Coating solution for optical polyester film primer and preparation method thereof

A technology of optical polyester film and coating solution, applied in polyester coatings, chemical instruments and methods, polyurea/polyurethane coatings, etc. Insufficient strength, UV resistance, high temperature and high humidity resistance, and the adhesion of the functional layer cannot meet the requirements, etc., to achieve the effect of strong adhesion, good smoothness, and low haze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

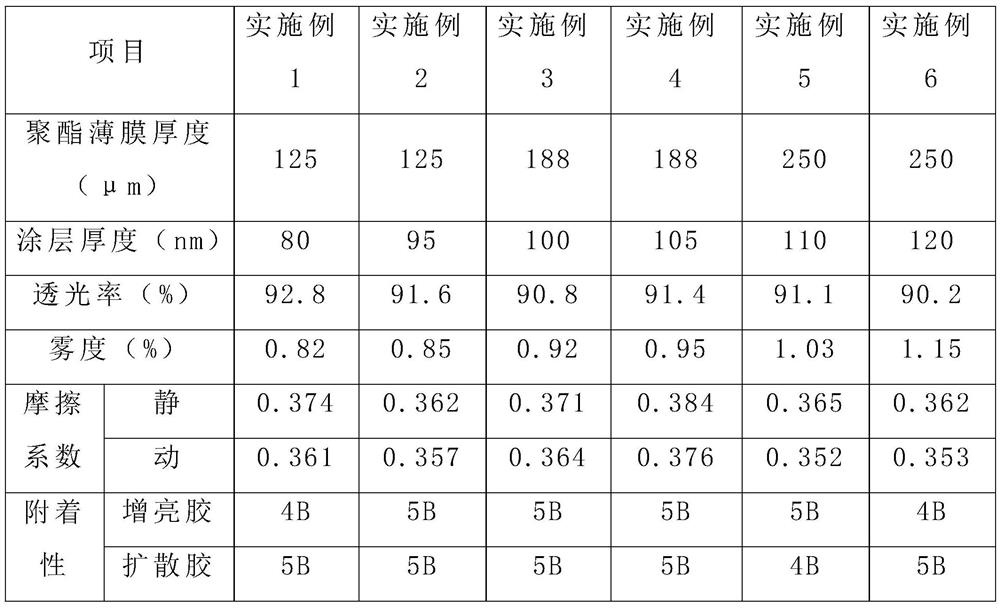

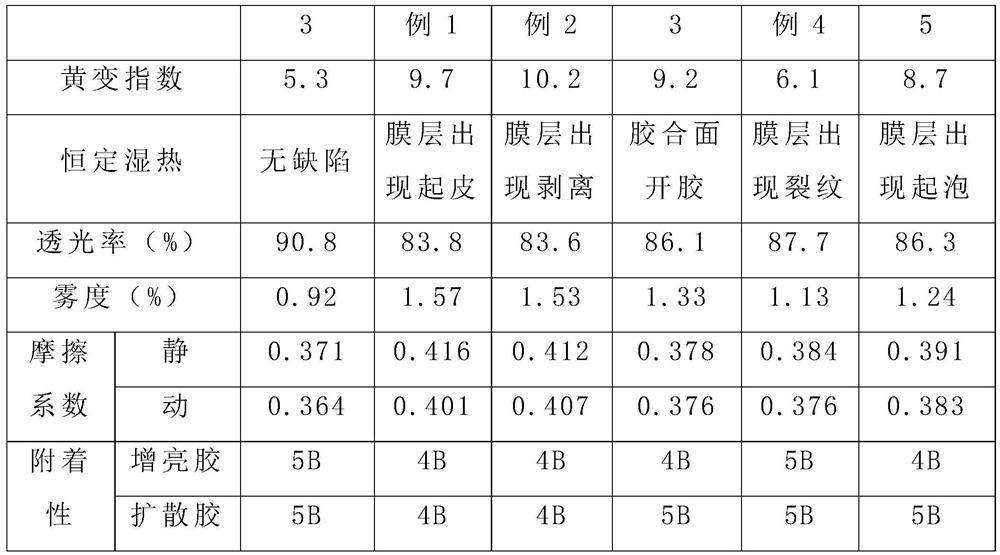

Examples

Embodiment 1

[0044] Take an organic solvent, add a wetting agent and blend to prepare a wetting agent solution, and take 80% of the total amount of deionized water in the component, slowly add the wetting agent solution to the above deionized water and mix and stir evenly to obtain Solution A: take water-based polyester and add deionized water to dilute to obtain a diluted solution, stir solution A, slowly add UV-resistant modified polyurethane, stir well, then slowly add water-based polyurethane, stir well, then slowly add diluted solution, continue Stir to obtain solution B; stir solution B, take deionized water to dilute melamine resin, take organic solvent and deionized water to dilute epoxy resin, slowly add to solution B respectively, continue stirring to obtain solution C; stir solution C, take Prepare an aqueous dispersion with a silicon dioxide content of 40% from nanoparticles, and dilute it with deionized water. After stirring evenly, slowly add it to solution C. After stirring e...

Embodiment 2

[0047] Take an organic solvent, add a wetting agent and blend to prepare a wetting agent solution, and take 80% of the total amount of deionized water in the component, slowly add the wetting agent solution to the above deionized water and mix and stir evenly to obtain Solution A: take water-based polyester and add deionized water to dilute to obtain a diluted solution, stir solution A, slowly add UV-resistant modified polyurethane, stir well, then slowly add water-based polyurethane, stir well, then slowly add diluted solution, continue Stir to obtain solution B; stir solution B, take deionized water to dilute melamine resin, take organic solvent and deionized water to dilute epoxy resin, slowly add to solution B respectively, continue stirring to obtain solution C; stir solution C, take Prepare an aqueous dispersion with a silicon dioxide content of 40% from nanoparticles, and dilute it with deionized water. After stirring evenly, slowly add it to solution C. After stirring e...

Embodiment 3

[0050] Take an organic solvent, add a wetting agent and blend to prepare a wetting agent solution, and take 65% of the total amount of deionized water in the component, slowly add the wetting agent solution to the above deionized water and mix and stir evenly to obtain Solution A: take water-based polyester and add deionized water to dilute to obtain a diluted solution, stir solution A, slowly add UV-resistant modified polyurethane, stir well, then slowly add water-based polyurethane, stir well, then slowly add diluted solution, continue Stir to obtain solution B; stir solution B, take deionized water to dilute melamine resin, take organic solvent and deionized water to dilute epoxy resin, slowly add to solution B respectively, continue stirring to obtain solution C; stir solution C, take Prepare an aqueous dispersion with a silicon dioxide content of 40% from nanoparticles, and dilute it with deionized water. After stirring evenly, slowly add it to solution C. After stirring e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com