Preparation method of homogeneous-phase aluminum-doped small-particle-size cobaltosic oxide

A technology of cobalt tetroxide and small particle size, applied in cobalt oxide/cobalt hydroxide, electrochemical generators, structural parts, etc., can solve the problems of incomplete precipitation of Co metal ions, increased wastewater treatment costs, and general uniformity of aluminum doping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

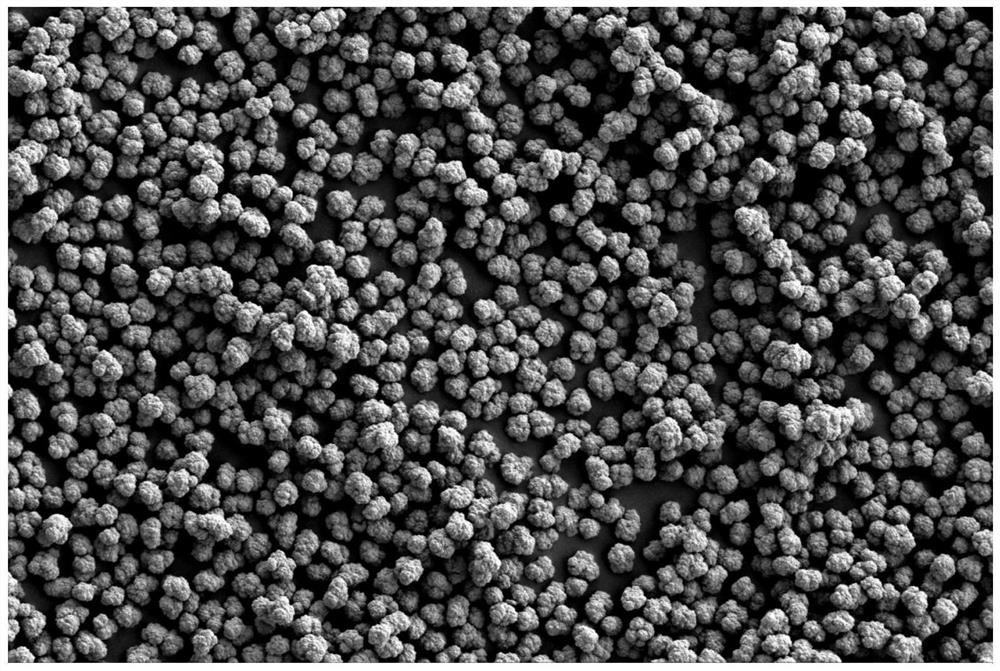

Embodiment 1

[0030] ①Prepare 110g / L cobalt sulfate solution, and add 2.713kg aluminum sulfate octadecahydrate and 0.11kg isopropanol and glycine mixed compound complexing agent to each cobalt solution, and stir evenly;

[0031] ② Add an appropriate amount of deionized water to the reaction vessel as the bottom liquid, adjust the pH of the bottom liquid to 11.0 with sodium hydroxide, and feed compressed air with an air flow rate of 0.7m 3 / h, the temperature is 68°C, under the stirring speed of 400rpm, the prepared cobalt-aluminum mixed solution and 80g / L sodium hydroxide solution are added to the reaction vessel at the same time, and the particle size of the slurry is measured every 2 hours during the process. The pH is measured once an hour, and the process pH is controlled at 11.5;

[0032] ③When the particle size of the slurry reaches the target particle size of 2.0-2.2 μm, stop inputting the cobalt-aluminum mixed solution, and continue to input the lye alone until the pH of the slurry ...

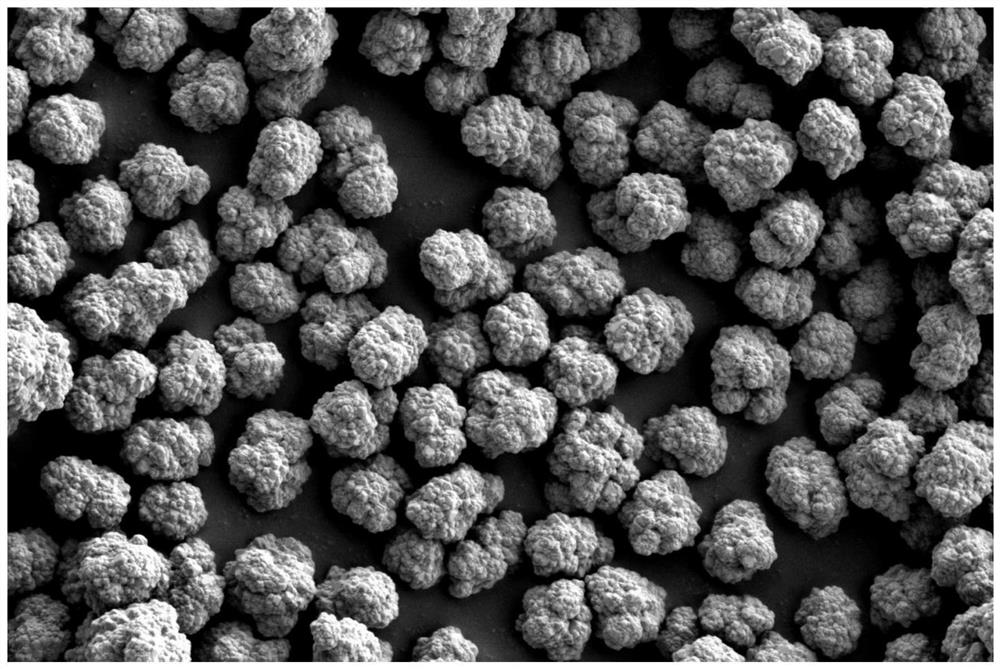

Embodiment 2

[0038] 1. Prepare 130g / L cobalt sulfate solution, and add 15.232kg aluminum sulfate octadecahydrate and 0.65kg glutamic acid and sodium sulfonate mixed compound complexing agent to each cobalt solution, and stir evenly;

[0039] ② Add an appropriate amount of deionized water to the reaction vessel as the bottom liquid, adjust the pH of the bottom liquid to 11.5 with sodium hydroxide, and feed compressed air with a flow rate of 1.4m 3 / h, the temperature is 72°C, under the stirring speed of 420rpm, the prepared cobalt-aluminum mixed solution and 100g / L sodium hydroxide solution are added to the reaction vessel at the same time, and the particle size of the slurry is measured every 2 hours during the process. The pH is measured once an hour, and the process pH is controlled at 11.0;

[0040] ③When the particle size of the slurry reaches the target particle size of 3.9-4.1 μm, stop inputting the cobalt-aluminum mixed solution, and continue to input the lye alone until the pH of t...

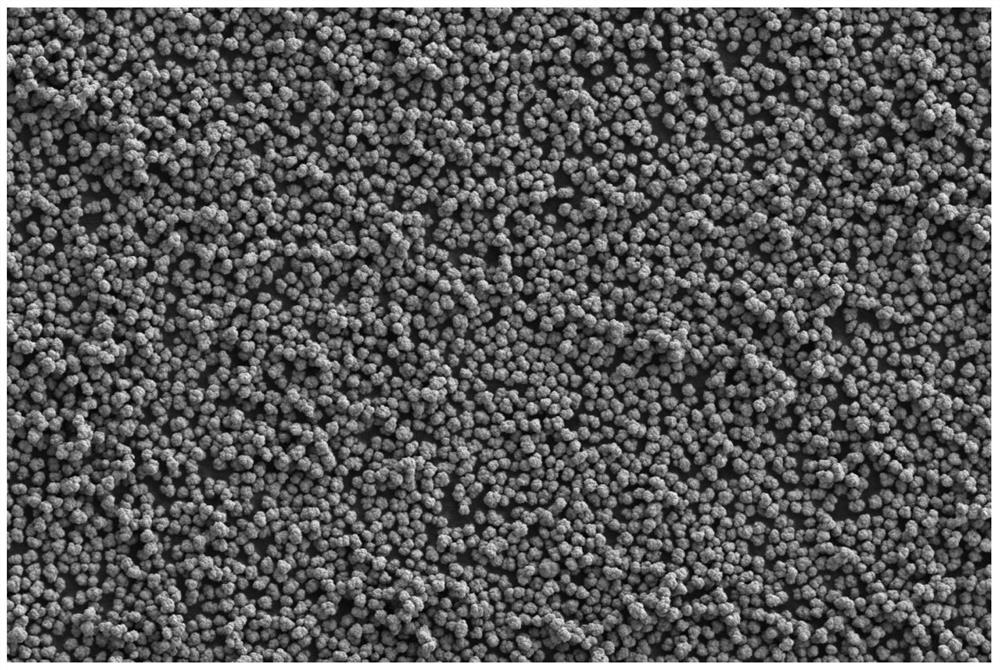

Embodiment 3

[0046] ① Prepare 150g / L cobalt sulfate solution, and add 31.450kg aluminum sulfate octadecahydrate and 1.5kg malic acid and ethanolamine mixed complexing agent to each cobalt solution, and stir evenly;

[0047] ② Add an appropriate amount of deionized water to the reaction vessel as the bottom liquid, adjust the pH of the bottom liquid to 12.0 with sodium hydroxide, and feed compressed air with an air flow rate of 2.1m 3 / h, the temperature is 75°C, under the stirring speed of 450rpm, the prepared cobalt-aluminum mixed solution and 120g / L sodium hydroxide solution are added to the reaction vessel at the same time, and the particle size of the slurry is measured every 2 hours during the process. The pH is measured once an hour, and the process pH is controlled at 10.6;

[0048] ③When the particle size of the slurry reaches the target particle size of 5.8-6.0 μm, stop inputting the cobalt-aluminum mixture, and continue to input the lye alone until the pH of the slurry is 11.8-12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com