Absorbent laminated sheet

A technology of absorbent and sheet materials, applied in the direction of absorbent pads, medical science, bandages, etc., to achieve the effects of excellent deformation resistance, excellent shape recovery, and improved utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

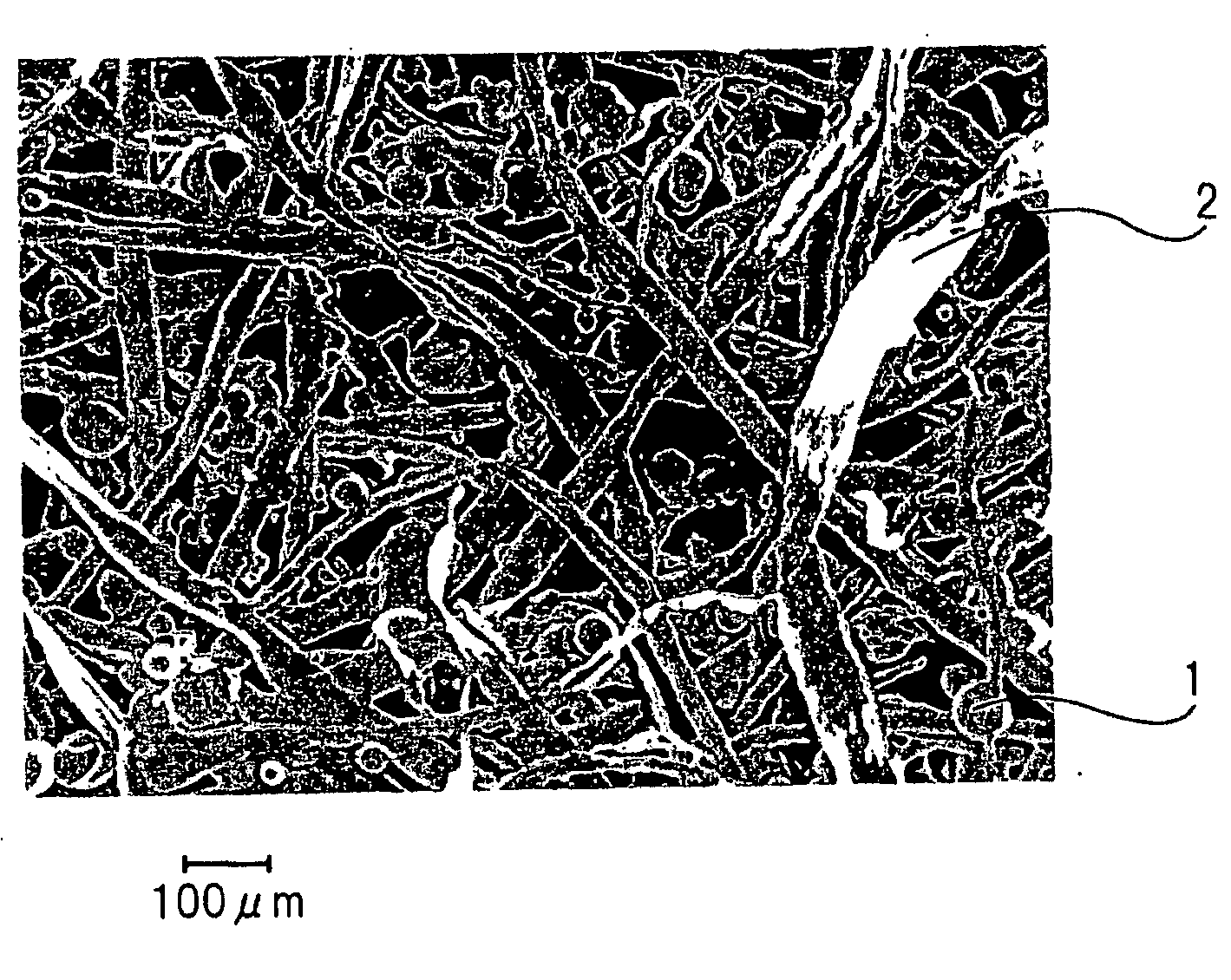

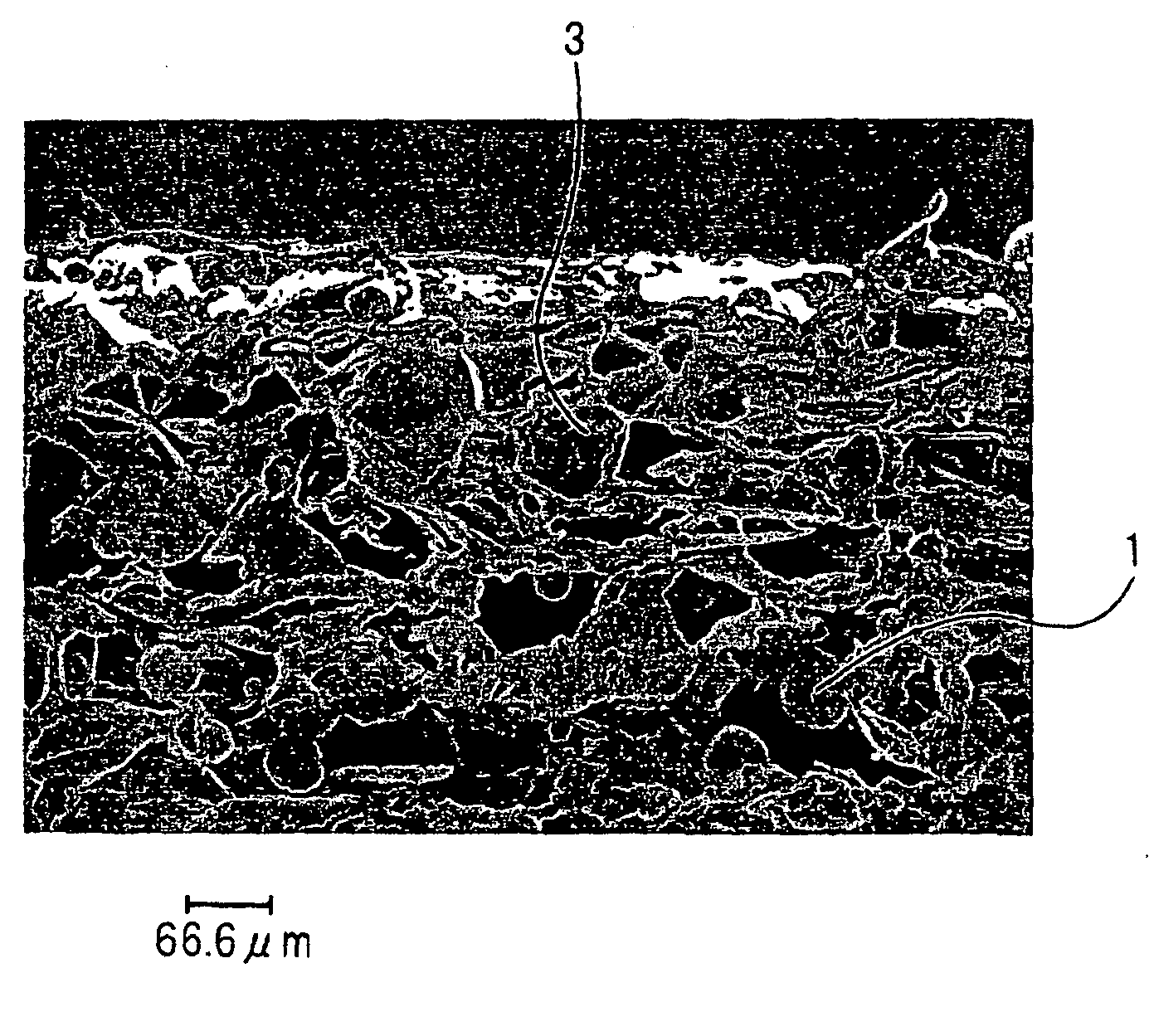

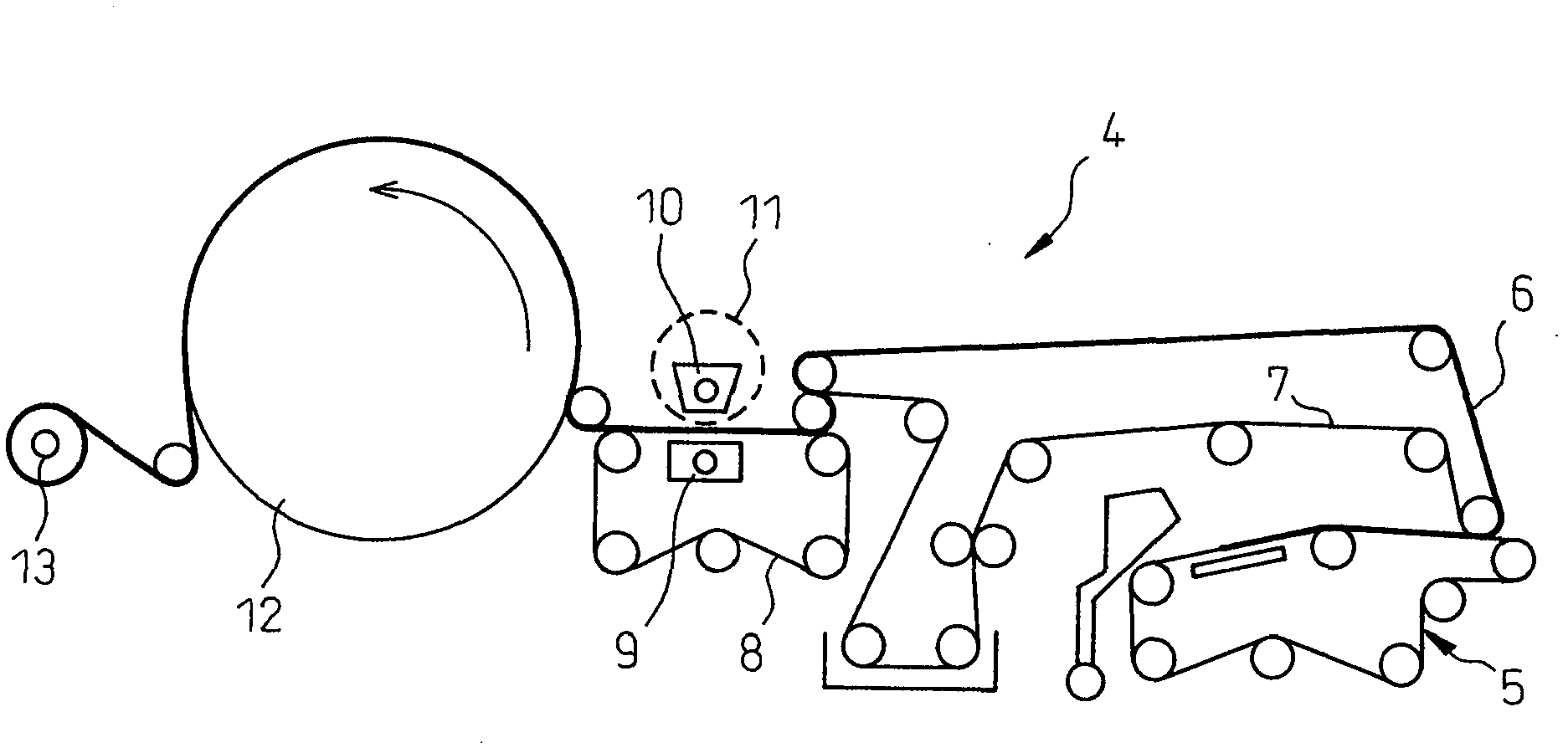

[0172] -Manufacture of bulky absorbent paper 1-

[0173] (i) As fiber raw materials, 70 parts by mass of unbeaten softwood bleached kraft pulp and 15 parts by mass of PP / PE core-sheath composite fiber 2.2 dtex x 5 mm (manufactured by Daiwa Bou Polytec Co., Ltd., NBF) were used; (ii) As the heat-expandable particles, 15 parts by mass of microcapsules (Matsumoto Microsufea-FUC-36, particle diameter 5-15 μm, expansion initiation temperature 75-85° C. manufactured by Matsumoto Yushi Pharmaceutical Co., Ltd.) in which a low-boiling point solvent was enclosed were used; And (iii) as an auxiliary agent, 0.5 parts by mass (as an active ingredient) of a cation-modified acrylic copolymer (manufactured by Meisei Chemical Industry Co., Ltd., Failex RC-104) as a heat-expandable particle fixing agent added to the pulp was used , acrylic copolymer (Meisei Chemical Industry Co., Ltd., Fayrex M) 0.3 parts by mass (as an active ingredient); as a paper strength enhancer, use polyamide-epichloroh...

manufacture example 2

[0176] -Manufacture of bulky absorbent paper 2-

[0177] Except for using a wire mesh that does not block the mesh, the rest are the same as in Manufacturing Example 1 to obtain a weight per unit area of 50g / m 2 , thickness 1.6mm, density 0.031g / cm 3 Bulk absorbent paper without embossed pattern2.

manufacture example 3

[0179] -Manufacture of water-resistant tissue paper 1-

[0180] In addition to using microcapsules (manufactured by Matsumoto Microcross Fea-FUC-36, manufactured by Matsumoto Yushi Pharmaceutical Co., Ltd.) in which heat-expandable particles are enclosed in a low-boiling point solvent, and cation-modified acrylic copolymer as a heat-expandable particle fixing agent added to pulp, (Fairex RC-104 manufactured by Meisei Chemical Industry Co., Ltd.) and an acrylic copolymer (Fairex M manufactured by Meisei Chemical Industry Co., Ltd.), the rest were carried out in the same manner as Production Example 1 to manufacture water-resistant tissue paper 1 (unit area Weight 50g / m 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com