Sewage processing agent

A sewage treatment agent, secondary treatment tank technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve ecological environment damage, secondary pollution, poor treatment effect, etc. problem, to achieve the effect of strong operability and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

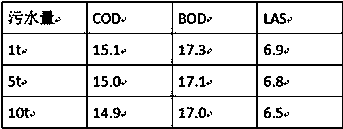

Examples

Embodiment 1

[0014] Sewage treatment agent, including the following raw materials in parts by weight, 45 parts of river sludge, 30 parts of corn stalks, 3 parts of ginkgo leaves, 18 parts of cactus, 8 parts of grape leaves, 18 parts of reed leaves, 7 parts of white sugar, 20 parts of bentonite 25 parts, plant ash 4 parts, oxalic acid 1 part, graphite powder 17 parts, polyacrylamide 22 parts, polyaluminum chloride 28 parts, sodium alginate 4 parts.

[0015] The preparation method of the sewage treatment agent comprises the following steps: (1) Mixing the river sludge and water evenly so that the water content of the river sludge is 75-85%, then adding crushed corn stalks and mixing evenly, statically at 45°C Set aside for 38 hours to obtain a mixture; the crushed corn stalks are passed through a 400-500 mesh sieve; (2) Ginkgo biloba leaves, cactus, grape leaves, and reed leaves are crushed, and sugar and water are added to obtain a mixture, and the mixture is fermented in an enzyme tank for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com