Plastic cylinder three-point positioning and punching mechanism

A three-point positioning, cylinder technology, applied in metal processing and other directions, can solve the problems of no specific clamping device, affecting the punching effect, and deformation of the cylinder, so as to achieve firm clamping and fixing, good effect, and disassembly and replacement. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

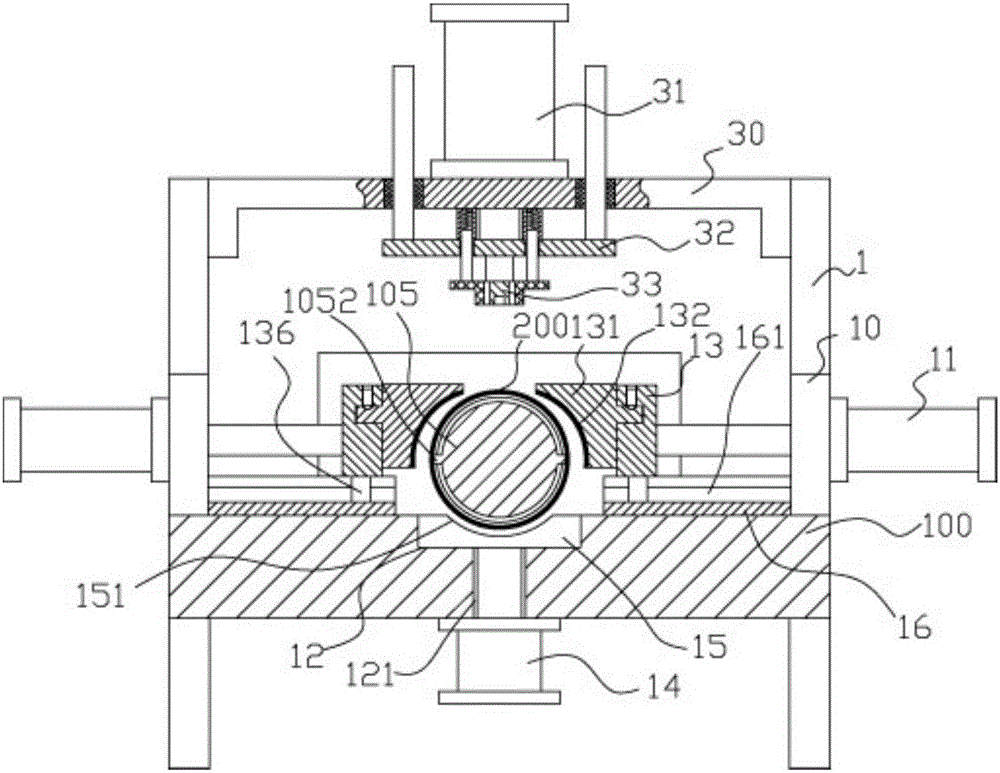

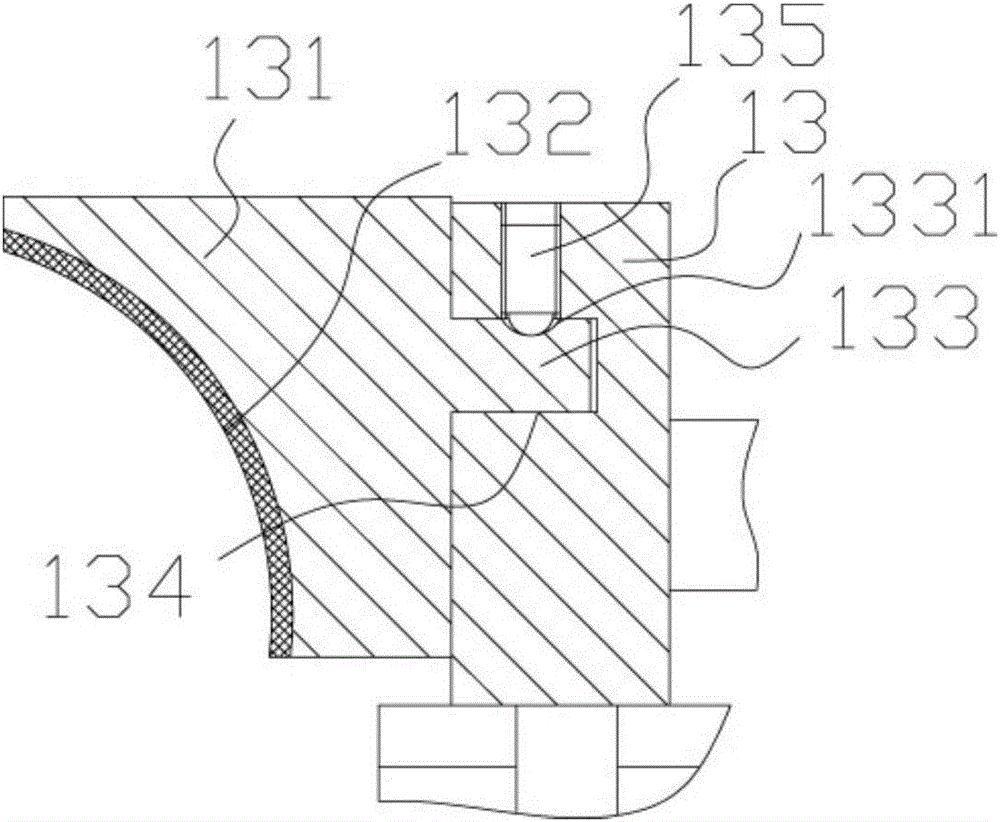

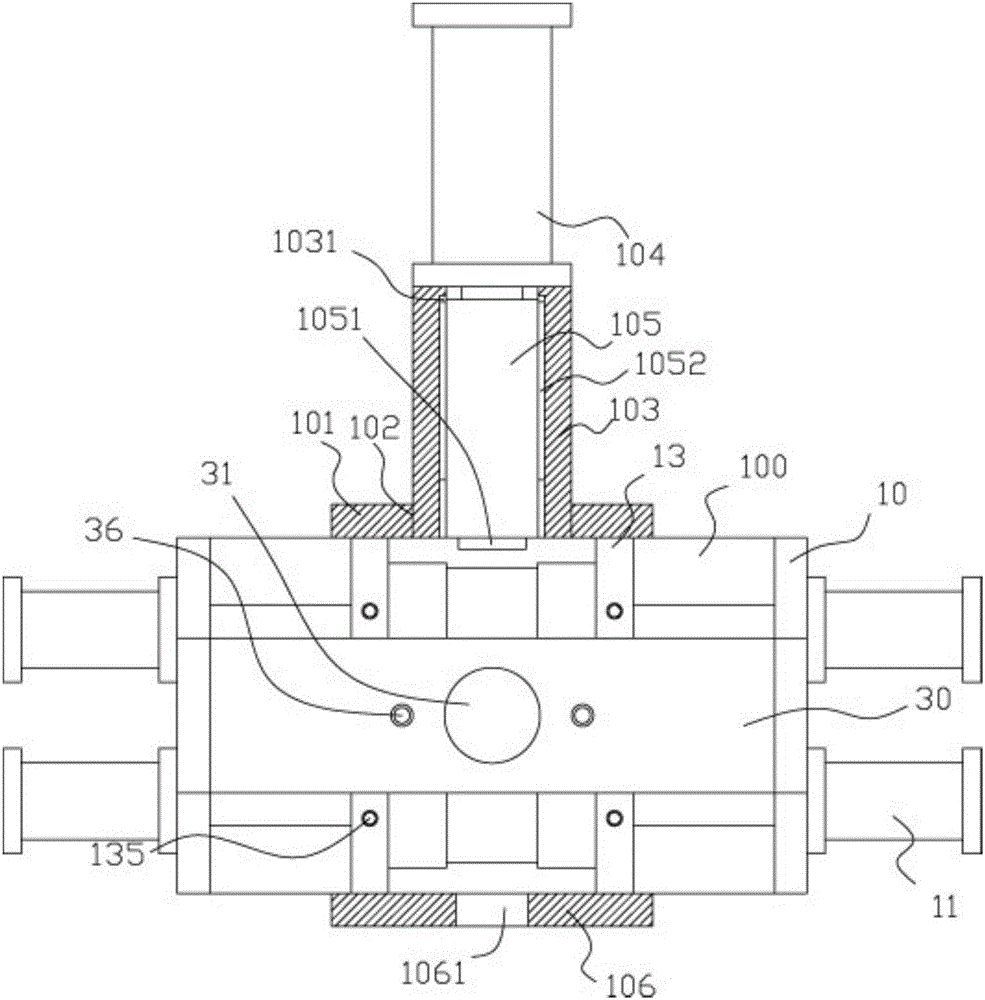

[0023] Example: see Figure 1 to Figure 5 As shown, a three-point positioning punching mechanism for a plastic cylinder includes a frame 100, and upper support plates 10 are fixed on both sides of the top plate of the frame 100, and the middle parts of the top surfaces of the two upper support plates 10 are It has an upper extension 1, and the two ends of the middle connecting frame 30 are fixedly connected to the two upper extensions 1 by bolts. The middle top surface of the middle connecting frame 30 is fixed with a punching cylinder 31, and the push rod of the punching cylinder 31 is vertical. Down through the middle part of the middle connecting frame 30, the push rod middle part of the punching cylinder 31 is fixed with a guide plate 32, and the end of the push rod of the punching cylinder 31 stretches out the guide plate 32 and is fixed with a punch 33;

[0024] The front portion of the top plate of the frame 100 is fixed with a connection support plate 101, and a guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com