Electrolyte and lithium ion battery

A technology of electrolyte and electrolyte salt, which is applied in the field of lithium-ion batteries, can solve problems affecting battery performance, strong oxidation of electrolyte, and easy precipitation, etc., and achieve the effect of improving cycle performance, facilitating dissociation, and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0067] The present invention will be specifically described below by way of examples, but the present invention is not limited by these examples.

reference example 1

[0068] [Reference Example 1] Synthesis of Compound

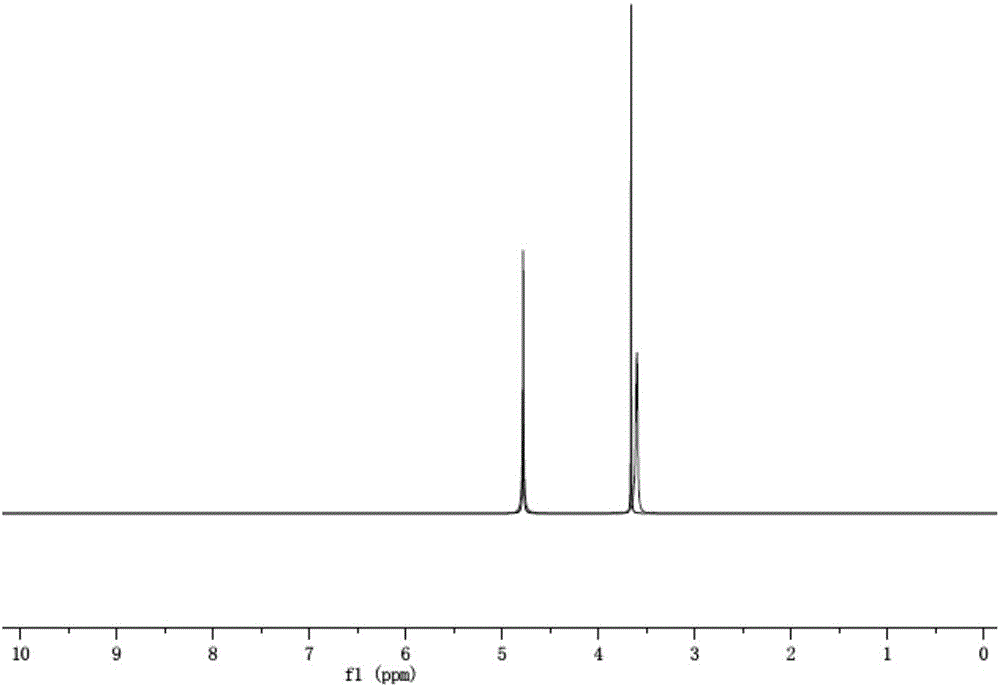

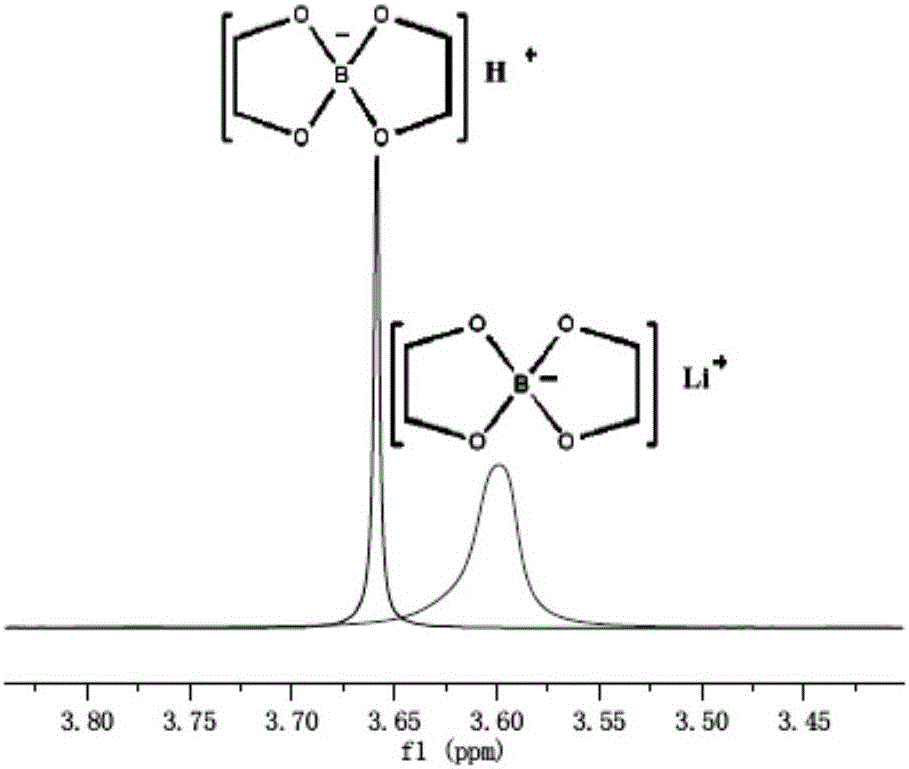

[0069] Synthesis of compound A of the general formula

[0070] first step:

[0071]

[0072] Step 2:

[0073]

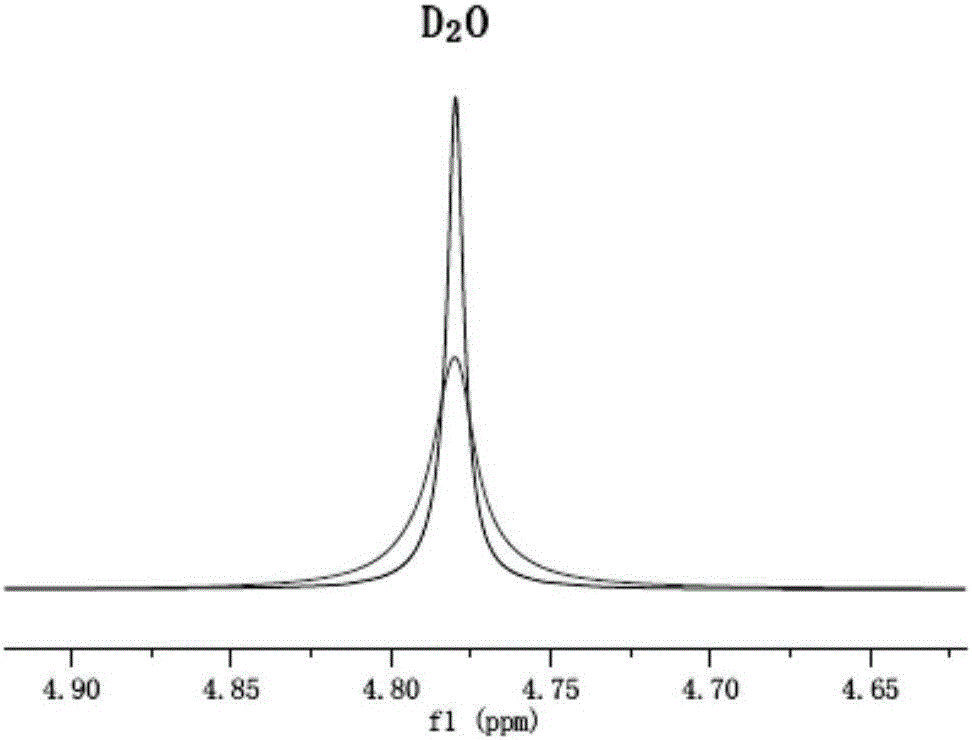

[0074] Operation steps: add 100 ml of toluene into a 250 ml single-necked bottle, then quantitatively add ethylene glycol (20.000 g, 322.37 mmol) and boric acid (9.966 g, 161.19 mmol), and reflux for 2 h under stirring conditions. Then use a water separator to separate the water, collect about 8.7g of water, stop the reaction, cool, concentrate to remove the solvent toluene, and fully remove the excess solvent with an oil pump to obtain 21.4g of white solid B-1-I.

[0075] LiOH (6.76g, 161.10mmol) was added to a 250ml single-necked bottle, the white solid B-1-I (21.4g) obtained in the previous step, toluene (200ml), and water (20ml) were reacted at 80°C for 4h, and after cooling down, Toluene and water were removed in vacuo, and dried in vacuo at 70 °C for 16 h to obtain a white powder B-1. This product...

Embodiment 1

[0081] Through the M6S process, the cathode is LiCoO 2 , the negative electrode is a soft-packed battery core of graphite, dried at 85°C to a moisture content of less than 200ppm, and the prepared electrolyte is injected into the battery core. The composition of the electrolyte is shown in Table 3, and the structural formula of the boron salt additive is shown in Table 1.

[0082] table 3:

[0083]

[0084]

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com