A method for starting an activated coke dry adsorption purification device

A purification device and active coke technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of long start-up process and inconvenience of timely commissioning, shorten start-up time, reduce adsorption activity, and shorten start-up time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

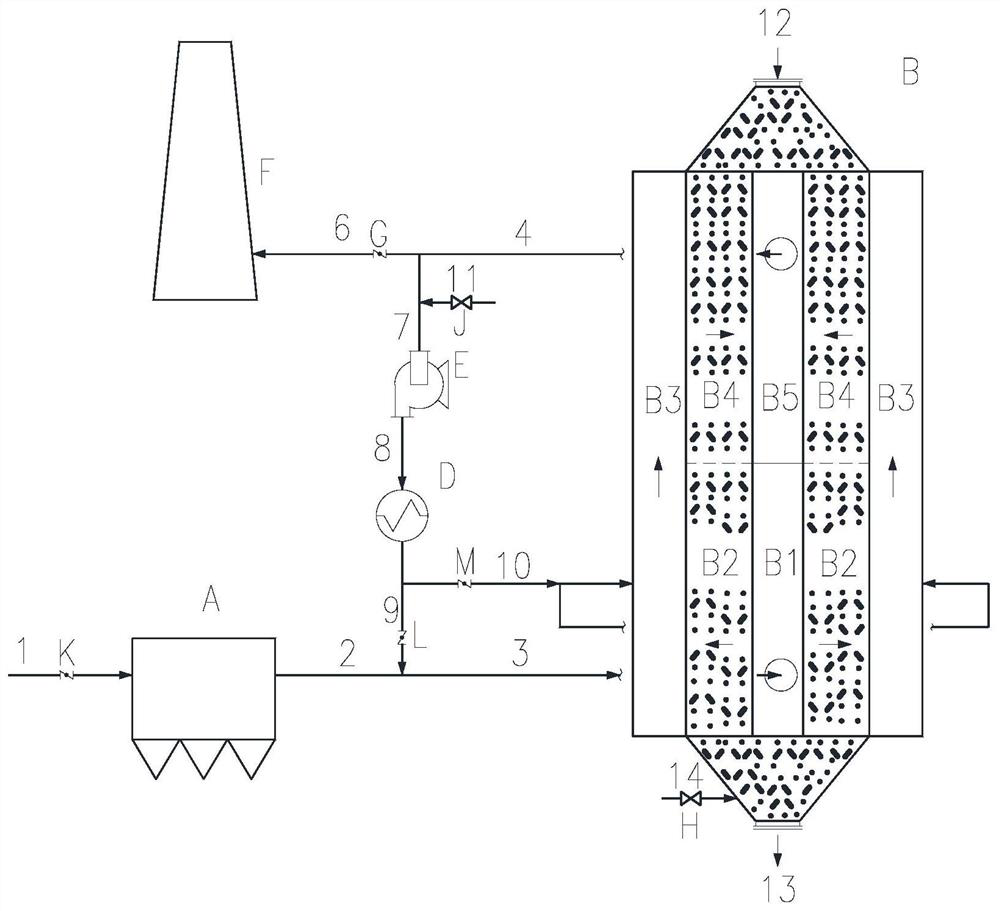

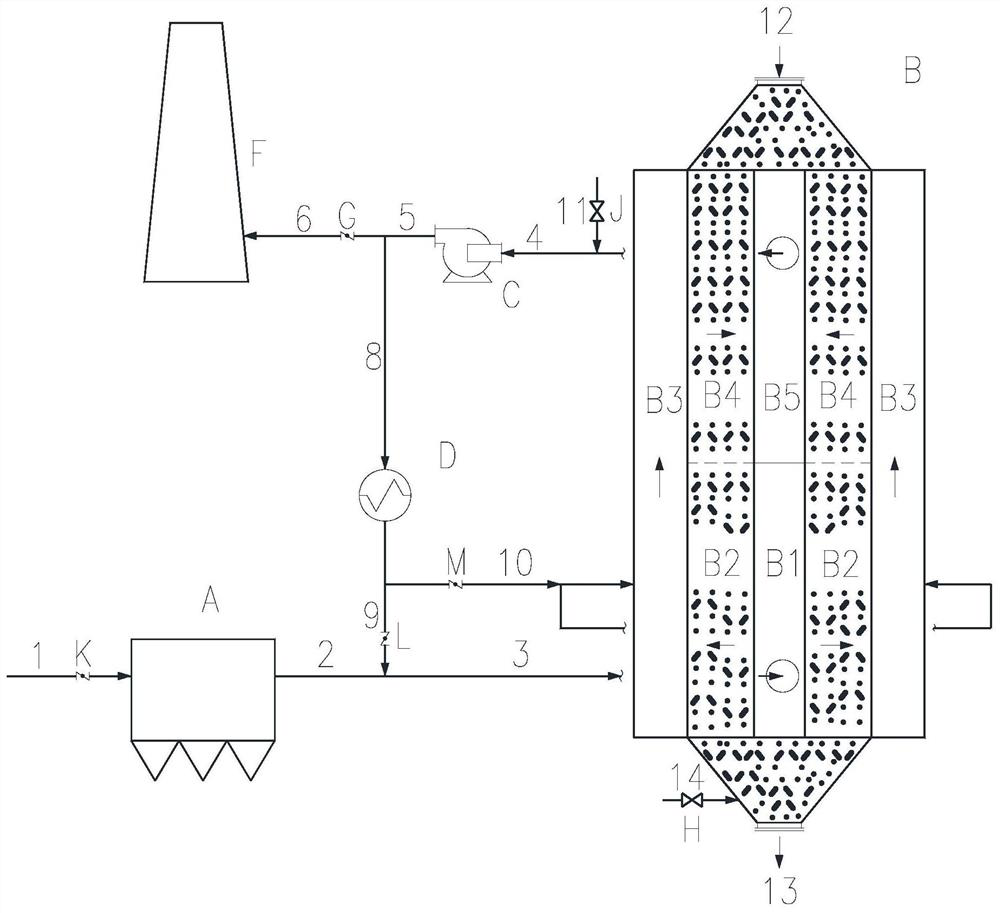

[0077] Use figure 1The reactive coke method is used to adsorb the purification device, and the starting method includes:

[0078] Step (1): Before the active focal absorbent tower is introduced into the flue gas start, open the valve J, open the butterfly valve L and butterfly valve M, turn off the butterfly valve G and butterfly valve K, slowly start the net flue gas boost fan E, introduce normal temperature air 11, Gradually establish air in active focal absorbent tie B --net flue gas boost fan E - 气 Cooler D --- activity focusing between Tight Tie B, then gradually increases net flue gas boost fan E The speed continues to introduce normal temperature air 11. When the speed of the net flue gas boost fan E is close to the design speed, and the active focal absorbent tower B pressure tends to stabilize, the valve J is closed, and the air is closed and closed, and the flue gas cooler D is opened, and there are many stable operation. Fresh-active focus was performed in 12 to 24 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com