Preparation method of porous nano flaky nickel phosphide material loaded by multiple substrates

A nano-flaky, substrate-loaded technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of unfavorable commercial production, cumbersome preparation process, poor mechanical properties, etc., and achieve excellent Catalytic activity and long-term electrolytic water stability, simple preparation process, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

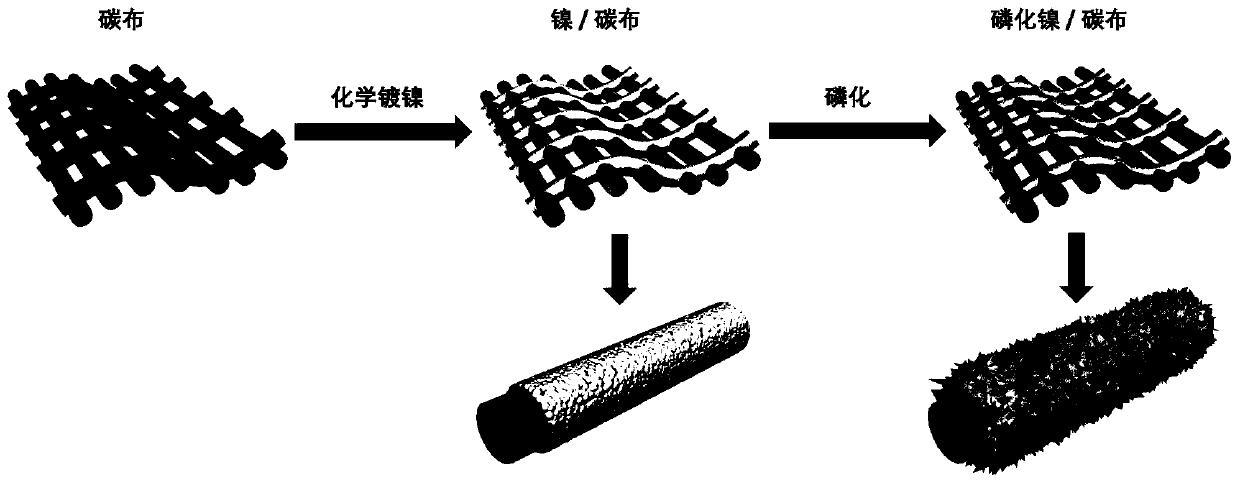

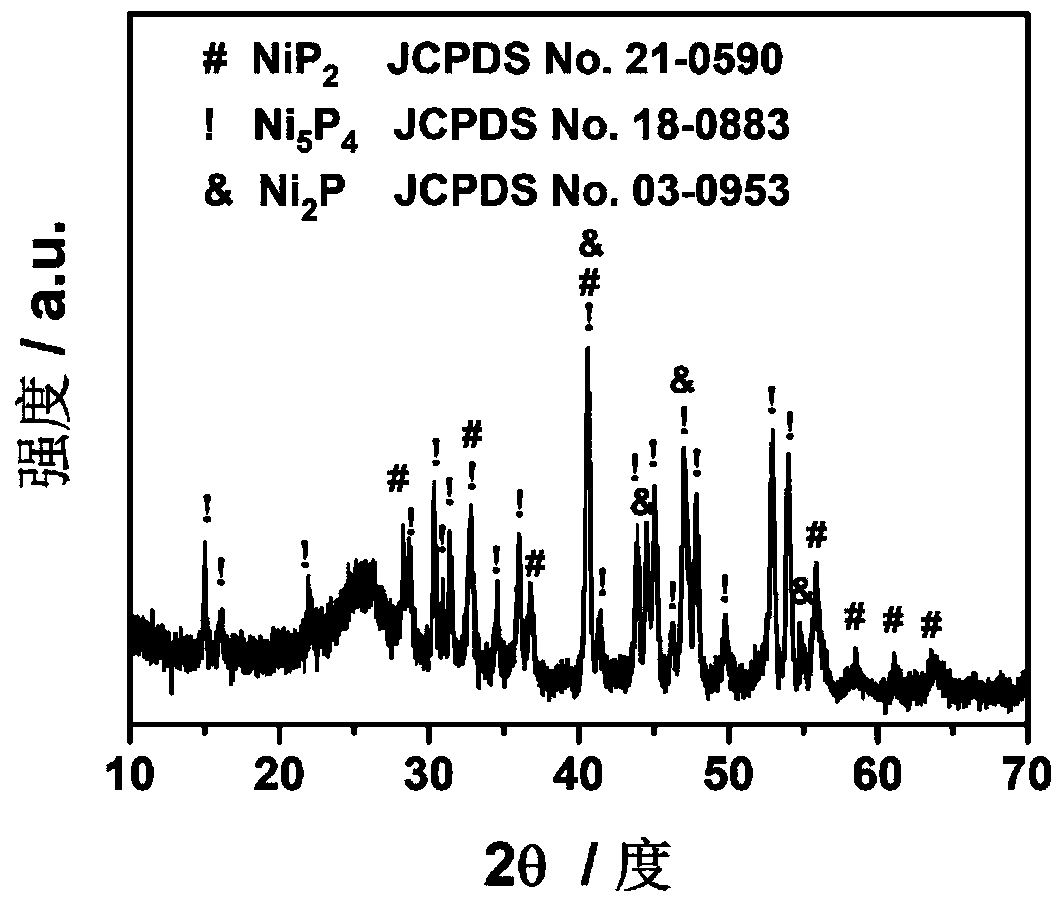

[0032] This example provides a general method that can be prepared on a variety of substrates in order to solve the problems in the prior art that the preparation process of high-performance nickel phosphide electrocatalysts is complicated, not environmentally friendly, poor in repeatability, and unfavorable for large-scale preparation. It is a combination of fast and easy electroless nickel plating technology and simple and easy repeatable semi-closed phosphating method. The obtained nickel phosphide material is a porous nanosheet, which has the characteristics of large specific surface area, high catalytic activity, low overpotential, low Tafel slope and good stability, and can be directly used as a cathode to assemble an electrolytic cell.

[0033] Specifically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com