Preparation method of triple shape memory composite material

A composite material and memory technology, which is applied in the field of preparation of triple shape memory materials, achieves the effect of simple preparation method, good shape recovery and shape retention performance, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Mix the epoxy resin: curing agent with a mass ratio of 5: 4, and mix them evenly by mechanical stirring, then add nano-silica and PEG (molecular weight: 200) and mix with a mass ratio of 10: 0.5 The solution is named as solution A after vacuuming and defoaming at 60°C for subsequent use, wherein the mass fraction of the mixed solution of nano-silica and PEG in solution A is 10%;

[0021] (2) Mix epoxy resin: curing agent: PEG according to the mass ratio of 5:4: 1.5, mix evenly by mechanical stirring, and name it as solution B after vacuumizing and defoaming at 60°C for later use;

[0022] (3) Pour 2 parts by weight of solution A into the mold, pre-cure at 60°C for 30 minutes, pour 1 part by weight of solution B, and continue curing for 3.5 hours to obtain the desired triple shape memory composite material.

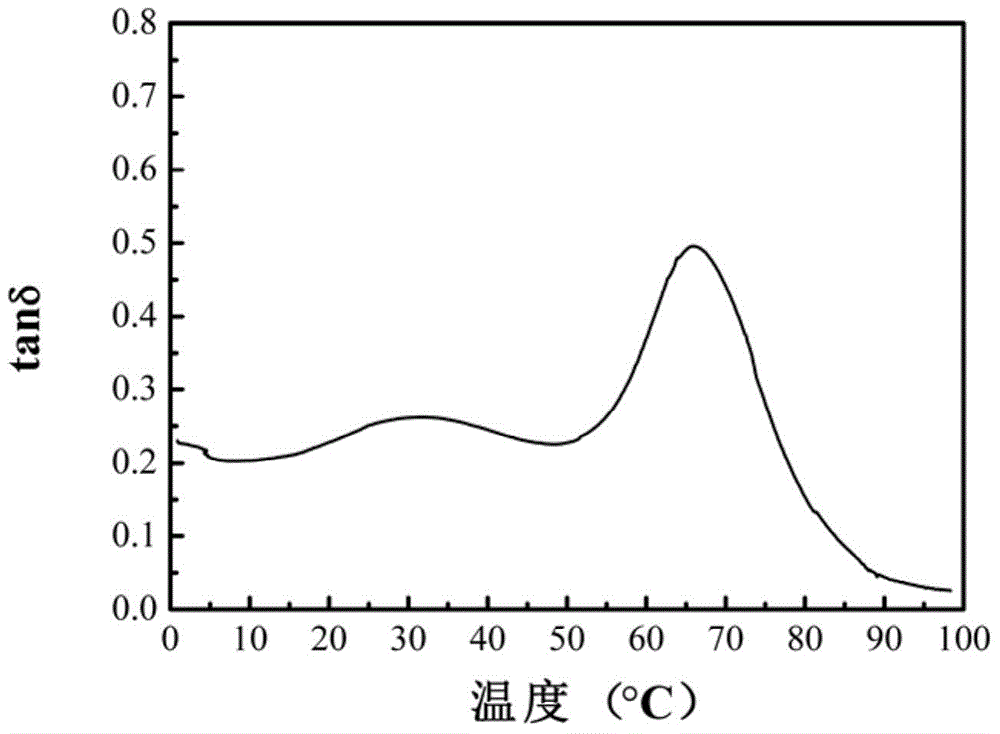

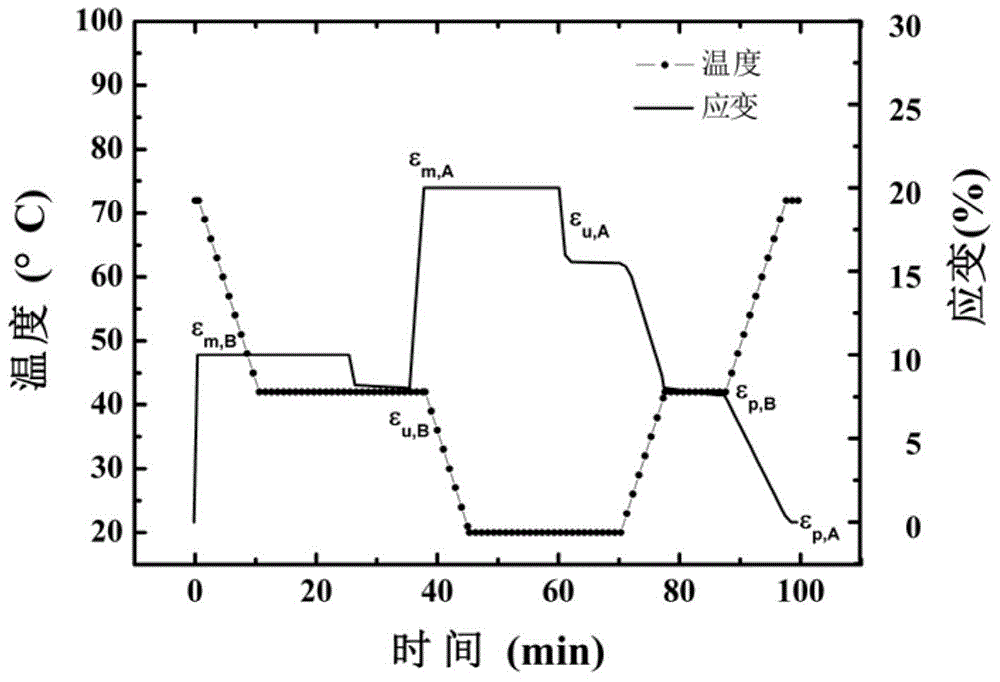

[0023] figure 1 It is the DMA diagram of the triple shape memory composite material prepared in this example. It can be seen from the figure that the material ...

Embodiment 2

[0025] (1) Mix the epoxy resin: curing agent in a mass ratio of 5: 3, mix evenly by mechanical stirring, and then add nano-silica and PEG (molecular weight: 200) in a mass ratio of 10: 2. The solution is named as solution A after vacuuming and defoaming at 60°C for subsequent use, wherein the mass fraction of the mixed solution of nano-silica and PEG in solution A is 10%;

[0026] (2) Mix epoxy resin: curing agent: PEG according to the mass ratio of 5:4: 2, mix evenly by mechanical stirring, and name it as solution B after vacuumizing and defoaming at 60°C for later use;

[0027] (3) Pour 1 part by weight of solution A into the mold, precure at 60°C for 30 minutes, pour 1 part by weight of solution B, and continue curing for 3.5 hours to obtain the desired triple shape memory composite material.

[0028] The DMA diagram and the triple shape memory diagram of the sample prepared in this embodiment are similar to those in Example 1.

Embodiment 3

[0030] (1) Mix the epoxy resin: curing agent in a mass ratio of 5: 4, mix evenly by mechanical stirring, then add nano-silica and PEG (molecular weight: 200) and mix in a mass ratio of 10: 3 Solution, after vacuuming and defoaming at 60°C, it is named as solution A for later use, wherein the mass fraction of nano-silica / PEG solution in solution A is 10%;

[0031] (2) Mix epoxy resin: curing agent: PEG according to the mass ratio of 5:4: 2, mix evenly by mechanical stirring, and name it as solution B after vacuumizing and defoaming at 60°C for later use;

[0032] (3) Pour 2 parts by weight of solution A into the mold, pre-cure at 60°C for 30 minutes, pour 1 part by weight of solution B, and continue curing for 3.5 hours to obtain the desired triple shape memory composite material.

[0033] The DMA diagram and the triple shape memory diagram of the sample prepared in this embodiment are similar to those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com