Starting method of activated coke dry adsorption purification device

A purification device and active coke technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of long start-up process and inconvenience of timely start-up, and achieve the effect of shortening start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

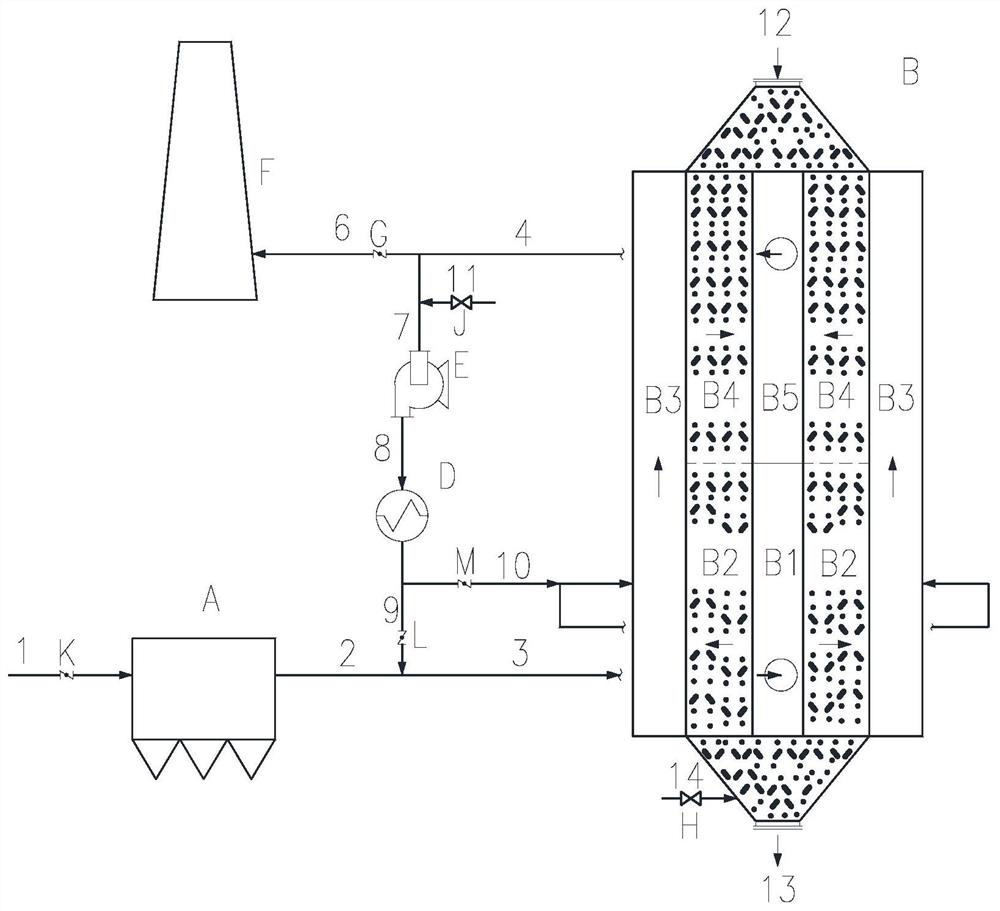

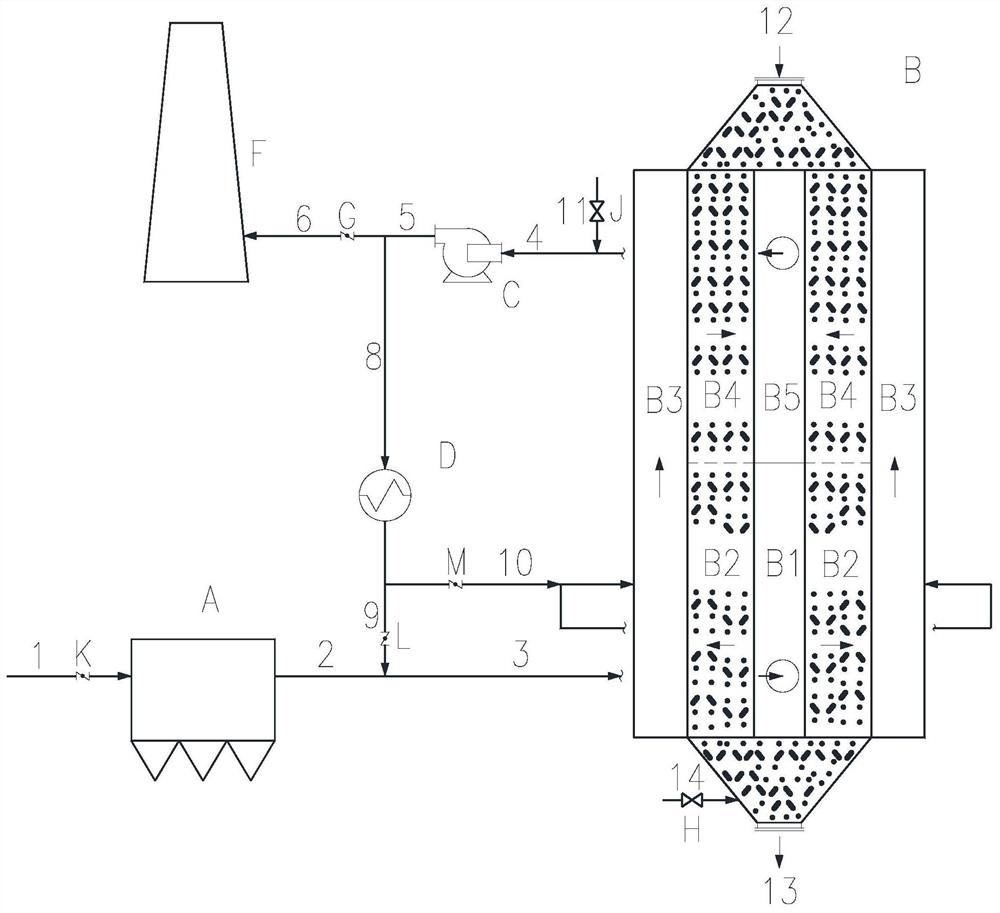

[0077] use as figure 1The activated coke dry method adsorption purification device shown, the start-up method includes:

[0078] Step (1): before the active coke adsorption tower introduces the flue gas to start work, first open the valve J, open the butterfly valve L and the butterfly valve M, close the butterfly valve G and the butterfly valve K, slowly start the clean flue gas booster fan E, and introduce normal temperature air 11, Gradually establish the circulation of air between the activated coke adsorption tower B---clean flue gas booster fan E---flue gas cooler D---activated coke adsorption tower B, and then gradually increase the net flue gas booster fan E The rotating speed continues to introduce normal temperature air 11. When the speed of the net flue gas booster fan E is close to the design speed and the pressure of the activated coke adsorption tower B tends to be stable, the valve J is closed to carry out a large-flow airtight cycle, and the flue gas cooler D ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com