Preparation method of unsaturated lignocellulose material for polyurethane shape memory material

A technology of lignocellulose and polyurethane materials, which is applied in the field of preparation of unsaturated lignocellulose materials used in polyurethane shape memory materials, can solve the problems of shape memory materials application limitations, damaged structures, etc., and improve the thermally induced length recovery rate , Improvement range and good folding resistance and shape recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

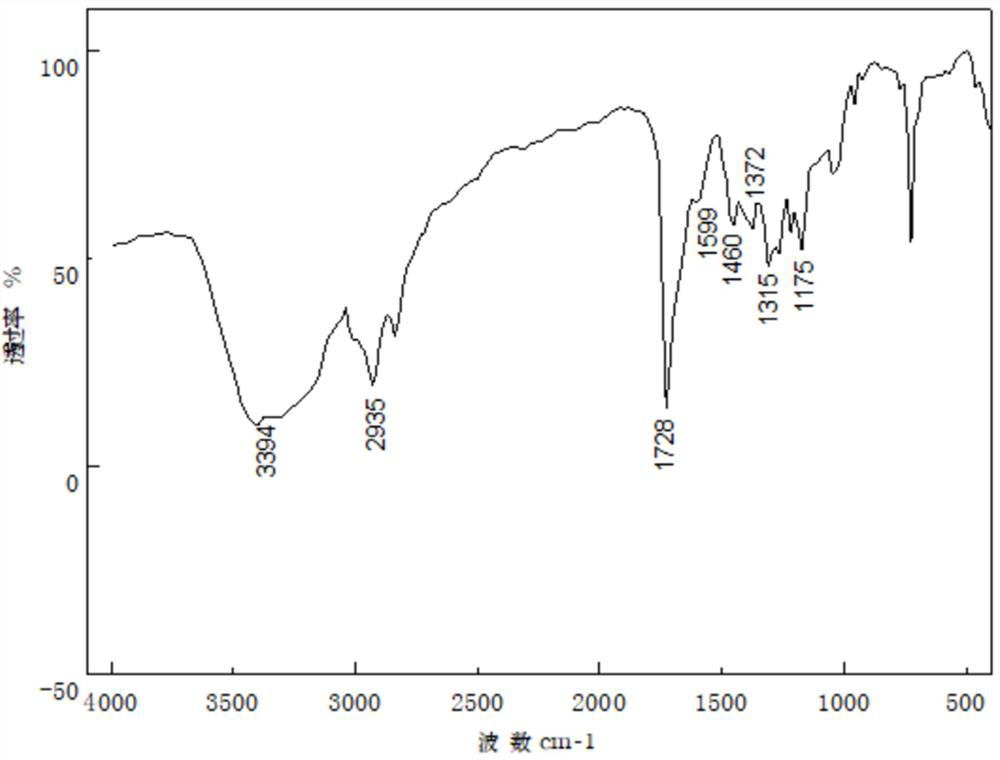

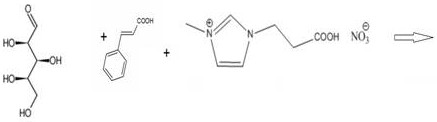

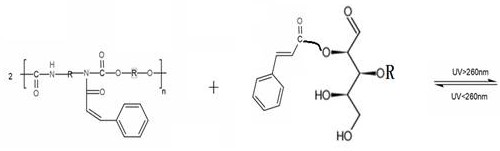

Method used

Image

Examples

Embodiment 1

[0044] Add 60g of polytetrahydrofuran into the reaction kettle, and heat it to 100 while stirring at 200r / min o C, evacuate to -0.1MPa, keep for 2h, then cool down to 45 o C, feed high-purity nitrogen to standard atmospheric pressure, add 30g of hexamethylene diisocyanate, 1g of cinnamic acid, and heat up to 80 o C, react for 4 hours, evacuate to -0.1MPa, keep for 2 hours, and then pass nitrogen to standard atmospheric pressure to obtain a prepolymer reaction liquid; mix 10g of 1,4-butanediol, 5g of isophorone diamine, 7g of unsaturated wood The cellulose material and 0.1g of bis(ethylhexanoyloxy)tin were mixed evenly, and quickly added to the prepolymer reaction solution under nitrogen protection, stirred at 200r / min for 1min, and then poured into a Teflon mold. When the reaction solution turns into a gel, it is pressurized and solidified for 60 minutes, demolded, and then the product obtained is heated at 100 o After curing at C for 15 hours, a shape-recoverable polyuretha...

Embodiment 2

[0048] Add 63.1g of poly-4-methylbutyrolactone diol into the reactor, and heat it to 102.3 while stirring at 226.6r / min o C, evacuate to -0.1MPa, keep for 2h, then cool down to 47 o C, feed high-purity nitrogen to standard atmospheric pressure, add 31.5g of isophorone diisocyanate, 1.2g of methyl cinnamate, and heat up to 80.8 o C, reacted for 3.8 hours, evacuated to -0.1MPa, kept for 2.2 hours, and then passed nitrogen to standard atmospheric pressure to obtain a prepolymer reaction liquid; -Methylphenyl)methane, 7g unsaturated lignocellulosic material, and 0.1g of dibutylene dilaurate are mixed uniformly, and are quickly added to the prepolymer reaction solution under nitrogen protection, and stirred at 200r / min for 1.3min, Then pour into the Teflon mold, when the reaction solution becomes gel, pressurize and solidify for 56min, demold, then the product obtained o After curing at C for 16.8 hours, a shape-recoverable polyurethane material was obtained.

[0049] The unsatu...

Embodiment 3

[0052] Add 66.2g of polypropylene glycol into the reactor and heat to 106.6 while stirring at 244.3r / min o C, evacuate to -0.1MPa, keep for 2h, then cool down to 48 o C, feed high-purity nitrogen to standard atmospheric pressure, add 32.6g biuret triisocyanate, 1.5g ethyl cinnamate, and heat up to 81.9 o C, reacted for 3.5h, evacuated to -0.1MPa, kept for 2.3h, and then passed nitrogen to standard atmospheric pressure to obtain a prepolymer reaction solution; 12.4g of 1,4-butanediol, 3.9g of diaminodiethyltoluene, Mix 9g of unsaturated lignocellulosic material and 0.1g of dimethyltin dichloride evenly, quickly add it to the prepolymer reaction solution under nitrogen protection, stir at 200r / min for 1.8min, and then pour it into a Teflon mold , when the reaction solution turns into a gel, it is pressurized and solidified for 51.3 minutes, demolded, and then the obtained product is prepared at 104.6 o After curing at C for 19.1 hours, a shape-recoverable polyurethane material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com