Rare earth compounded coagulating agent for treating waste water and its preparation method

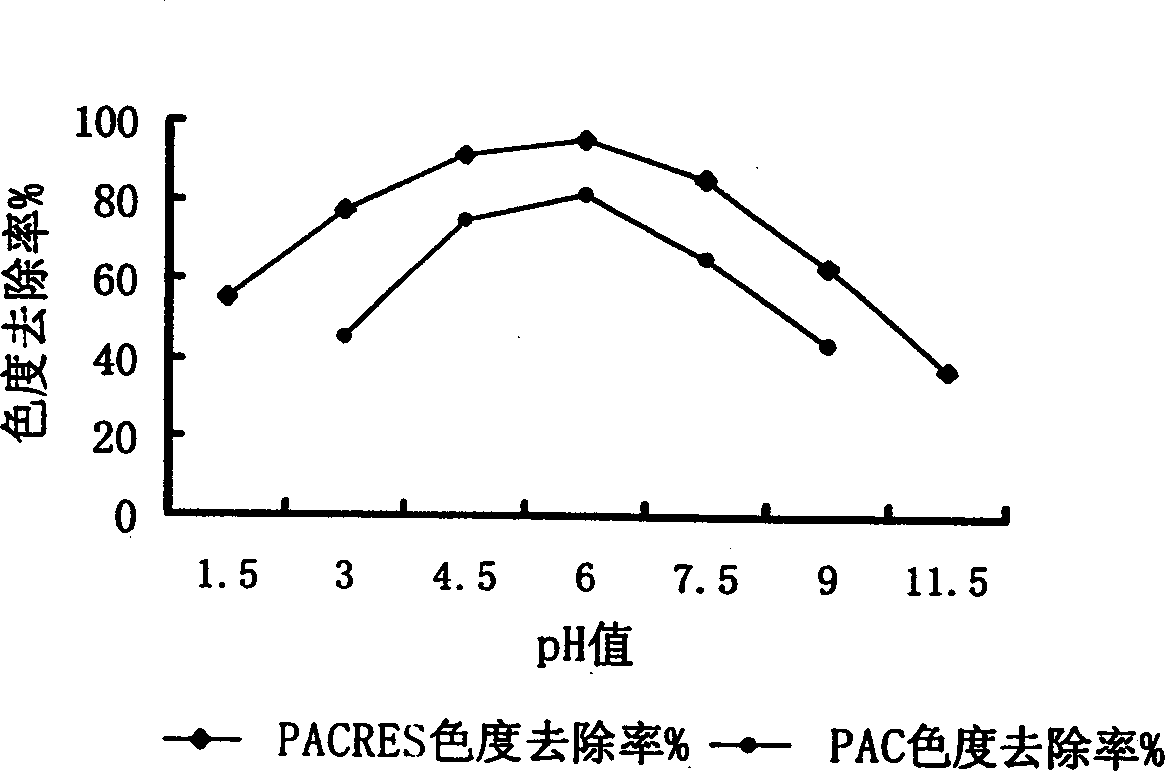

A technology of rare earth compounding and wastewater treatment, which is applied in the direction of flocculation/sedimentation water/sewage treatment, separation methods, chemical instruments and methods, etc., can solve the problems of high consumption, high price, unsatisfactory removal of wastewater chroma, etc. Small amount, good coagulation effect, excellent coagulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: 1. get 25 grams of mixed rare earth oxides, the purity is 99%, and its average molar number is 0.075 mol, slowly add 13.47 ml concentration under stirring and be 98% sulfuric acid (its quality is 26.14 grams, and the molar number is 0.2667 mol) , Ln 2 o 3 : SO 4 2- The molar ratio is 1:3.556, and it is fully reacted under stirring, and the rare earth sulfate compound produced is dissolved in the sulfuric acid when the pH value is 1.5, and 35 ml of its clear solution is taken for later use. ② Take 1000ml of liquid polyaluminum chloride solution, its Al 2 o 3 The content is 12%, the basicity is 60%, the consumption of the liquid polyaluminum chloride solution is controlled at a Ln / Al molar ratio of 0.05834: 1, and the liquid polyaluminum chloride solution is continuously stirred vigorously at a temperature of 65°C, slowly Add 35ml of the prepared sulfuric acid solution of rare earth sulfuric acid compound, keep it warm for 1.5h, the basicity is 55%, lea...

Embodiment 2

[0029] Embodiment 2: 1. get 14 grams of mixed rare earth oxides, purity 99%, its average molar number is 0.042mol, slowly add 7.35ml concentration under stirring and be the sulfuric acid of 98% (its quality is 14.55 grams, and molar number is 0.1455mol) , Ln 2 o 3 : SO4 2- The molar ratio is 1:3.464, stirring continuously to make it fully react, the rare earth sulfate compound produced is dissolved in the sulfuric acid when the pH value is 2, and 18ml of its clear solution is taken for later use. ② Take 982ml of liquid polyaluminium chloride solution, its Al 2 o 3 The content is 11%, the basicity is 69%, the dosage of the liquid polyaluminum chloride solution is controlled at a Ln / Al molar ratio of 0.03333:1, and the temperature is 75°C, with continuous vigorous stirring, and slowly adding the prepared rare earth sulfate The sulfuric acid solution of the compound was 18ml, kept warm for 2h, the basicity was 65%, left to mature for 24h, and then dried to obtain a solid prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com