Patents

Literature

198results about How to "Firmly clamped" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

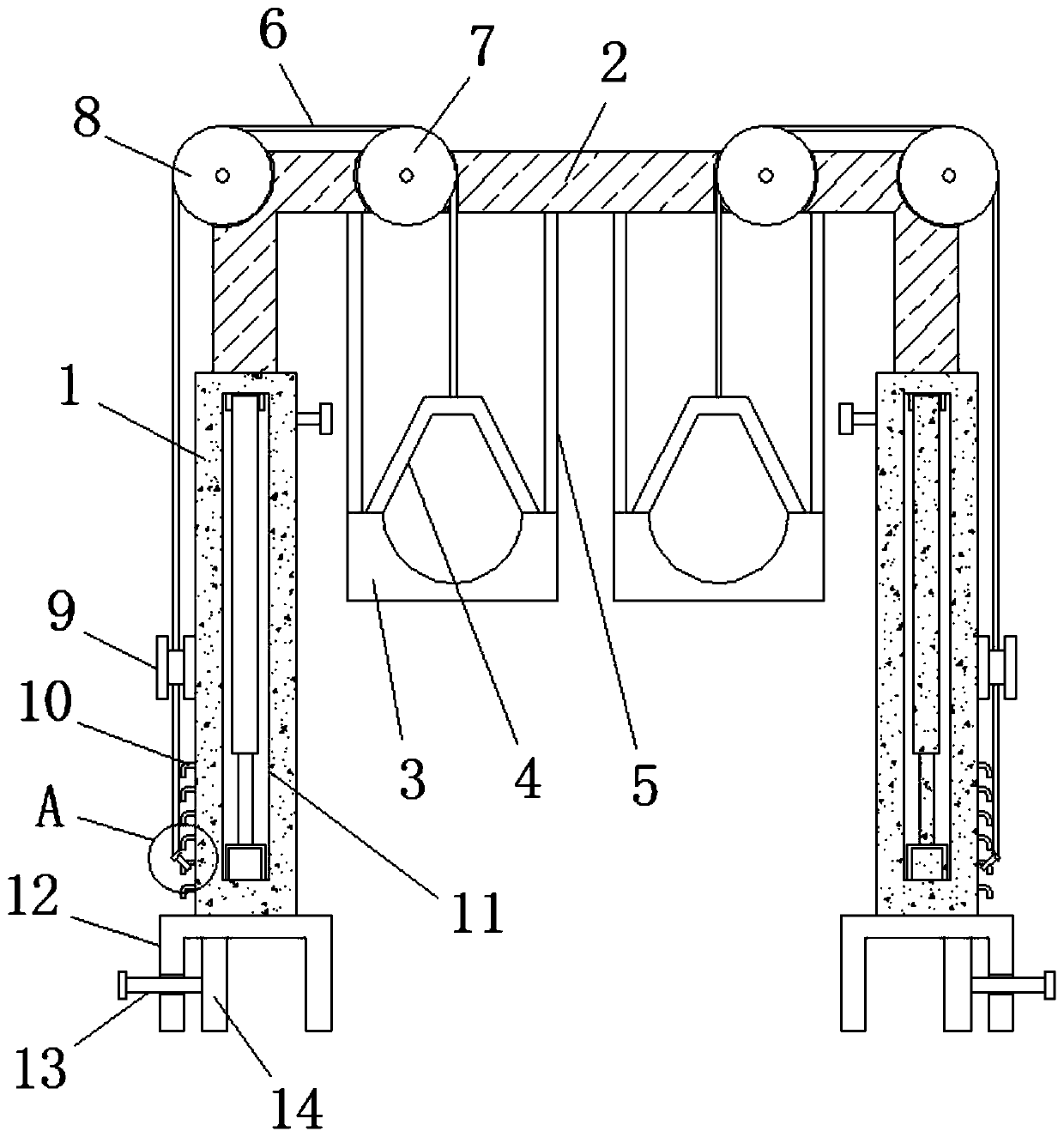

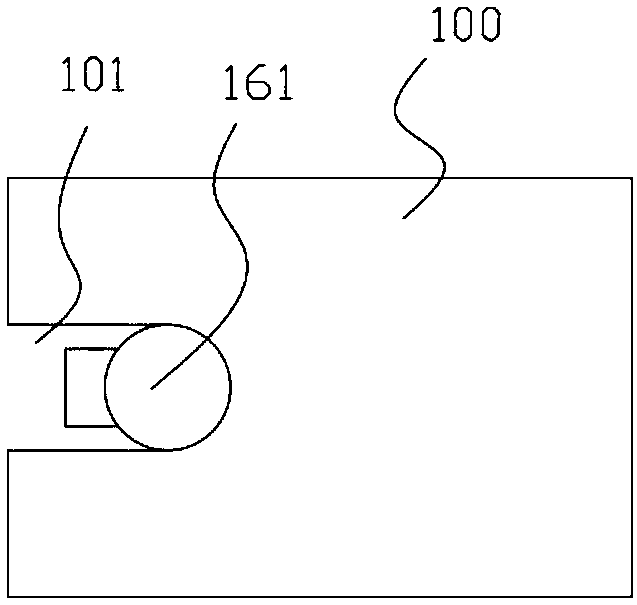

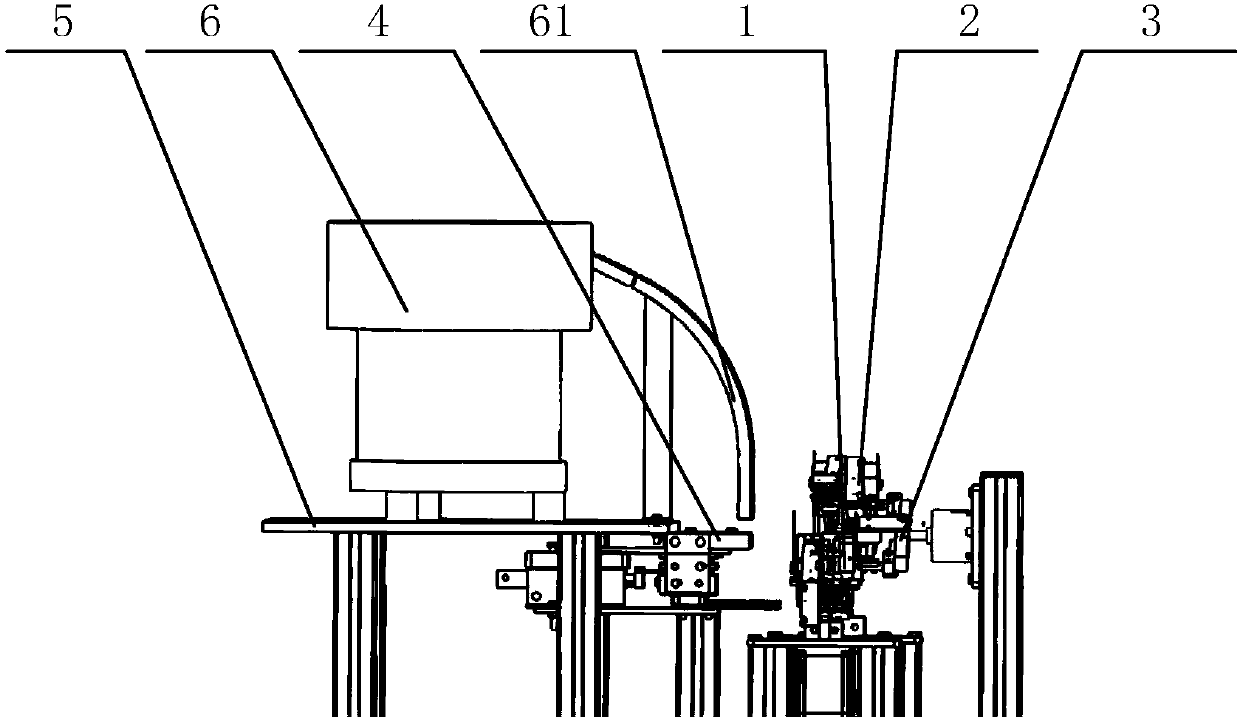

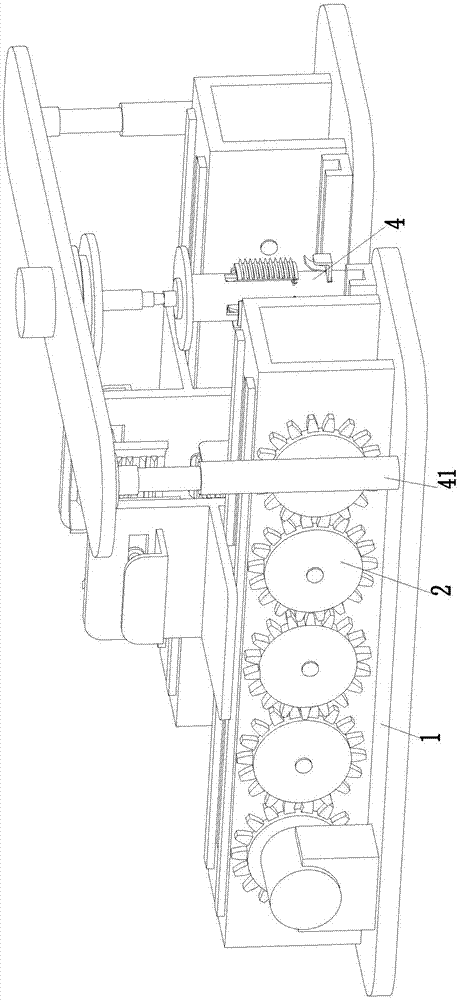

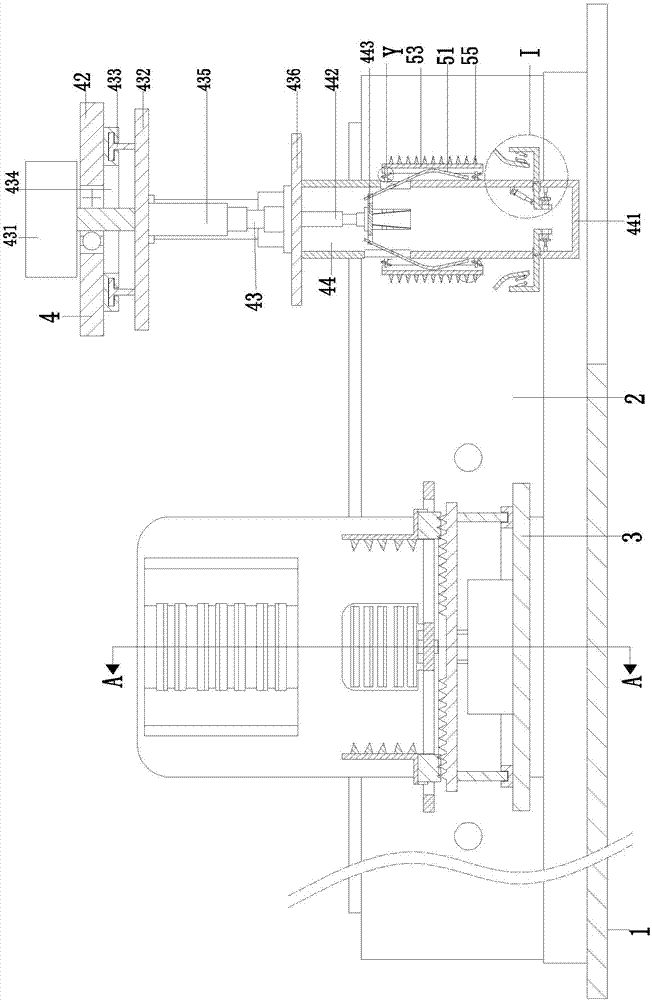

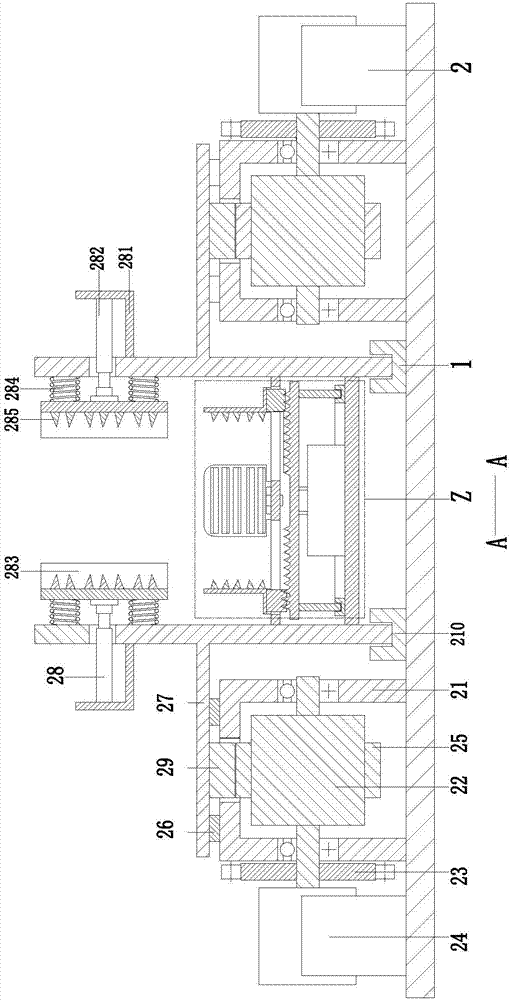

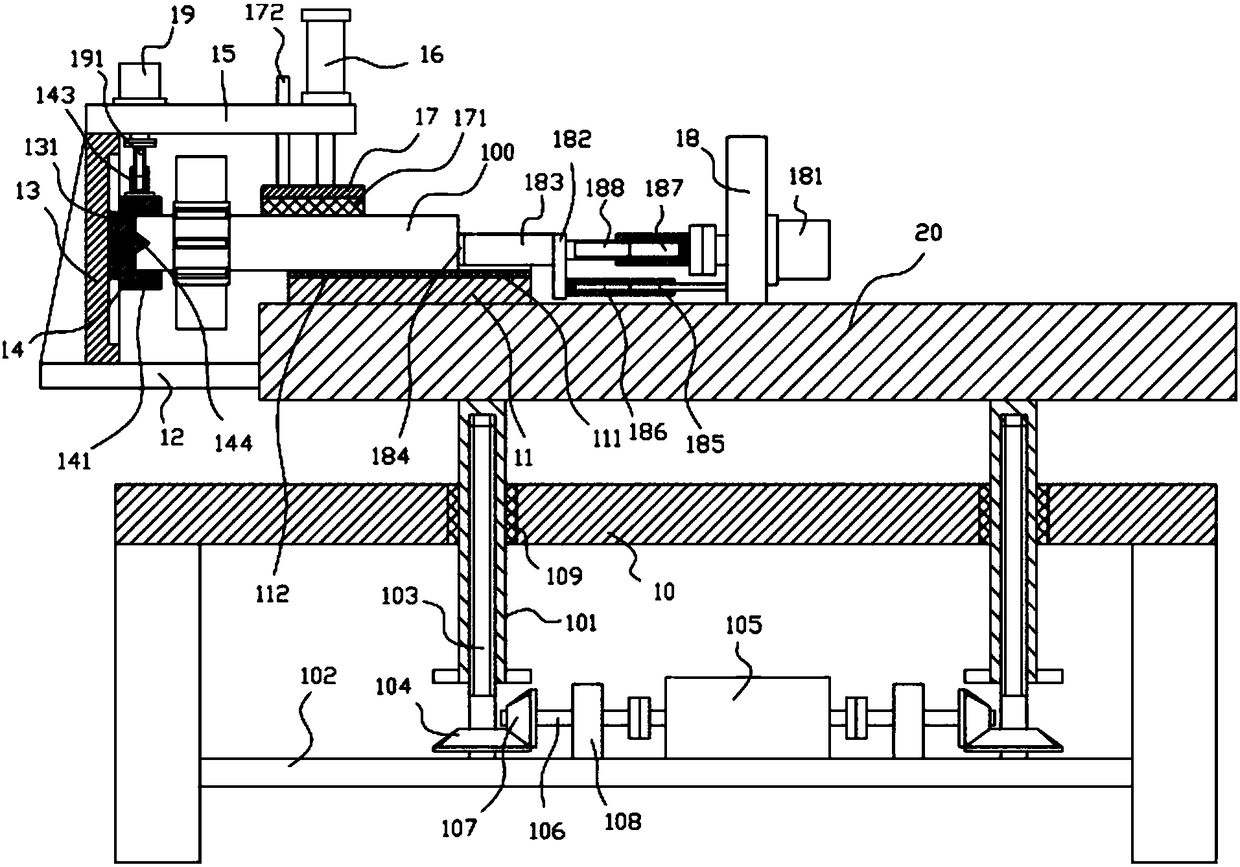

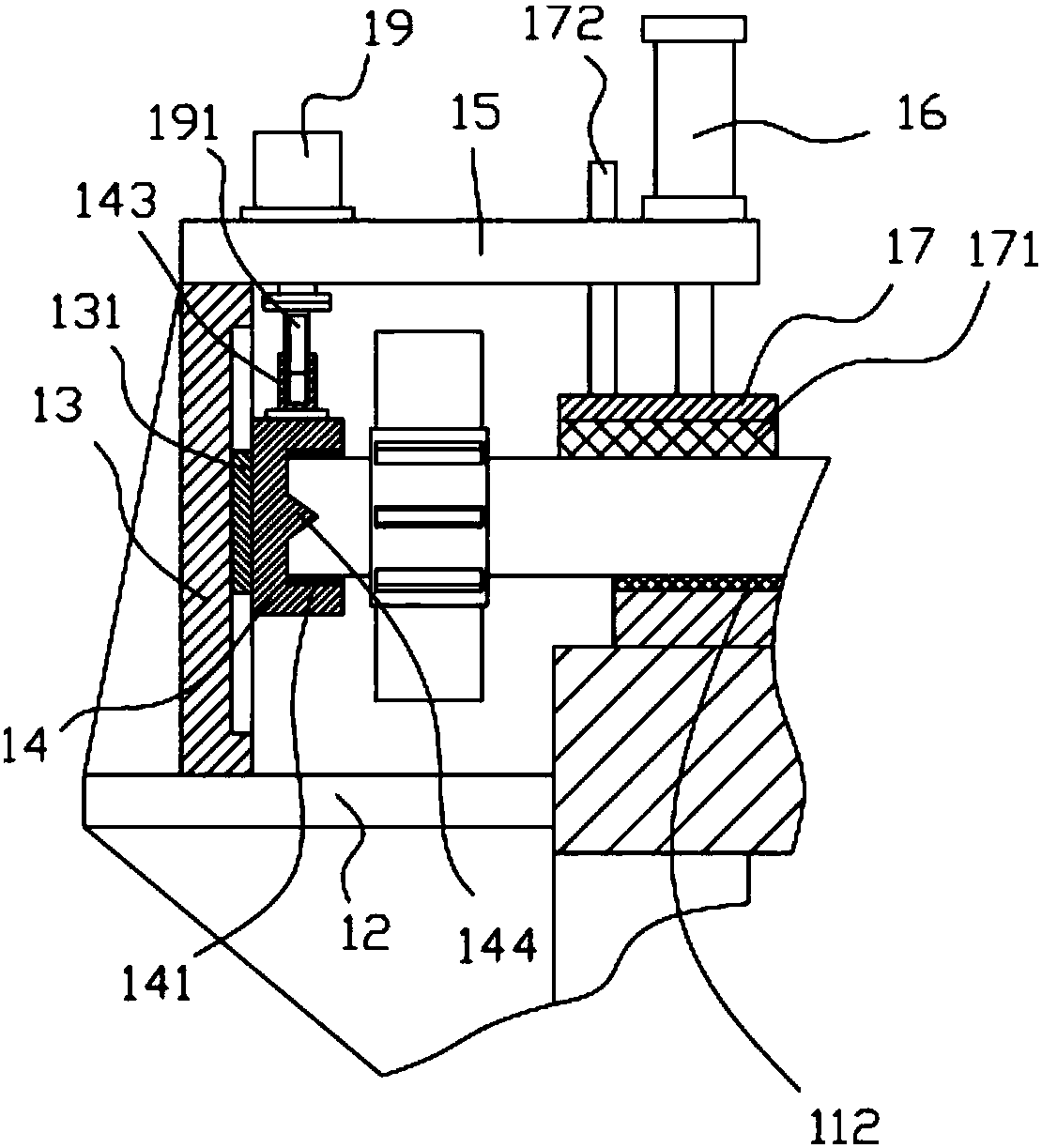

Full-automatic winding production line and processing method thereof

PendingCN109436951ASimple structureIncrease flexibilityFilament handlingProduction lineWinding machine

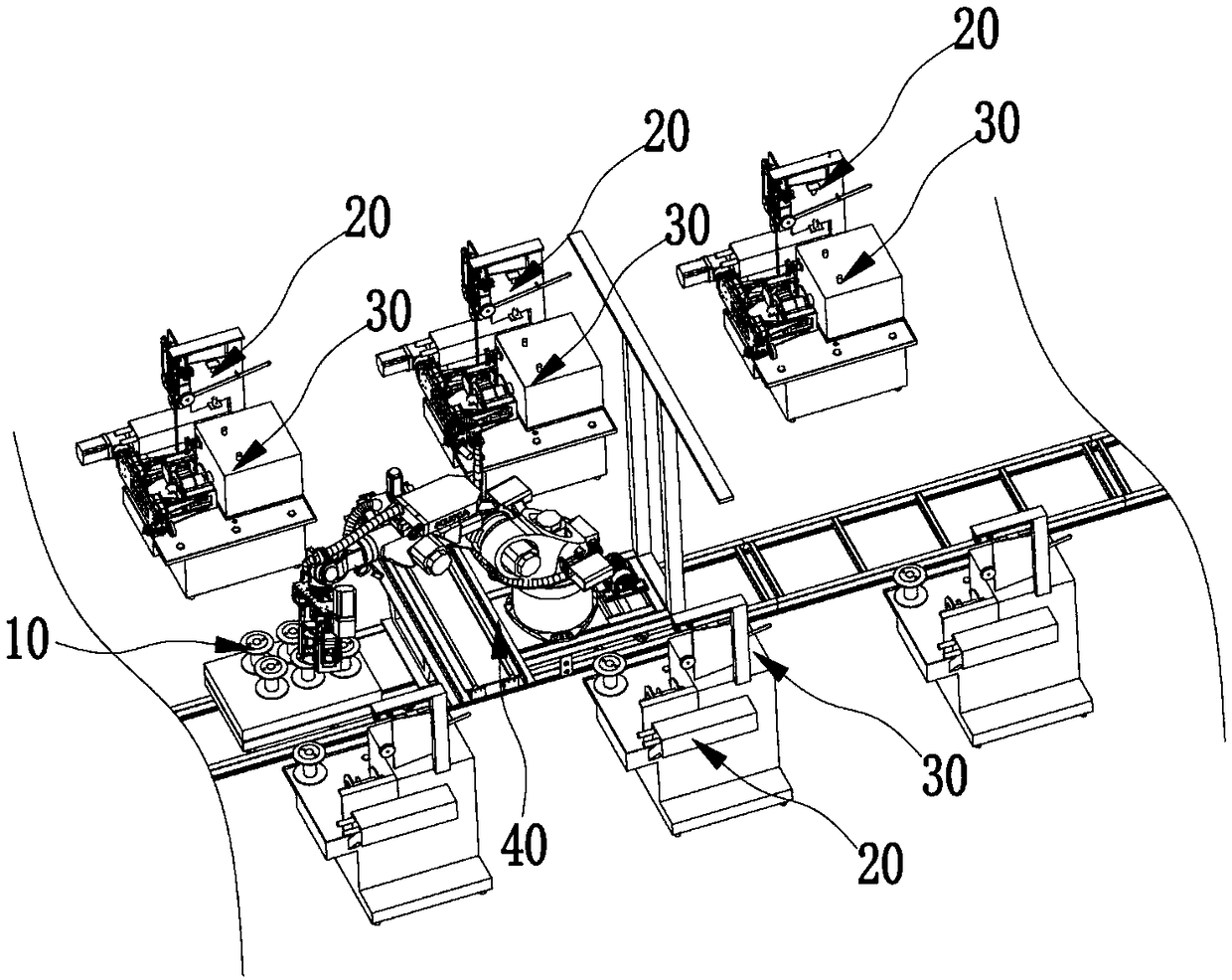

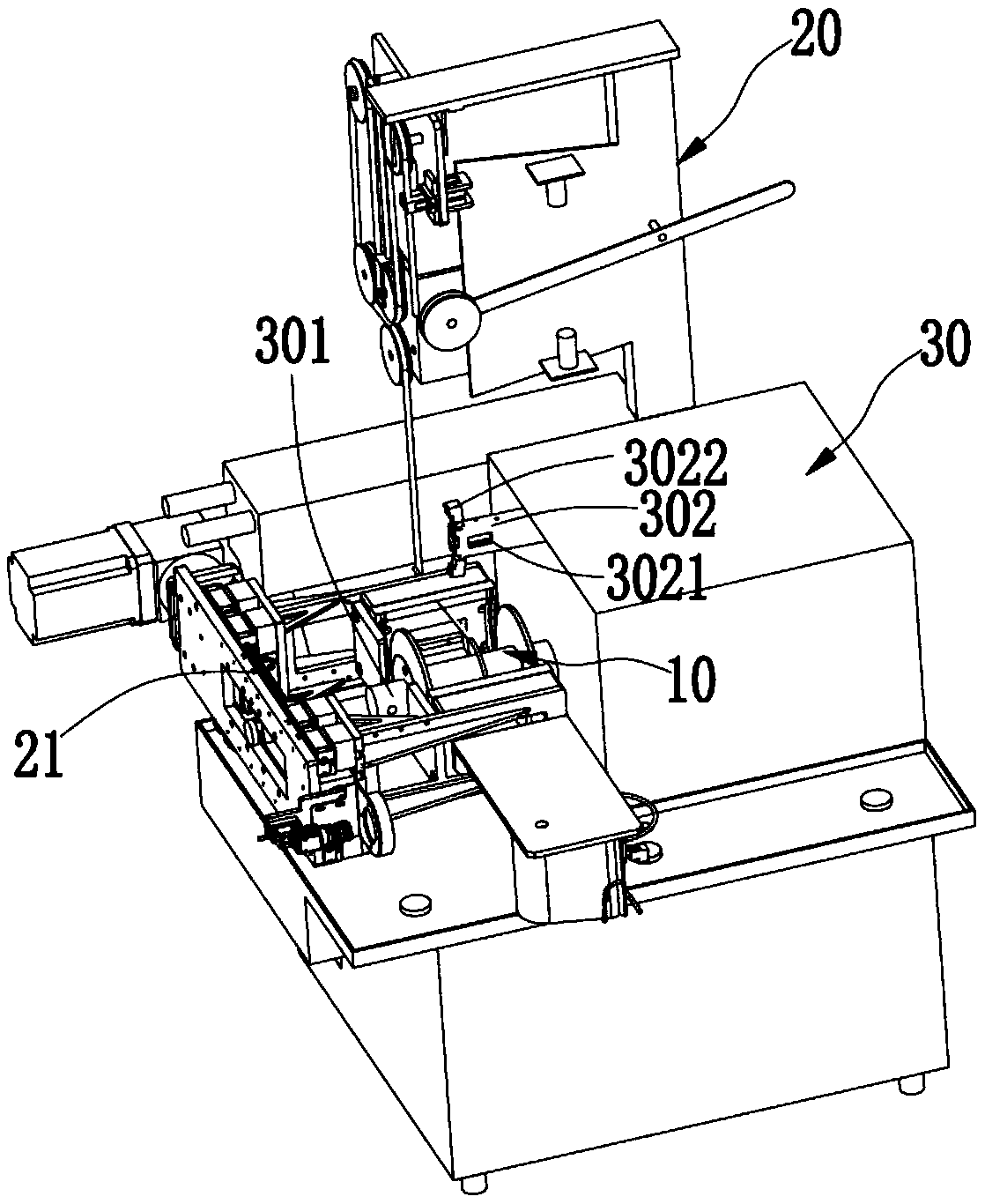

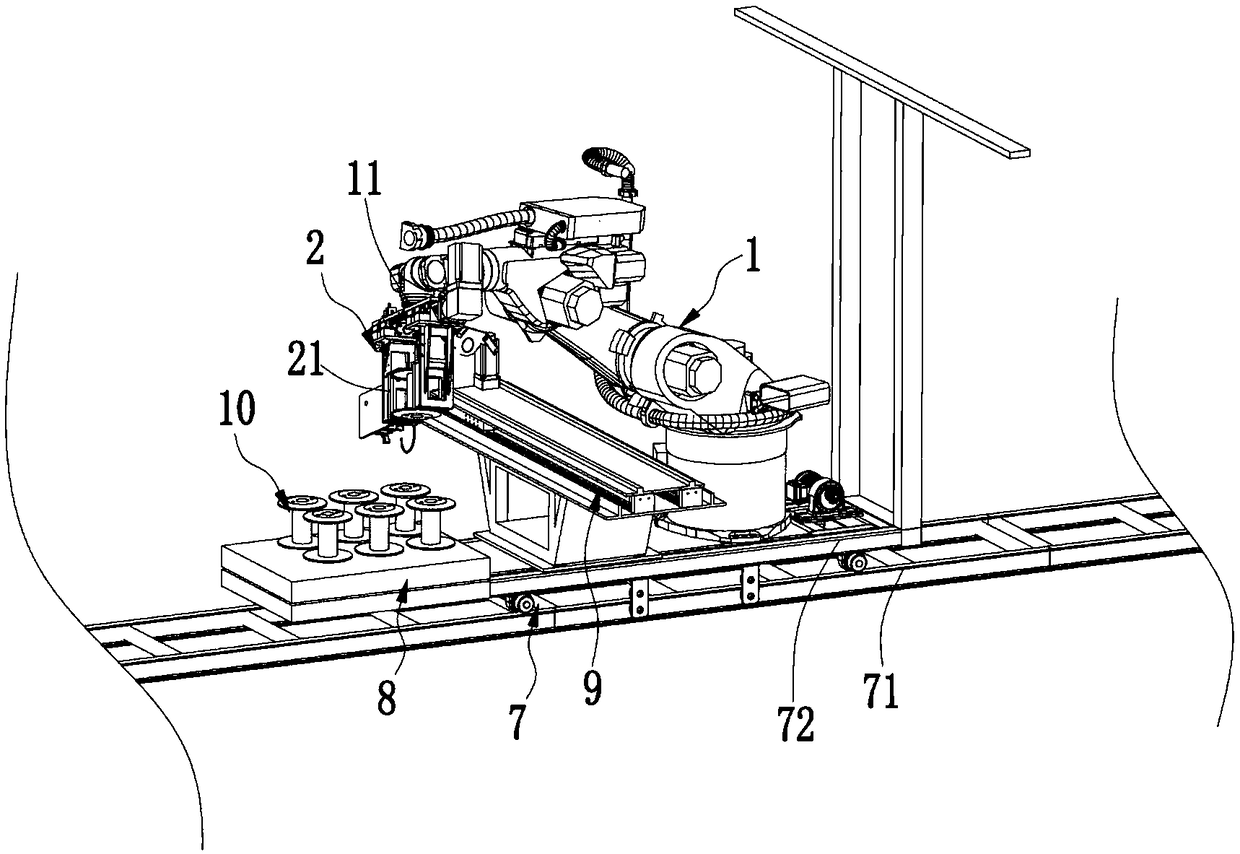

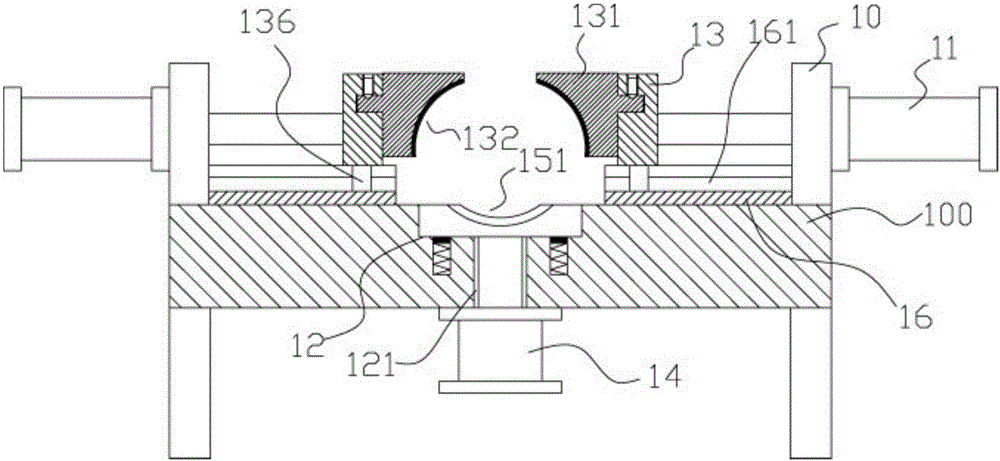

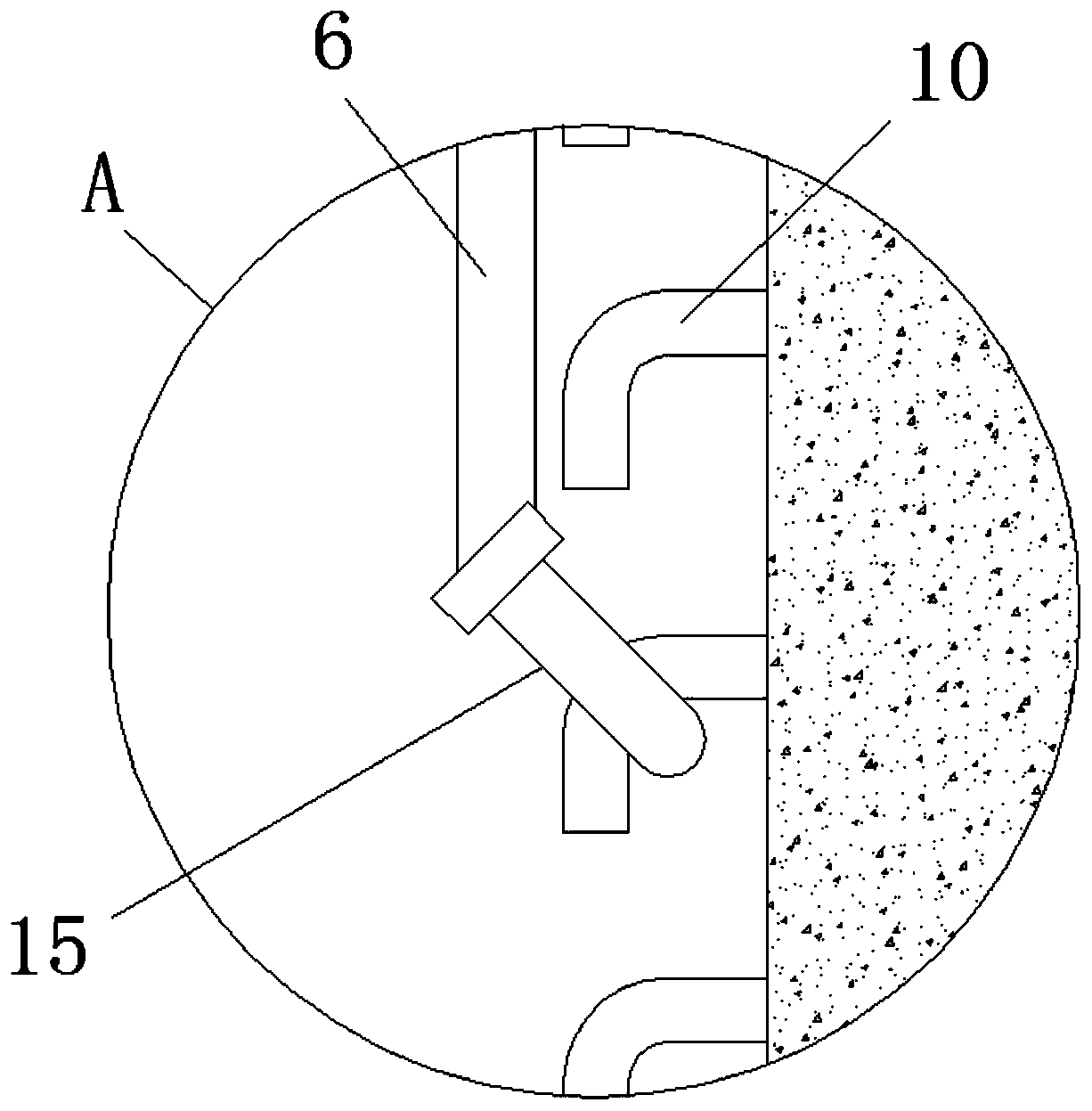

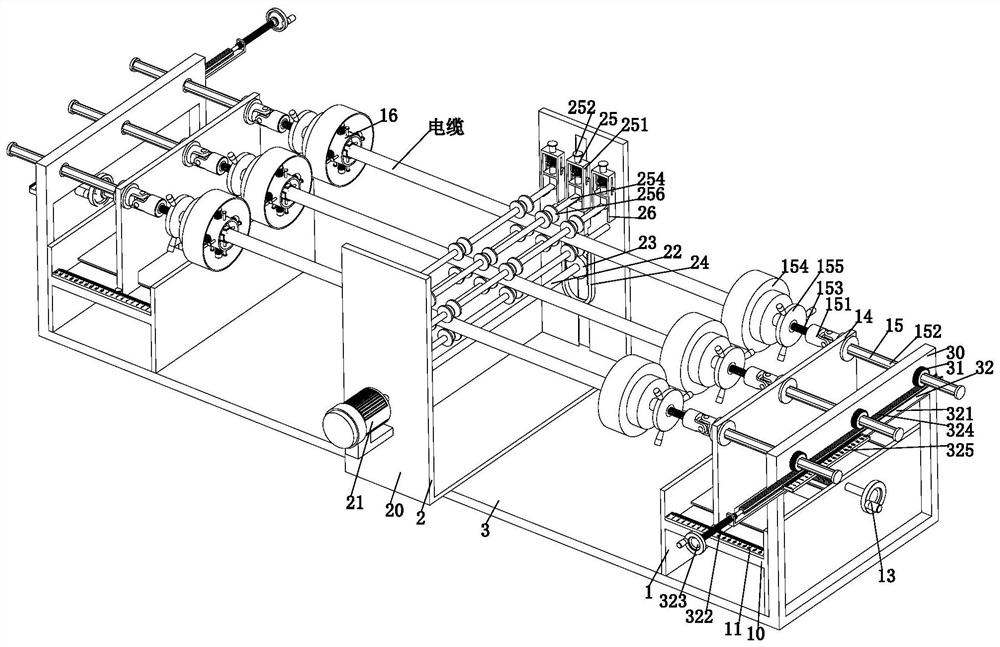

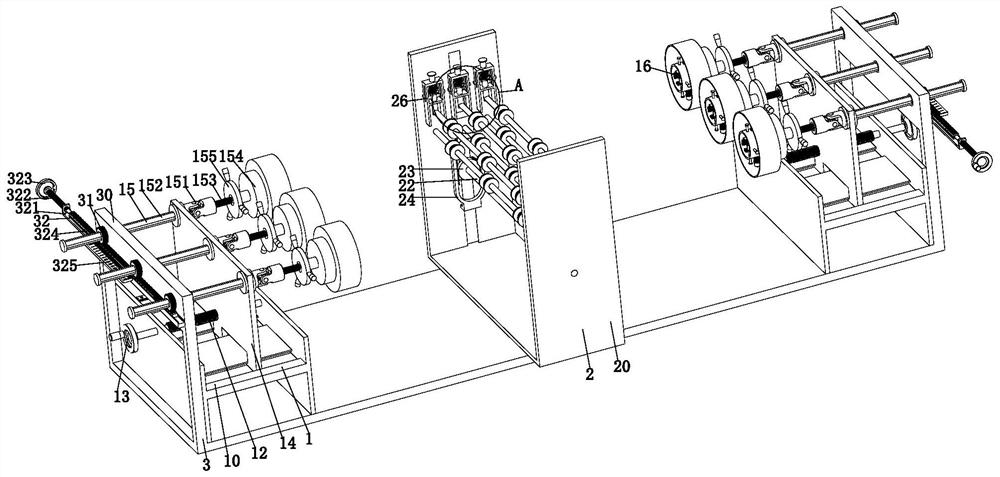

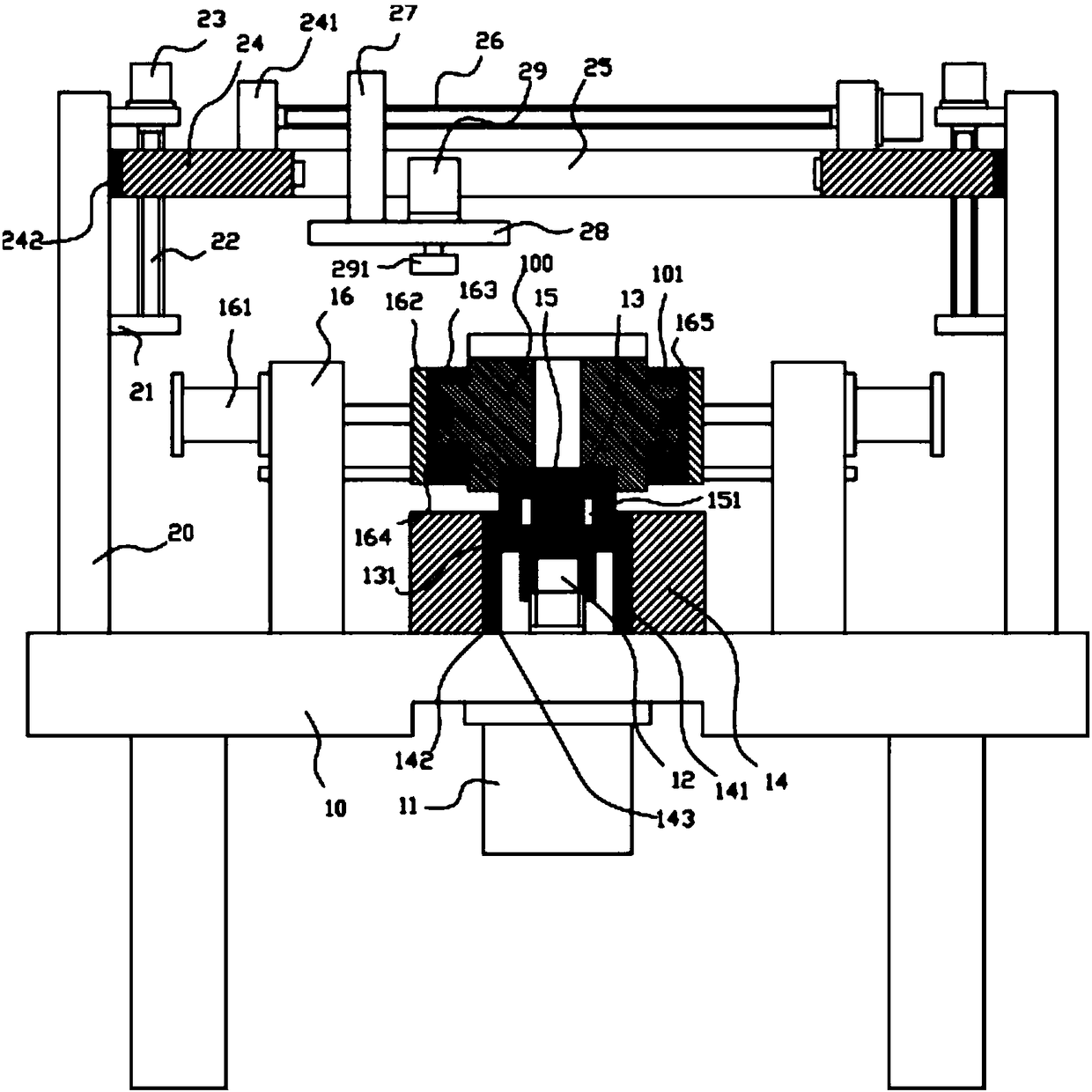

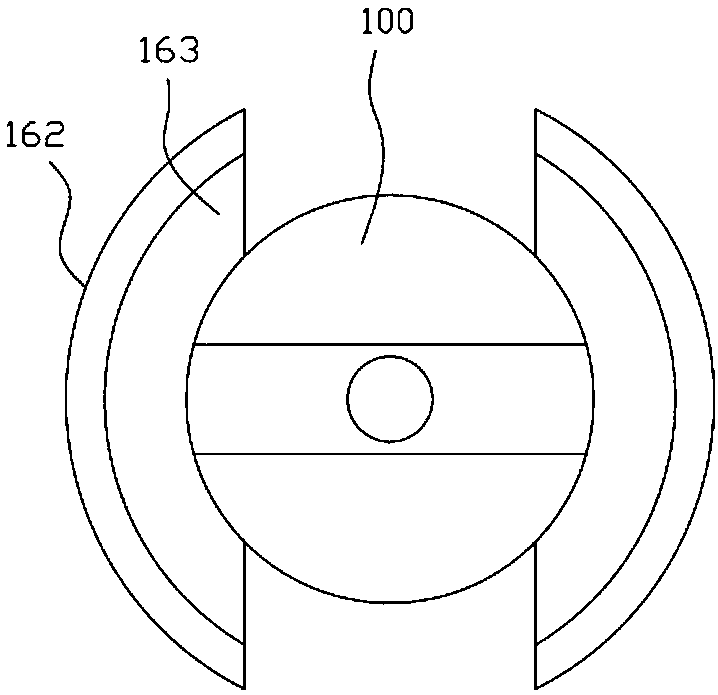

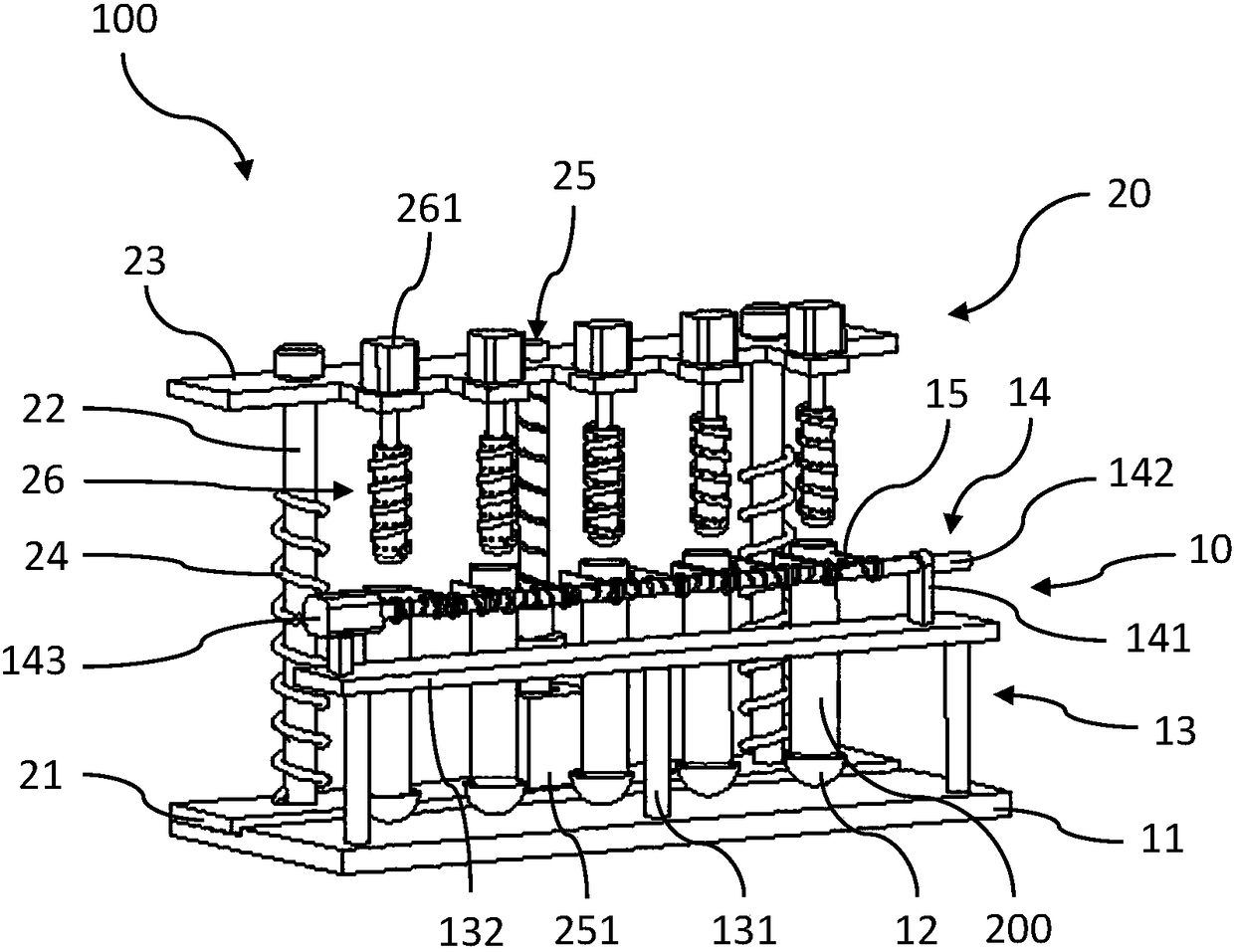

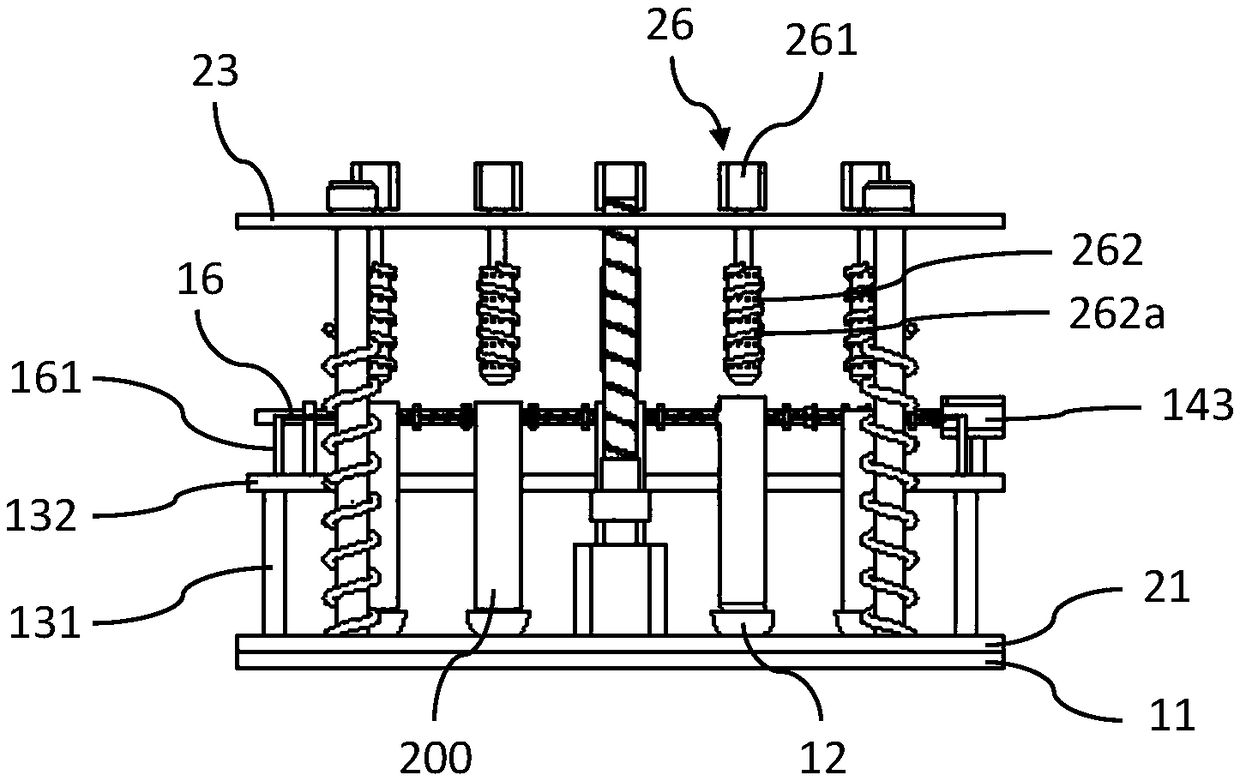

The invention discloses a full-automatic winding production line and a processing method thereof. The full-automatic winding production line comprises at least one automatic feeding machine, at leastone winding machine and an automatic winding disc feeding and discharging robot, wherein the automatic feeding machine is used for supplying a filament-shaped body; the winding machine is used for fixing a winding disc and driving the winding disc to rotate; and the automatic winding disc feeding and discharging machine can move the winding disc onto the winding machine and taking the winding discdown from the winding machine, and the position of the filament-shaped body can be determined visually when the filament-shaped body is grabbed and cut off. According to the scheme, the automatic winding disc feeding and discharging robot cooperates with the automatic feeding machine and the winding machine, so that the whole process of feeding, winding and discharging is achieved automatically,and the novel full-automatic winding production line which is simple in structure and capable of controlling the winding process easily is provided; in addition, the visual positioning technique can effectively and accurately determine the position of the filament-shaped body, so that automatic grabbing and shearing are made possible; and the visual positioning technique is good in flexibility andhigh in accuracy and efficiency, so that the winding efficiency is improved.

Owner:WUXI MINGONG TECH

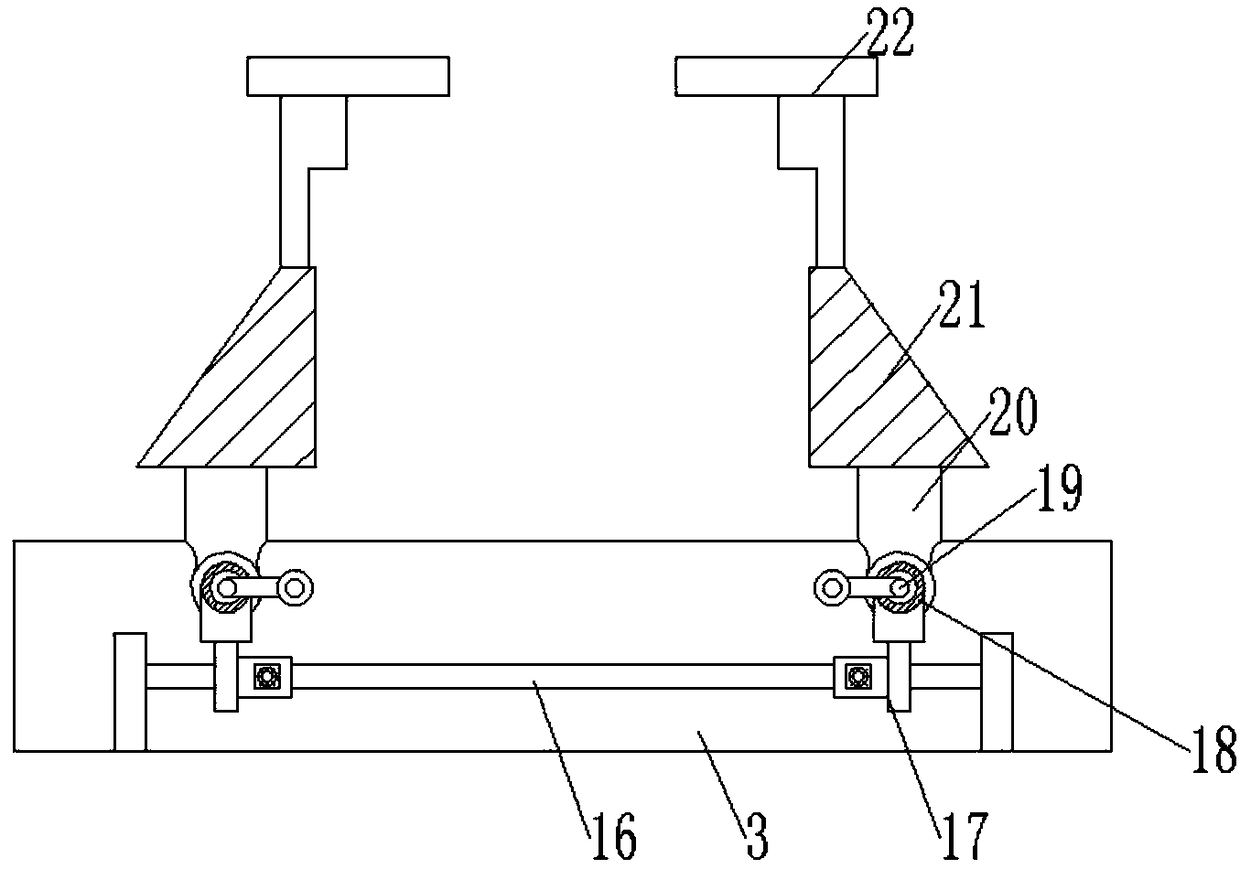

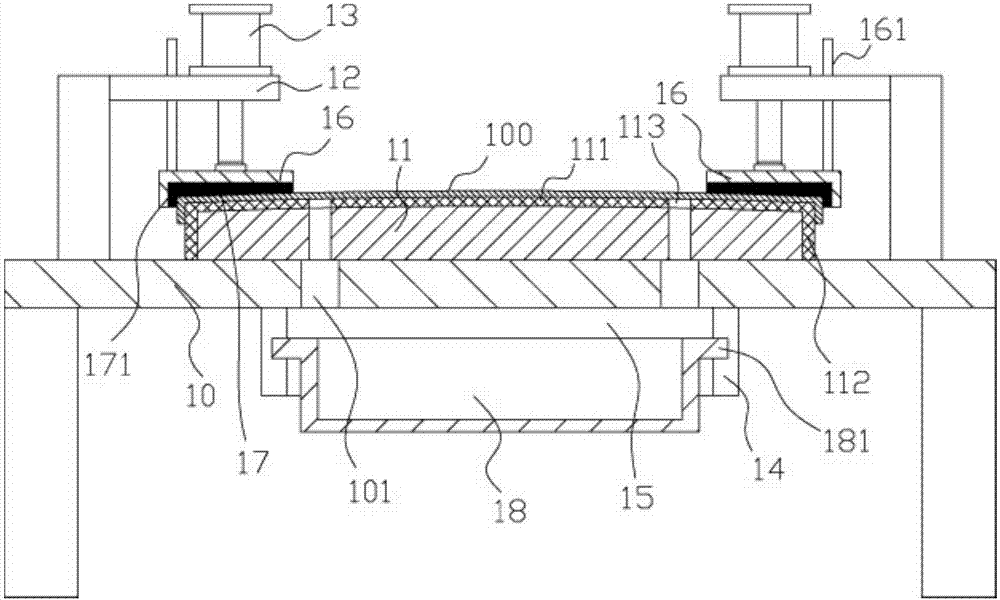

Three-point positioning mechanism for plastic cylinder

The invention discloses a three-point positioning mechanism for a plastic cylinder. The three-point positioning mechanism comprises a rack. Upper supporting plates are fixed to the top faces of the two sides of a top plate of the rack. At least two clamping cylinders are fixed to the outer side walls of the upper supporting plates. Push rods of the two clamping cylinders penetrate through the corresponding upper supporting plates, and connecting plates are fixed to the ends of the push rods of the clamping cylinders. Clamping blocks are fixed to opposite faces of the two connecting plates, and arc grooves are formed in the opposite walls of the two clamping blocks. A connecting groove is formed in the middle of the top face of the top plate of the rack, an expandable through hole is formed in the top face of the connecting groove, and a lifting cylinder is fixed to the bottom face of the top plate of the rack. The plastic cylinder is automatically clamped in a three-point positioned mode through the two arc grooves and the upper arc groove by adopting the clamping cylinders and the lifting cylinder, the plastic cylinder is fixedly and firmly clamped, and the effect is good; meanwhile, the clamping blocks are convenient to connect and mount and also convenient to dismount and replace.

Owner:太仓意欣智能科技有限公司

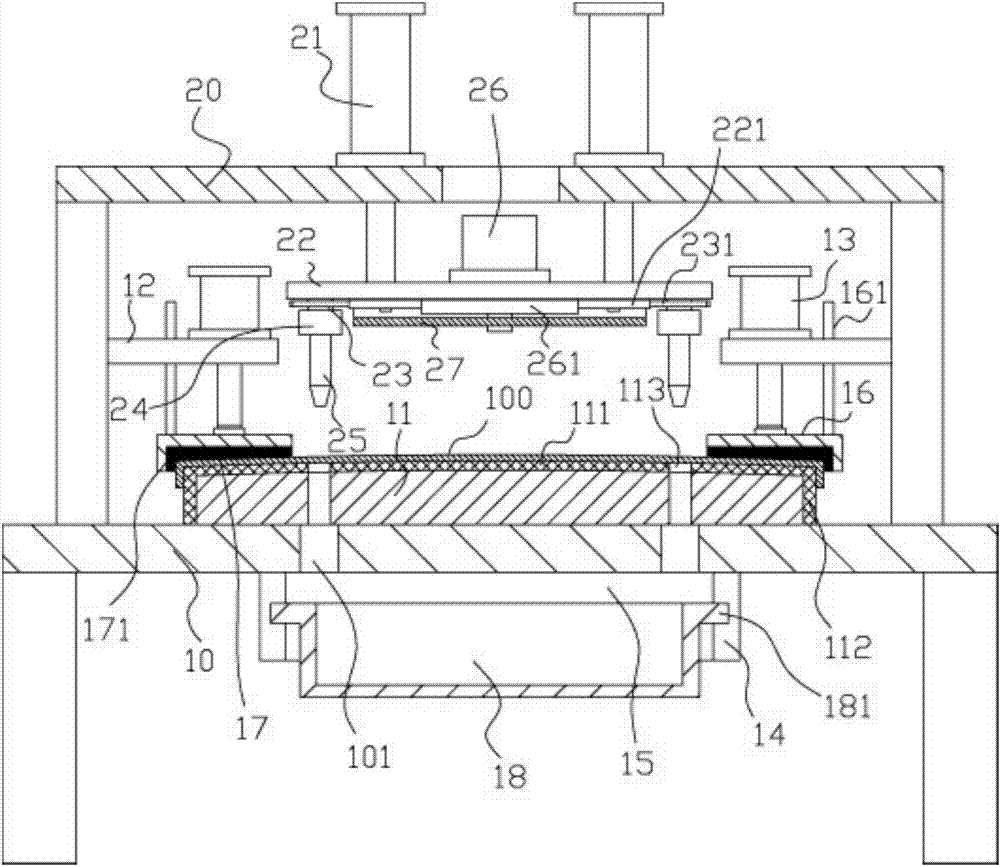

Firefighting main unit shell punching device

InactiveCN106270128AFirmly clampedHigh degree of automationMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention discloses a firefighting main unit shell punching device, which comprises a rack, wherein sliding grooves are formed in the two sides of the middle part of a top plate of the rack; connecting plates are fixedly arranged at the left and right ends of the top plate of the rack; clamping oil cylinders are fixedly arranged on the outer sidewalls of the connecting plates; pushrods of the clamping oil cylinders penetrate through the connecting plates, and are fixedly provided with clamping blocks; the bottoms of the clamping blocks are inserted and sleeved in the sliding grooves; a shell to be machined is arranged on the middle part of the top plate of the rack, and is clamped between the two clamping blocks; multiple vertical discharge through grooves are formed in the top plate of the rack below a bottom plate of the shell to be machined; an upper support plate is fixedly arranged at the top ends of the two connecting plates; a punching cylinder is fixedly arranged on the middle part of the top surface of the upper support block; a pushrod of the punching cylinder penetrates through the upper support plate, and is fixedly provided with a middle support block which is inserted and sleeved in the shell to be machined; the outer sidewall of the middle support block is closely attached to the inner sidewall of the shell to be machined; multiple punches are fixedly arranged on the bottom surface of the middle support block. The device is firm in clamping and fixing and high in automation degree.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

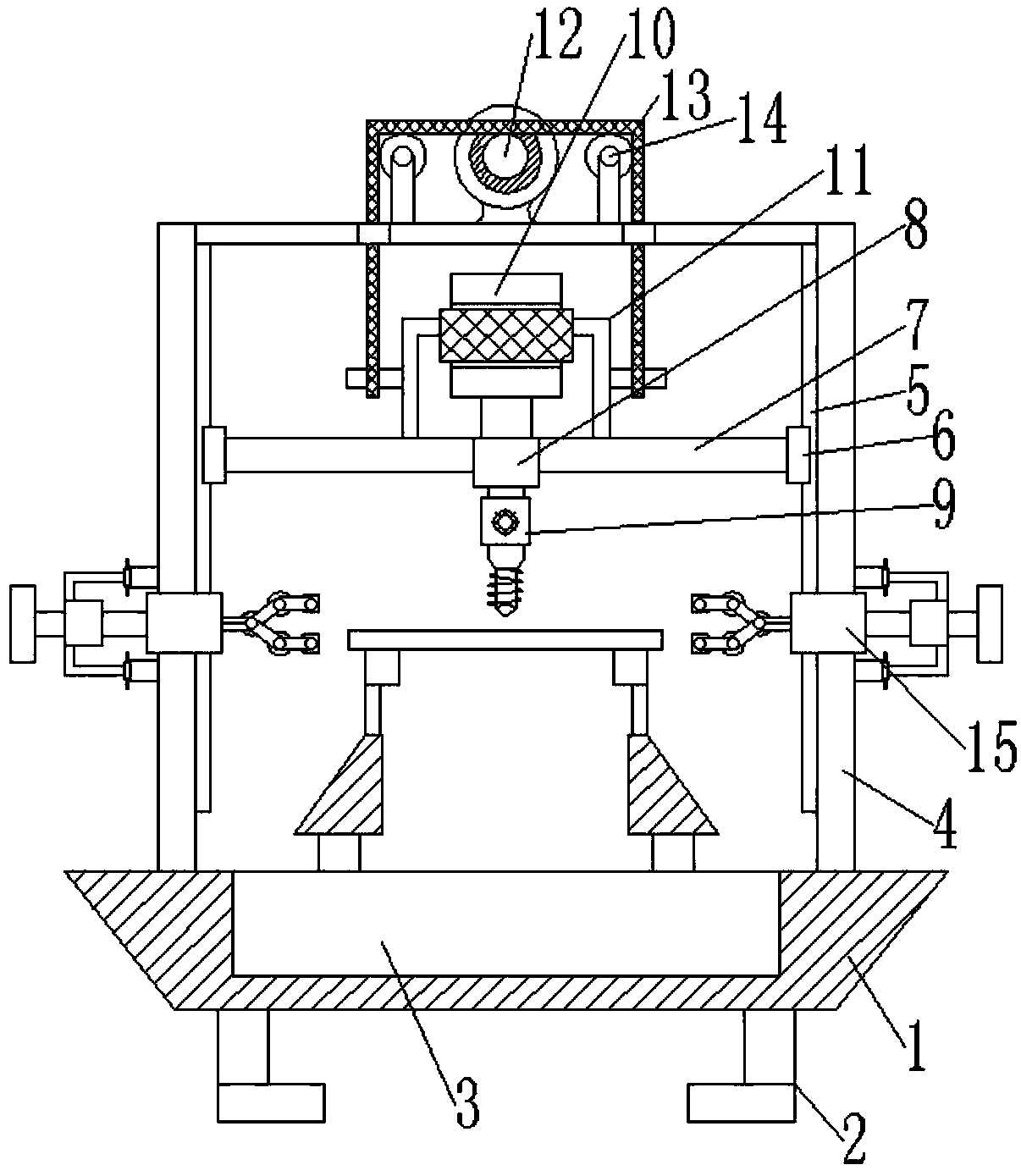

Small-batch automobile anti-collision beam punching mechanism provided with lifting waste box

InactiveCN108015315AFirmly clampedPrecise clamping and fixingMaintainance and safety accessoriesBoring/drilling machinesPunchingArchitectural engineering

The invention discloses a small-batch automobile anti-collision beam punching mechanism provided with a lifting waste box. The small-batch automobile anti-collision beam punching mechanism comprises arack, wherein a plurality of vertical through slots are formed in the middle part of a top plate of the rack; the top surface of the middle part of the top plate of the rack is fixedly equipped witha long mounting block; the top surface of the top plate of the rack is fixedly equipped with a main supporting frame; two vertical supporting plates of the main supporting frame are fixedly arranged at the two sides of the top surface of the top plate of the rack; regulating through slots are formed in middle parts of the two vertical supporting plates of the main supporting frame; transverse supporting plates are fixedly arranged on upper and lower parts of the outer side wall of each of the two vertical supporting plates of the main supporting frame; the two ends of each regulating screw arehinged on the two corresponding transverse supporting plates; a regulating motor is fixedly arranged on the top surface of the transverse supporting plate above; the output shaft of each regulating motor is a spline shaft; the spline shaft is inserted into a spline hole in the top end of each regulating screw; and a movable block is in threaded connection in each regulating screw. The small-batchautomobile anti-collision beam punching mechanism is firm and accurate in clamping and fastening, automatically punches, can collect chippings generated by punching, is good in effect and is high inefficiency.

Owner:FOSHAN DAPUGUANG ELECTROMECHANICAL TECH CO LTD

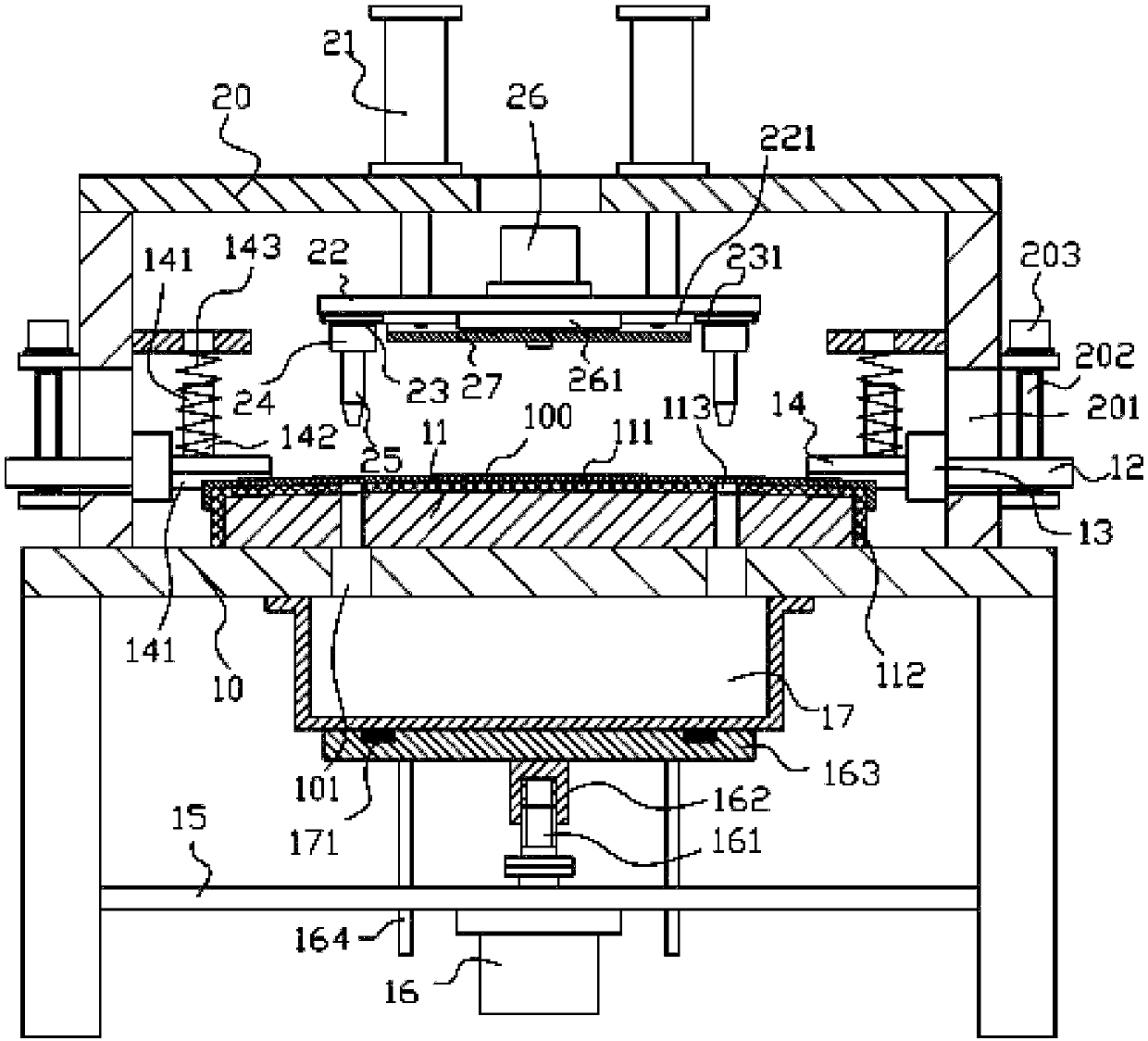

Automatic punching mechanism for small-batch automobile anti-collision beams

InactiveCN107999821AFirmly clampedPrecise clamping and fixingMaintainance and safety accessoriesBoring/drilling machinesPunchingEngineering

The invention discloses an automatic punching mechanism for small-batch automobile anti-collision beams. The automatic punching mechanism comprises a rack. A plurality of vertical through grooves areformed in the middle portion of a top plate of the rack. The top face of the middle portion of the top plate of the rack is fixedly provided with a long installation block. The top face of the long installation block is fixedly provided with an arc-shaped elastic block. The side walls of the long installation block are fixedly provided with side elastic blocks. The bottom face of a top plate of the anti-collision beam to be bent abuts against the top face of the arc-shaped elastic block. The arc-shaped elastic block is inserted into a lower cavity of the anti-collision beam to be bent, and theside elastic blocks abut against the inner side walls of the lower cavity of the anti-collision beam to be bent. The top face of the top plate of the rack is fixedly provided with a main supporting frame. Two vertical supporting plates of the main supporting frame are fixed to the two sides of the top face of the top plate of the rack. The middle portions of the two vertical supporting plates ofthe main supporting frame are fixedly provided with a transverse plate, and the top face of the transverse plate is fixedly provided with a compressing air cylinder. The automatic punching mechanism for the small-batch automobile anti-collision beams is firm and accurate in clamping and fixing, capable of automatically carrying out punching, very convenient to use, good in effect and high in efficiency.

Owner:FOSHAN DAPUGUANG ELECTROMECHANICAL TECH CO LTD

Mechanism for punching side wall of firefighting main machine shell

InactiveCN106216488AFirmly clampedPrecise punchingMetal-working feeding devicesPositioning devicesCamEngineering

The invention discloses a mechanism for punching the side wall of a firefighting main machine shell. The mechanism comprises a rack; an inserting groove is formed in the middle of the top surface of the rack; a first clamping plate and a second clamping plate which are both in L shapes and are arranged oppositely are inserted into the inserting groove in a sleeved mode and correspond to the edge parts of the two sides of a to-be-machined shell correspondingly; slide grooves are formed in the positions, on the two sides of the inserting groove, of the top surface of the rack; punching plates are inserted in the slide grooves in a sleeved mode; punching heads are formed in the positions, facing the upper end of the side wall of the to-be-machine shell, of the punching plates; impact cams are arranged on the side, back onto the punching heads, of the punching plates; transmission gear rings are formed in the arc-shaped walls, opposite to convex parts, of the impact cams and are connected with rotary gears in an engaged mode; a middle supporting block is inserted into the to-be-machined shell in a sleeved mode; a blanking groove is formed in the middle of the middle supporting block; and impact through holes corresponding to the punching heads of the punching plates are formed in the left side wall and the right side wall of the blanking groove. By means of the mechanism, the firefighting main machine shell can be firmly clamped and fixed, and the punching efficiency is high.

Owner:绍兴柯桥远达纺织有限公司

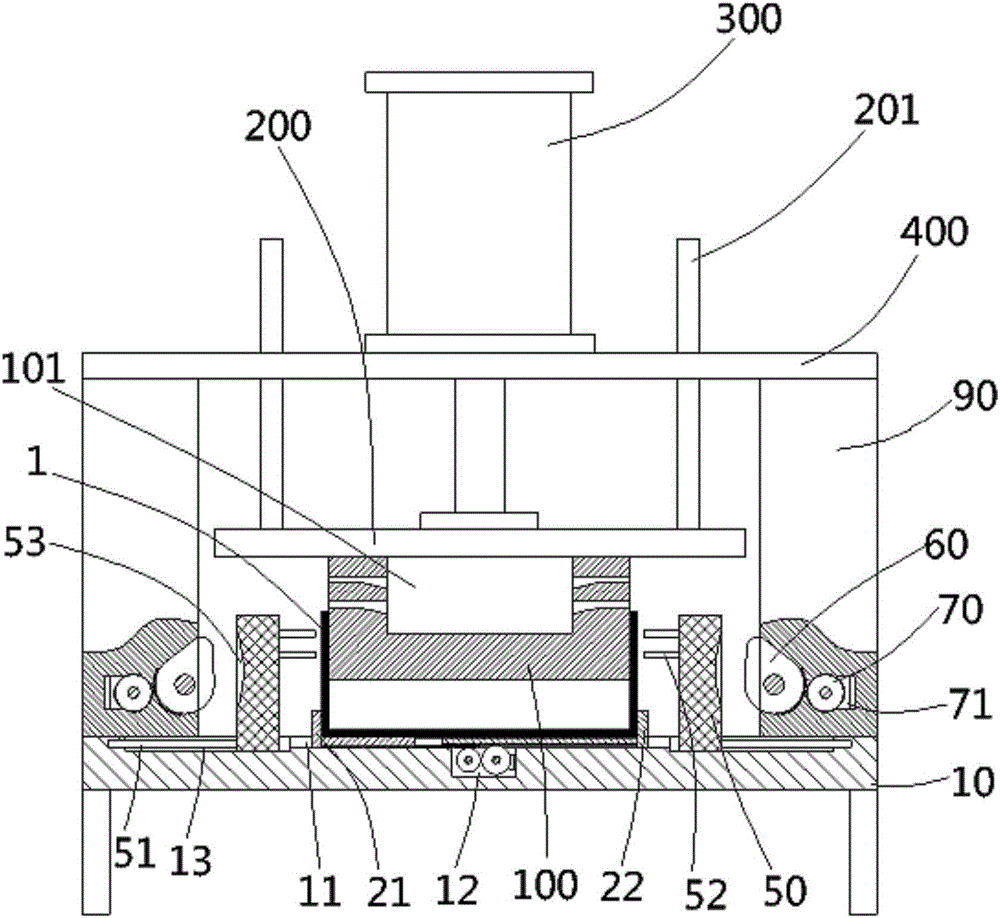

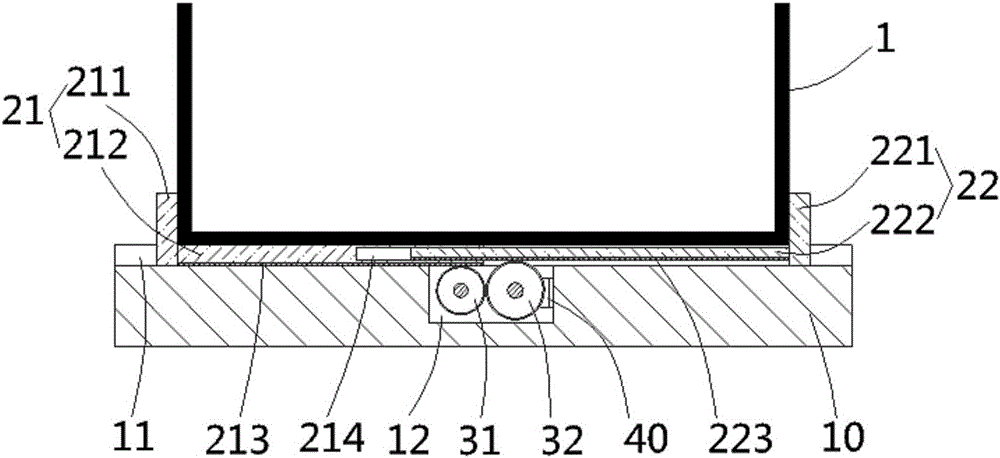

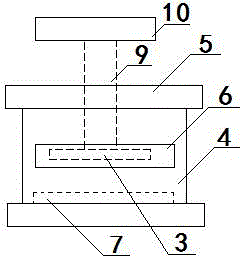

Plastic cylinder three-point positioning and punching mechanism

The invention discloses a plastic cylinder three-point positioning and punching mechanism which comprises a frame. Upper supporting plates are fixed to the top faces of the two sides of a top plate of the frame, and upper extending parts are arranged on the middle portions of the top faces of the two upper supporting plates. The two ends of a middle connecting rack are fixedly connected to the two upper extending parts through bolts, and a punching air cylinder is fixed to the top face of the middle of the middle connecting rack. A push rod of the punching air cylinder vertically and downwards penetrates through the middle of the middle connecting rack, a guiding plate is fixed to the middle of the push rod of the punching air cylinder, and a punch is fixed to the end, extending out of the guiding plate, of the push rod of the punching air cylinder. A connecting groove is formed in the middle of the top face of the top plate of the frame. A cylinder is clamped automatically in a three-point positioning mode through two arc grooves and an upper arc groove by means of clamping air cylinders and a lifting air cylinder, and a middle-supporting column is inserted into the cylinder to achieve middle-supporting; automatic punching is achieved, the cylinder cannot deform in punching, the cylinder is fixedly and firmly clamped, and the effect is good.

Owner:平邑仁安中医药产业发展有限公司

On-bed leg support device for orthopedic nursing

InactiveCN111134988ASolve the problem of long recovery periodGuaranteed stabilityDiagnosticsChiropractic devicesPhysical medicine and rehabilitationOrthopedic department

The invention discloses an on-bed leg support device for orthopedic nursing and relates to the field of medical nursing. Aiming at the problem that the rehabilitation time is long since an orthopedicpatient lying or sitting cannot have support training on legs, the invention discloses the scheme that the device comprises support columns and a suspension rack, wherein two support columns are symmetrically distributed; a U-shaped suspension rack is mounted at the top ends of the two support columns in a sliding manner; U-shaped side walls of the suspension rack are mounted inside the support columns in a sliding manner; moveable plates are mounted inside the support columns in a sliding manner; clamping blocks are fixedly connected with sides, close to side walls of the suspension rack, ofthe moveable plates; airbags are arranged inside the support columns; and the airbags are positioned on sides, far away from the suspension rack, of the moveable plates. The device not only can be stably clamped and fixed on a hospital bed to provide a suspension and support function on a patient, but also is capable of assisting the patient to take effective rehabilitation training operation andshortening the rehabilitation time of legs of the patient, and is applicable to popularization.

Owner:LUOYANG ORTHOPEDIC TRAUMATOLOGICAL HOSPITAL

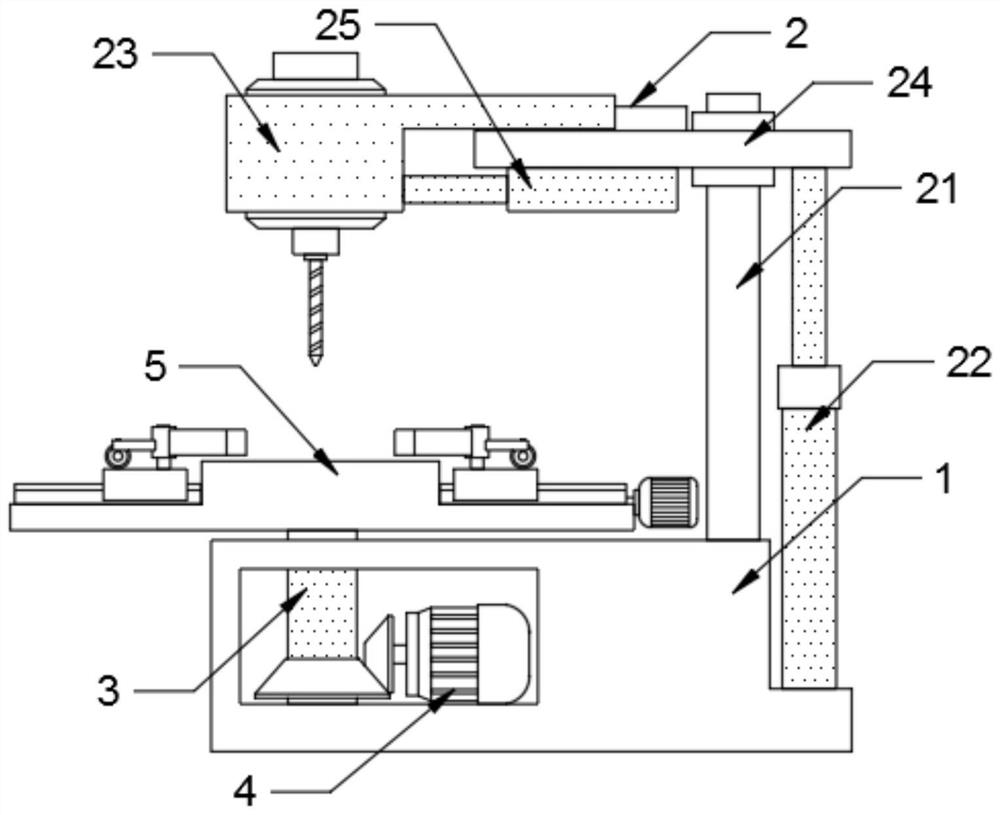

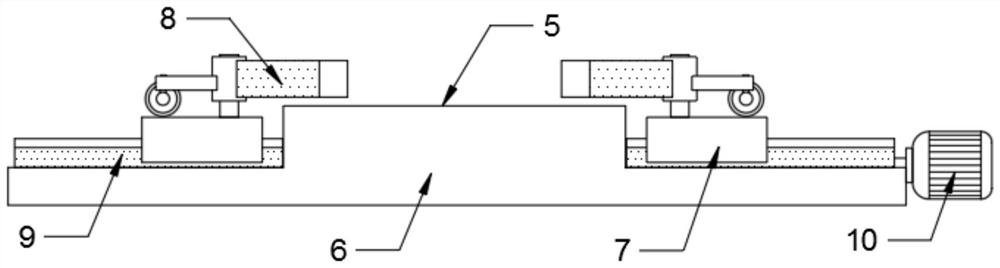

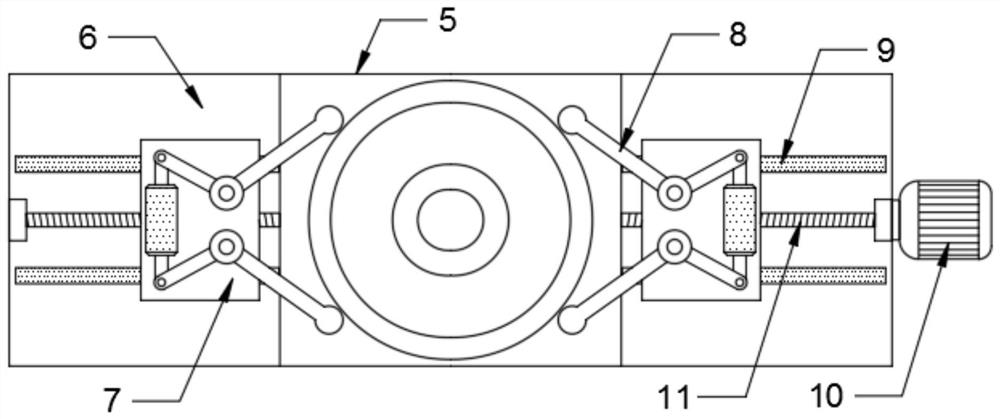

System and method for testing performance of copper core low-voltage cable after manufacturing and processing

ActiveCN113376006AReduce frictional resistanceFlexible operationMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesLow voltageCable machine

The invention provides a system and a method for testing the performance of a copper core low-voltage cable after manufacturing and processing, and the system comprises a double-item detection mechanism, a single-item detection mechanism and a joint control mechanism. Since an existing cable mechanical performance testing device can only test the cable of one model and size, when mechanical performance testing is carried out on cables of different models and sizes, testing can be carried out only by replacing devices of corresponding models, and mechanical performance testing of the cables has limitation and is high in testing cost; and testing of the mechanical performance of the cables is divided into a plurality of specific small testing, and the existing testing device for the mechanical properties of the cable cannot meet the operation execution of various tests, is difficult to ensure the comprehensive detection of different mechanical properties of the cable, and cannot meet the strict test requirements of various properties of the cable after being manufactured and processed, and the like.

Owner:山东兖矿集团长龙电缆制造有限公司

Middle-supporting type plastic cylinder three-point positioning mechanism

The invention discloses a middle-supporting type plastic cylinder three-point positioning mechanism which comprises a frame. Upper supporting plates are fixed to the top faces of the two sides of a top plate of the frame, and a connection supporting plate is fixed to the front portion of the top plate of the frame. A guiding connection sleeve is inserted into a central through hole formed in the middle of the connection supporting plate, the outer side wall of the rear end of the guiding connection sleeve is welded and fixed to the inner side wall of the central through hole, and a middle-supporting cylinder is fixed to the front end of the guiding connection sleeve. A middle-supporting column is fixed to a push rod of the middle-supporting cylinder and inserted into the guiding connection sleeve. A cylinder is clamped automatically in a three-point positioning mode through two arc grooves and an upper arc groove by means of clamping air cylinders and a lifting air cylinder, and the middle-supporting column is inserted into the cylinder to achieve middle-supporting; it is guaranteed that the cylinder cannot deform in cutting, the cylinder is fixedly and firmly clamped, and the effect is good; meanwhile, clamping blocks are convenient to connect, mount, dismount and replace.

Owner:ZHEJIANG SANLENG PLASTIC

Irregular hardware block pressing sleeve mechanism capable of precisely adjusting position

InactiveCN107553185AAutomatic compressionSimple structurePositioning apparatusMetal working apparatusEngineeringThreaded rod

The invention discloses an irregular hardware block pressing sleeve mechanism capable of precisely adjusting position. The irregular hardware block pressing sleeve mechanism comprises a rack. The topface of a top plate of the rack is fixedly provided with an upper supporting frame. The top face of the middle portion of the top plate of the rack is fixedly provided with an installation groove. Anelastic protection block is embedded into the installation groove. The bottom face of the elastic protection block is fixed to the bottom face of the installation groove. A piece to be machined is inserted and clamped into a main groove in the top face of the elastic protection block. The middle portion of a top plate of the upper supporting frame is provided with a transverse through groove. Thetop faces, on the two sides of the transverse through groove, of the top plate of the upper supporting frame are fixedly provided with supporting plates. The two ends of a transverse threaded rod arehinged to the two supporting plates. The outer side wall of one supporting plate is fixedly provided with an adjusting motor. A fine adjustment block is screwed into the transverse threaded rod, the middle portion of the bottom face of the fine adjustment block is fixedly provided with a movable frame, and the movable frame is inserted into the transverse through groove. The irregular hardware block pressing sleeve mechanism capable of precisely adjusting the position is simple in structure, clamping is fixed and firm, a compressing plate can be finely adjusted leftwards and rightward in the transverse direction, it is guaranteed that the position is accurate, and the piece to be machined can be automatically compressed.

Owner:FOSHAN RUIPUDA OPTOELECTRONICS TECH CO LTD

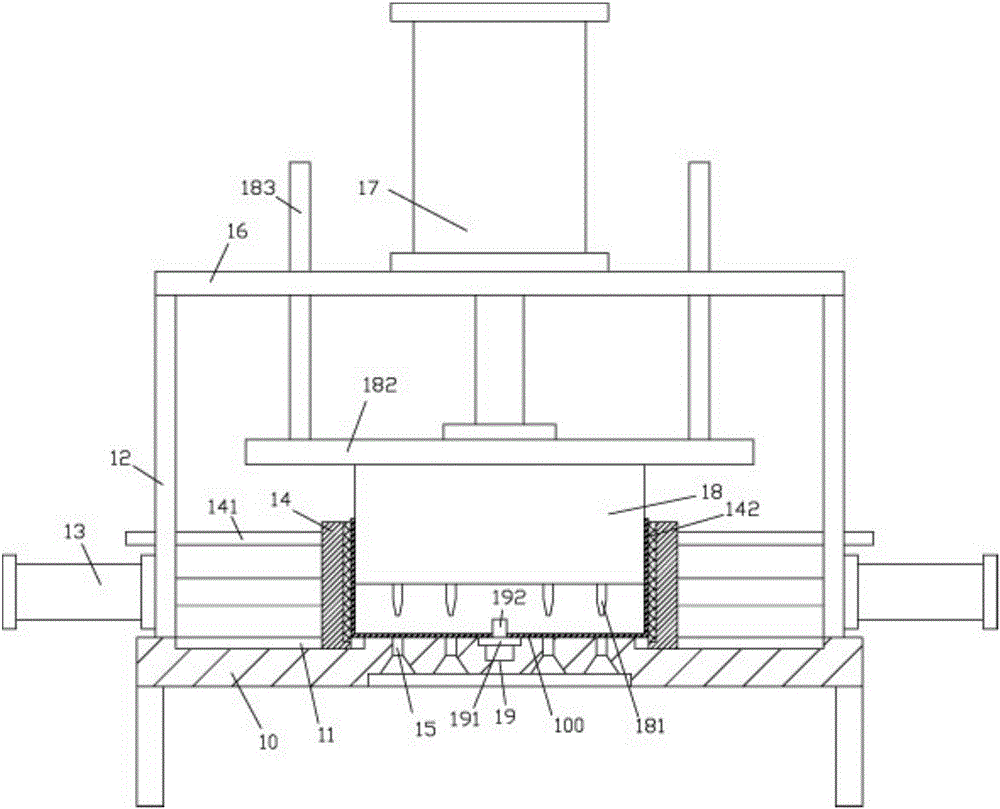

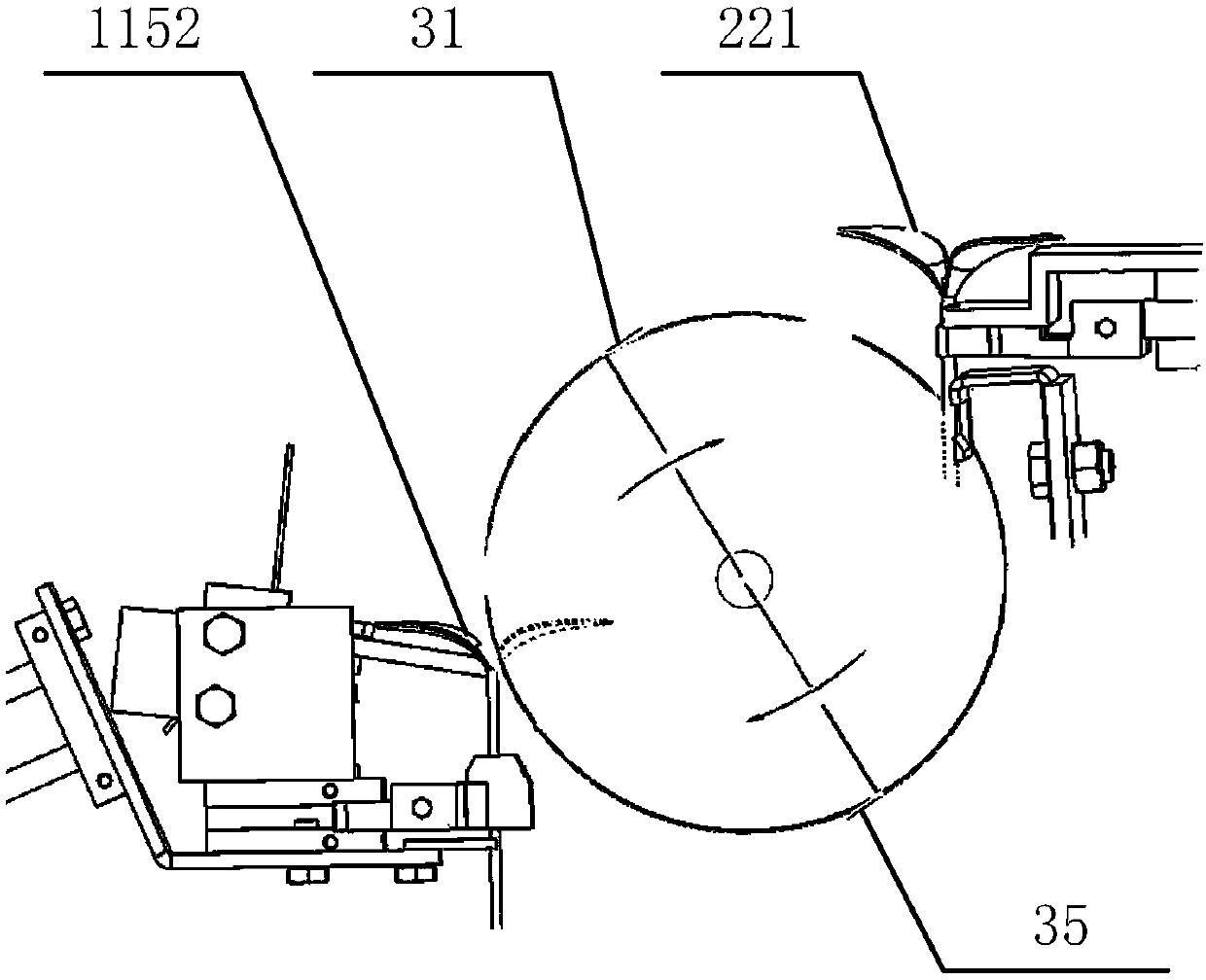

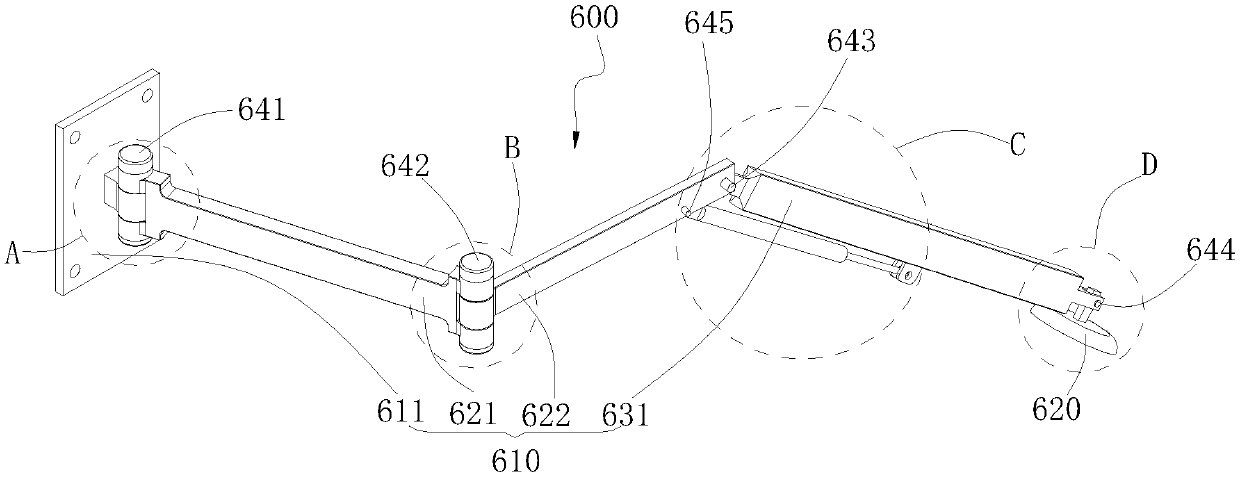

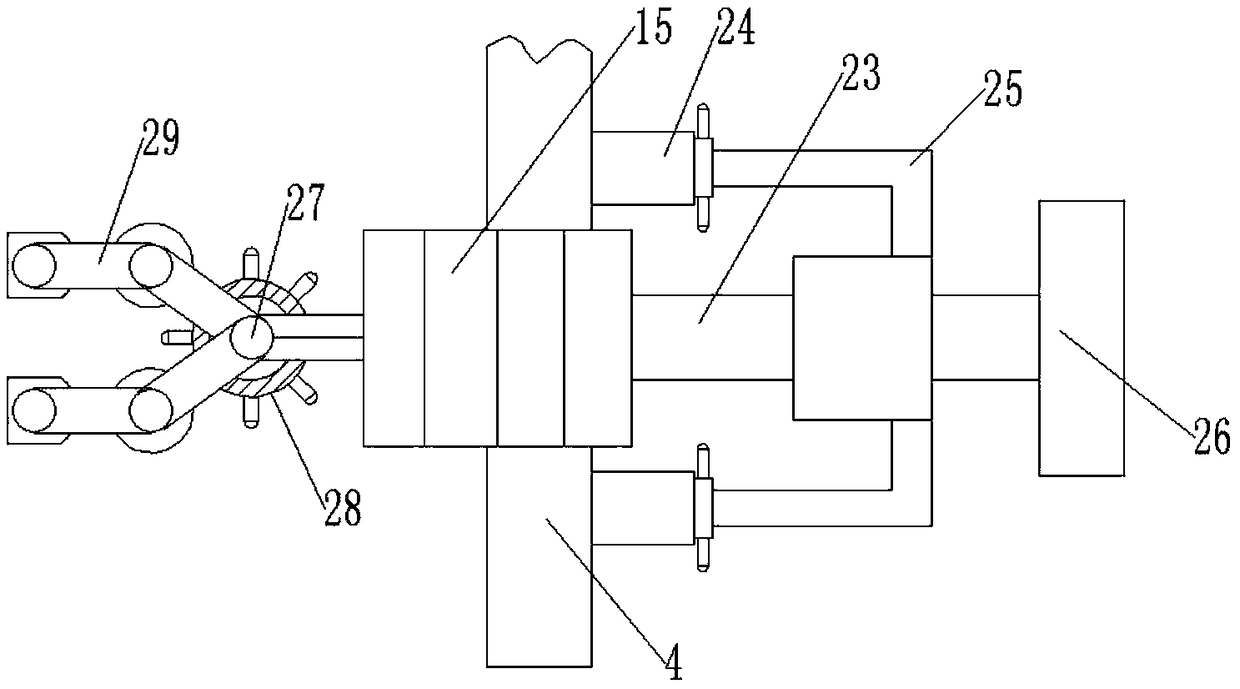

Automatic grafting device

The invention belongs to the technical field of agricultural machinery, and relates to an automatic grafting device. The automatic grafting device includes a stock clamping and transporting mechanicalarm, a scion clamping and transporting mechanical arm, a seedling cutting device, an automatic clip providing device, a rack and a grafting-clip automatic arranging and transporting device; the seedling cutting device and the automatic clip providing device are correspondingly arranged at the front and middle of the rack respectively; the stock clamping and transporting mechanical arm and the scion clamping and transporting mechanical arm are correspondingly arranged at the left and right sides of the rack respectively; the grafting-clip automatic arranging and transporting device is arrangedon the rear of the rack and is used for sequentially transporting grafting clips to the automatic clip providing device. The automatic grafting device is simple in structure, high in grafting speed and precision, and reliable and convenient in seedling providing, seedling clamping damage is reduced, regarding stock and scion seedlings, not only seedling providing positioning but also seedling cutting pivoting can be achieved, shifting the seedlings into the clips during grafting can also be achieved, and transporting and clamping of the grafting clips are reliable.

Owner:张铁中

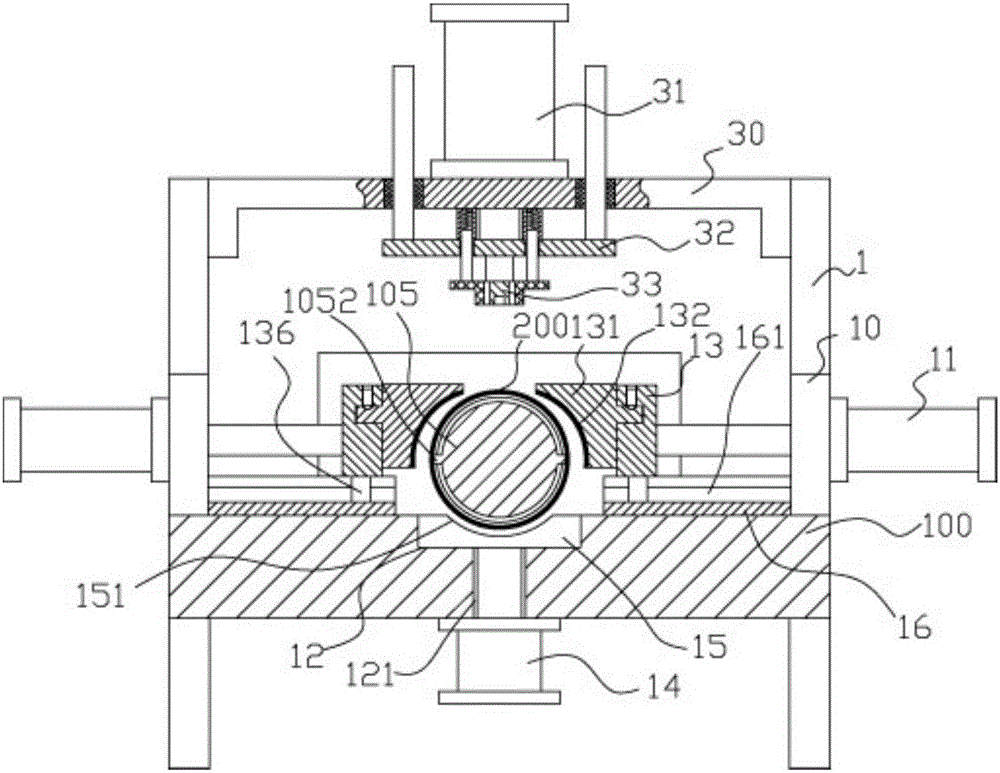

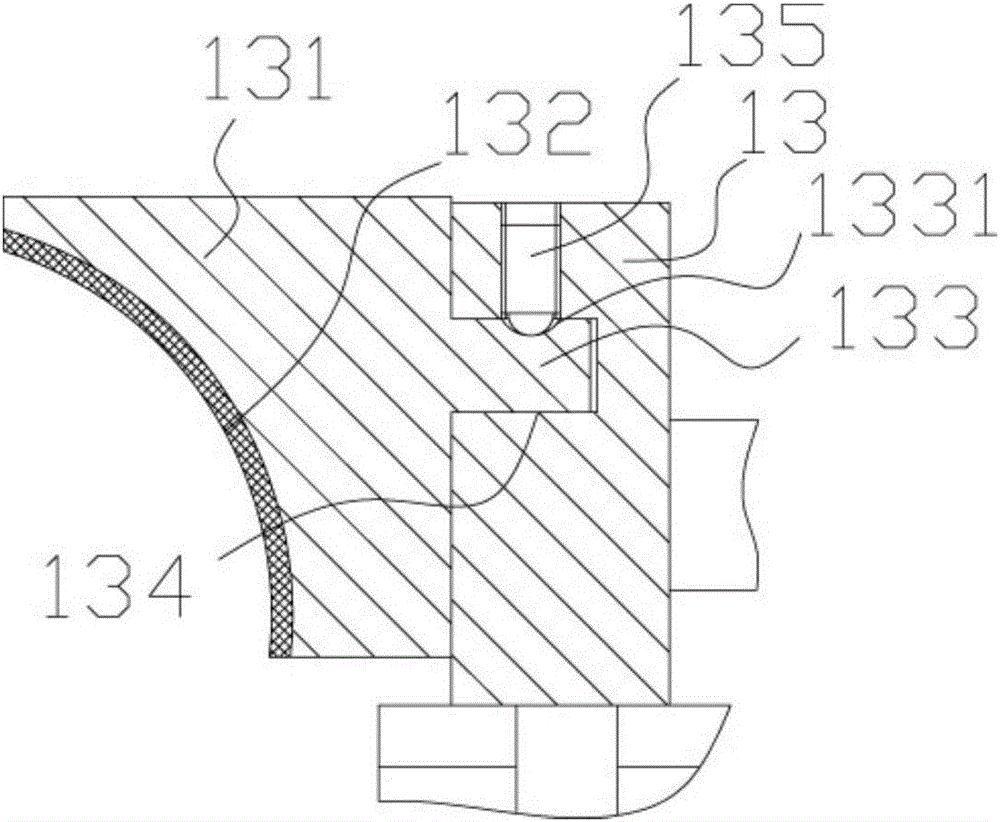

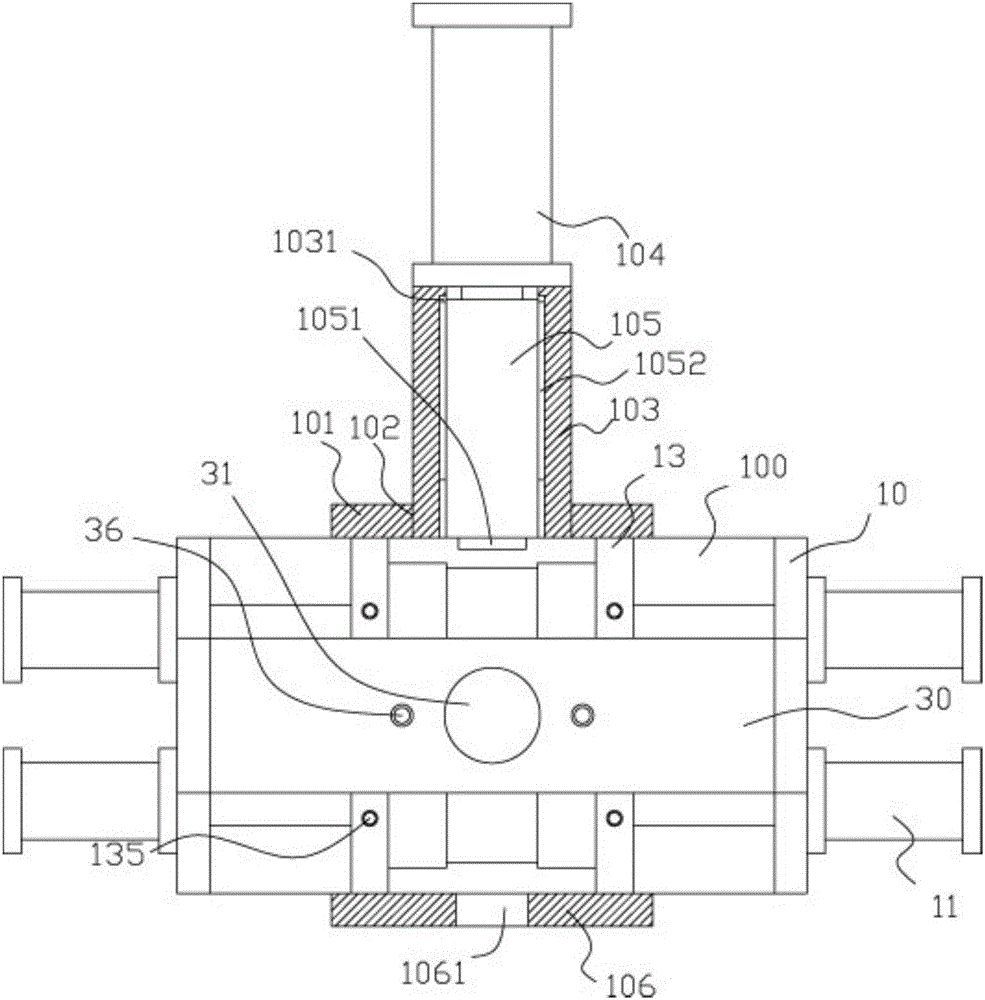

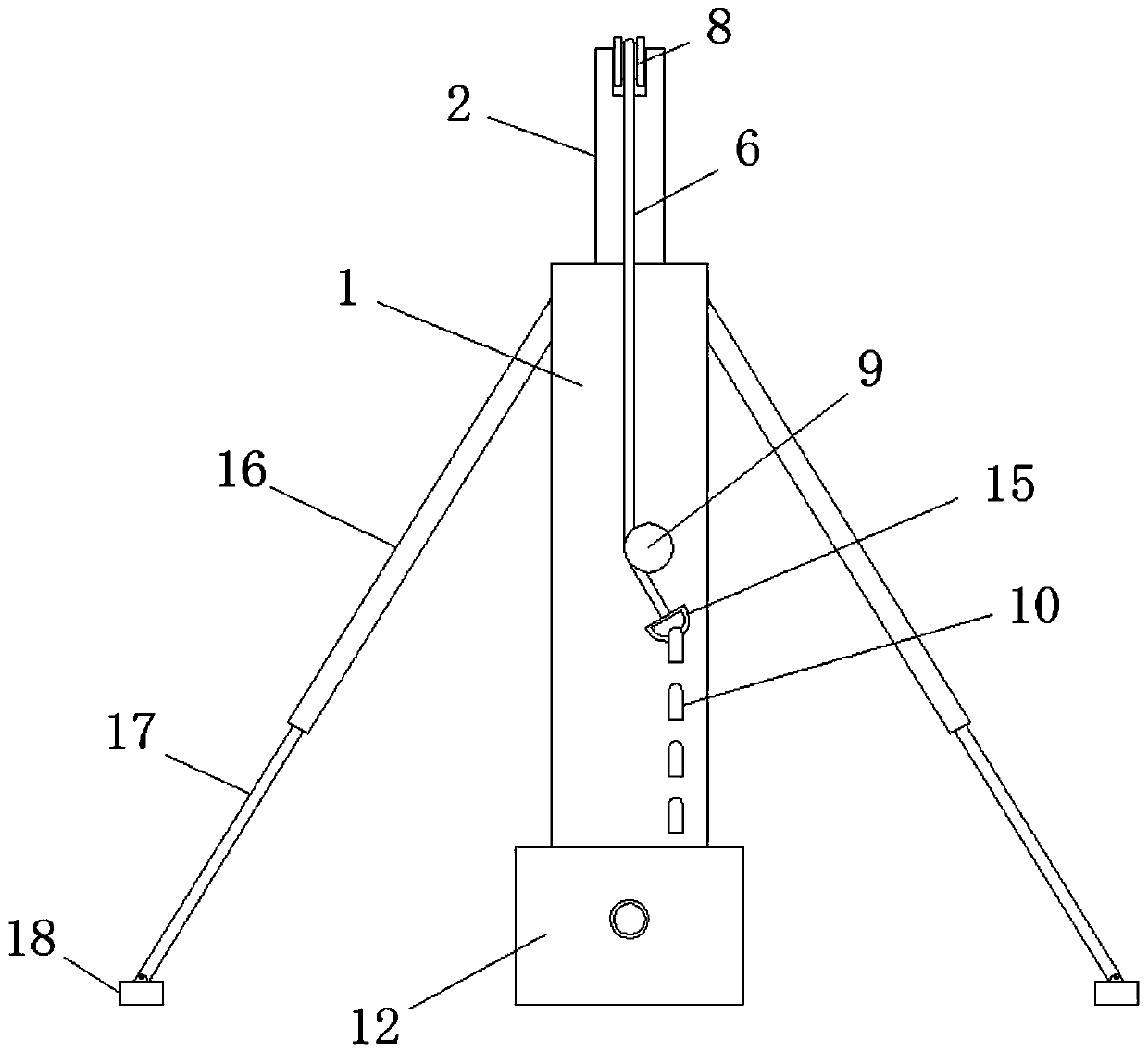

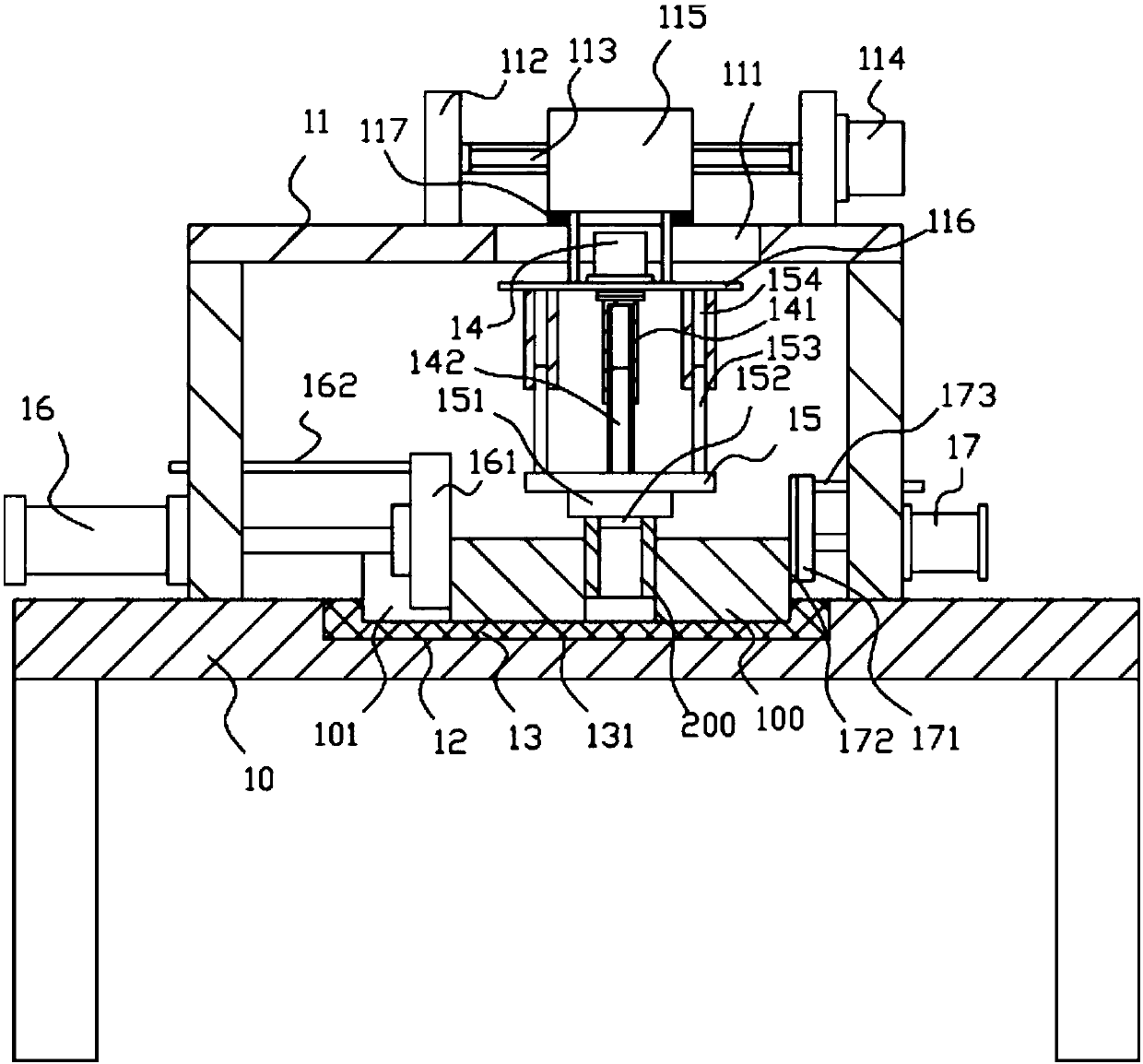

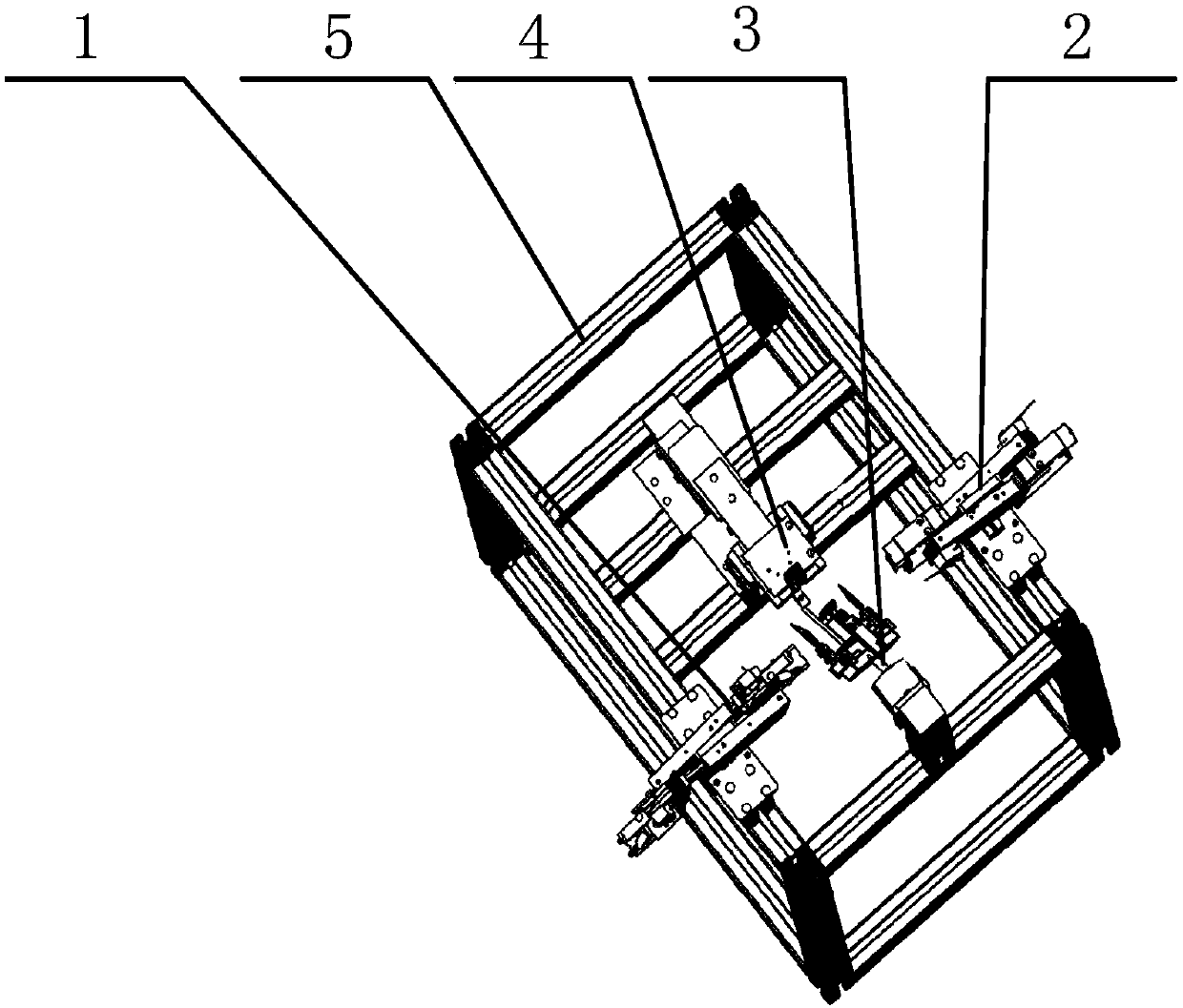

Automatic installation equipment of sewage inspection well special for drainage pipeline system

InactiveCN107354991ARealize the mechanized automatic installation functionEffective limitSewerage structuresSewer pipelinesEngineeringSewage

The invention relates to an automatic installation equipment for a special sewage inspection well for a drainage pipeline system, which includes a bottom plate, two moving devices are symmetrically installed on the top of the bottom plate, a locking device is installed between the two moving devices, and a fixed lifting device is installed at the front end of the bottom plate device, two mobile devices, a locking device and a fixed lifting device are used in conjunction with each other to complete the mechanized automatic installation process of the sewage inspection well. The invention can solve the problems existing in the installation process of the existing cement sewage inspection wells that need to be manually installed with the help of existing hoisting equipment, need to be manually transported by existing mobile equipment to the cement material sewage inspection wells, and need to be manually installed according to different specifications of cement sewage inspection wells The inspection well adjusts the fixed lifting tools. The existing mobile equipment cannot provide safe fixed facilities. Manual adjustment of the fixed tools is labor-intensive and low in efficiency. It can realize the mechanized and automatic installation function of the cement inspection well.

Owner:俞樑兵

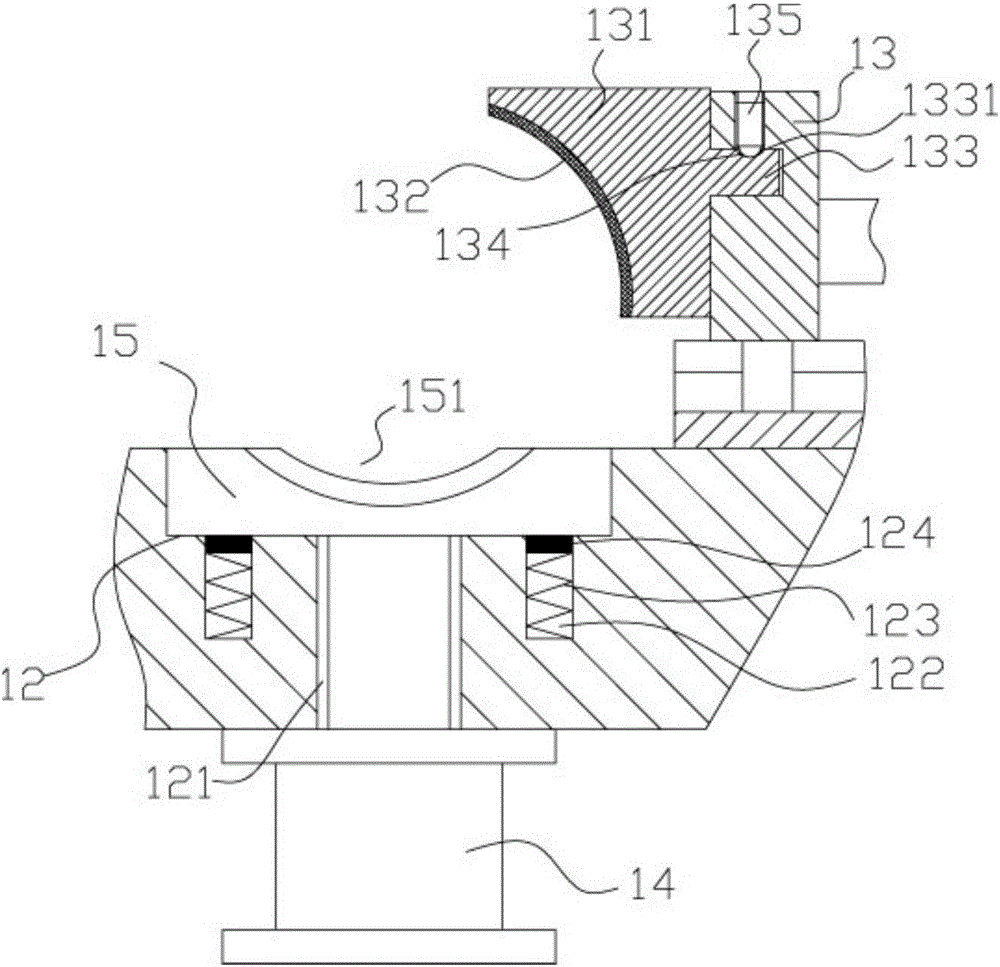

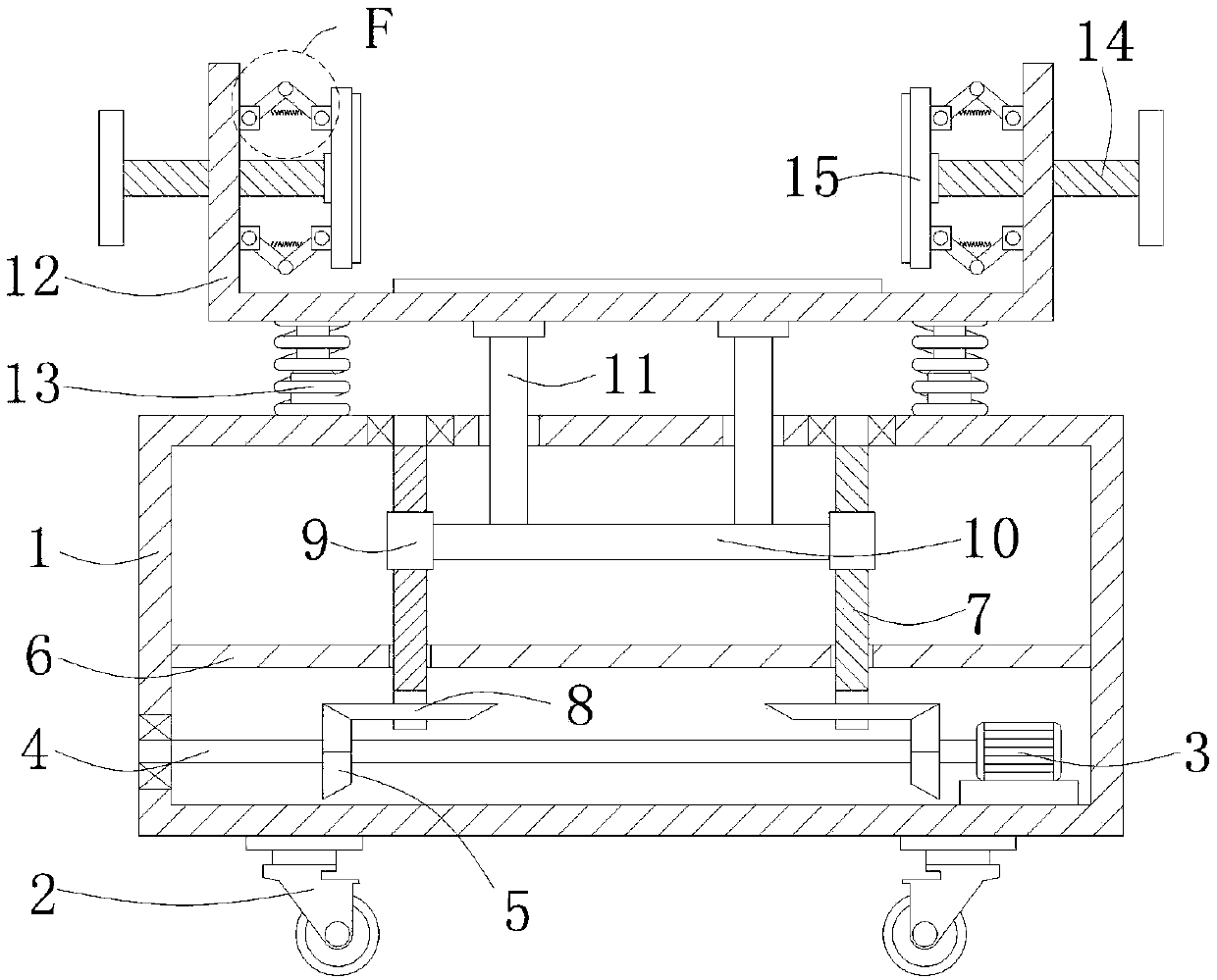

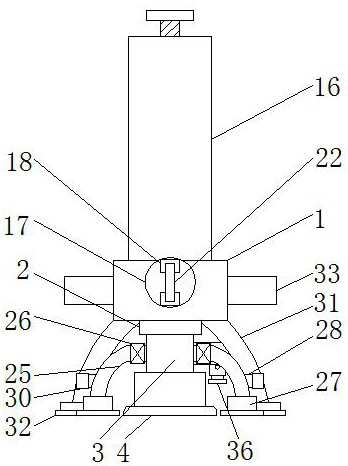

Lifting clamping mechanism for car gear shaft maintenance

The invention discloses a lifting clamping mechanism for car gear shaft maintenance. The lifting clamping mechanism includes a machine frame and a lifting main plate, the lifting main plate is locatedabove a top plate of the machine frame, and two vertical regulating threaded sleeves are inserted in the top plate of the machine frame in a sleeving mode; the top ends of the vertical regulating threaded sleeves extend out of the top surface of the top plate of the machine frame to be fixed to the bottom surface of the lifting main plate, the lower side wall of support legs of the machine frameis fixedly provided with a lower horizontal fixing plate, and lifting vertical screws are hinged to two sides of the top surface of the horizontal fixing plate; the upper portions of the lifting vertical screws are in screw joint with the vertical regulating threaded sleeves, the lower portions of the vertical regulating threaded sleeves are located below the top plate of the machine frame, and the lower portions of the lifting vertical screws are fixedly provided with transmission bevel gears; and the middle portion of the top surface of the lower horizontal fixing plate is fixedly provided with a two-output-shaft motor, two output shafts of the two-output-shaft motor are connected with transition shafts through couplings, and the end portions of the transition shafts are fixedly providedwith the driving bevel gears. According to the lifting clamping mechanism for the car gear shaft maintenance, a gear shaft can be clamped and fixed and can perform high-low position regulation according to the need, the clamping and the fixing are firm, and the maintenance is convenient.

Owner:FOSHAN HUAPU RUILIAN ELECTROMECHANICAL TECH CO LTD

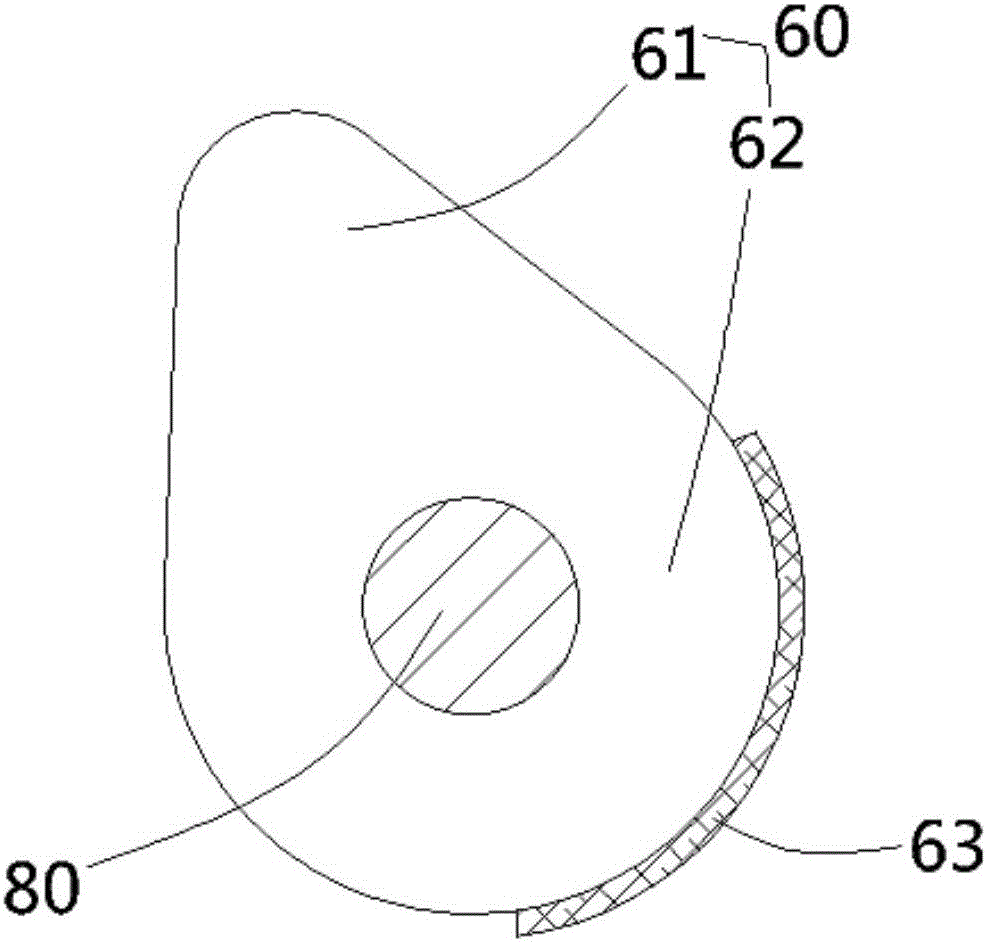

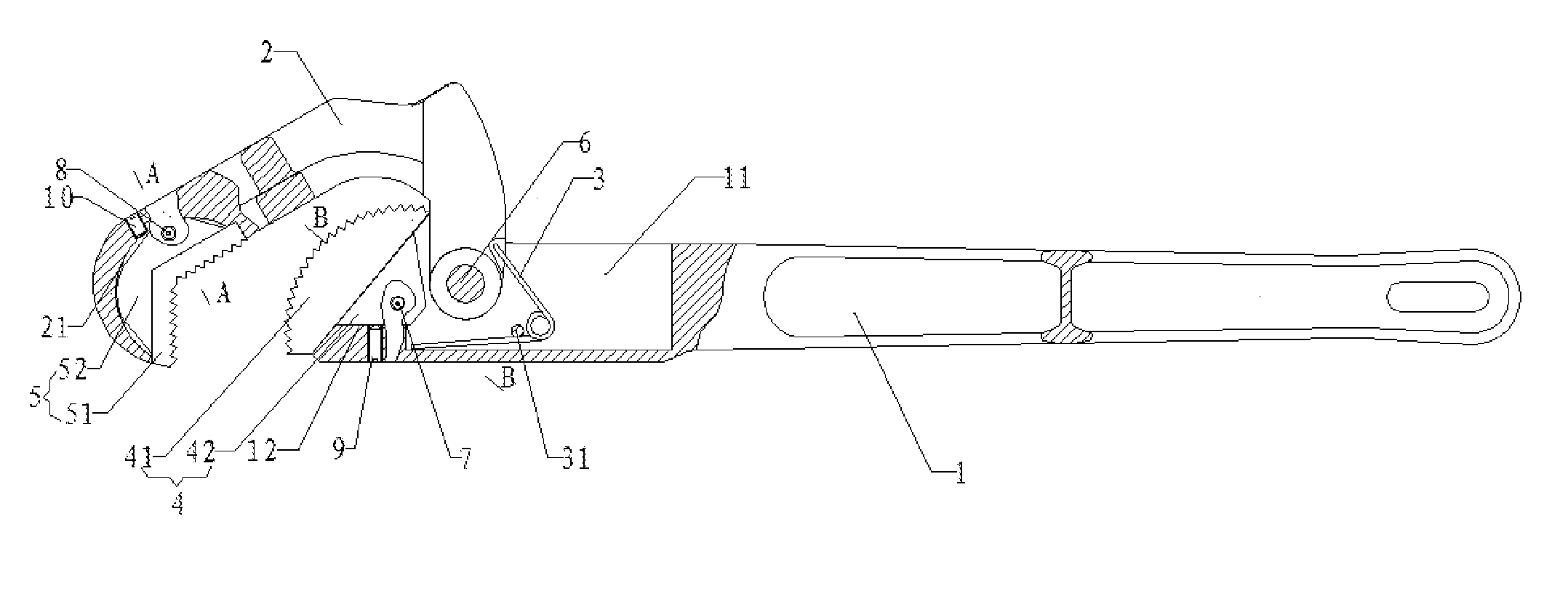

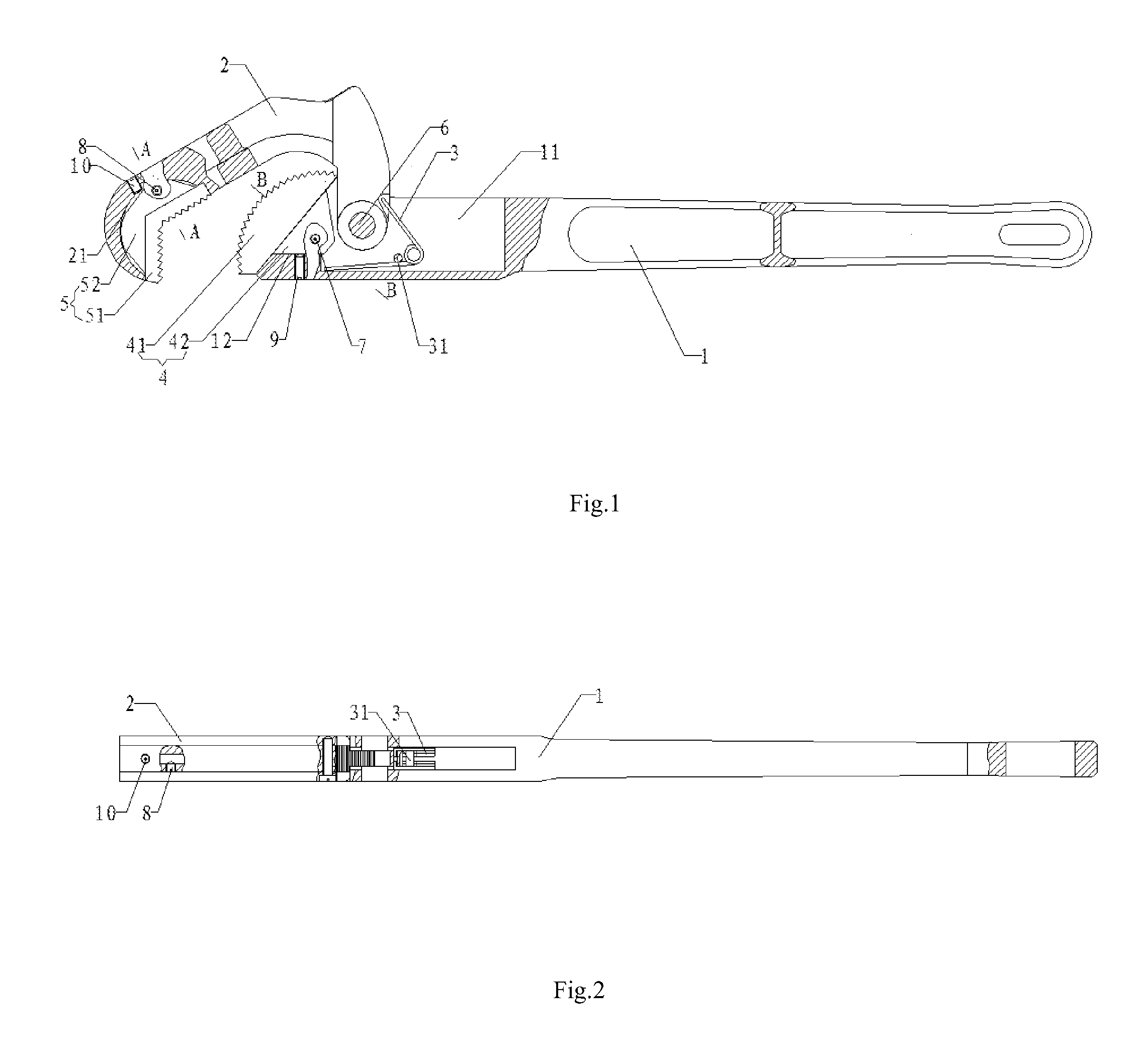

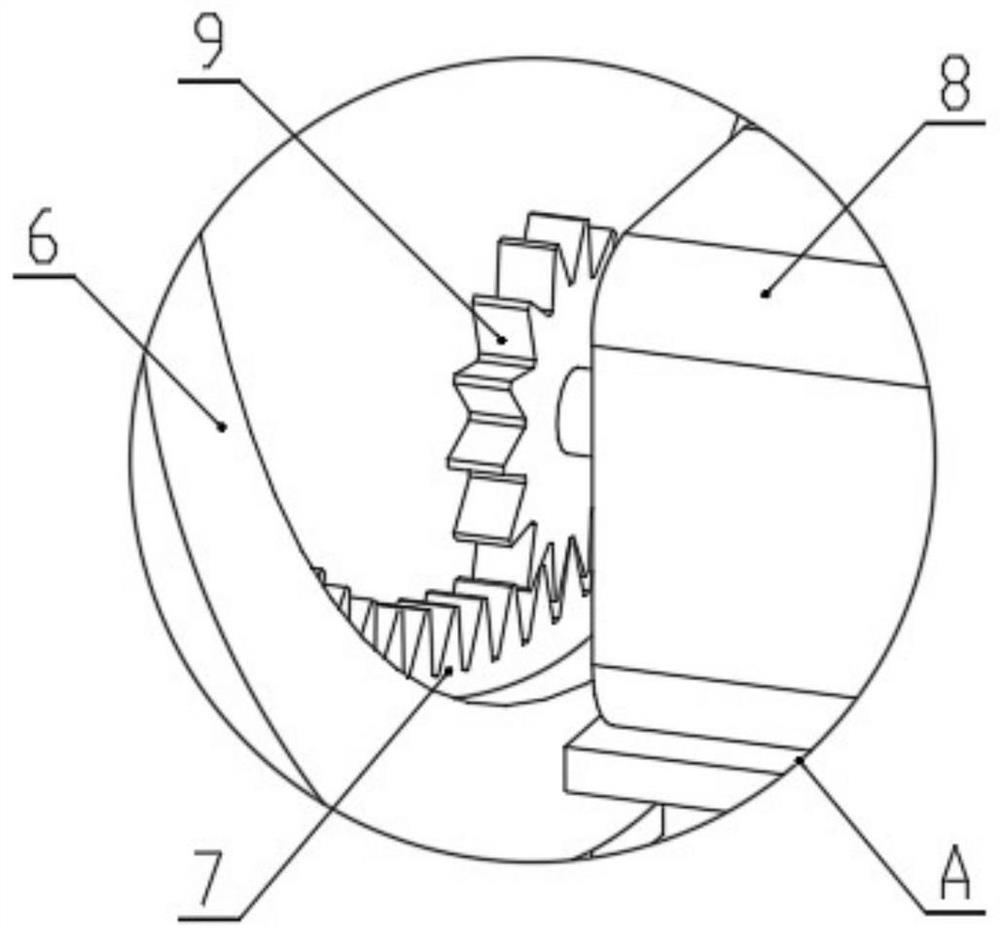

Multi-purpose ratchet piper pliers

InactiveUS20150360350A1Quality improvementReasonable structureSpannersWrenchesUpper toothEngineering

A piece of multi-purpose ratchet pipe plier comprise a handle, an upper jaw clamp, a pin shaft, a torsion spring, an arc-shaped tooth surface insert block and an upper tooth surface inert block, wherein the upper jaw clam is hinged on the handle through the pin shaft, the torsion spring is arranged in the assembly slot of the handle and connect with upper jaw clam and the bottom of assembly slot in the ends, the arc-shaped tooth surface insert block is fixed on the handle by tenon, and the upper tooth surface insert block is fixed on the upper jaw clamp by tenon. The anti-skip teeth on the handle and the upper jaw clamp are disassembled and replaced, the whole plier opening can clamp the pipe through the tooth surfaces at three different directions for realizing anti-skip function.

Owner:JIANG ZHANGMEI

Steel bending machine capable of improving clamping stability

The invention discloses a steel bending machine capable of improving the clamping stability. The steel bending machine comprises a mechanical arm; a fixing column and an air cylinder are fixedly arranged on one side of the mechanical arm; the air cylinder is located above the fixing column; a connecting rod is fixedly arranged on a piston rod of the air cylinder; a movable base is fixedly arrangedat the end, far away from the air cylinder, of the connecting rod; a mounting hole is formed in the movable base; a sleeve is fixedly sleeved with the mounting hole; the fixing column penetrates through the sleeve in a sliding mode and extends to the outer side of the sleeve; a support is fixedly arranged at the top of the movable base and is of an L-shaped structure; a fixing block is fixedly arranged at the end, far away from the connecting rod, of the support; and a limiting block is fixedly welded to the end, far away from the mechanical arm, of the fixing column. The steel bending machine has the advantages of being simple in structure, efficient and practical, the stability for clamping steel bars can be improved, in addition, clamp heads can be replaced conveniently and quickly, and the clamp heads matched with the steel bars are replaced, so that the steel bars can be clamped and fixed more stably.

Owner:如皋市煜腾金属材料科技有限公司

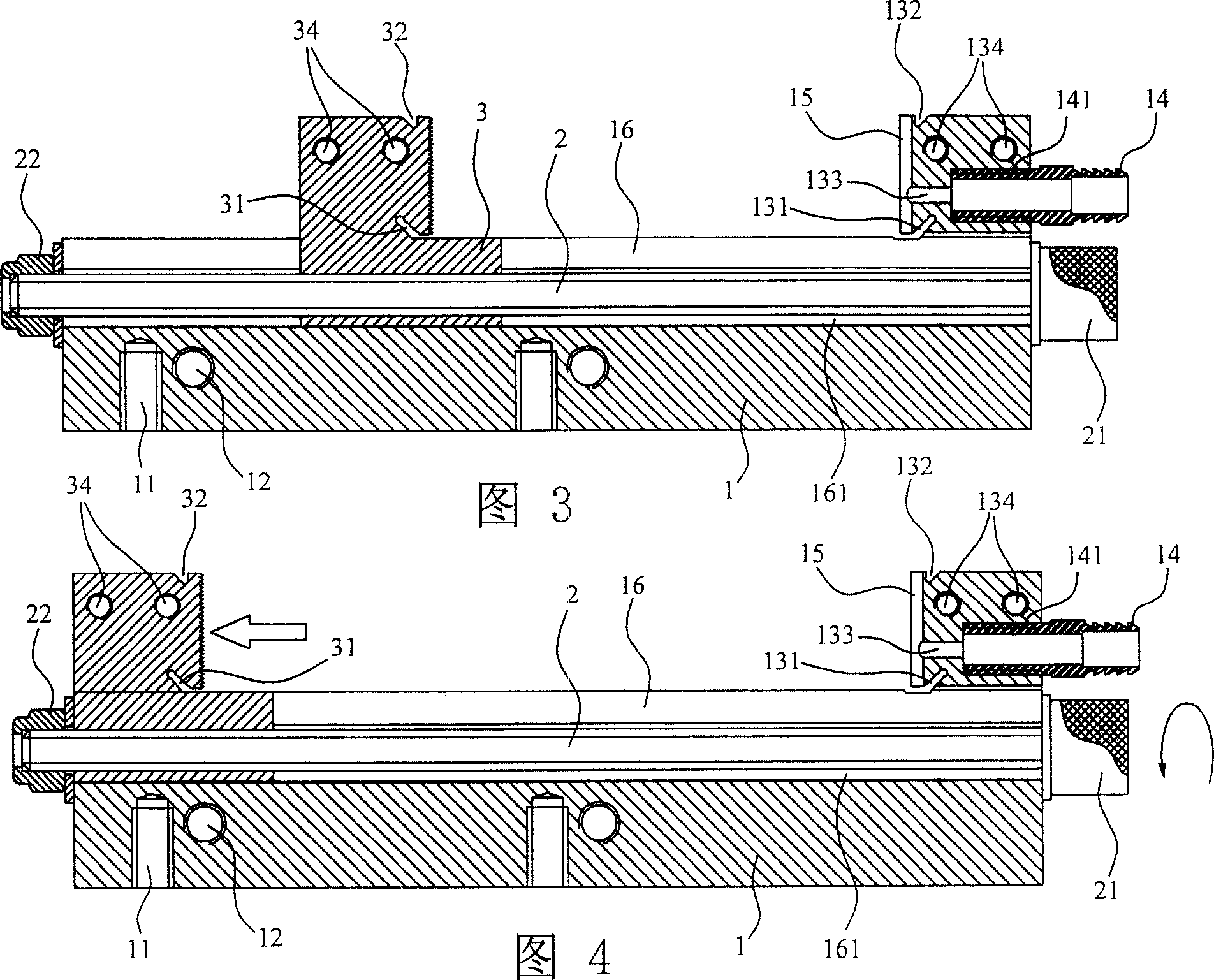

Transverse groove milling mechanism of end-grooved axle for automobile

InactiveCN108393723AFirmly clampedEasy to processWorkpiecesMilling equipment detailsTransverse grooveArchitectural engineering

The invention discloses a transverse groove milling mechanism of an end-grooved axle for an automobile. The transverse groove milling mechanism comprises a rack, wherein a lifting motor is fixed on the middle bottom surface of a top plate of the rack; an output shaft of the lifting motor penetrates the top surface of the top plate of the rack and is in screw connection with a lifting screw sleeve;a lifting block is fixed at the top end of the lifting screw sleeve; a guiding block is fixed to the top middle of the top plate of the rack; a central penetration via hole is formed in the middle ofthe guiding block; the output shaft of the lifting motor, the lifting screw sleeve and the lifting block are inserted into the central penetration via hole; the upper part of the lifting block extends out of the top surface of the guiding block; a permanent magnet block is fixed on the top surface of the lifting block; vertical support plates are fixed on the left side and the right side of the top middle of the top plate of the rack; outer support plates are fixed on the left side and the right side of the top surface of the top plate of the rack; and adjusting and supporting plates are fixed to the upper parts and the middles of opposite wall surfaces of the two outer support plates. The transverse groove milling mechanism can clamp and fix a to-be-processed axle and automatically perform groove milling, is firm in clamping and fixing and is convenient to process.

Owner:FOSHAN RUIPUDA OPTOELECTRONICS TECH CO LTD

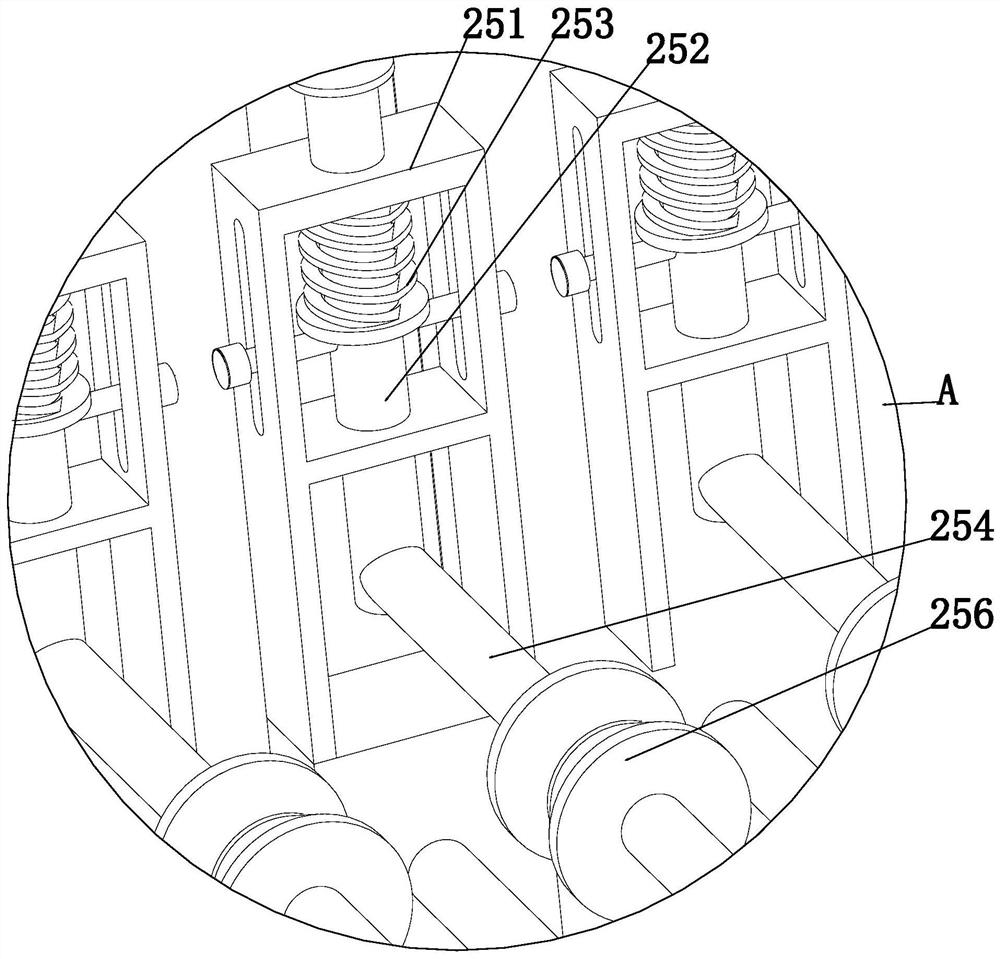

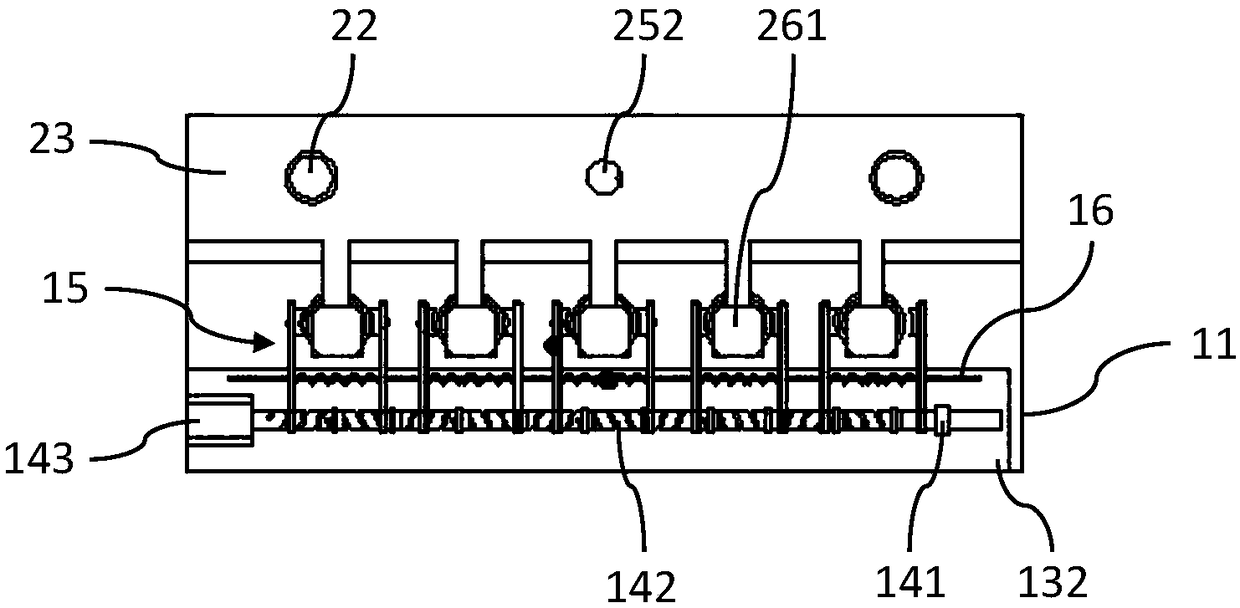

Test tube clamping unit and automatic test tube cleaning device

InactiveCN108543786AFirmly clampedImprove work efficiencyHollow article cleaningBiochemical engineeringTesting tubes

The invention provides a test tube clamping unit and an automatic test tube cleaning device with the test tube clamping unit. The test tube clamping unit is used for clamping and fixing multiple testtubes simultaneously and comprises a first base, multiple test tube supporting blocks, an installing rack, a first driving assembly and test tube clamps; the multiple test tube supporting blocks are arranged on the first base at intervals, and the test tube supporting blocks are provided with grooves which are matched with the shapes of the bottoms of test tubes and used for supporting and positioning the test tubes; the installing rack is fixedly arranged on the first base; the first driving assembly is fixedly arranged on the installing rack; and the number of the test tube clamps is the same as that of the test tube supporting blocks, and the test tube clamps are installed on the first driving assembly, arranged to correspond to the multiple test tube supporting blocks one to one and driven by the first driving assembly to be folded or unfolded to clamp or loosen the opening portions of the test tubes. The automatic test tube cleaning device is used for clamping, fixing and cleaningthe multiple test tubes simultaneously and comprises the test tube clamping unit used for clamping and fixing the test tubes and a cleaning unit which is fixedly connected with the test tube clampingunit and used for cleaning the test tubes.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Adjustable mounting seat and air energy water heater

InactiveCN109612108ATo achieve height adjustmentAchieve regulationFluid heatersIndustrial engineeringWater heater

The invention provides an adjustable mounting seat, which comprises a base. Universal wheels are arranged at the bottom of the base, a rotating motor is arranged in an inner cavity of the base and sleeves a rotating shaft, and a driving bevel gear sleeves the rotating shaft; the base is fixedly connected with a supporting plate, a screw is inserted into the supporting plate, and a driven bevel gear and a sliding block sleeve the screw; the sliding block is fixedly connected with a lifting plate, and the lifting plate is provided with a supporting rod; the supporting rod is fixedly connected with a U-shaped supporting table, and the U-shaped supporting table is provided with a telescopic rod; a locking screw is inserted into the U-shaped supporting table and fixedly connected with a fixed plate; the U-shaped supporting table is provided with a first fixing block, and a first hinge rod is hinged to the first fixing block; and a second fixing block is arranged on the fixed plate, and a second hinge rod is hinged to the second fixing block. The technical problem that outdoor unit bases of existing air energy water heaters cannot be adjusted and thus cannot adapt to outdoor units, withdifferent sizes, of the air energy water heaters can be solved.

Owner:CHANGSHA QIUDIANBING INFORMATION TECH CO LTD

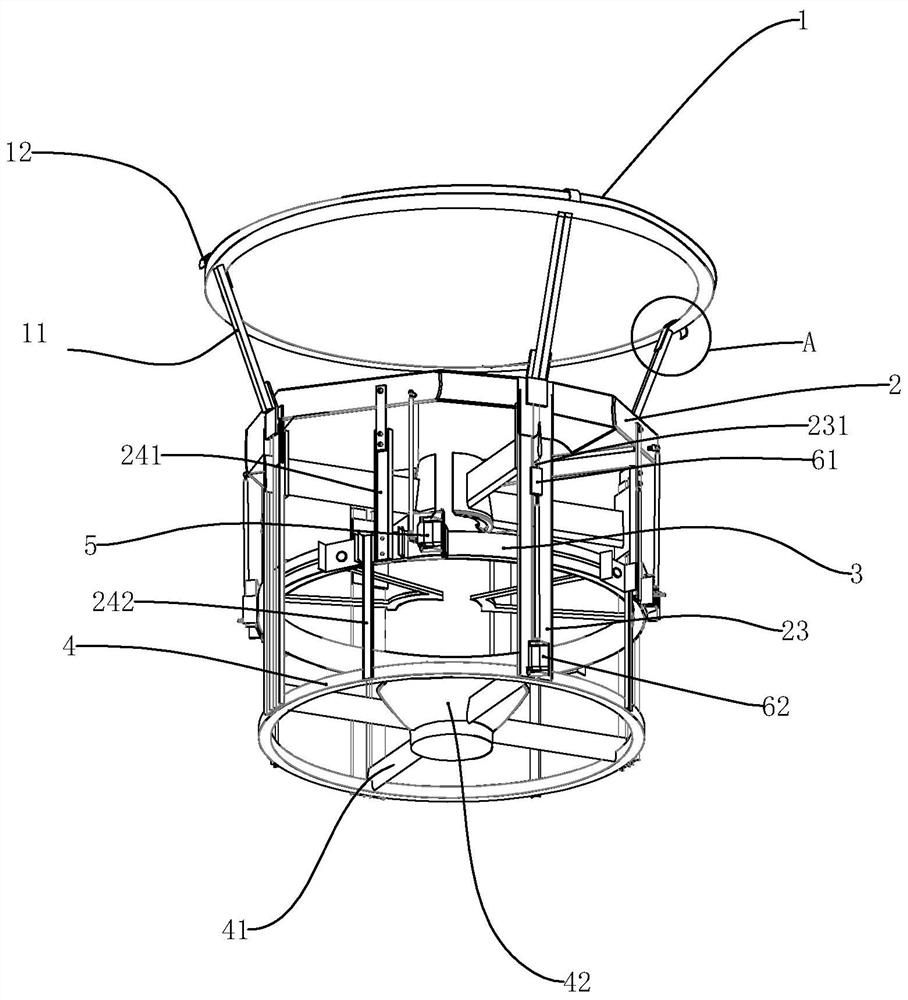

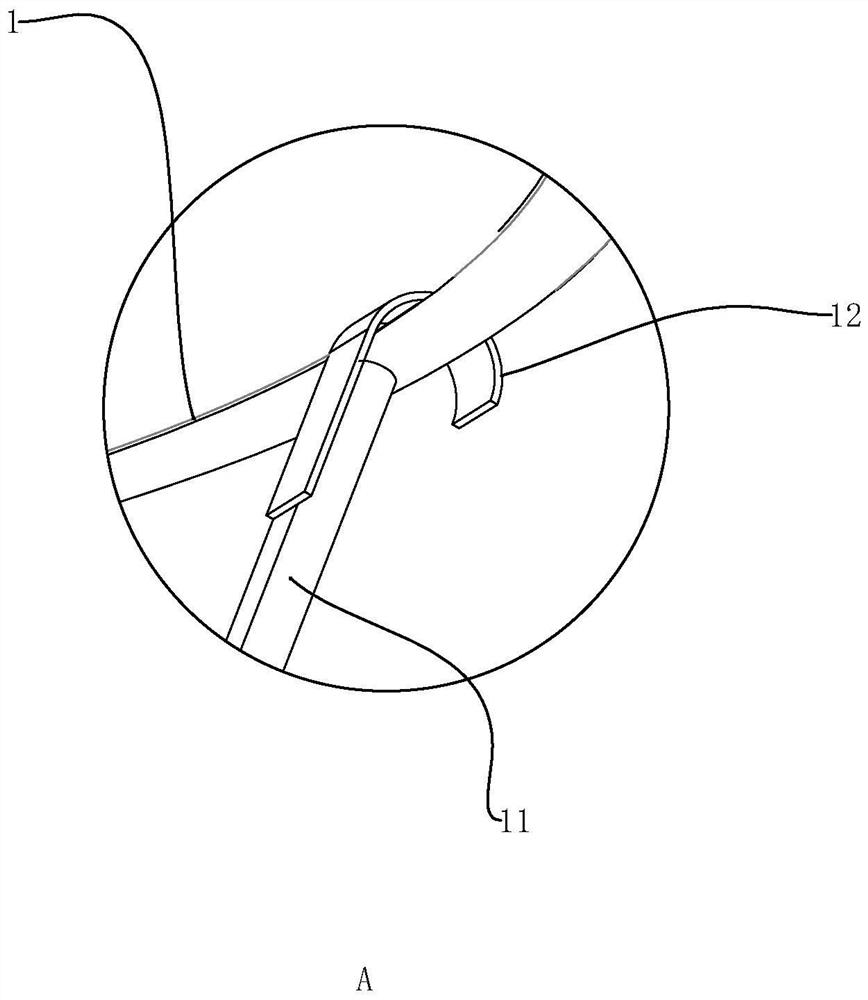

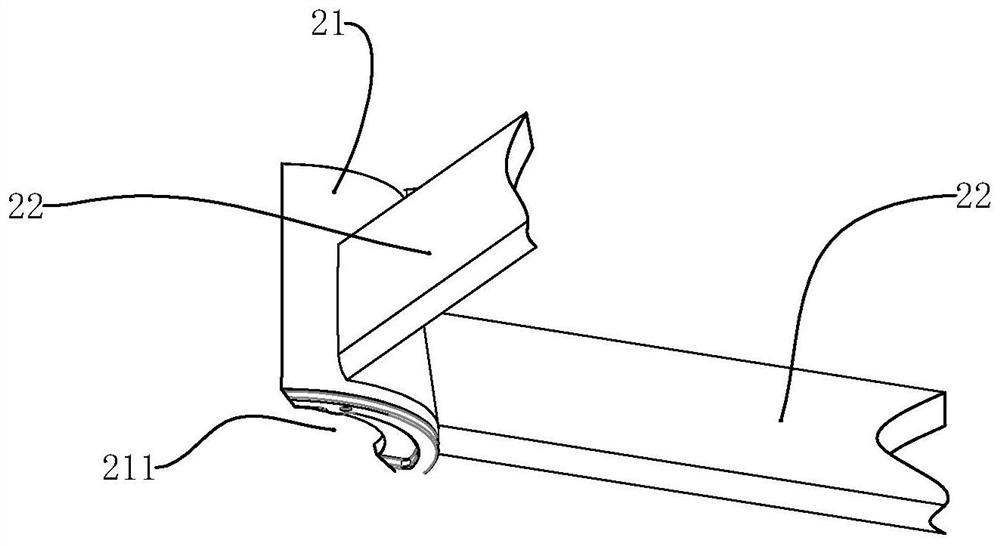

AUV underwater recovery system

PendingCN111824374AFirmly clampedSafe recycling processLifeboat handlingUnderwater vesselsEngineeringStructural engineering

The invention discloses an AUV underwater recovery system, which comprises a butt joint frame and a clamping mechanism. The butt joint frame comprises an inlet end and a recovery frame. The recovery frame comprises a framework structure composed of a front ring frame, a middle ring frame and a tail ring frame. The framework structure is formed by connecting axially-extending connecting plates at intervals in the circumferential direction. The inlet end comprises a guide ring, the guide ring is fixedly connected with the front ring frame through a supporting rod, an AUV detection sensor is arranged on the middle ring frame, and a supporting plate and a positioning seat are arranged in the tail ring frame; the clamping mechanism comprises at least two positioning plates; a connecting arm isfixedly connected to the outer side of the positioning plate, a limiting clamping groove allowing the connecting arm to penetrate through is formed in the connecting plate, a jacking block in inclinedplane sliding fit with part of the connecting arm is assembled in the limiting clamping groove, and a power cylinder for driving the jacking block to ascend and descend so as to push the connecting arm to do telescopic motion in the radial direction of the cylindrical recovery frame is installed on the connecting plate. According to the recovery system, the AUV to be recovered can be stably clamped and fixed, and the recovery process is safely and reliably conducted.

Owner:TIANJIN RES INST FOR WATER TRANSPORT ENG M O T +1

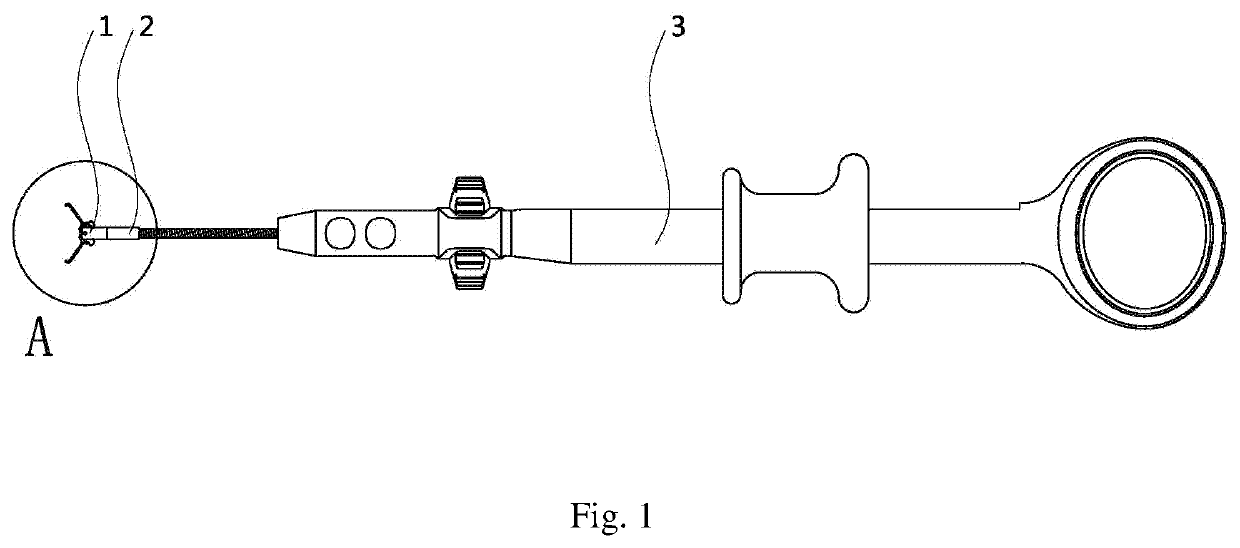

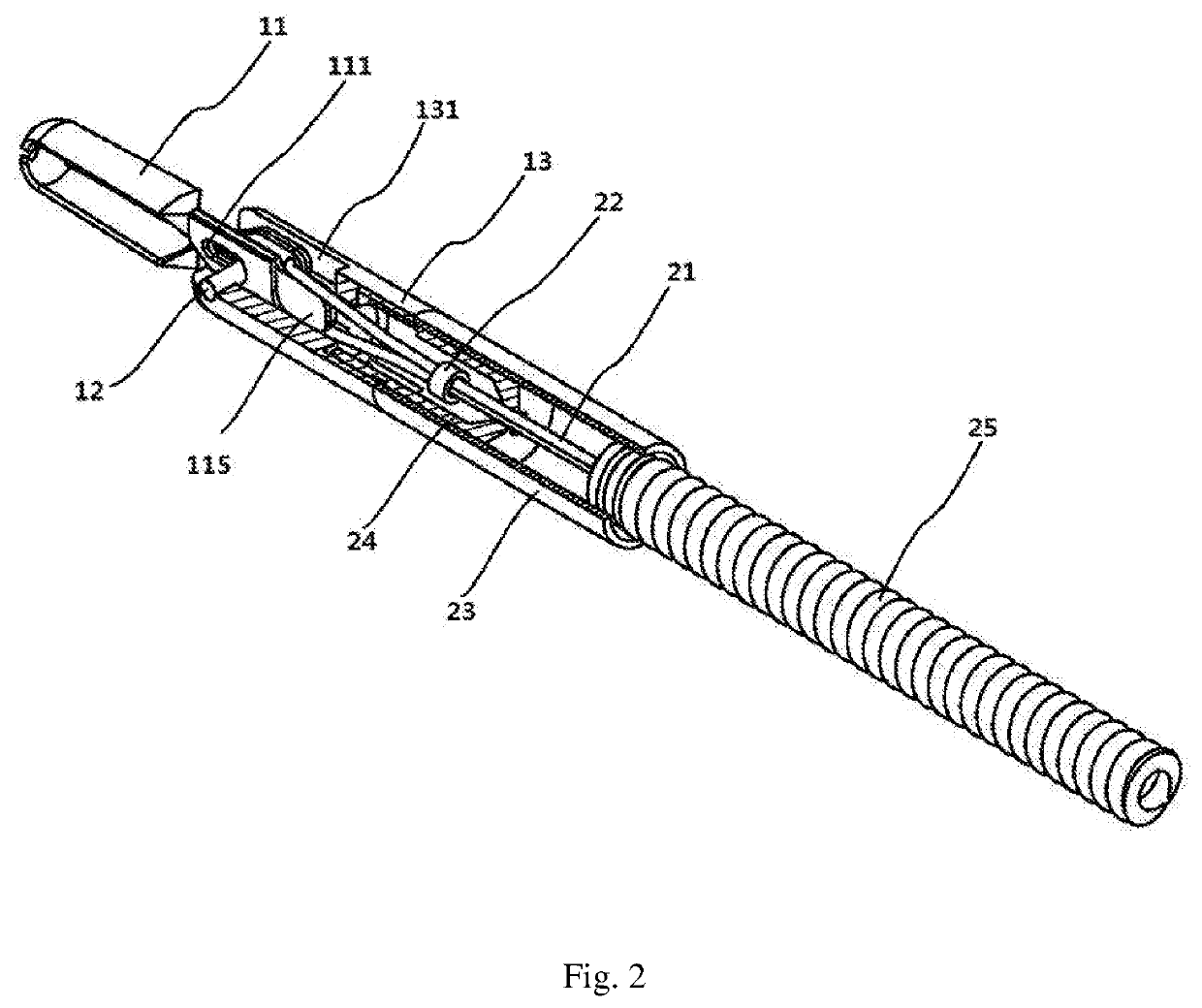

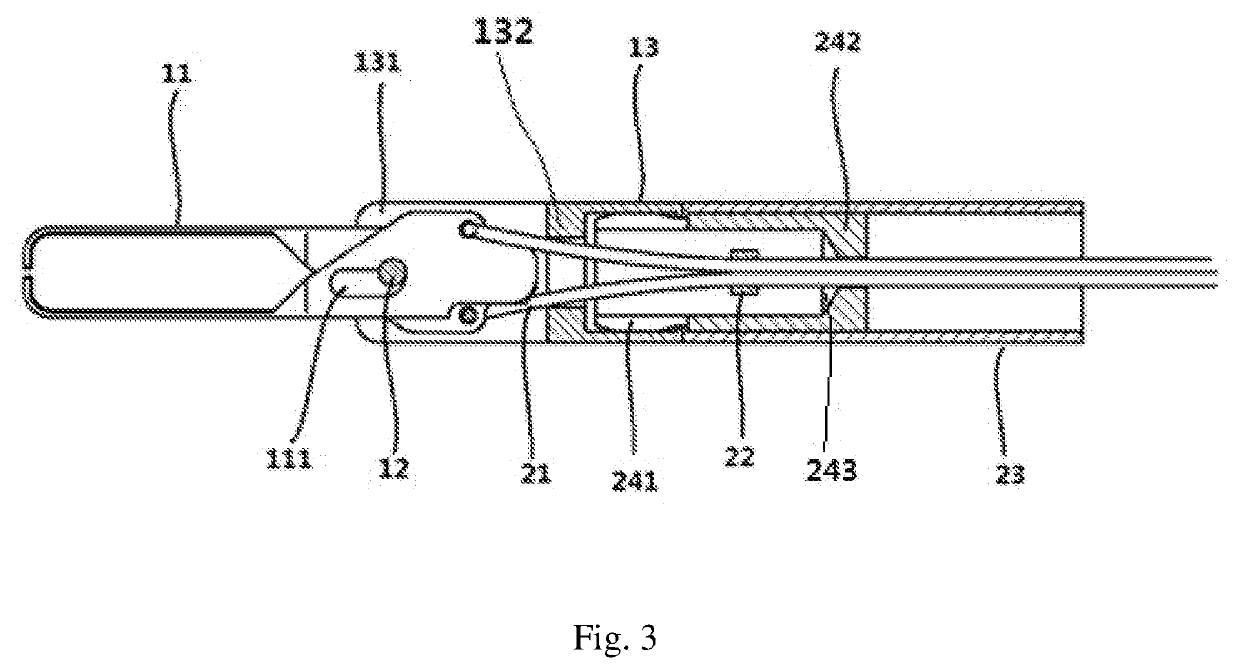

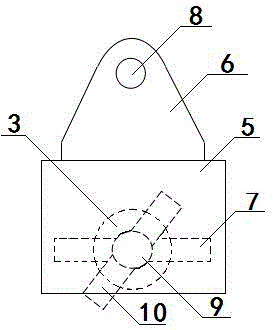

Hemostatic Clip Device

ActiveUS20190336130A1Simple structurePulling smoothlySurgical forcepsWound clampsBiomedical engineeringClip device

The present invention relates to a medical instrument, and particularly relates to a hemostatic clip device. The device includes a clamping component and a holder component. The head portion of the sleeve is provided with open slots for clamping arms to move. The tail ends of the outer side edges of clamping arms each is provided with a recess. A hole, corresponding to the position of the recess of one clamping arm, is formed in the other one. The sleeve is connected with the sleeve holder through inner core. The head end of the double-wire supporting arm is connected with the holes, and the other end is connected with wire rope and passes through the sleeve, the inner core, the sleeve holder and a bourdon tube so as to be connected with an operation handle. The device has the advantages of simple structure, firm clamping, convenient use and the like.

Owner:ALTON SHANGHAI MEDICAL INSTR

Discharging processing electrode clamp

The present invention discloses one kind of electrode fixture for electric discharge machining. The electrode fixture includes one pedestal with one top open slot, one raised side clamping part, one longitudinal locating slot, one V-shaped notch and one oil nozzle; one horizontal screw inside the open slot of the pedestal; and one sliding block screwed to the screw capable of reciprocating relatively to the pedestal with the rotation of the screw. It may hold one cylindrical electrode in the V-shaped notch or one long sheeted electrode in the locating slot, and possesses wide application range and stable holding and locating effect.

Owner:卓建材

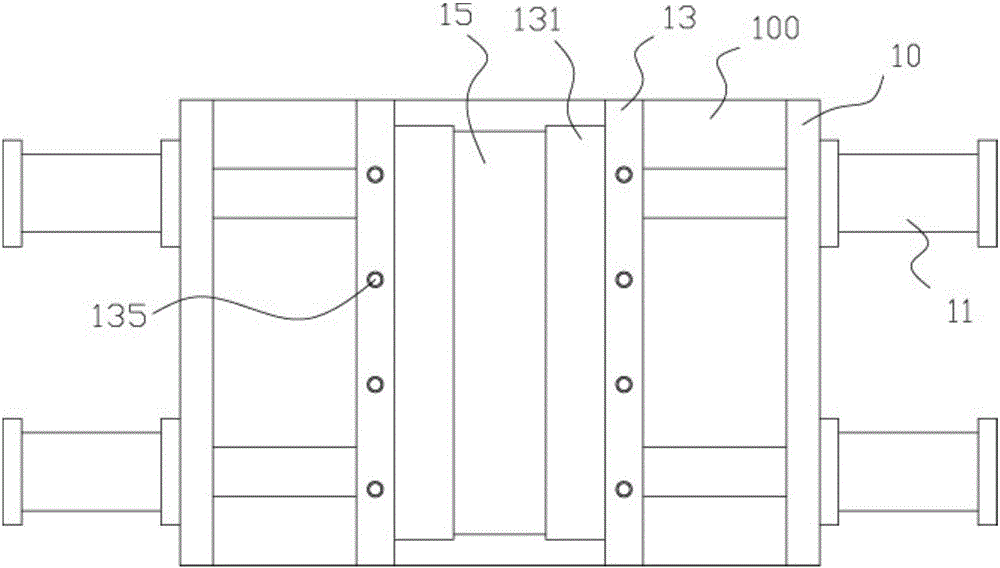

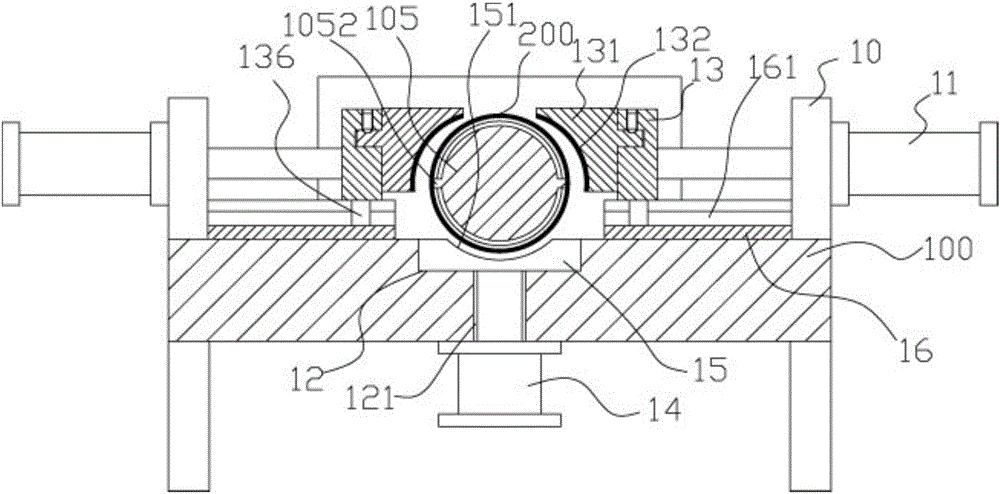

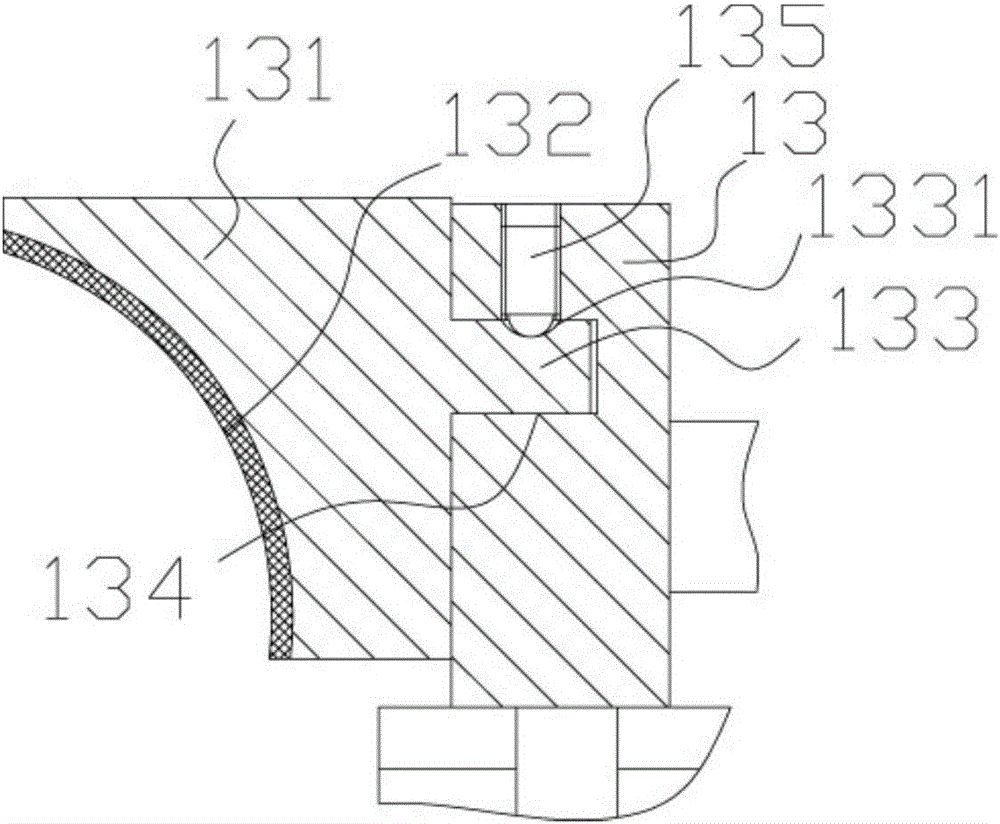

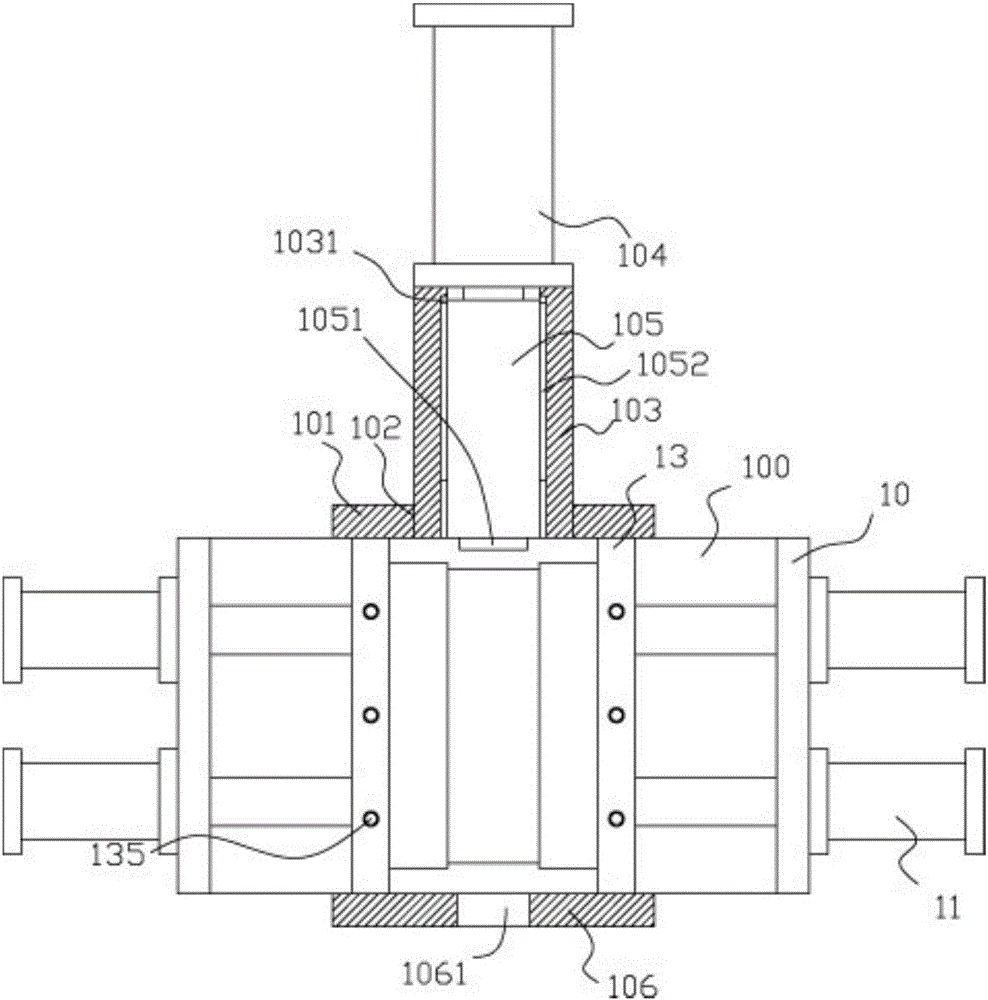

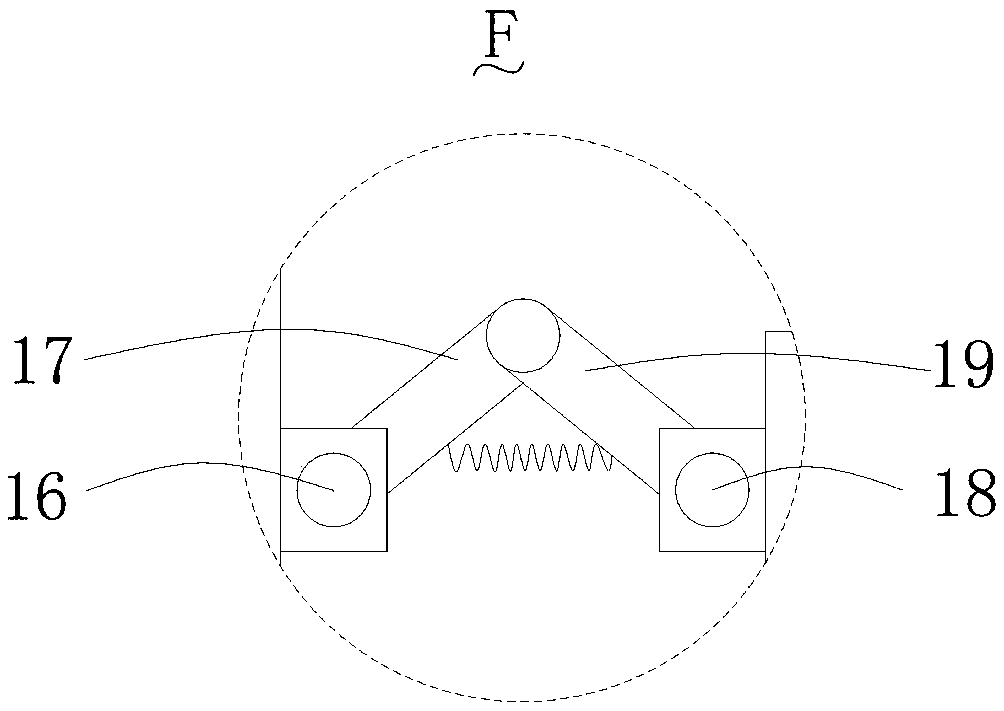

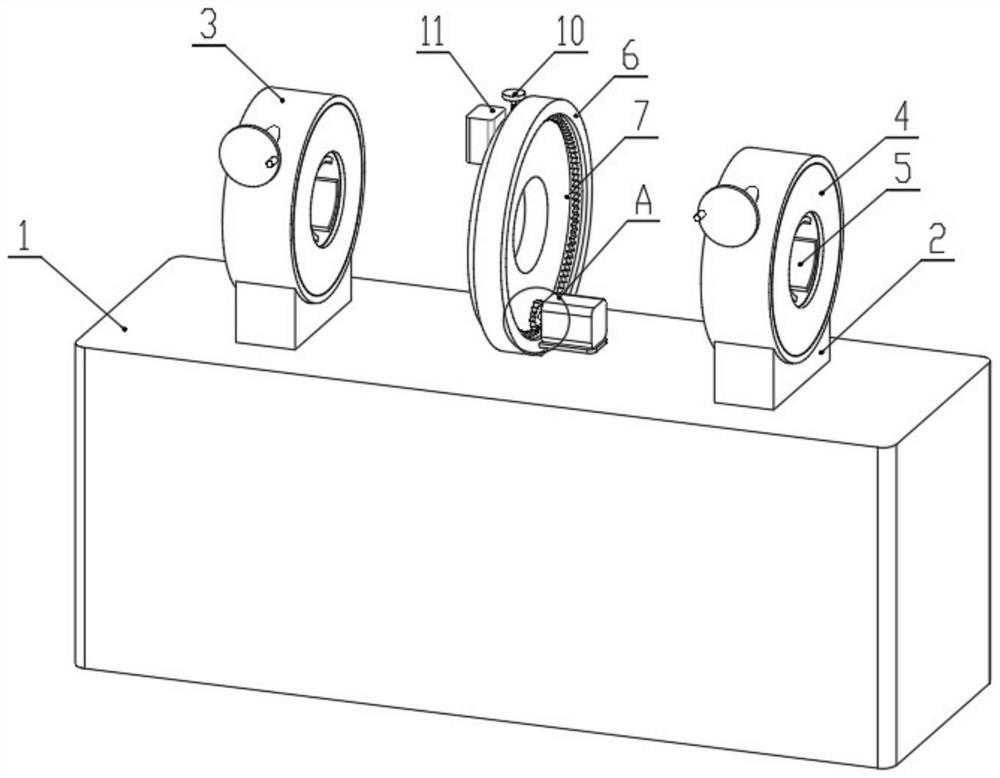

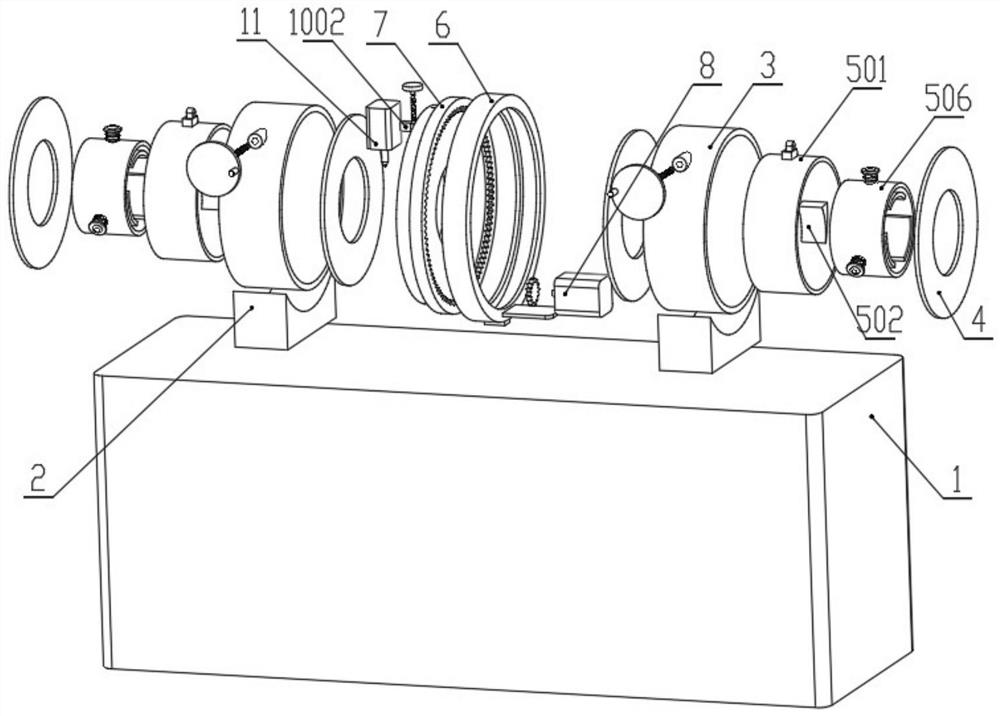

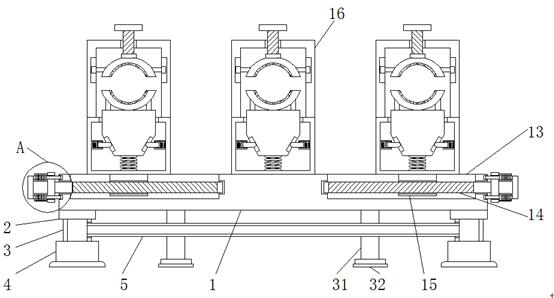

Automatic welding device and method for pipeline butt-joint machining

InactiveCN114029693AGuaranteed accuracy and stabilityQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesSteel tubeManufacturing engineering

The invention discloses an automatic welding device and method for pipeline butt-joint machining. The automatic welding device comprises a workbench, fixing seats, clamping frame bodies, side cover plates and clamping adjusting mechanisms, wherein the fixing seats are connected to the left side and the right side of the upper end face of the workbench; the clamping frame body is fixedly connected to the position of the upper side of the fixing seat; the side cover plates are connected to the left side and the right side of the clamping frame body; and the clamping adjusting mechanism is arranged in the clamping frame body. According to the automatic welding device for pipeline butt-joint machining, steel pipes can be conveniently, rapidly and stably clamped and fixed, so that the butt-joint precision and stability of the steel pipes can be effectively guaranteed, the welding quality of the steel pipes is improved, the steel pipes can be conveniently, automatically and uniformly welded, the welding machining efficiency of the steel pipes is improved, the steel pipes with different diameters can be conveniently welded through adjustment of a distance adjusting mechanism, and the applicability of the welding device is improved.

Owner:NANJING NIEBO INTERNET OF THINGS TECH CO LTD

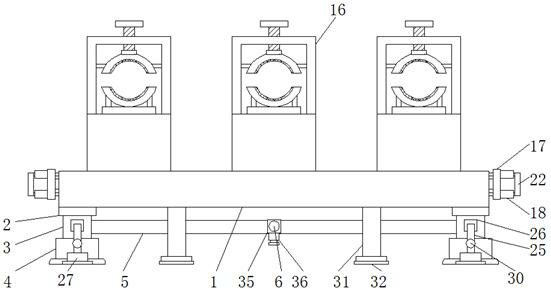

Automobile cooling liquid pipeline arranging device

ActiveCN111649175AEasy to fixEasy to check and maintainPipe supportsSuction cupsStructural engineeringCooling fluid

The invention relates to the technical field of automobile accessories, in particular to an automobile cooling liquid pipeline arranging device. The automobile cooling liquid pipeline arranging devicecomprises a bottom plate, wherein base plates are fixedly mounted on the left and right sides of the bottom end of the bottom plate; and supporting round pipes are vertically and fixedly mounted in the middle parts of the bottom ends of the base plates. The automobile cooling liquid pipeline arranging device is easy to operate and can arrange cooling liquid pipes orderly to examine and maintain the cooling liquid pipes conveniently. The arranging separation distances between adjacent cooling liquid pipes can be adjusted according to an actual mounting condition, so that it is convenient to better mount and arrange the cooling liquid pipes and it can be suitable for pipe expansion of the cooling liquid pipes due to temperature rise. The cooling liquid pipes can be clamped and fixed stablywhile the cooling liquid pipes are prevented from being damaged. The automobile cooling liquid pipeline arranging device can be suitable for mounting and fixing the cooling liquid pipes of different diameters, and is simple in fixing mode with an automobile body, easy to operate, convenient to mount and detach and time-saving and labor-saving. The automobile cooling liquid pipeline arranging device is more firmly connected to the automobile body by means of multiple fixation, so that the automobile cooling liquid pipeline arranging device is worth being popularized and used.

Owner:荆州市天宇汽车配件有限公司

Easy-to-adjust punching device for lamp shades of automobile brake lamps

InactiveCN108656211AHigh flexibilityImprove assembly performanceMetal working apparatusDrill bitEngineering

The invention discloses an easy-to-adjust punching device for lamp shades of automobile brake lamps. The easy-to-adjust punching device comprises a fixed base. An installation groove is formed in theouter wall of the top of the fixed base. A power box is welded on the inner wall of the installation groove. Support columns are welded on the outer walls on both sides of the top of the fixed base. Sliding guide rails are welded on the outer walls on the opposite sides of the two support columns. Sliding seats are slidably connected on the outer walls on one sides of the sliding guide rails, lifting plates are welded on the outer walls on the opposite sides of the two sliding seats, and first installation holes are formed in the outer walls on the tops of the lifting plates. According to theeasy-to-adjust punching device, a drill bit has higher flexibility in position, the processing requirements of the automobile brake lamps with different specifications can be met, the automobile brakelamps can be stably clamped and fixed, meanwhile the fixing angles of the automobile brake lamps can be adjusted, and the assembly performance of the automobile brake lamps is improved.

Owner:HUBEI HAILIAN TECH CONSULTATION CO LTD

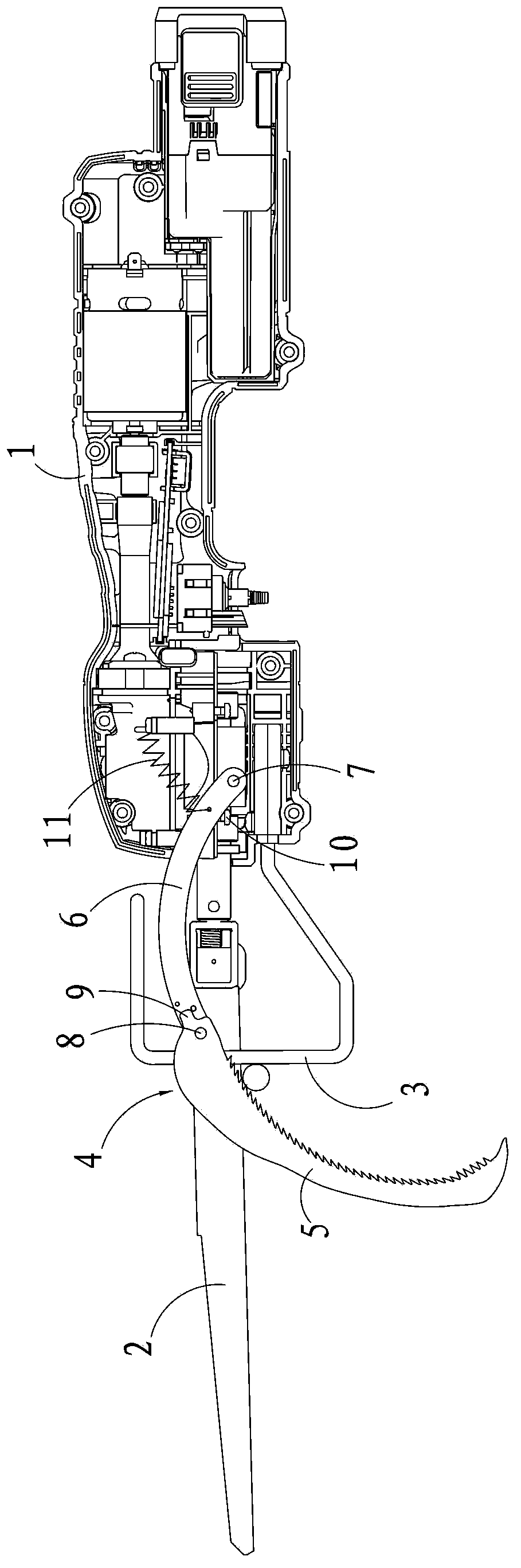

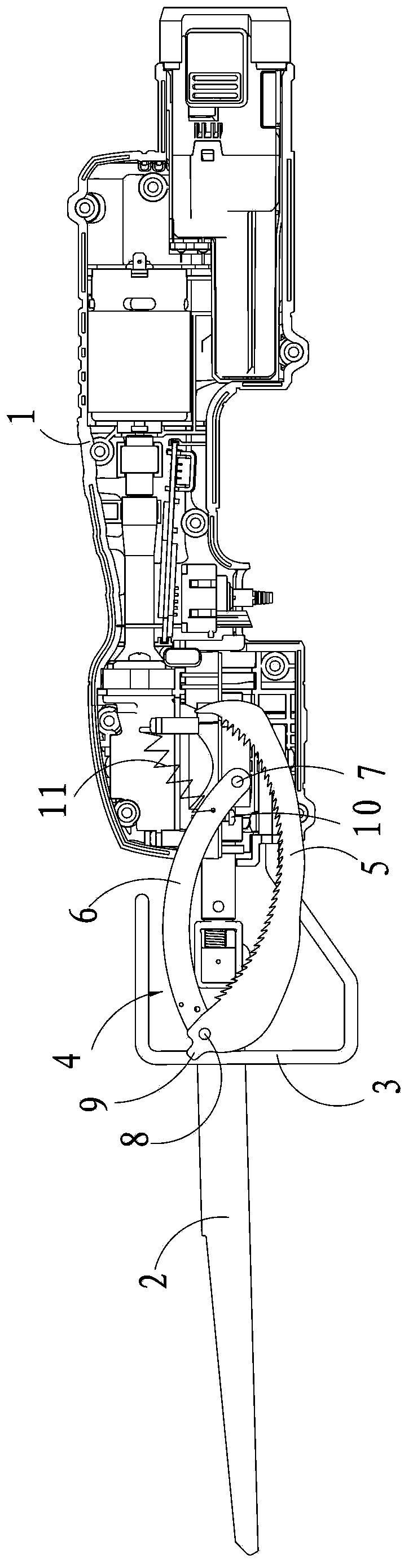

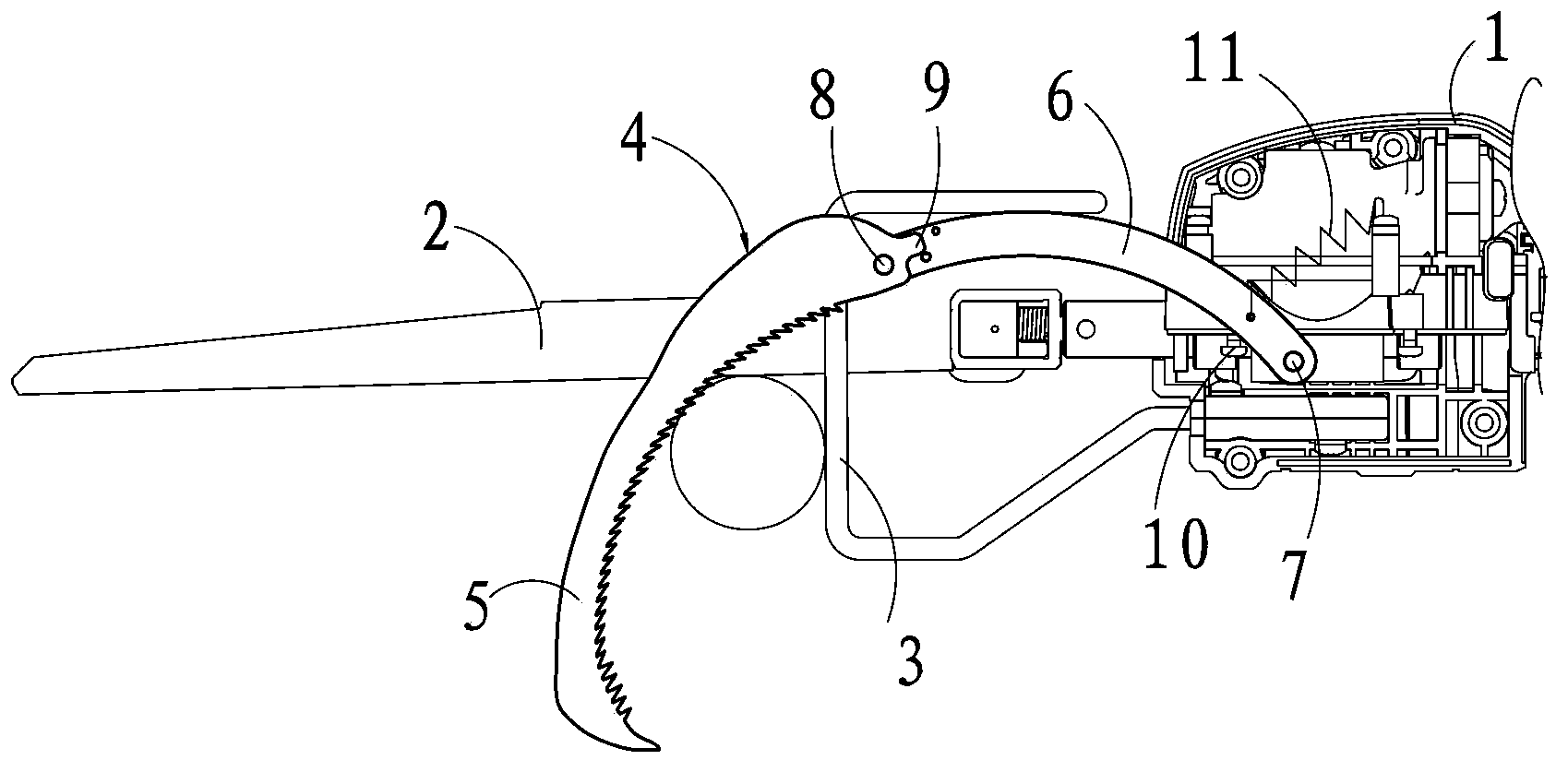

Electric reciprocating saw

ActiveCN103895068AFirmly clampedEasy to cutMetal sawing devicesCross-cut reciprocating sawsStructural engineeringMechanical engineering

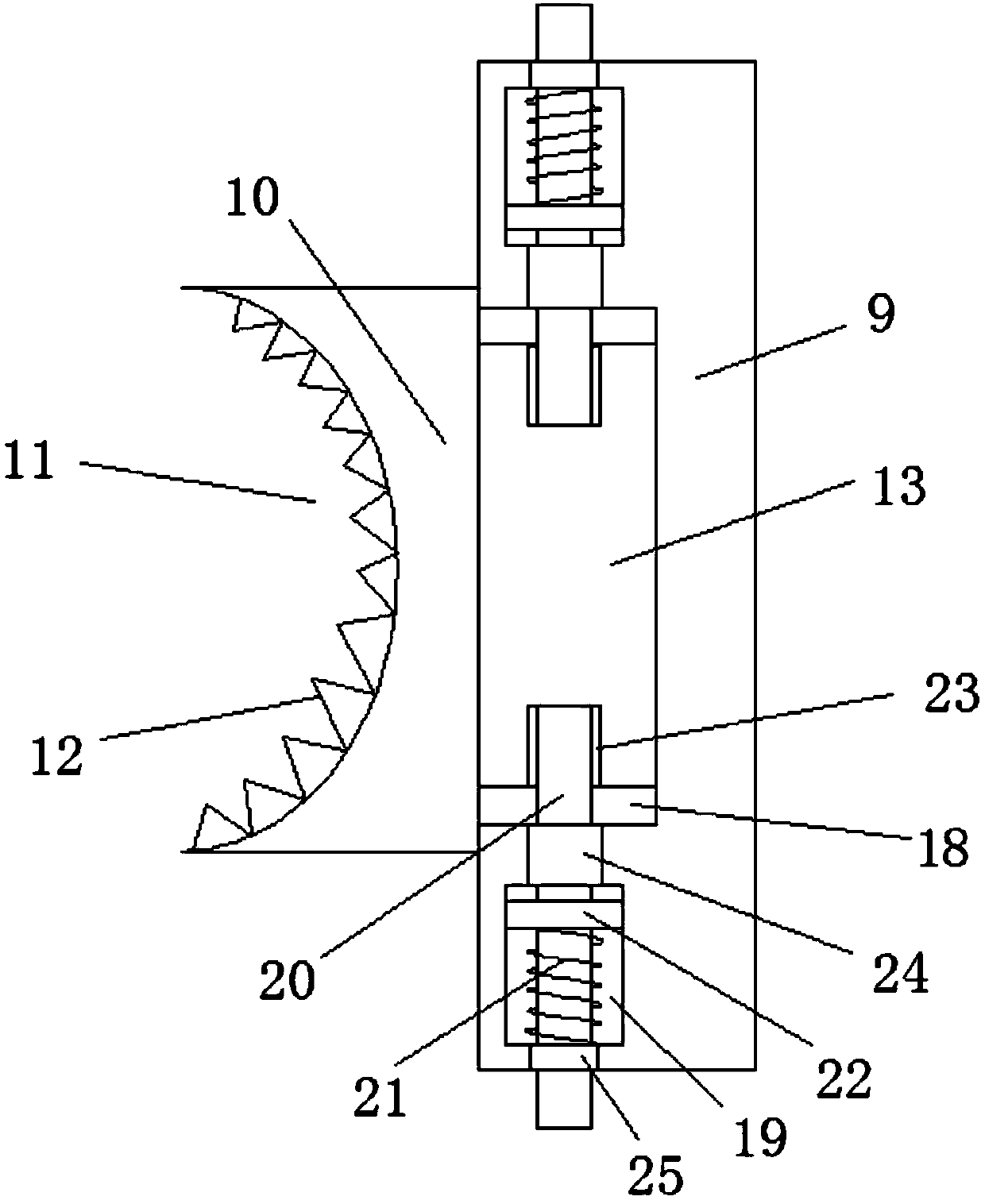

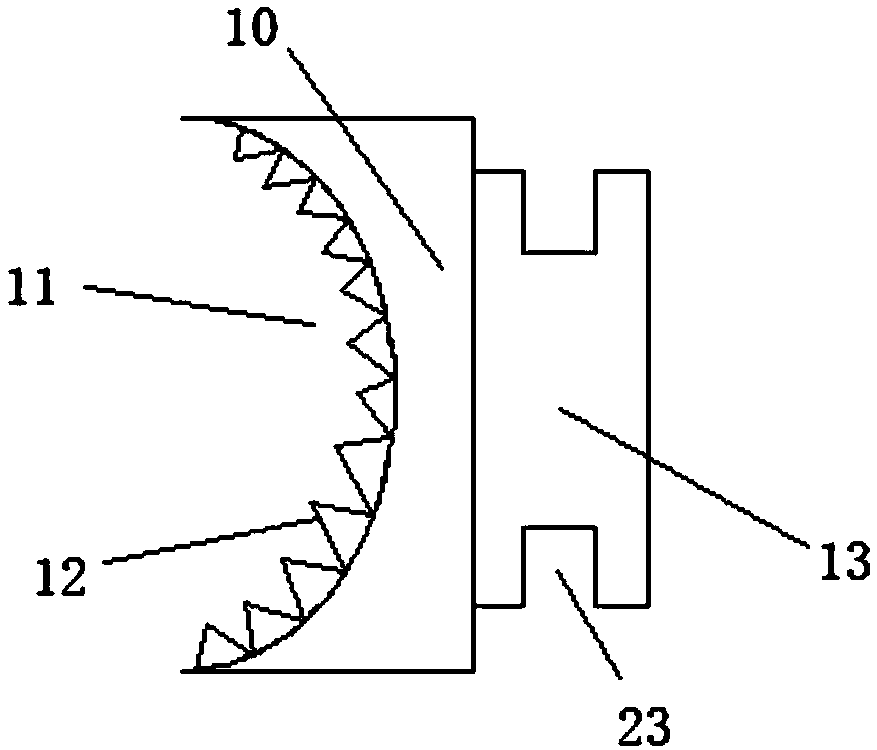

An electric reciprocating saw comprises a base frame, a power driving mechanism and a saw blade, wherein the power driving mechanism is arranged on the base frame, and the saw blade is driven by the power driving mechanism. A stopper is arranged in the front of the base frame, the saw blade linearly extends forwards from the stopper, a positioning clamp is arranged on the base frame, the positioning clamp is connected with the base frame by rotating around a first rotating shaft, the positioning clamp comprises a positioning clamp body, one side edge, used for abutting against wood to be cut, of the positioning clamp body is in an arc concaved inwardly, and the arc edge is provided with a plurality of teeth used for abutting against the wood to be cut. When the positioning clamp is in use, a clamping space capable of containing the wood to be cut can be formed between the positioning clamp body and the stopper; when cut by the electric reciprocating saw, the wood can be clamped between the stopper and the positioning clamp body, and friction is generated between the teeth on the positioning clamp and the wood, so that the wood is stably clamped between the stopper and the positioning clamp body, cutting is convenient to finish, and the structure is simple.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

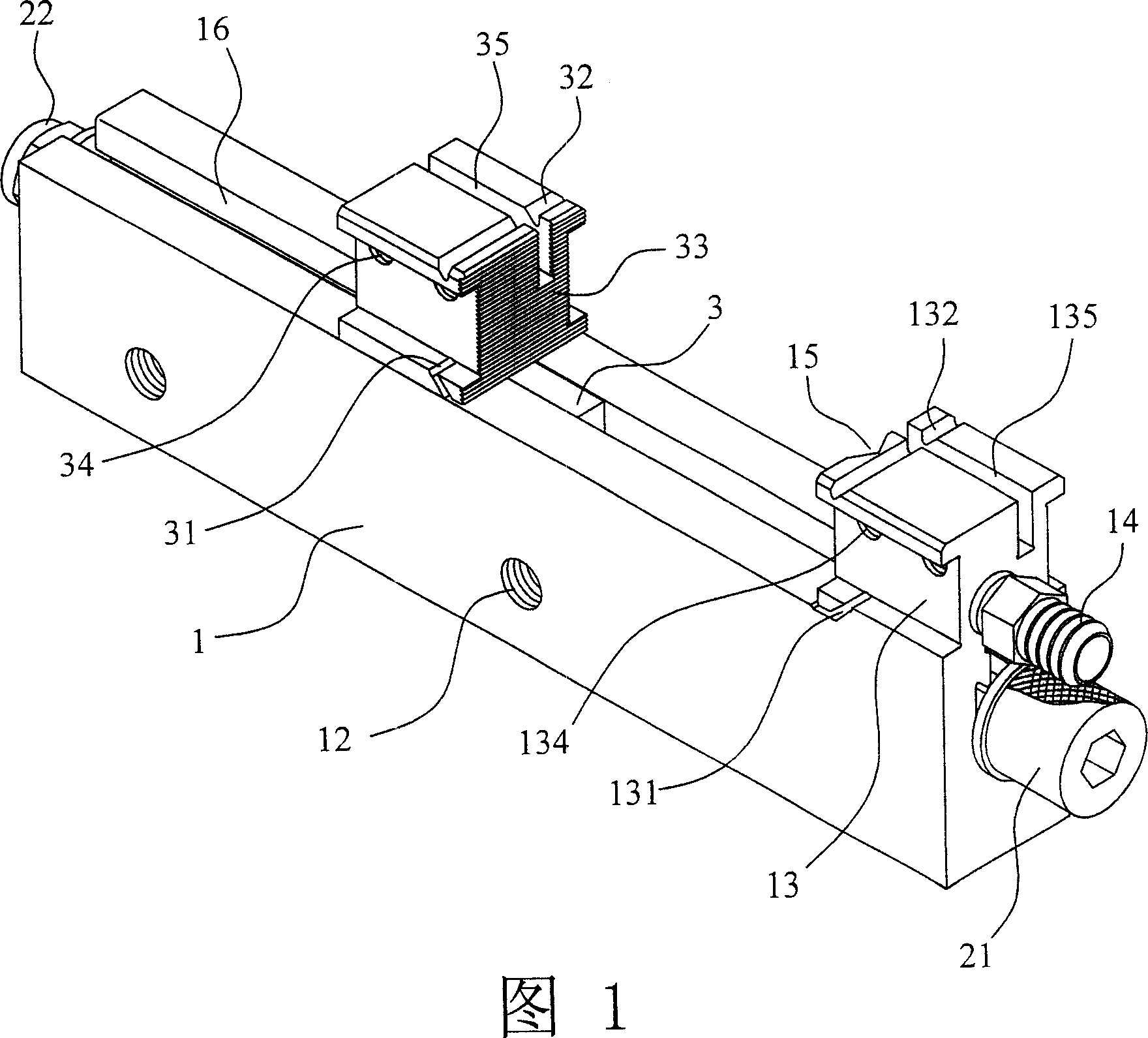

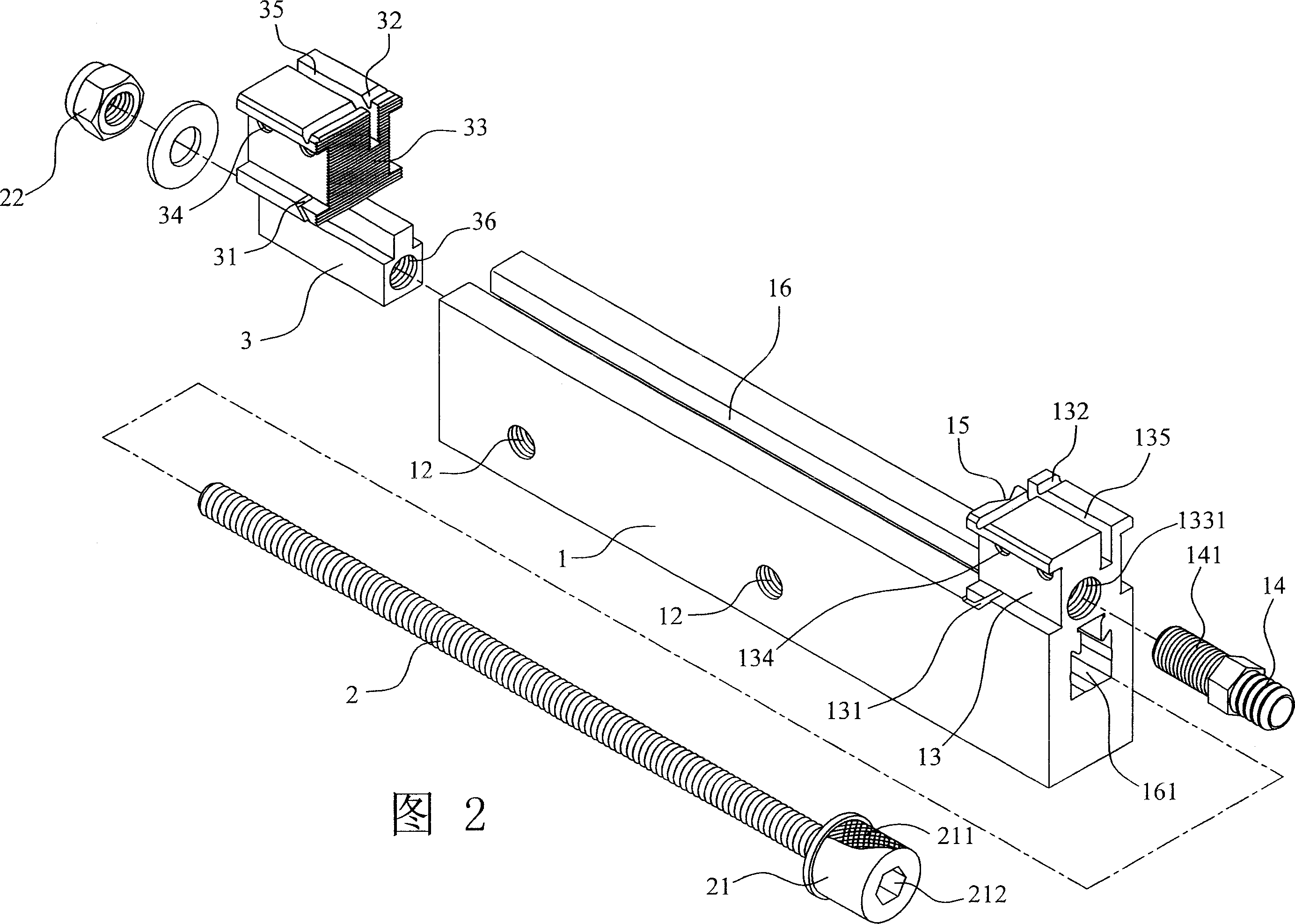

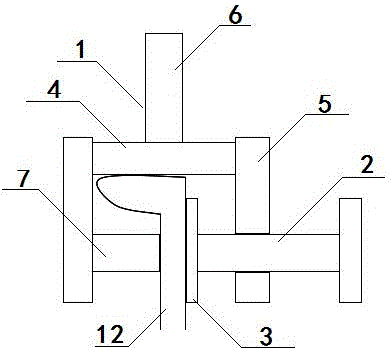

Flat-bulb steel clamping tool for non-welding installation of ribbed plate and installation method of tool

InactiveCN106625347AEffective clampingAvoid re-cutting processWork holdersMetal-working hand toolsEngineeringMechanical engineering

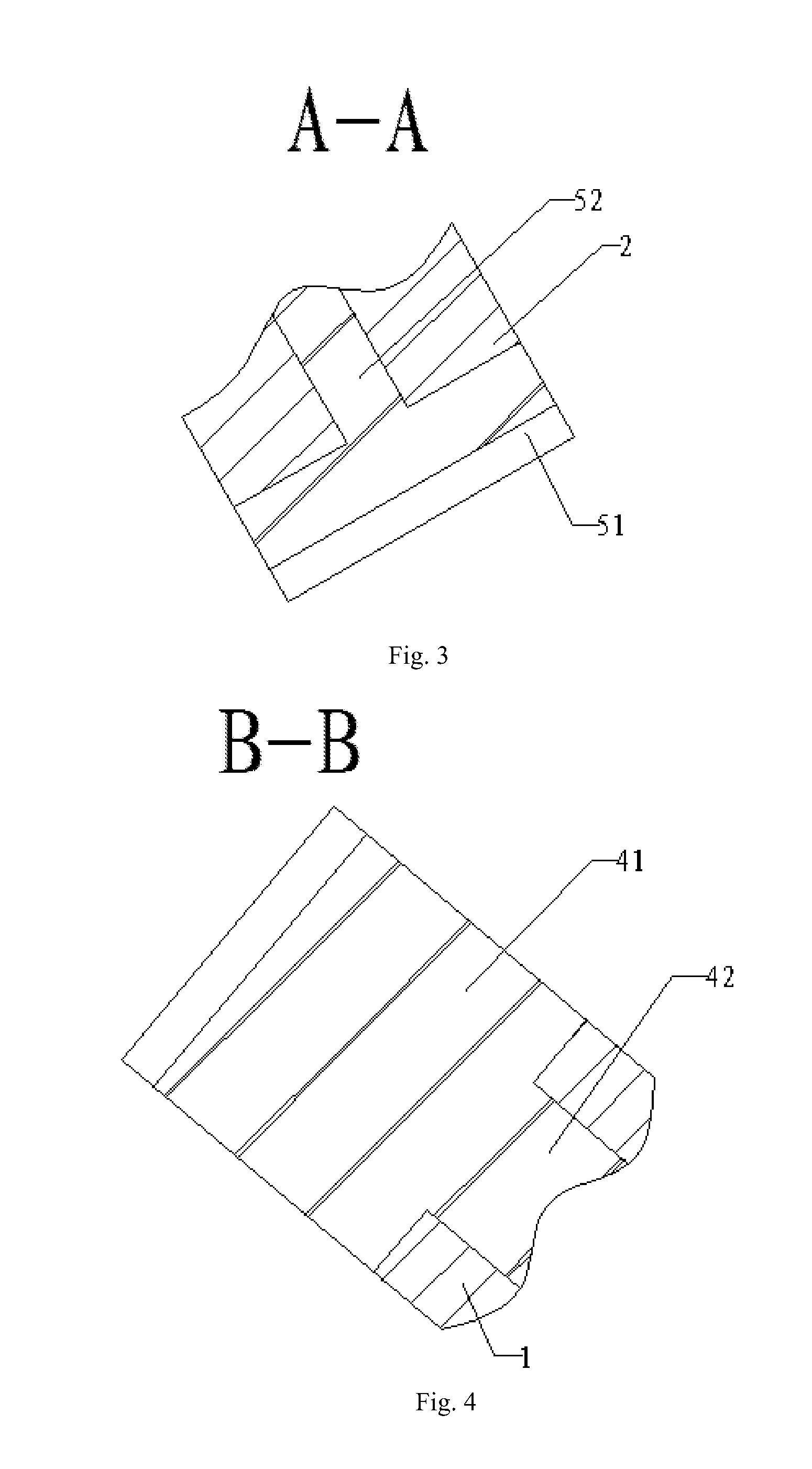

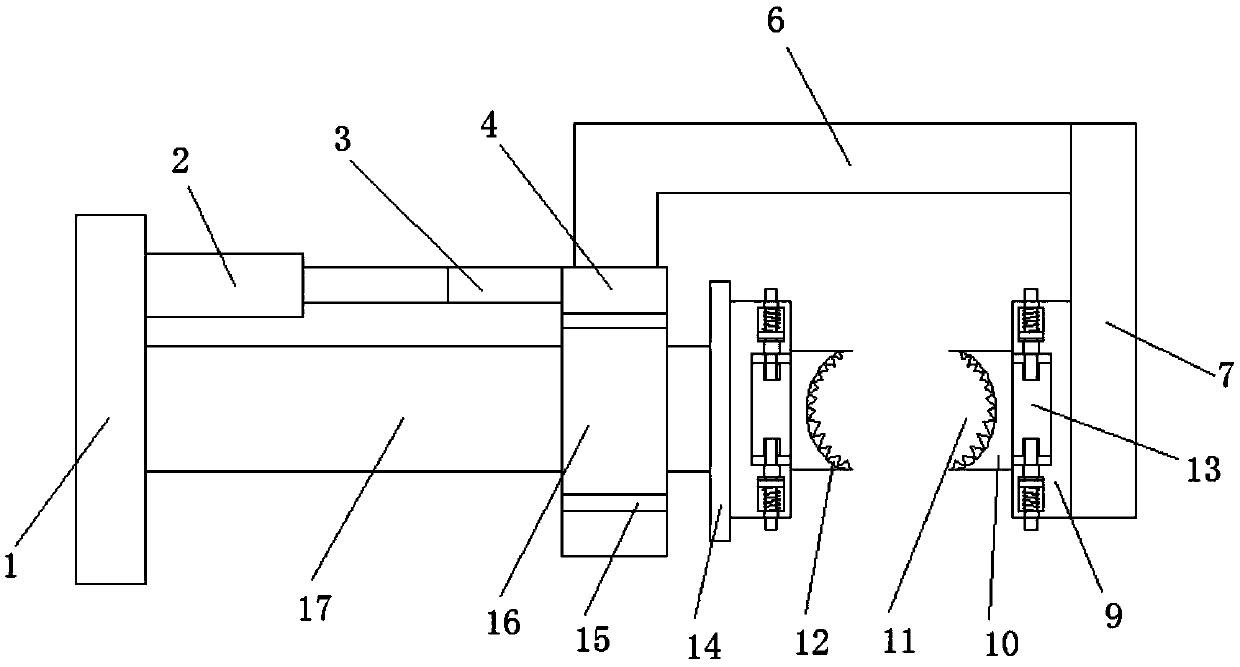

The invention relates to a flat-bulb steel clamping tool for non-welding installation of a ribbed plate. The tool comprises a body (1), a fixing rod (2) and a base plate (3), the body (1) comprises a top plate (4), end plates (5), a connection plate (6) and a fixed convex plate element (7), the connection plate (6) is fixed to the top plate (4) and provided with a connection hole (8), the end plates (5) are fixed to the two ends of the top plate (4) respectively, the fixed convex plate element (7) is arranged on the inner side of one end plate (5), a bolt hole is formed in the middle of the other end plate (5), the fixing rod (2) is connected with the body (1) through the bolt hole, the fixing rod (2) comprises a screw (9) and a handle (10), and the handle (10) and the base plate (3) are fixed to the two ends of the screw (9) respectively. The invention further relates to an installation method of the flat-bulb steel clamping tool for non-welding installation of the ribbed plate. The tool has the advantages of being convenient to use, improving production efficiency and saving cost.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

Clamping mechanism for anti-collision beam punching of small-batch vehicles

InactiveCN107953134AFirmly clampedPrecise clamping and fixingPositioning apparatusMetal-working holdersPunchingEngineering

The invention discloses a small-batch clamping mechanism for punching anti-collision beams of automobiles. The top surface of the elongated installation block is fixed with an arc-shaped elastic block, the side wall of the elongated installation block is fixed with a side elastic block, and the bottom surface of the top plate of the anti-collision beam to be bent is pressed against the top of the arc-shaped elastic block On the surface, the arc-shaped elastic block is inserted into the lower cavity of the anti-collision beam to be bent, and the side elastic block is pressed against the inner side wall of the lower cavity of the anti-collision beam to be bent; the top plate of the frame Support frames are fixed on the top surfaces of both sides, and a compression cylinder is fixed on the top surface of the transverse plate of the support frame. The push rod of the compression cylinder passes through the transverse plate of the support frame and is fixed with a pressing block. The bottom surface of the pressing block has a slot; It is clamped and fixed firmly and accurately, which is convenient for subsequent manual drilling or mechanical automatic drilling, which is very convenient.

Owner:FOSHAN DAPUGUANG ELECTROMECHANICAL TECH CO LTD

Gear production clamping part and drilling equipment thereof

The invention discloses a gear production clamping part. The gear production clamping part comprises a machining table, a drilling mechanism, a rotating column and a driving motor; the drilling mechanism is installed on one side of the machining table and comprises an electric drill mechanism, and the electric drill mechanism is arranged over the machining table; the rotating column is rotationally installed on the surface of the machining table, a driving motor is arranged on the inner side of the machining table, and the driving motor is in transmission connection with the rotating column; the clamping mechanism for center positioning is fixedly installed at the position, located on the surface of the machining table, of the top of the rotating column; and the electric drill mechanism isright opposite to the clamping mechanism in position. The gear production clamping part adopts the symmetrical splayed rotary clamping mechanism, and high-precision synchronous moving feeding of bidirectional threads is cooperated, so that stable clamping and fixing of the gear are achieved; high-quality drilling machining can be conducted on the gear in cooperation with the drilling mechanism; and the splayed clamping mode effectively prevents the gear from being extruded and damaged.

Owner:嘉兴市光炬五金科技有限公司

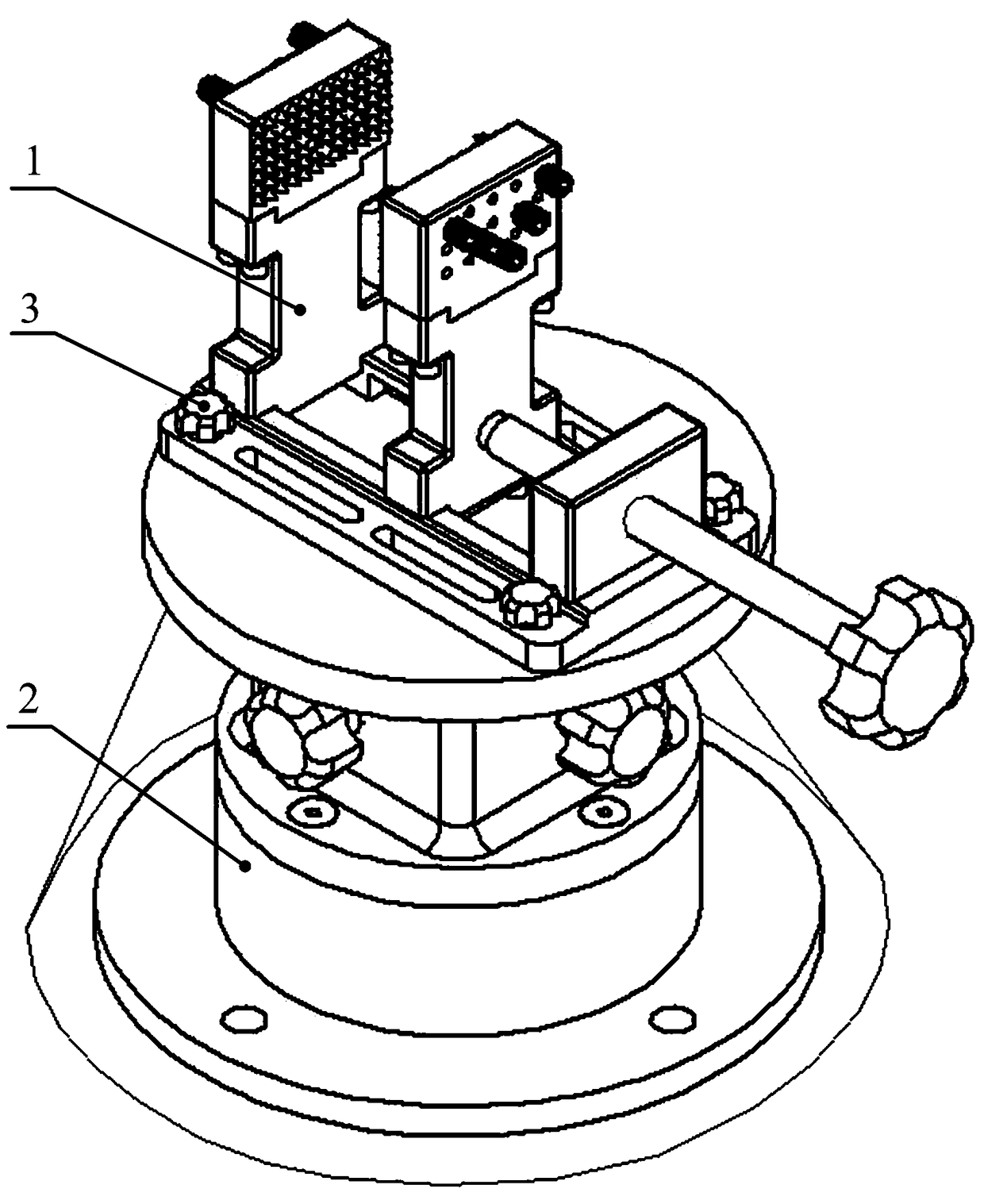

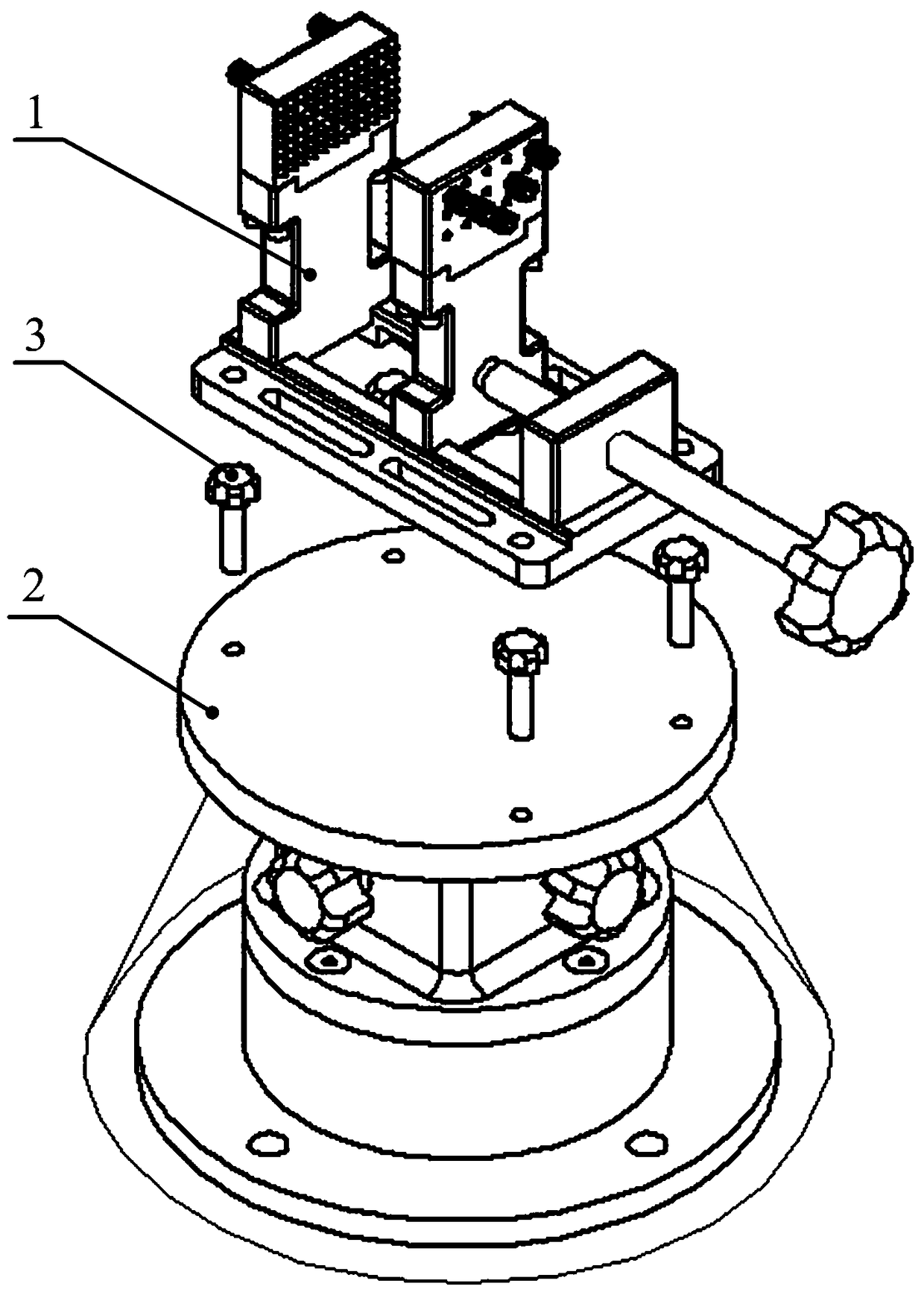

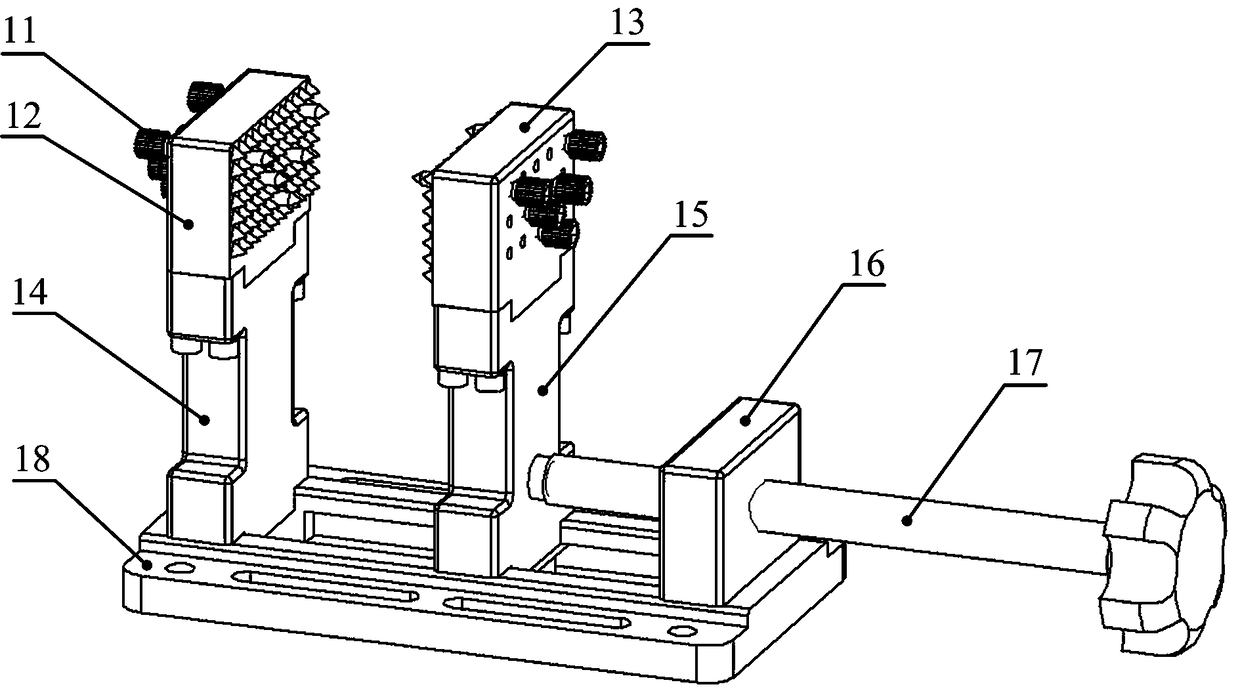

Bone clamping device

PendingCN108524015AAchieve clampingAchieve fixationInstruments for stereotaxic surgeryBone clampOrthopedic department

The invention discloses a bone clamping device, and belongs to the field of medical instruments. The device comprises a clamping portion and a rotary working table; the clamping portion is fixed by the rotary working table through a torx connecting bolt; and the bone clamping device can be integrally or separately used according to actual conditions, and is suitable for various application scenarios. The shortcoming that a special bone clamping instrument does not exist in various replacements of traditional allograft bones can be overcome, problems that a traditional auxiliary tool cannot maintain clamping stability and cannot bear spraying cooling of normal saline, the types of clamped bones are limited, a large clamping range cannot be provided, a sufficient operation space cannot be provided, flexible rotary positioning cannot be carried out, and the operation is complicated are solved, surgical bones can be stably clamped, the bone clamping device is suitable for most of types ofbones, a sufficient operation space is provided for robots or doctors in an orthopedics department, the bone clamping device is simple to operate and controllable in power, precision of operation to bones is improved, and the surgery efficiency is improved.

Owner:苏州尚贤医疗机器人技术股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com