Flat-bulb steel clamping tool for non-welding installation of ribbed plate and installation method of tool

A technology for clamping tools and spherical flat steel, which is applied in the direction of workpiece clamping devices, hand-held tools, manufacturing tools, etc., can solve the problems of less repeated use of the connecting plate, increase the working time, and affect the quality of parts, etc., to achieve clamping The effect of holding firmly, reducing operating time, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The flat bulb steel clamping tool and its installation method without welding installation ribs of the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments, in order to understand its structure type and use process more clearly, but The protection scope of the patent of the present invention cannot be limited by this.

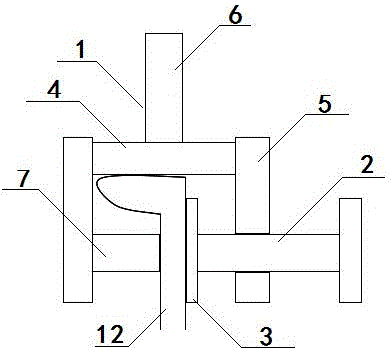

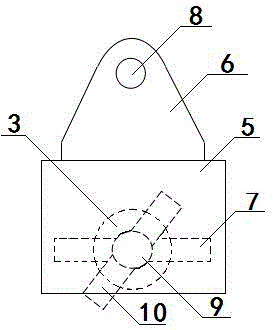

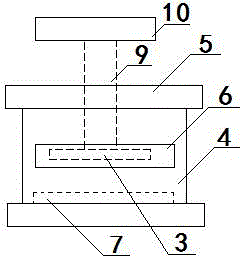

[0027] As shown in the figure, a bulb flat steel clamping tool without welding mounting ribs, the tool includes a body 1, a fixed rod 2 and a backing plate 3, the body 1 includes a top plate 4, an end plate 5, a connecting plate 6 and Fixed convex plate 7, the top plate 4 is a rectangular plate, the bottom of the connecting plate 6 is vertically welded and fixed on the middle part of the upper surface of the top plate 4, the connecting plate 6 is provided with a connecting hole 8, the connecting plate 6 It is an ear-shaped plate, and the connecting hole 8 is arranged on the upper end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com