Automatic installation equipment of sewage inspection well special for drainage pipeline system

A technology for automatic installation and drainage pipes, which is applied in the sewer system, waterway system, water supply device, etc., and can solve the problems of complicated operation, inability to provide fixed facilities, and low labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

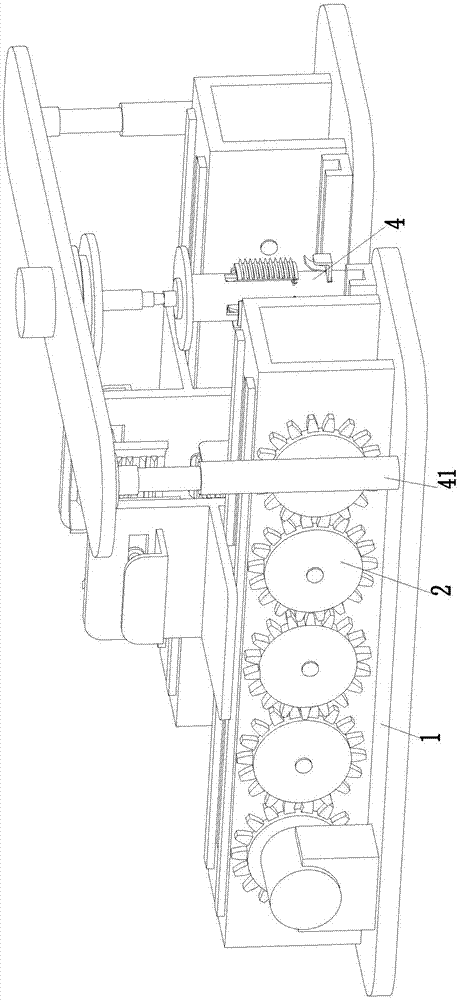

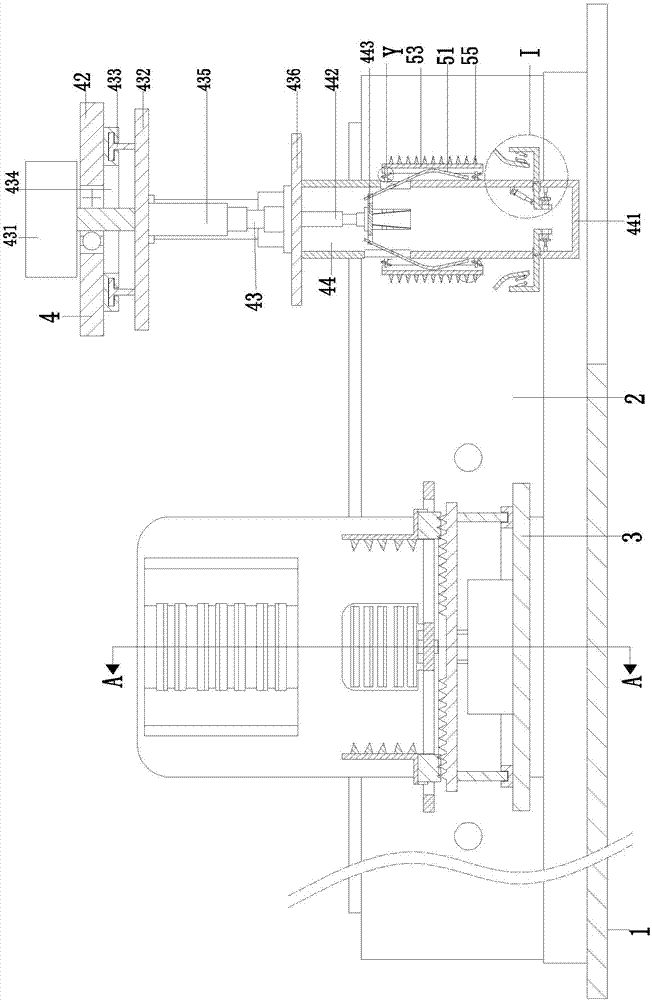

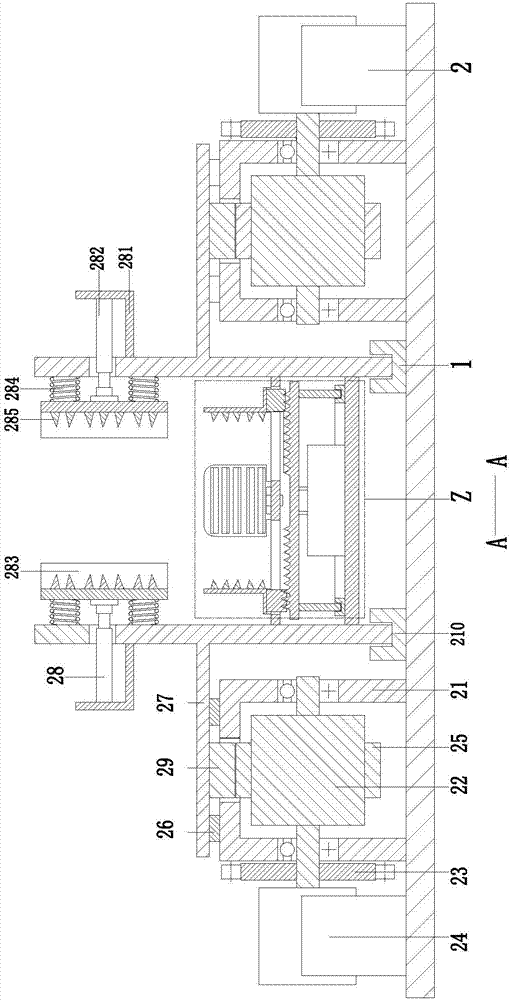

[0028] Such as Figure 1 to Figure 6 As shown, an automatic installation device for sewage inspection wells dedicated to drainage pipeline systems includes a base plate 1, the front end of the base plate 1 is an open structure, and two mobile devices 2 are symmetrically installed on the left and right sides of the base plate 1. Between the two mobile devices 2 A locking device 3 is installed between them. The two moving devices 2 can drive the locking device 3 to move. The locking device 3 can lock the cement sewage inspection well to avoid accidents during the movement. The front end of the bottom plate 1 A fixed lifting device 4 is provided, and the fixed lifting device 4 can automatically install the cement material sewage inspection well to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com