Method for preparing coagulant and application thereof

A coagulant and gel technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of secondary pollution and high treatment cost, and achieve reduction The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

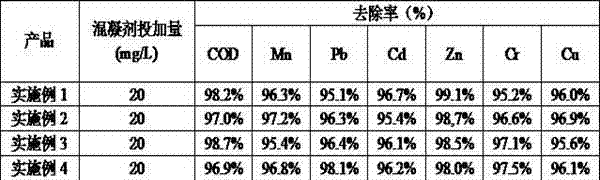

Examples

Embodiment 1

[0026] Embodiment 1: a kind of preparation method of coagulant, comprises the steps:

[0027] (1) Accurately weigh aluminum hydroxide and sodium hydroxide at a mass ratio of 1.8:1 and place it in a reaction vessel; add a small amount of water to control the mass concentration of the sodium hydroxide solution to 50%; The temperature of the system was raised to slightly boiling; the complete reaction required 30 min;

[0028] (2) After the reaction solution in step (1) is cooled to room temperature, quickly add hydrochloric acid solution with a volume concentration of 19%, control the basicity of the reaction solution to 2.4, and stir rapidly to obtain a gel containing active aluminum hydroxide The mixed solution of polyaluminum chloride with high salinity;

[0029] (3) After the aluminum hydroxide gel-polyaluminum chloride mixed solution obtained in step (2) is mixed evenly, heat at 80°C for 0.5 hour; and age for three days to obtain a stable coagulant product.

Embodiment 2

[0030] Embodiment 2: a kind of preparation method of coagulant comprises the steps:

[0031] (1) Accurately weigh aluminum hydroxide and sodium hydroxide at a mass ratio of 1.5:1 and place them in the reaction vessel; add a small amount of water to control the mass concentration of the sodium hydroxide solution to 60%; The temperature of the system was raised to slightly boiling; it took 25 min for complete reaction;

[0032] (2) After the reaction solution in step (1) is cooled to room temperature, quickly add hydrochloric acid solution with a volume concentration of 28%, control the basicity of the reaction solution to 2.7, and stir rapidly to obtain a gel containing active aluminum hydroxide The mixed solution of polyaluminum chloride with high salinity;

[0033] (3) After the aluminum hydroxide gel-polyaluminum chloride mixed solution obtained in step (2) is mixed evenly, heat at 60°C for 0.5 hour; and age for three days to obtain a stable coagulant product.

Embodiment 3

[0034] Embodiment 3: a kind of preparation method of coagulant, comprises the steps:

[0035] (1) Accurately weigh aluminum hydroxide and sodium hydroxide at a mass ratio of 1.8:1 and place it in the reaction vessel; add a small amount of water to control the mass concentration of the sodium hydroxide solution to 60%; The temperature of the system was raised to slightly boiling; it took 25 min for complete reaction;

[0036] (2) After the reaction solution in step (1) is cooled to room temperature, quickly add hydrochloric acid solution with a volume concentration of 19%, control the basicity of the reaction solution to 2.4, and stir rapidly to obtain a gel containing active aluminum hydroxide The mixed solution of polyaluminum chloride with high salinity;

[0037] (3) After the aluminum hydroxide gel-polyaluminum chloride mixed solution obtained in step (2) is mixed evenly, heat at 80°C for 1 hour; and age for three days to obtain a stable coagulant product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com