Electric reciprocating saw

A reciprocating saw, electric technology, applied in the direction of motorized reciprocating cross-cutting saw, circular saw, sawing equipment, etc., can solve the problems of reduced cutting efficiency, large machine vibration, troublesome operation, etc., to achieve the effect of easy cutting and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

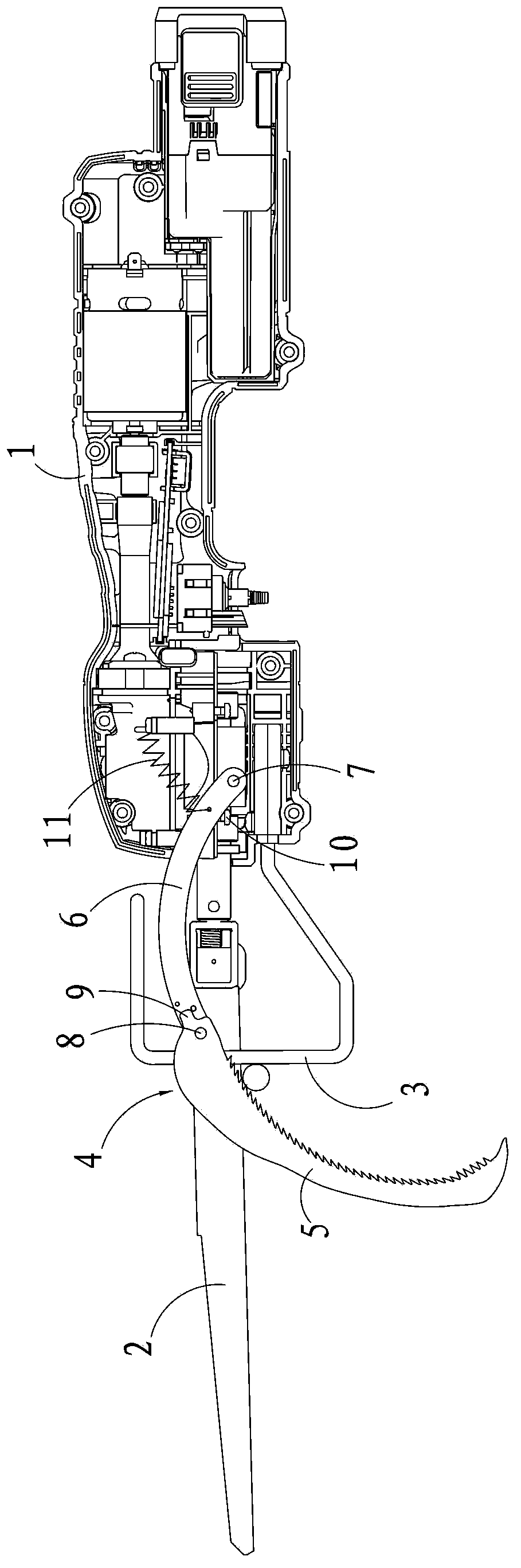

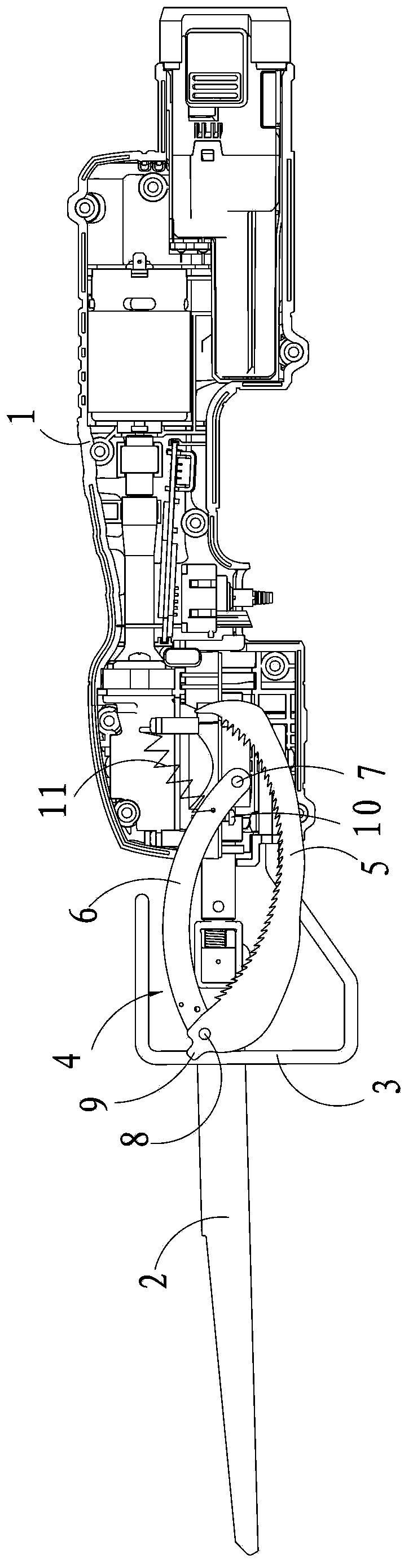

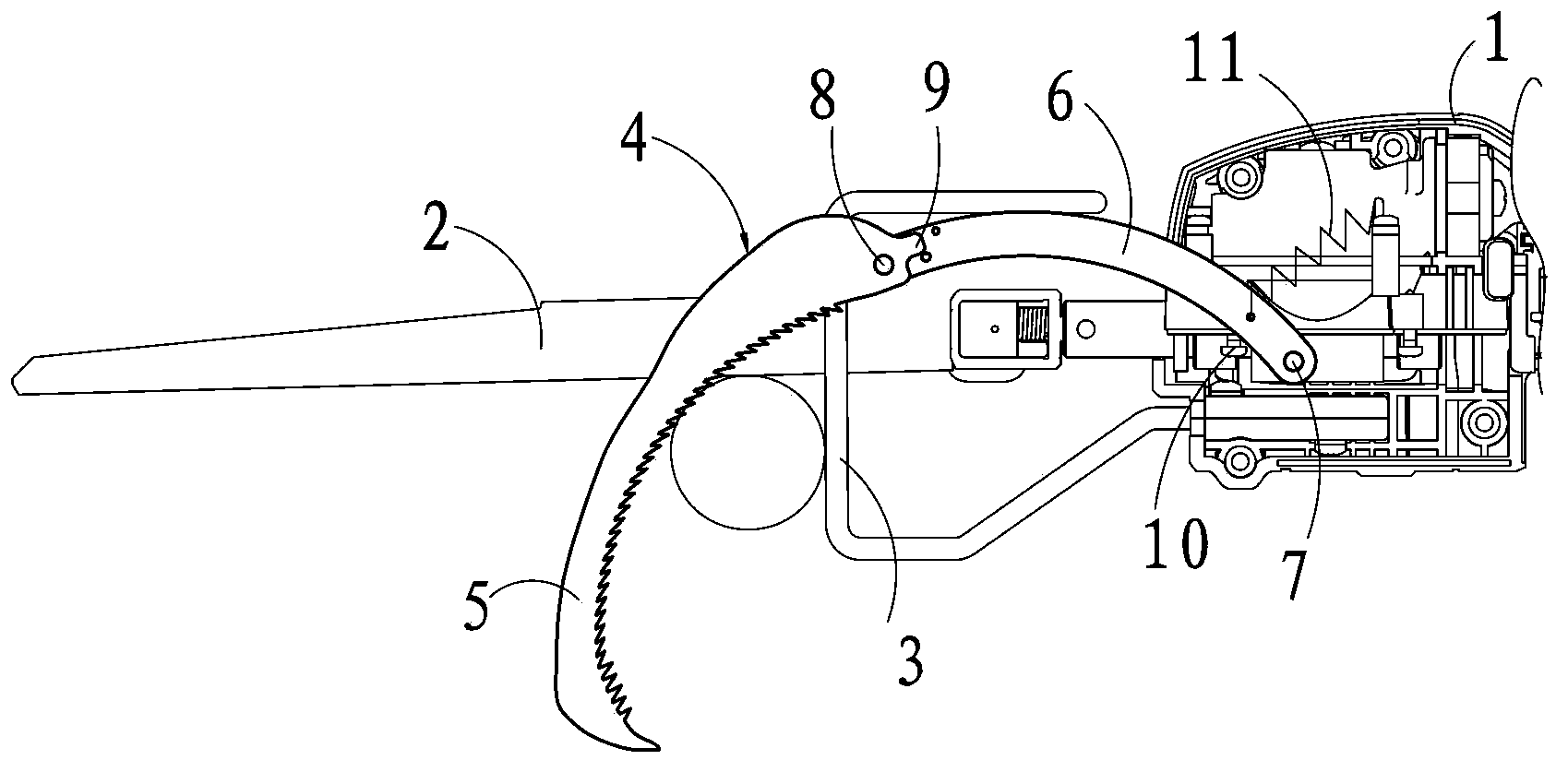

[0020] As shown in the drawings, an electric reciprocating saw includes a base frame 1, a power driving mechanism arranged on the base frame 1, and a saw blade 2 driven by the power driving mechanism. The power drive mechanism includes motors, controllers, etc.

[0021] The front part of the base frame 1 has a stopper 3, and the saw blade 2 extends forward in a linear form from the stopper 3. When in use, the saw blade 2 performs reciprocating cutting motions back and forth.

[0022] The base frame 1 is provided with a positioning clip 4, the positioning clip 4 is connected with the base frame 1 in a rotational manner around the first axis 7, the positioning clip 4 includes a positioning clip body 5, and the positioning clip body 5 is used to conflict with the wood to be cut. The side edge is an arc-shaped edge that is concave inward, and there are multiple teeth on the arc-shaped edge that are used to interfere with the wood to be cut. When the positioning clip 4 is used, a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com