Transverse groove milling mechanism of end-grooved axle for automobile

A technology of grooving and shaft body, applied in milling machine equipment, details of milling machine equipment, metal processing machinery parts, etc., can solve the problems of easy sliding, low efficiency, low clamping firmness, etc., to achieve firm clamping and fixing, convenient processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

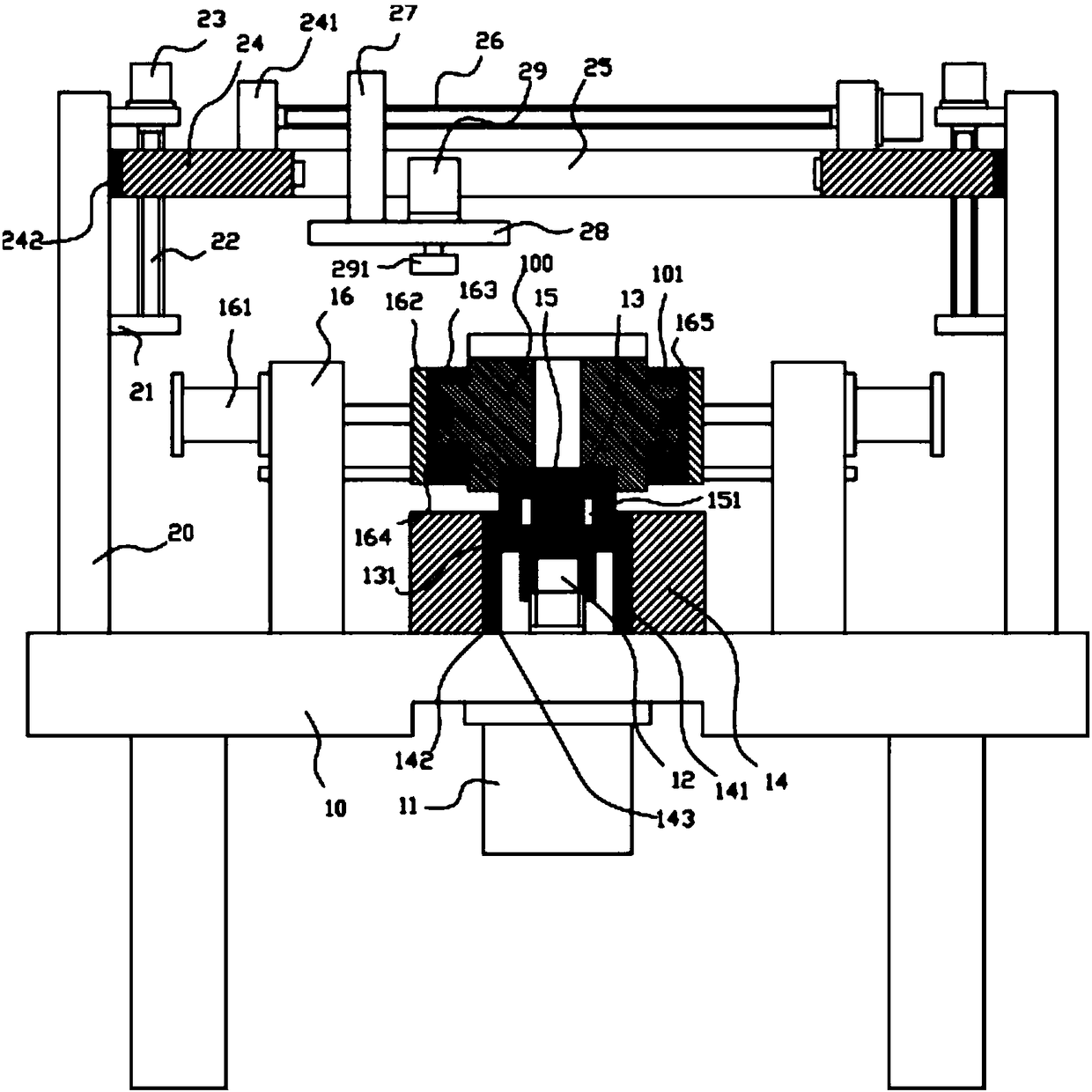

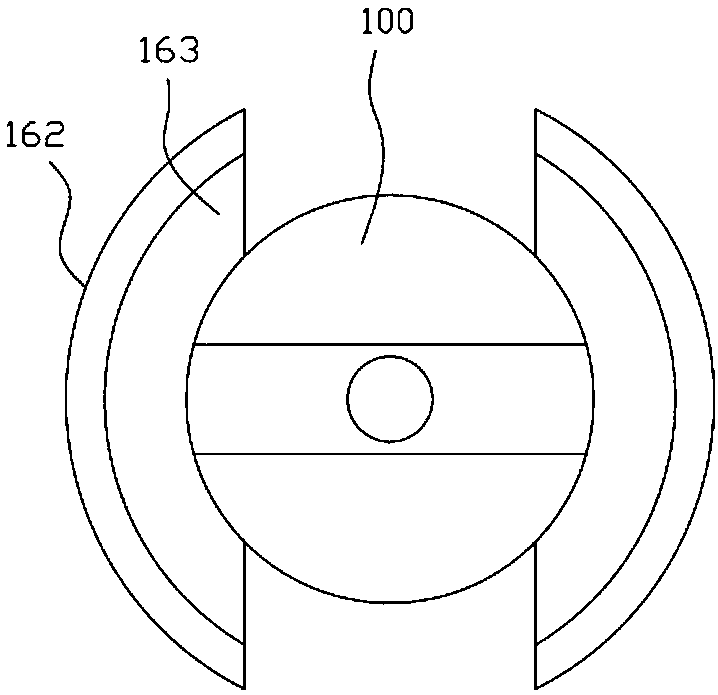

[0018] Example: see Figure 1 to Figure 2 As shown, an end slotting shaft body transverse milling mechanism for automobiles includes a frame 10, a lifting motor 11 is fixed on the bottom surface of the middle part of the top plate of the frame 10, and the output shaft of the lifting motor 11 passes through the frame 10. The top surface of the top plate of the frame 10 is screwed with a lifting screw sleeve 12, and the top of the lifting screw sleeve 12 is fixed with a lifting block 13, and the middle part of the top surface of the top plate of the frame 10 is fixed with a guide block 14, and the middle part of the guide block 14 has a central through-hole. Hole 141, the output shaft of lifting motor 11, lifting nut 12 and lifting block 13 are inserted in the center through hole 141, and the top surface of lifting block 13 stretches out the top surface of guide block 14, and the top surface of lifting block 13 is fixed with Permanent magnet block 15;

[0019] The middle left a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com