the grafting reaction, wash in hot water at about 60°C for 8 hours, change the water ever...

Embodiment 3

[0043] Grafting phosphorylcholine chitosan derivatives on the surface of medical polyurethane materials, and using ozone for surface oxidation treatment

[0044] The cleaned and dried polyurethane catheter material with a length of 4 cm was activated in ozone with a concentration of 20 mg / L for 40 min. After the reaction was completed, the polyurethane conduit material was taken out and placed in a 5 wt % carbodiimide solution for 9 hours of reaction, washed and dried. Prepare 50ml phosphorylcholine chitosan derivative solution of 5wt% in a three-necked flask, put it into an oil bath with a temperature of 60°C, and under magnetic stirring, firstly add the polyurethane catheter material into the reaction system, and pass it into the nitrogen protection. Slowly drop 1 ml of 95% acrylic acid solution into the reaction system with a dropper. The reaction time is 12h. After the grafting reaction, wash in hot water at about 50°C for 12 hours, change the water every 2 hours, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com