Material storage tray of LCD (liquid crystal display) and production process of material storage tray

A technology of liquid crystal display and production process, which is applied to other household appliances, containers to prevent mechanical damage, types of packaging items, etc. It can solve the problems that the strength, elasticity, ventilation and heat dissipation of the storage tray cannot be guaranteed, and achieve good cushioning resistance. Compressive capacity, improve stability, and prevent slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

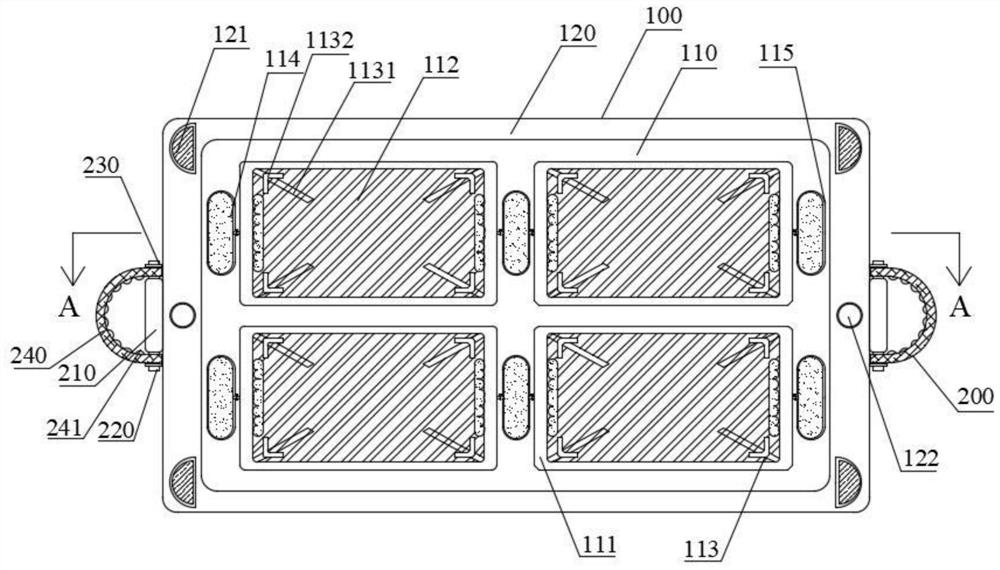

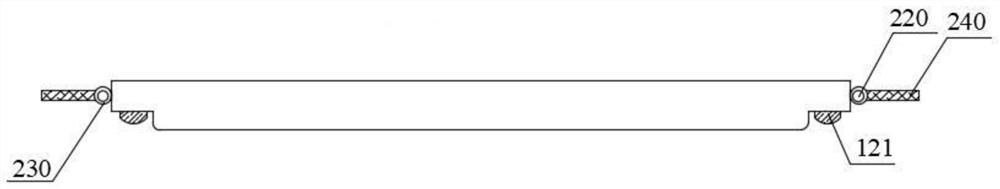

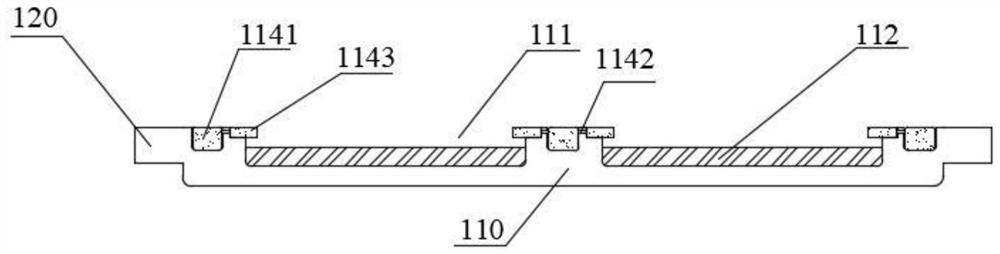

[0040] like figure 1 As shown, the present embodiment provides a storage tray for an LCD liquid crystal display, including a storage tray body 100. The storage tray body 100 includes a central storage area 110 and a stacking area 120 located on the outer edge of the storage area 110. The storage area 110 is recessed inward as a whole, and a plurality of liquid crystal display placement cavities 111 are distributed in its internal array, and each liquid crystal display placement cavity 111 is used to place an LCD liquid crystal display, and the liquid crystal display placement cavity 111 is interference-fitted with Vibration cushion 112, liquid crystal display chamber 111 is provided with an adjustable fastening mechanism 113 on the cushion 112, and the storage area 110 is provided with an airbag damping mechanism 114 for alleviating the shaking of the LCD liquid crystal display.

[0041] The storage tray of the LCD liquid crystal display of the present embodiment is provided w...

Embodiment 2

[0051] like Figure 1-6 , Figure 9 As shown, the present embodiment provides the production process of the material storage tray of the LCD liquid crystal display, comprising the following steps:

[0052] S1. Preparation of storage tray body material: Dissolve polyurethane shape memory resin in N,N-dimethylformamide to obtain a sol, add elastomer and dicyandiamide to the sol at 25-35°C, and stir until it becomes a gel state, extruded by a twin-screw extruder, and supercritically dried to obtain the main material of the storage tray;

[0053] Among them, polyurethane shape memory resin is to add isocyanate, polyol and chain extender into the reactor, and carry out stirring polymerization at 40-50 ° C to obtain a linear polymer containing partial crystallization. The polymer uses its partial crystallization phase as the stationary phase. The polyurethane soft segment that undergoes reversible change between the glass state and the rubber state at the glass transition temperat...

Embodiment 3

[0062] This embodiment provides the production process of the material storage tray of the LCD liquid crystal display screen, and the difference from Embodiment 1 is that the elastomer in step S1 is selected from polyolefin thermoplastic elastomers; the addition amount of N,N-dimethylformamide is 16 times the mass of polyurethane shape memory resin; the mass ratio of polyurethane shape memory resin, elastomer, and dicyandiamide is 14:8:4; the extrusion temperature of twin-screw extruder is 206°C; the drying medium used in supercritical drying It is absolute ethanol, the drying pressure is 22MPa, the drying temperature is 46°C, and the drying time is 10 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com