Middle-supporting type plastic cylinder three-point positioning mechanism

An intermediate support and three-point positioning technology, which is applied in metal processing and other directions, can solve the problems of no specific clamping device, affecting the cutting effect, and deformation of the cylinder, so as to achieve firm clamping and fixing, convenient disassembly and replacement, and good results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

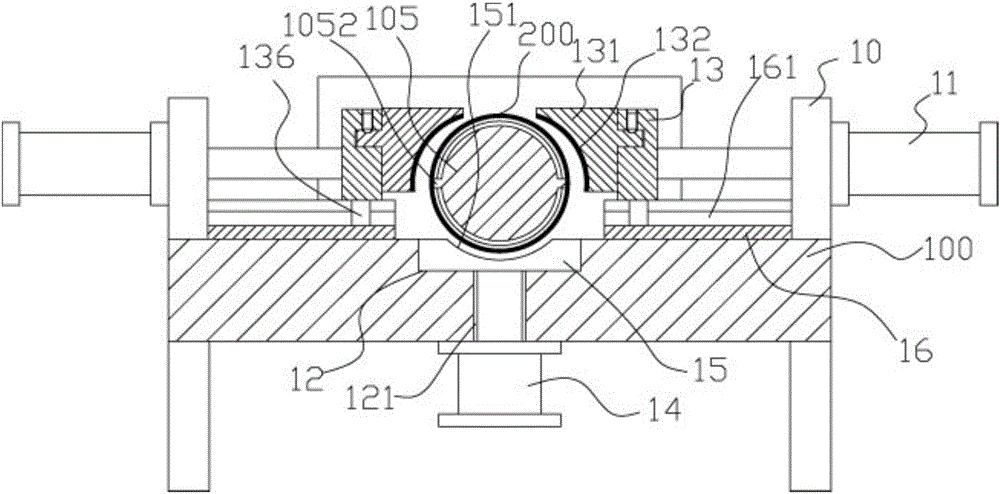

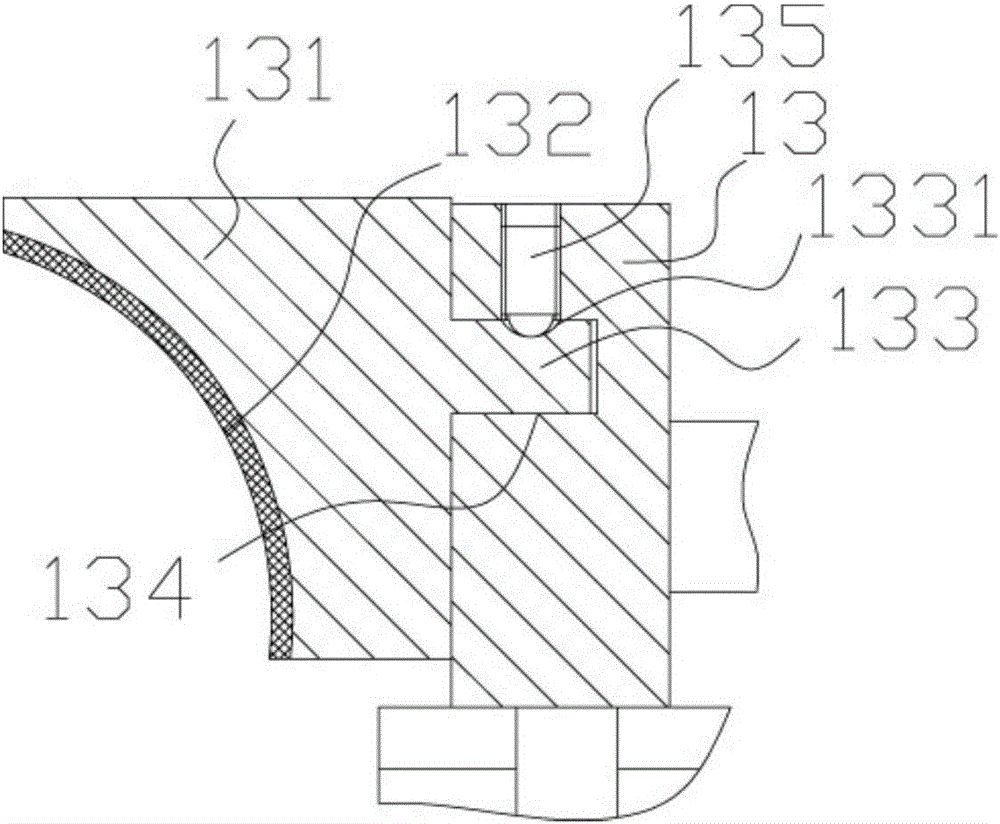

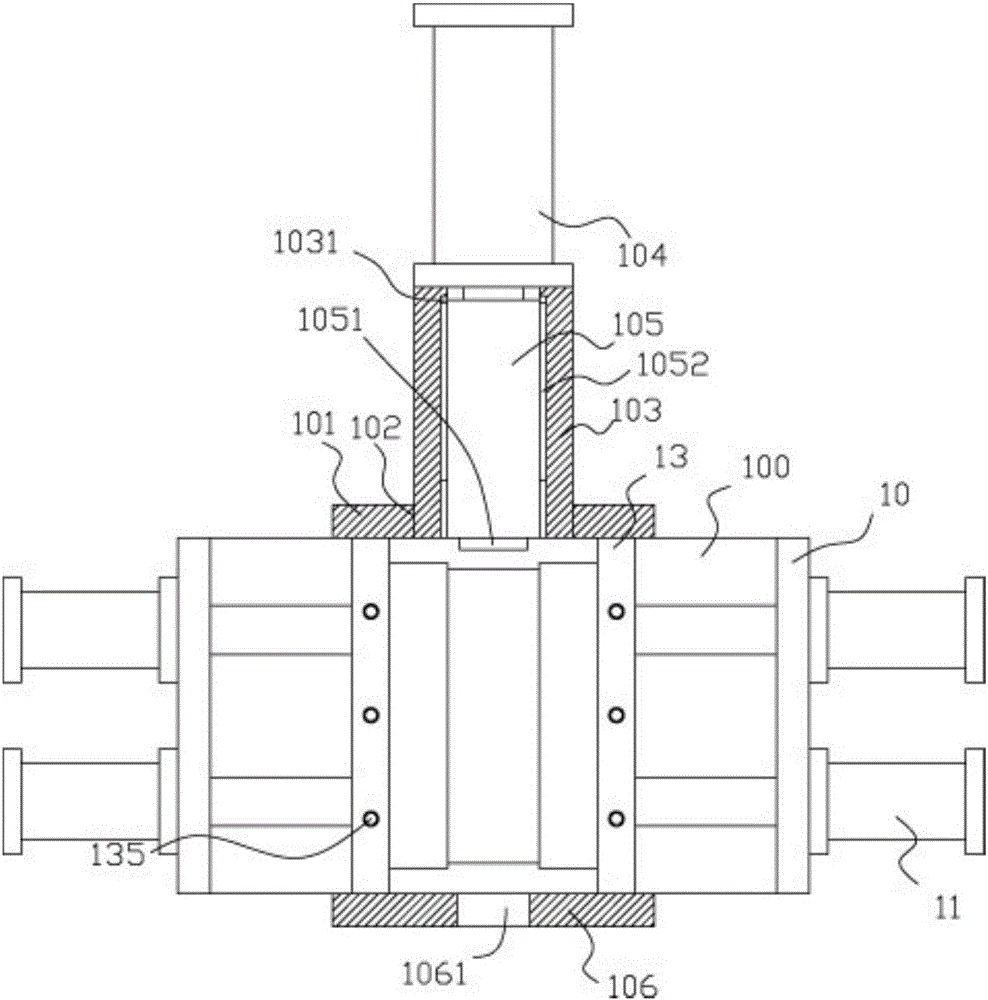

[0018] Example: see Figure 1 to Figure 4 As shown, a three-point positioning mechanism for supporting a plastic cylinder in the middle includes a frame 100, upper support plates 10 are fixed on both sides of the top plate of the frame 100, and an upper support plate 10 is fixed on the front of the top plate of the frame 100. Connect the support plate 101, the central through hole 102 in the middle of the connection support plate 101 is inserted with a guide connection sleeve 103, the rear outer side wall of the guide connection sleeve 103 is welded and fixed on the inner side wall of the center through hole 102, the guide connection sleeve The front end of 103 is fixed with an intermediate support cylinder 104, the push rod of the intermediate support cylinder 104 is fixed with an intermediate support column 105, and the intermediate support column 105 is inserted into the guide connecting sleeve 103;

[0019] At least two clamping cylinders 11 are fixed on the outer wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com