Multifunctional comfort fiber with functions of phase transition temperature regulation, moisture absorption and moisture wicking

A moisture-wicking, multi-functional technology, applied in the field of comfort fibers, to avoid the loss of phase change enthalpy, obvious moisture-wicking, low leakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

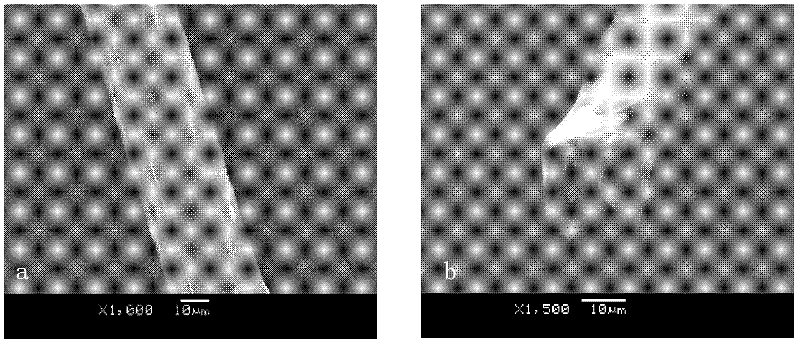

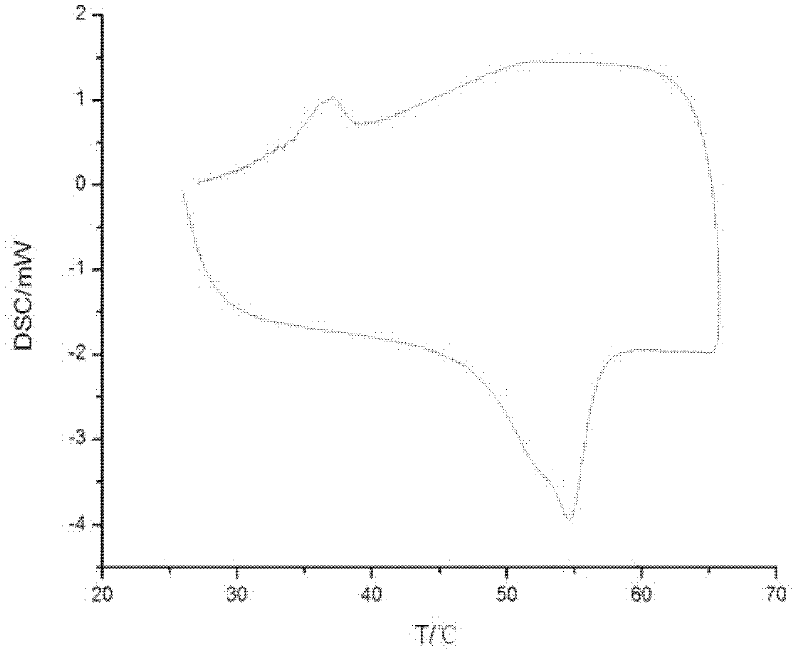

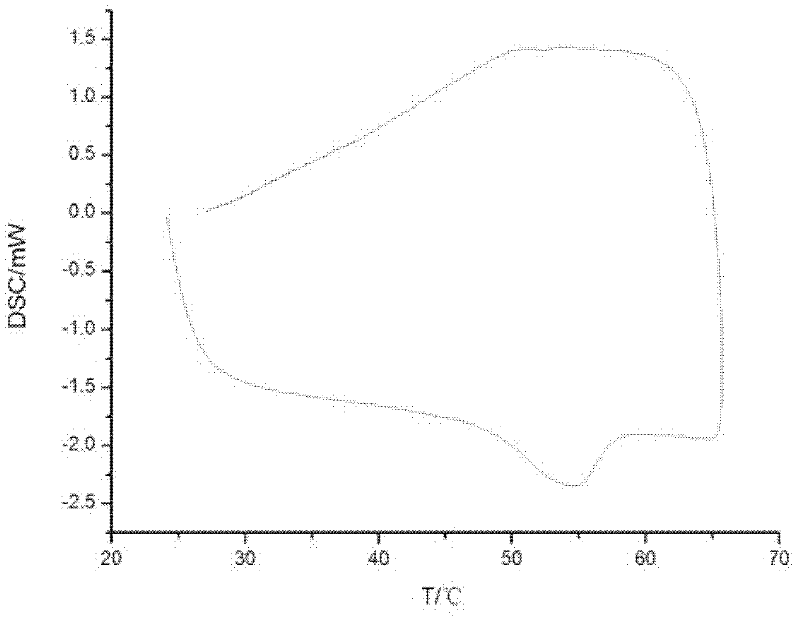

Image

Examples

Embodiment 1

[0029] ① Preparation of interpenetrating network composite phase change materials: N-methylolacrylamide is used as network monomer, N, N-methylenebisacrylamide is used as crosslinking agent, ammonium persulfate is used as initiator, polyethylene glycol is a phase change material.

[0030] Wherein, cross-linking agent 1.5g, monomer 8g, initiator 0.3g, polyethylene glycol (molecular weight 2000) 24g, water 50ml.

[0031] The network monomer, cross-linking agent, polyethylene glycol and solvent water are weighed and reset in the flask according to the above ratio. After dissolving, ultrasonically disperse for 5 minutes, add the initiator, disperse at 30°C for 5 minutes, and then transfer to 75°C React in a water bath for 3 hours, and then dry at a low temperature of 30°C.

[0032] ② Phase-change temperature-regulating fiber preparation: Polyethylene glycol acrylate is used as a compatibilizer, and the composite phase-change material and polypropylene are melt-blended and spun in...

Embodiment 2

[0037] ① Preparation of interpenetrating network composite phase change material: as in Example 1.

[0038] ② Phase-change temperature-regulating fiber preparation: Polyethylene glycol acrylate is used as a compatibilizer, and the composite phase-change material and polypropylene are melt-blended and spun in a screw extruder in proportion to obtain a phase-change temperature-regulating fiber. Geometric parameters of screw extruder: D, 20mm; L / D, 25; process parameters: speed, 35r / min; ℃.

[0039] Among them, 7.5g of composite phase change material, 42.5g of polypropylene, and 2.5g of polyethylene glycol acrylate.

Embodiment 3

[0041] ① Preparation of interpenetrating network composite phase change material: as in Example 1.

[0042] ② Phase-change temperature-regulating fiber preparation: Polyethylene glycol acrylate is used as a compatibilizer, and the composite phase-change material and polypropylene are melt-blended and spun in a screw extruder in proportion to obtain a phase-change temperature-regulating fiber. Geometric parameters of screw extruder: D, 20mm; L / D, 25; process parameters: speed, 35r / min; ℃.

[0043] Among them, 5g of composite phase change material, 45g of polypropylene, and 2.5g of polyethylene glycol acrylate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

| Phase change enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com