Manufacturing method for nanometal transparent conductive film

A transparent conductive film and nano-metal technology, applied in the manufacture of cables/conductors, insulation of conductors/cables, circuits, etc., can solve the problems of insufficient film hardness, poor environmental tolerance of films, and inability to apply to electronic product manufacturing, etc. Effect of hardness and environmental resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

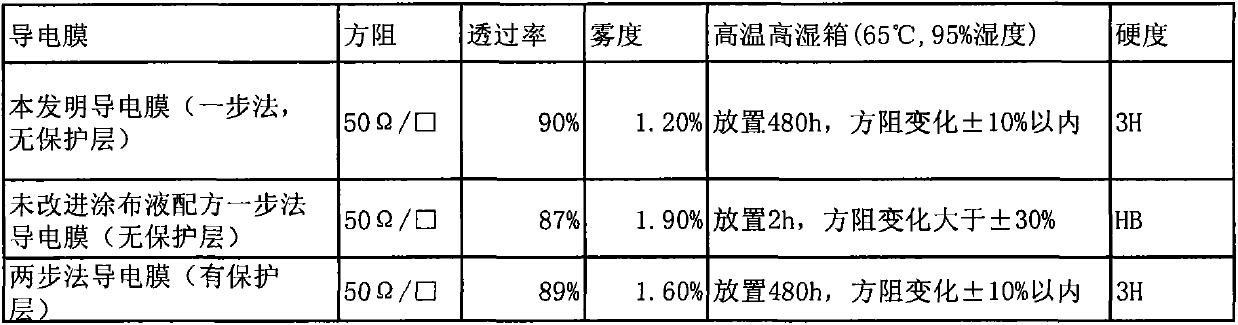

Examples

Embodiment 1

[0023] The formula of the conductive layer coating solution is: the nano-metal wire is selected as a nano-silver wire, the wire length should be 20 μm, the wire diameter should be 35 nm, the content of the nano-silver wire is 0.1%, 0.2% polyvinyl alcohol, 0.02% nano-spherical silica, The particle size is 10nm, 0.01% of γ-glycidyl etheroxypropyltrimethoxysilane, 0.02% of polyethylene glycol octylphenyl ether, and 0.4% of PEDOT:PSS. The specific preparation method is to take 250g of 0.2% nano silver wire initial suspension, the solvent of this suspension is pure water, add 237.85g of 0.4% polyvinyl alcohol aqueous solution to it while stirring, and finally add 10g of 1% silver wire respectively Silicon oxide hydrosol, 0.05g of γ-glycidyl etheroxypropyltrimethoxysilane, 0.1g of polyethylene glycol octylphenyl ether, and 2g of %PEDOT:PSS were fully stirred to complete the preparation.

[0024] Coat the prepared coating ink onto the substrate by spin coating, then pre-bake it in an...

Embodiment 2

[0026] The formula of the coating liquid is: the nano-metal wire is selected as the nano-silver wire, the wire length should be 20 μm, the wire diameter should be 35 nm, the content of the nano-silver wire is 0.1%, 0.2% polyvinyl alcohol, 0.02% nano-spherical silica, the particle size 10nm, 0.01% γ-glycidyl etheroxypropyl trimethoxysilane, 0.02% polyethylene glycol octylphenyl ether, 0.4% nano-zinc oxide, nano-zinc oxide is linear, particle size 30m, line length 20μm . The specific preparation method is to take 250g of 0.2% nano silver wire initial suspension, the solvent of this suspension is pure water, add 237.85g of 0.4% polyvinyl alcohol aqueous solution to it while stirring, and finally add 10g of 1% silver wire respectively Silicon oxide hydrosol, 0.05g of γ-glycidyl etheroxypropyl trimethoxysilane, 0.1g of polyethylene glycol octylphenyl ether, and 2g of nanometer zinc oxide powder were fully stirred and prepared.

[0027] Coat the prepared coating ink onto the substr...

Embodiment 3

[0029] The formula of the coating liquid is: the nano-metal wire is selected as the nano-silver wire, the wire length should be 20 μm, the wire diameter should be 35 nm, the content of the nano-silver wire is 0.1%, 0.2% polyvinyl alcohol, 0.1% polyurethane acrylic resin, 0.01% polyvinyl alcohol Ethylene glycol octyl phenyl ether, 0.2% nano-zinc oxide, the nano-zinc oxide is linear, the particle size is 30m, and the line length is 20μm. The specific preparation method is to take 250g of 0.2% nano silver wire initial suspension, the solvent of this suspension is pure water, add 242.9g of 0.4% polyvinyl alcohol aqueous solution to it while stirring, and finally add 5g of 10% polyurethane The acrylic resin hydrosol, 0.1g of polyethylene glycol octyl phenyl ether, and 2g of nano-zinc oxide powder are fully stirred and prepared.

[0030] Coat the prepared coating ink onto the substrate by spin coating, then pre-bake it in an oven at 100 degrees for 5 minutes, and then put it in an o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com