Firefighting main unit shell punching device

A technology of punching device and fire-fighting main engine, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problem of unsatisfactory fixation troubles and unsatisfactory effects, and achieve the effect of high automation, firm clamping and fixing, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

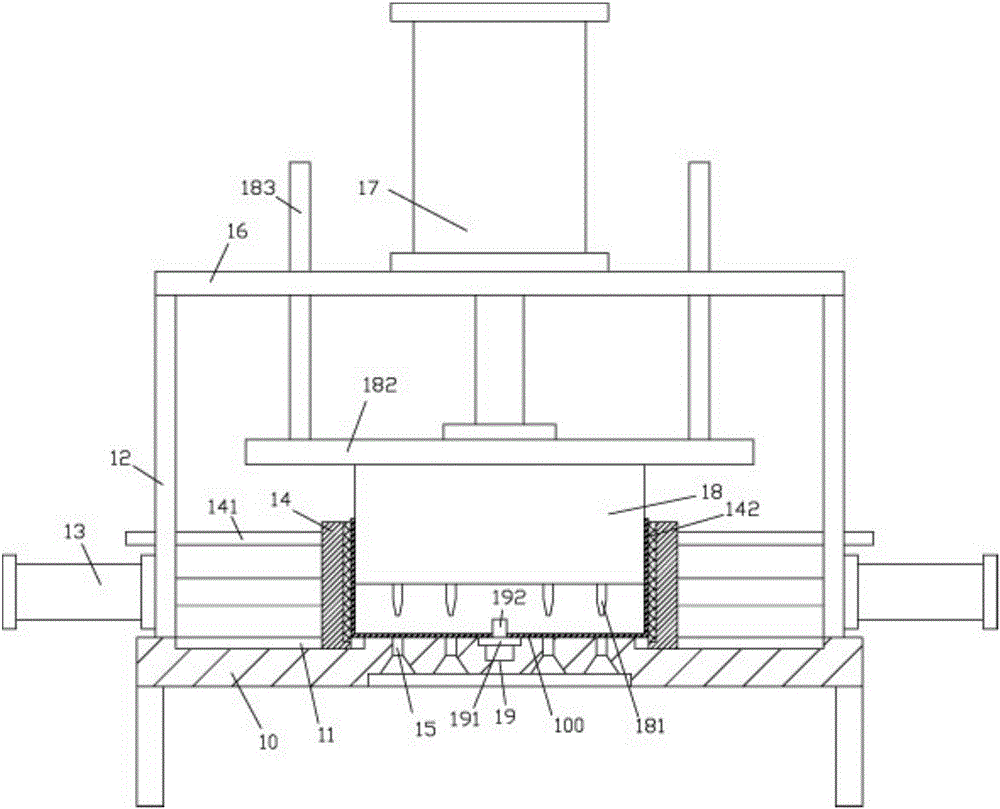

[0018] Examples, see e.g. figure 1 As shown, a fire-fighting host shell punching device includes a frame 10, the two sides of the middle part of the top plate of the frame 10 have sliding grooves 11, the left and right ends of the top plate of the frame 10 are fixed with connecting plates 12, connected A clamping oil cylinder 13 is fixed on the outer side wall of the plate 12, and the push rod of the clamping oil cylinder 13 passes through the connecting plate 12 and is fixed with a clamping block 14. The bottom of the clamping block 14 is inserted in the sliding groove 11, to be processed The casing 100 is placed in the middle of the top plate of the frame 10, the casing 100 to be processed is clamped between two clamping blocks 14, and the top plate of the frame 10 below the bottom plate of the casing 100 to be processed has a plurality of vertical Straight feeding channel 15, the upper support plate 16 is fixed on the top of the two connecting plates 12, the middle part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com