Patents

Literature

39results about How to "Excellent shape recovery performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

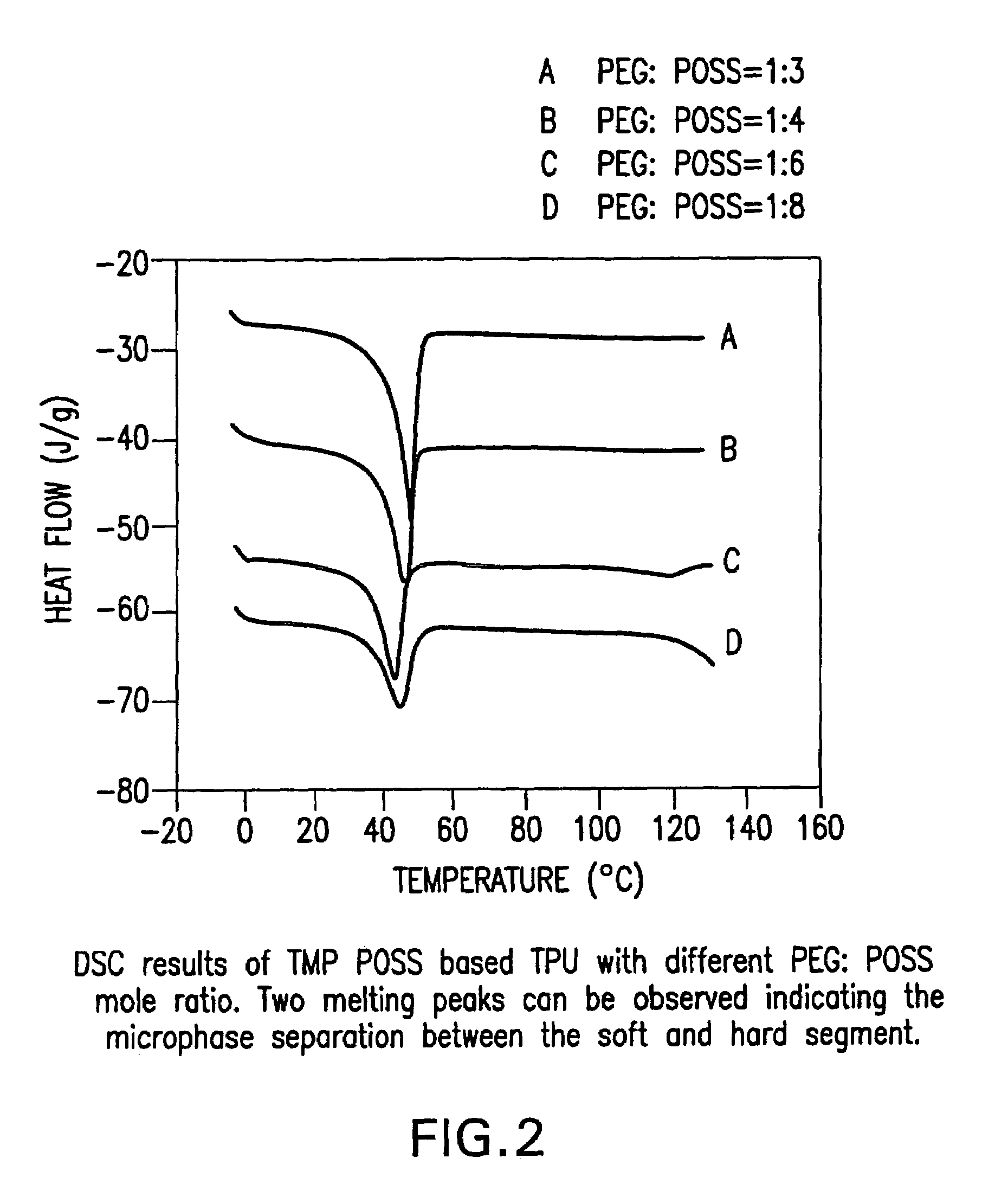

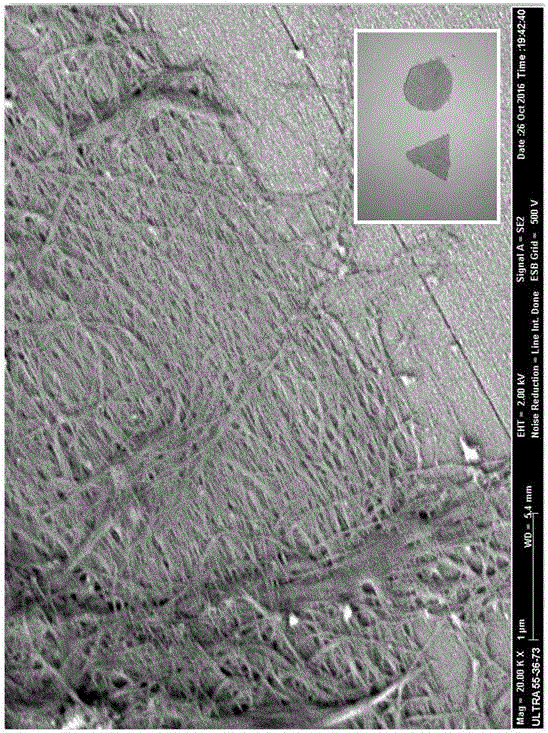

Shape memory polymers based on semicrystalline thermoplastic polyurethanes bearing nanostructured hard segments

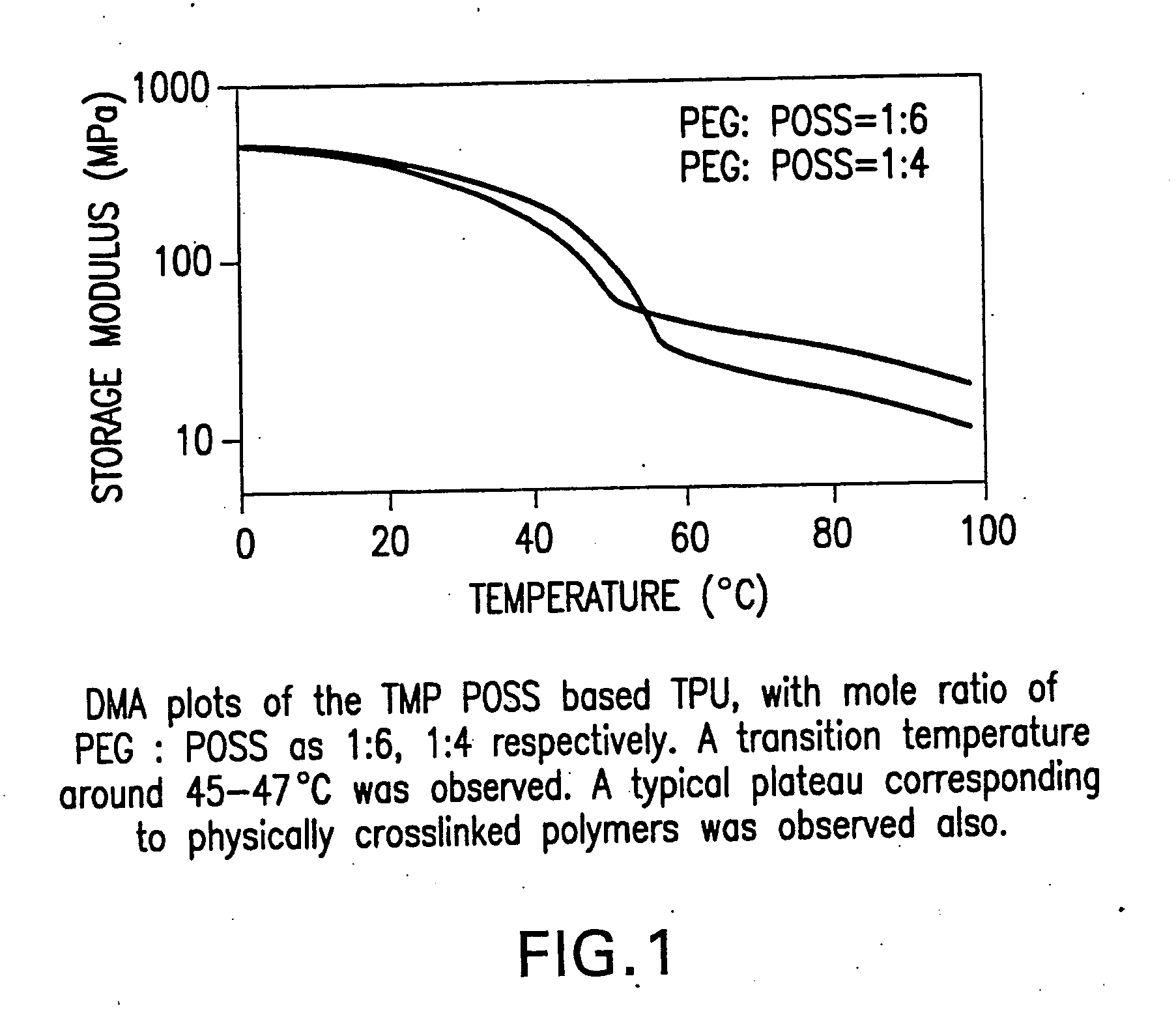

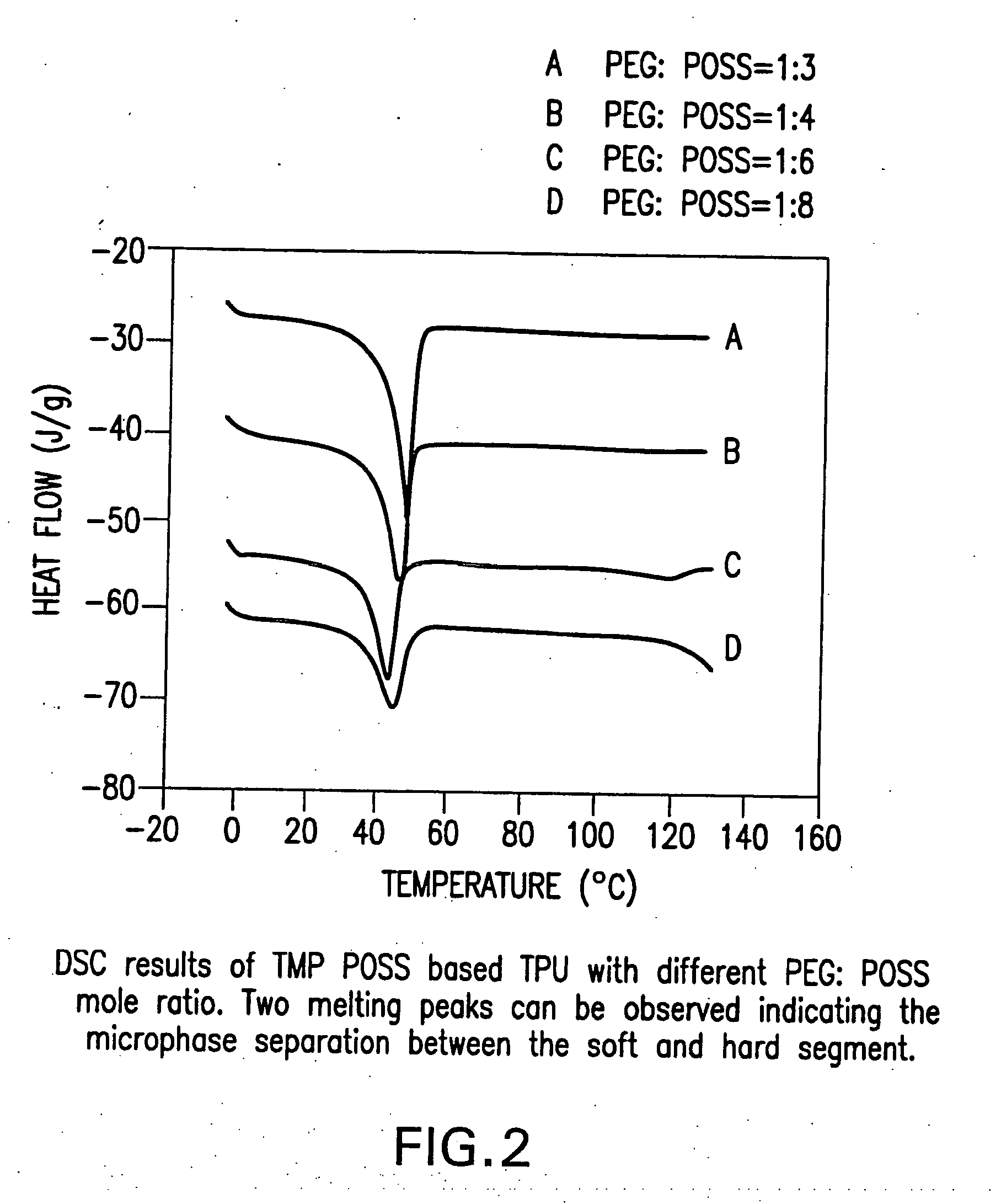

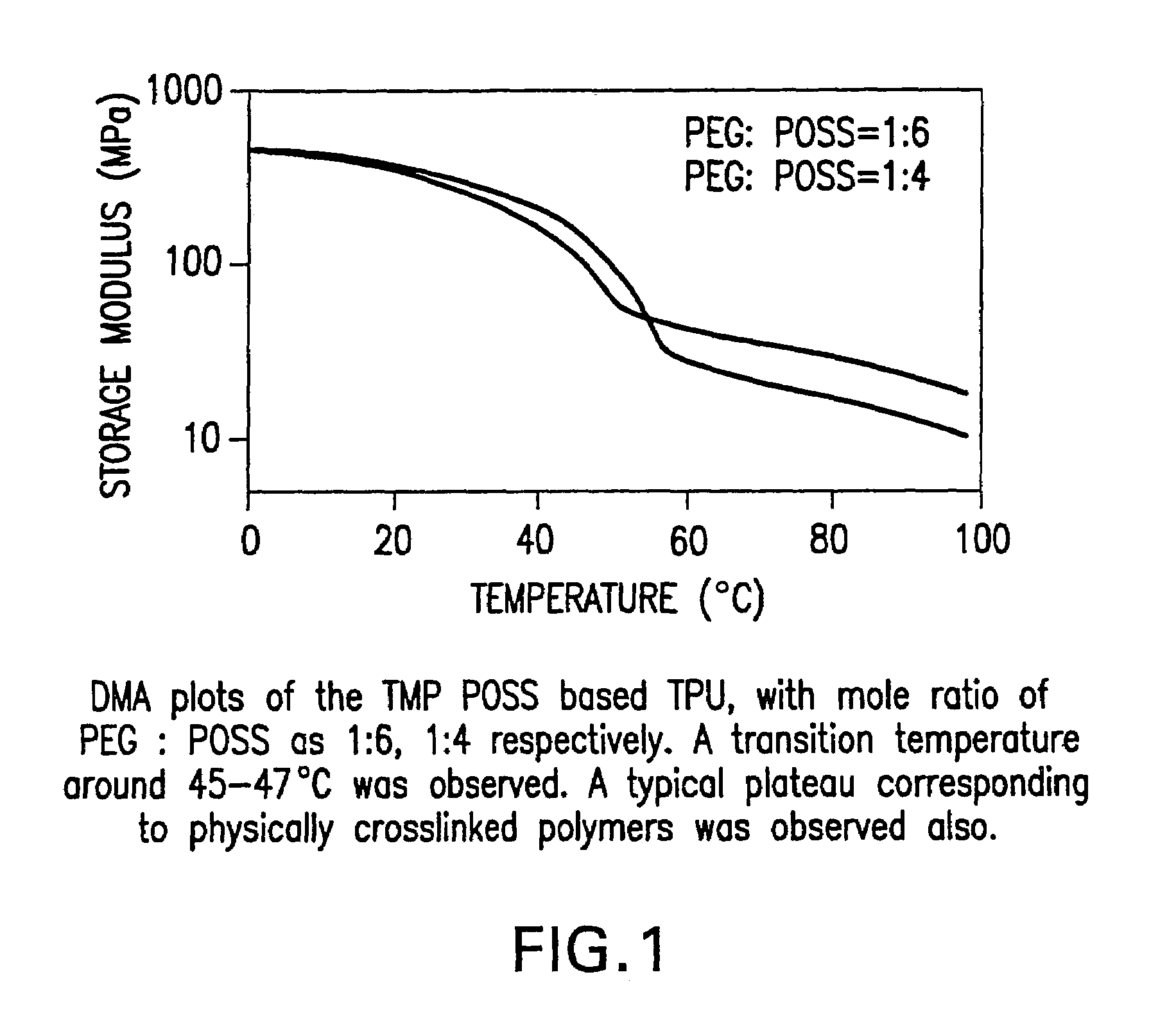

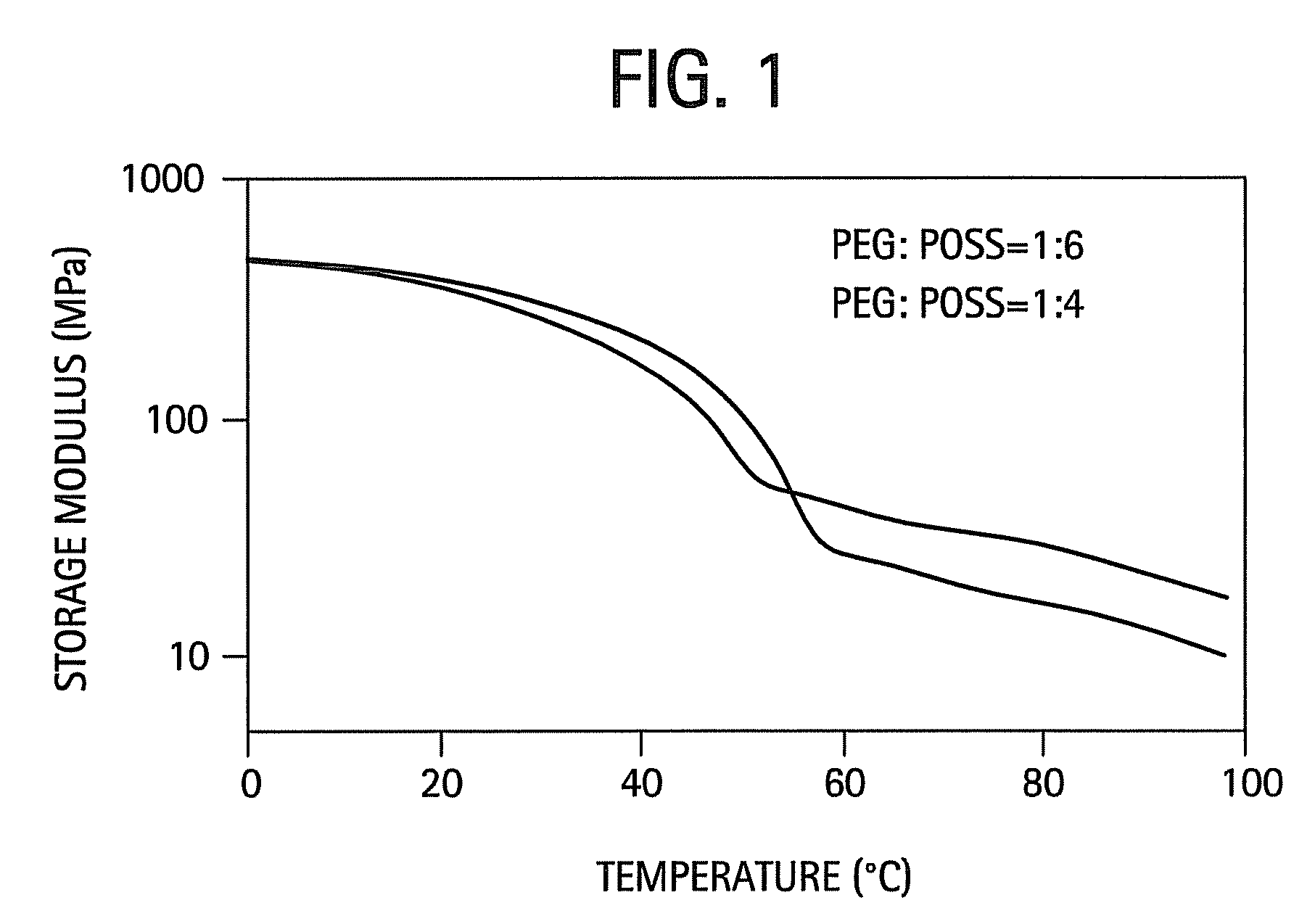

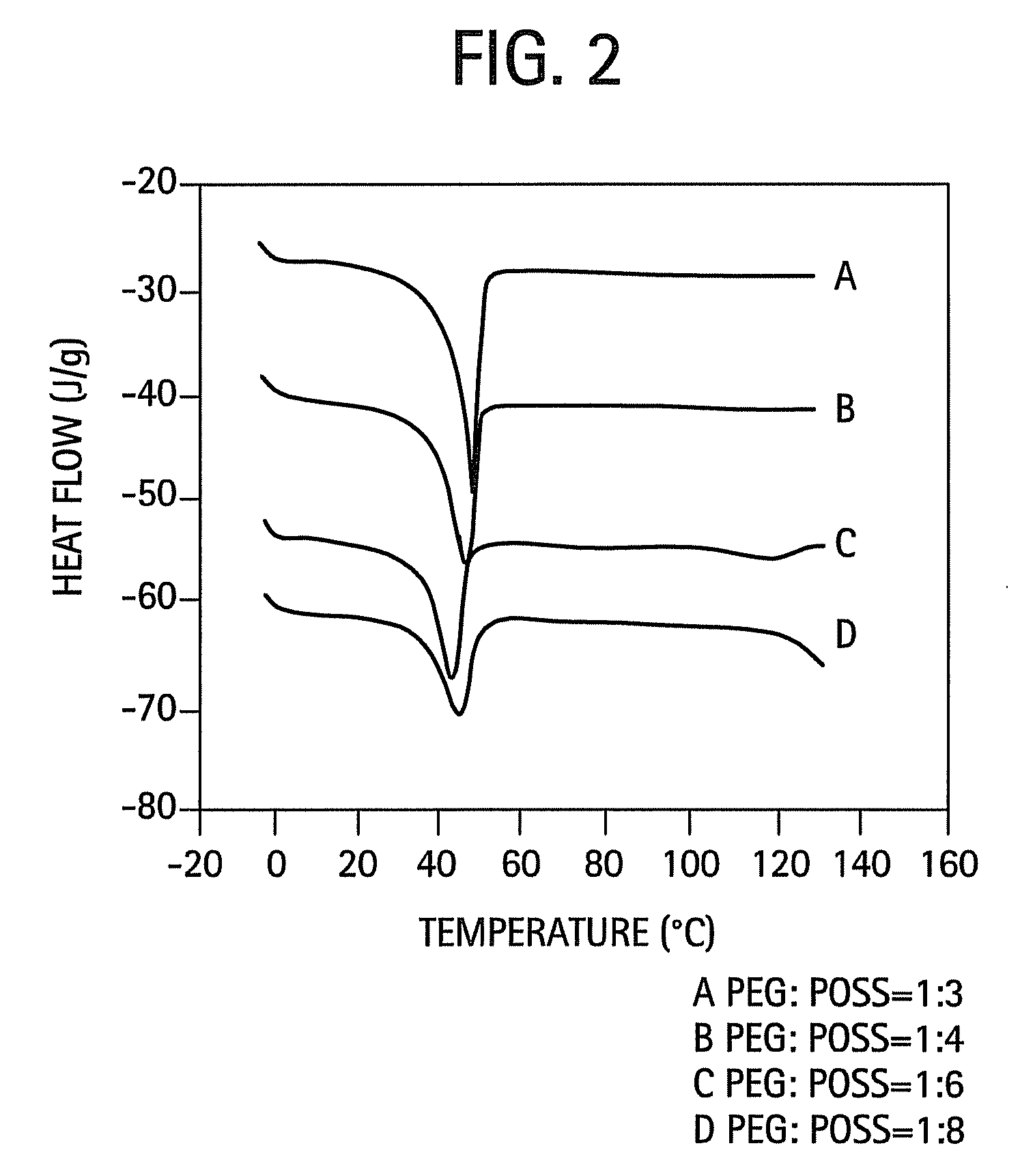

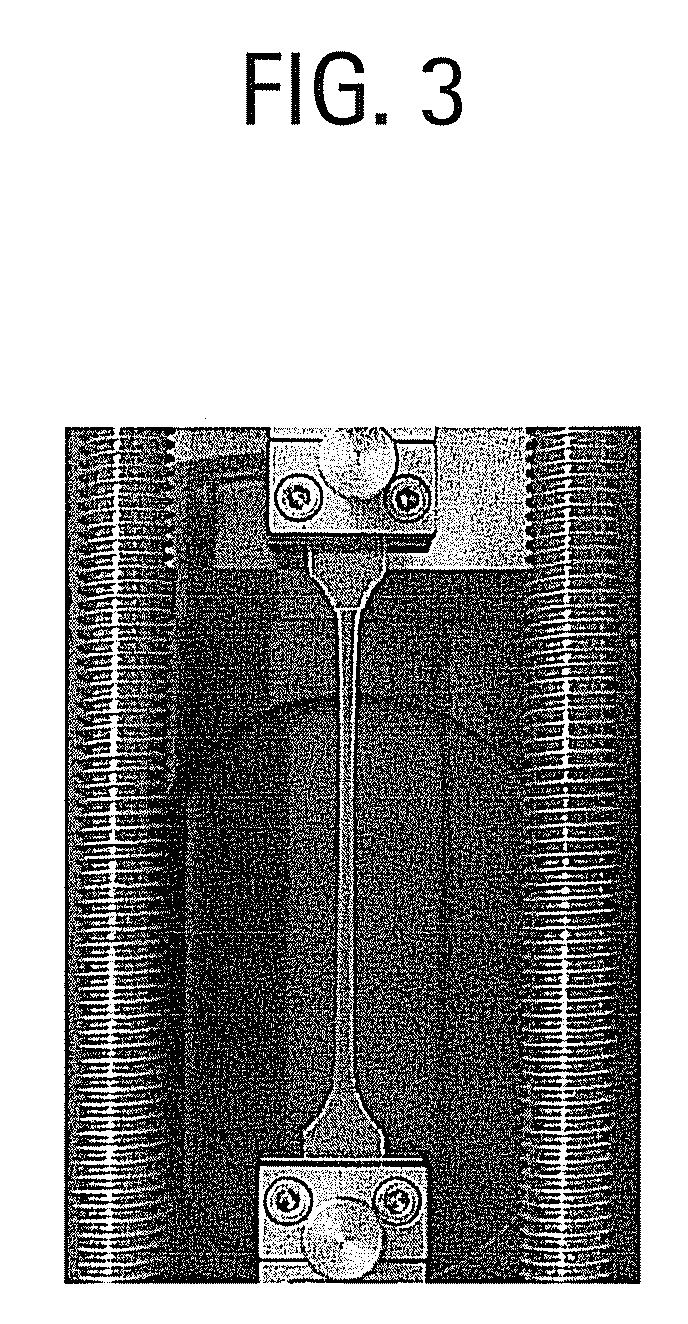

InactiveUS20050245719A1Sharp and tunable transition temperatureAbove melting pointPolymer scienceAdhesive

Thermoplastic polyurethanes having an alternating sequence of hard and soft segments in which a nanostructured polyhedral oligosilsesquioxane diol is used as a chain extender to form a crystalline hard segment constituting SMPs. The polyurethanes are formed by reacting a polyol, a chain extender dihydroxyl-terminated polyhedral oligosilsesquioxane and a diisocyanate. The polyurethanes have multiple applications including for example, implants for human health care, drug delivery matrices, superabsorbant hydrogels, coatings, adhesives, temperature and moisture sensors, etc.

Owner:UNIV OF CONNECTICUT

Shape memory polymers based on semicrystalline thermoplastic polyurethanes bearing nanostructured hard segments

InactiveUS7524914B2Above the melting point of the POSS domainsAdjustable stiffnessPolymer scienceAdhesive

Thermoplastic polyurethanes having an alternating sequence of hard and soft segments in which a nanostructured polyhedral oligosilsesquioxane diol is used as a chain extender to form a crystalline hard segment constituting SMPs. The polyurethanes are formed by reacting a polyol, a chain extender dihydroxyl-terminated polyhedral oligosilsesquioxane and a diisocyanate. The polyurethanes have multiple applications including for example, implants for human health care, drug delivery matrices, superabsorbant hydrogels, coatings, adhesives, temperature and moisture sensors, etc.

Owner:UNIV OF CONNECTICUT

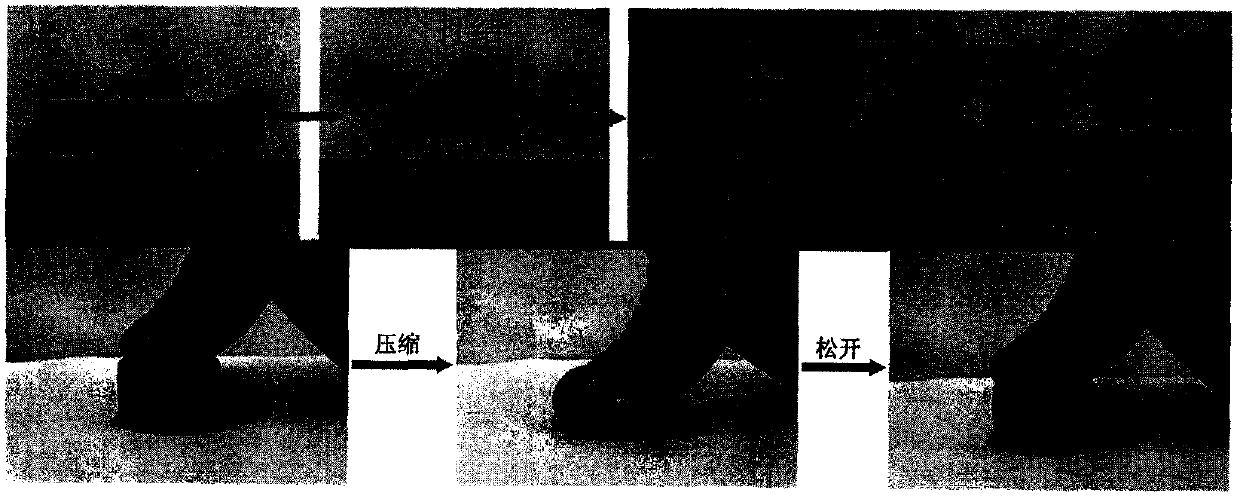

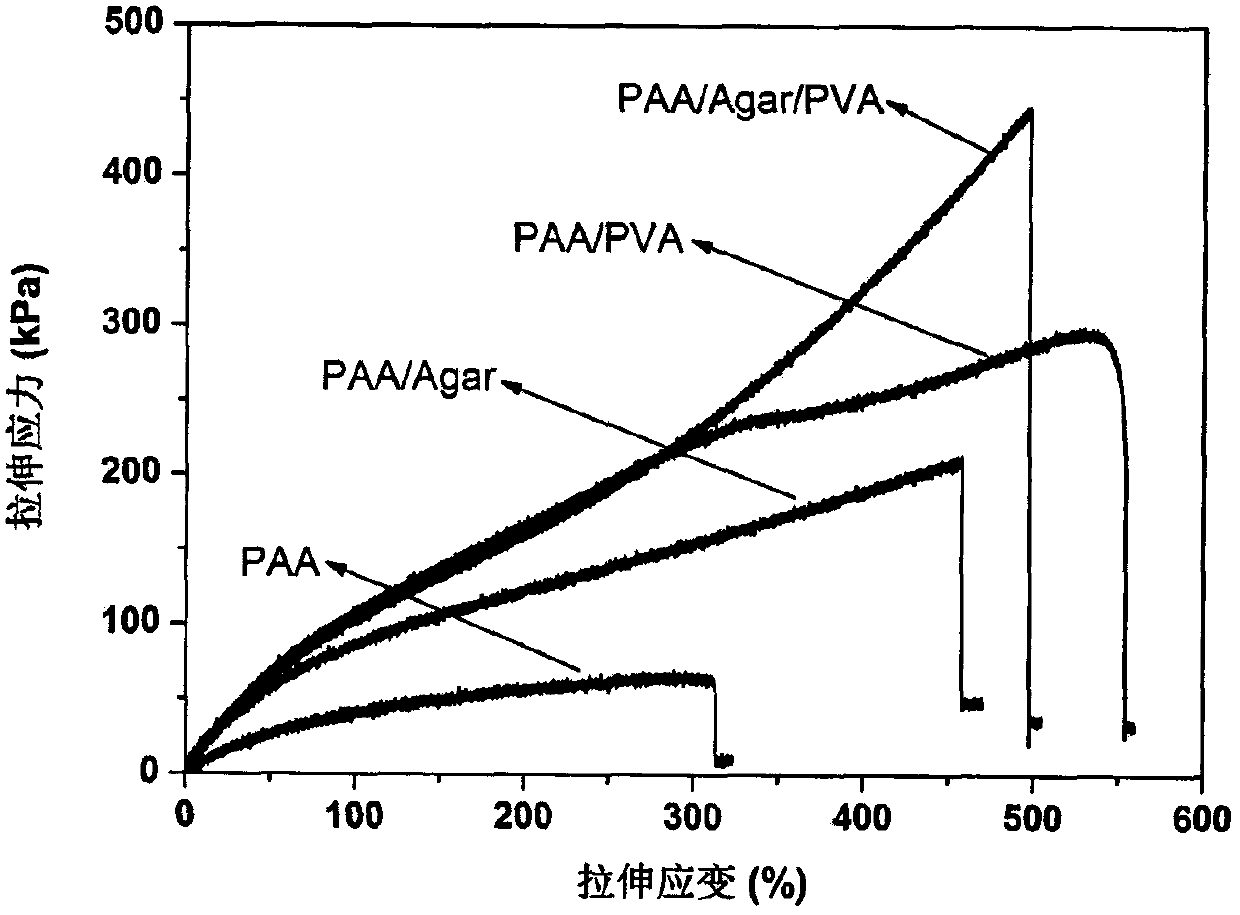

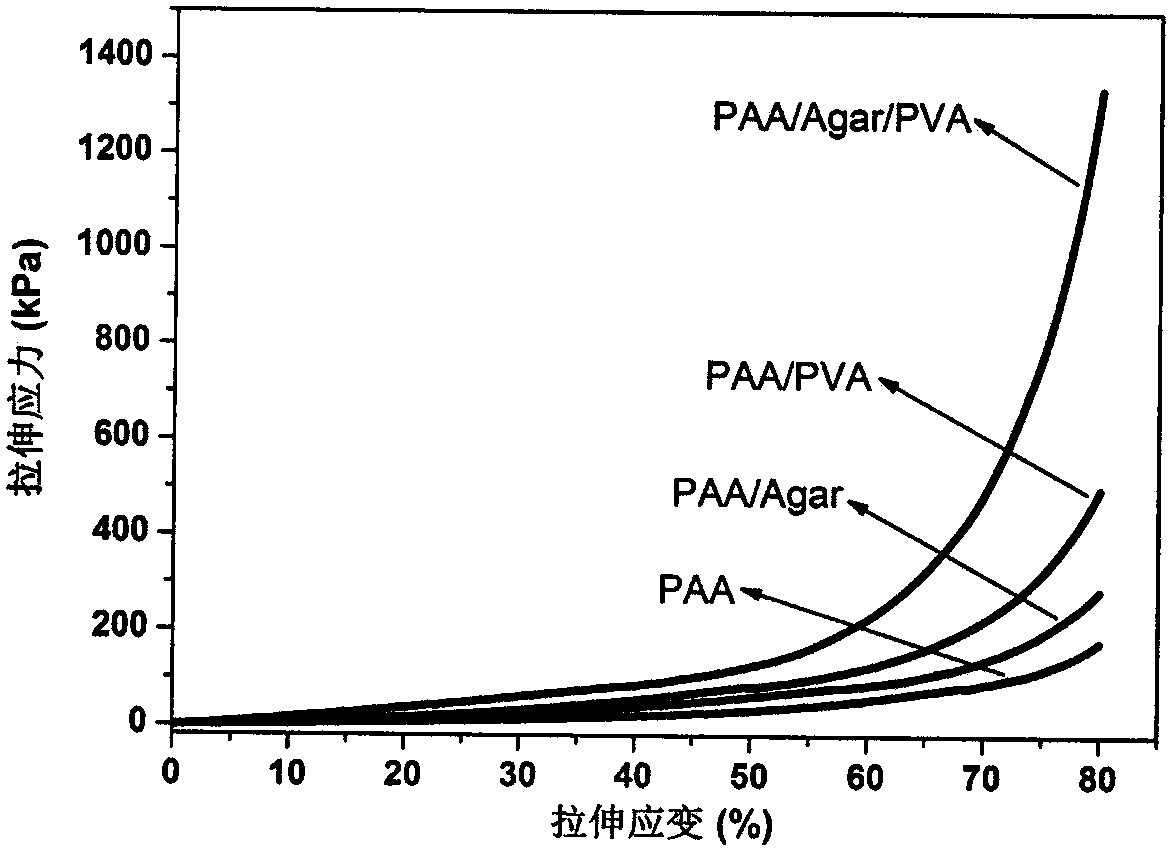

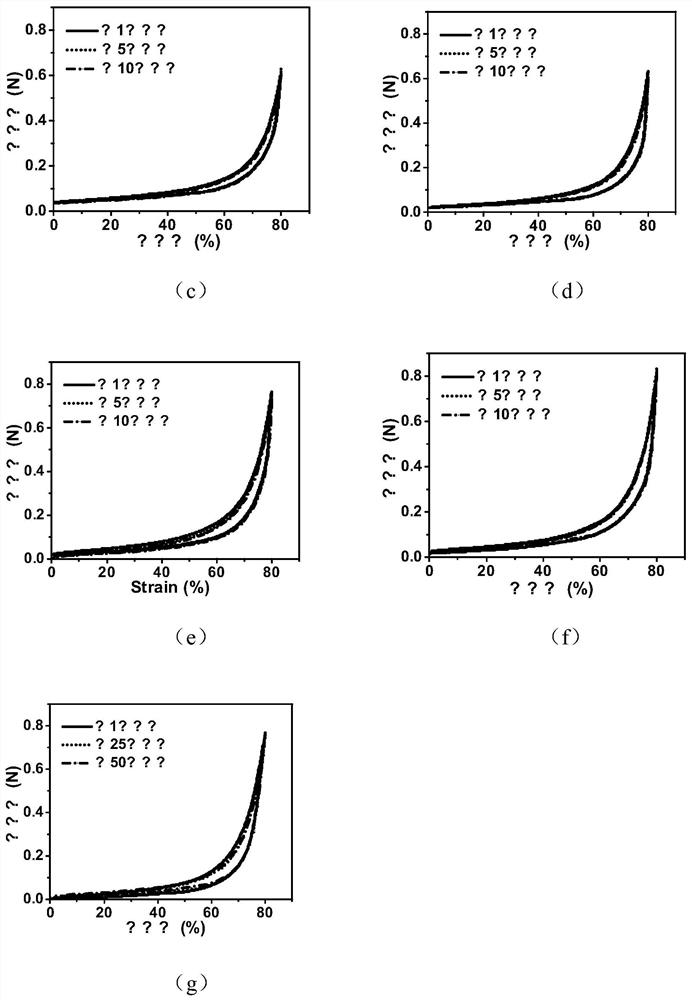

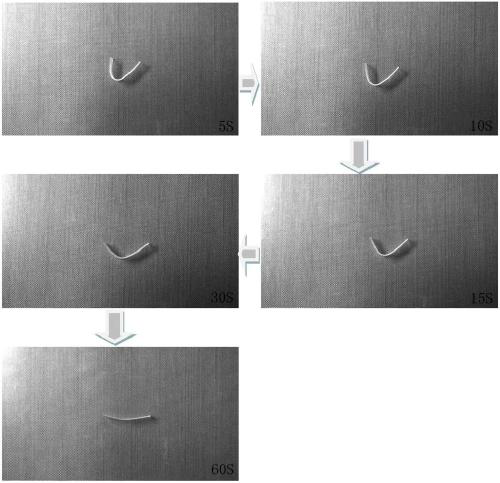

High-strength self-repair three-network hydrogel preparation method

InactiveCN107903406AGood tensile and compressive propertiesExcellent shape recovery performanceFreeze thawingPolyvinyl alcohol

The invention relates to a high-strength self-repair hydrogel preparation method, which comprises: 1, preparing a polyvinyl alcohol, agar and acrylic acid composite solution; and 2, preparing a high-strength self-repair three-network hydrogel. According to the present invention, the high-strength hydrogel is prepared by using the one-pot method through polymerization, cooling and freezing-thaw cycle, wherein the three polymers provide the effects of hydrogen bonding and macromolecular entanglement so as to make the hydrogel have high mechanical strength; during the preparation, iron ions are added, and can form the good coordination effect with the carboxyl group of the polyacrylic acid, such that the hydrogel has good self-repair property; the prepared polyacrylic acid / agar / polyvinyl alcohol three-network hydrogel has advantages of high mechanical strength and good self-repair performance, simple preparation process, wide raw material source, low cost and environmental protection, andcan be used as tissue engineering, scaffold repair materials, agricultural sensors and the like, and can be widely used in biomedical materials, agricultural materials and other fields.

Owner:刘 志勇 +3

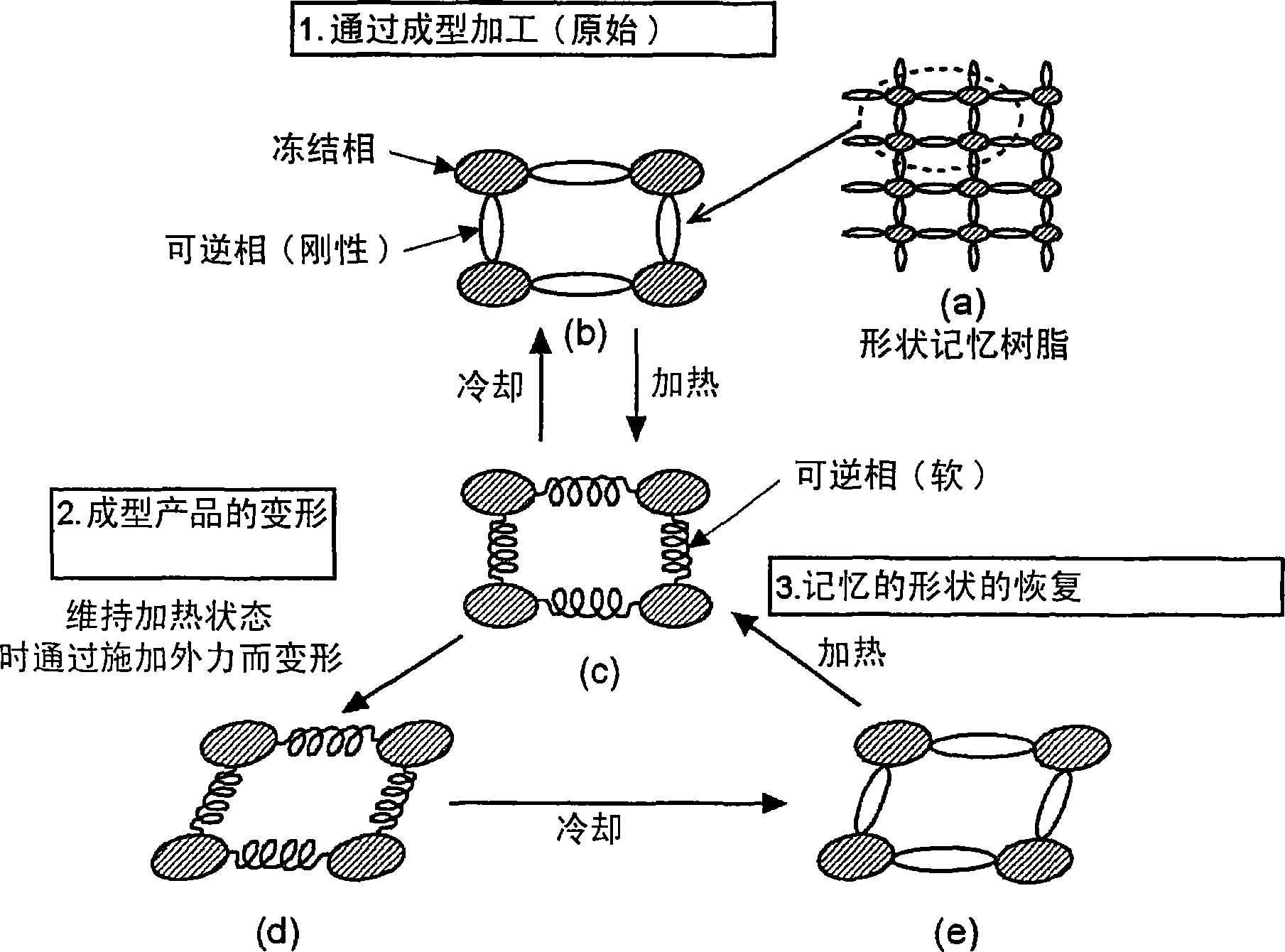

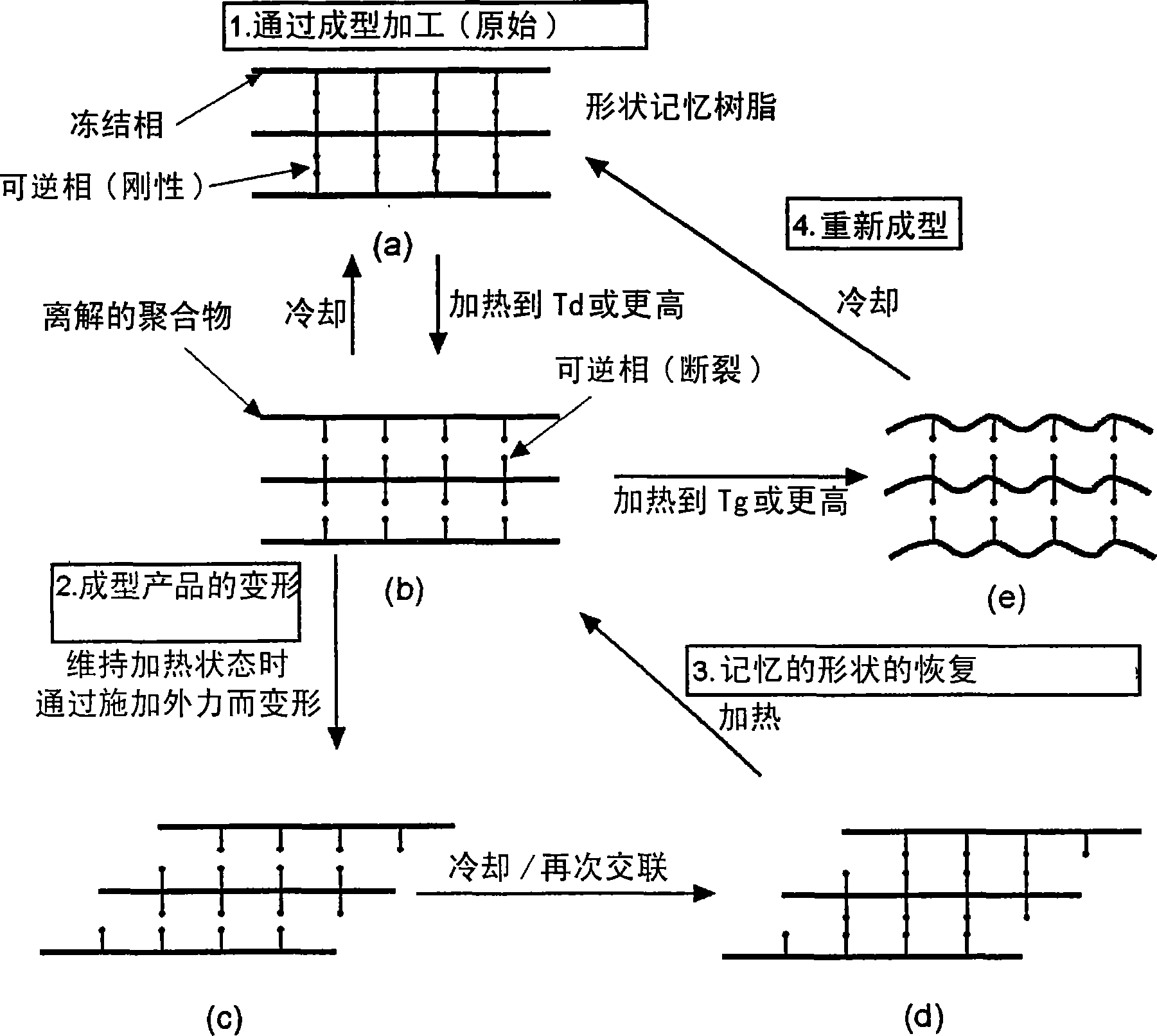

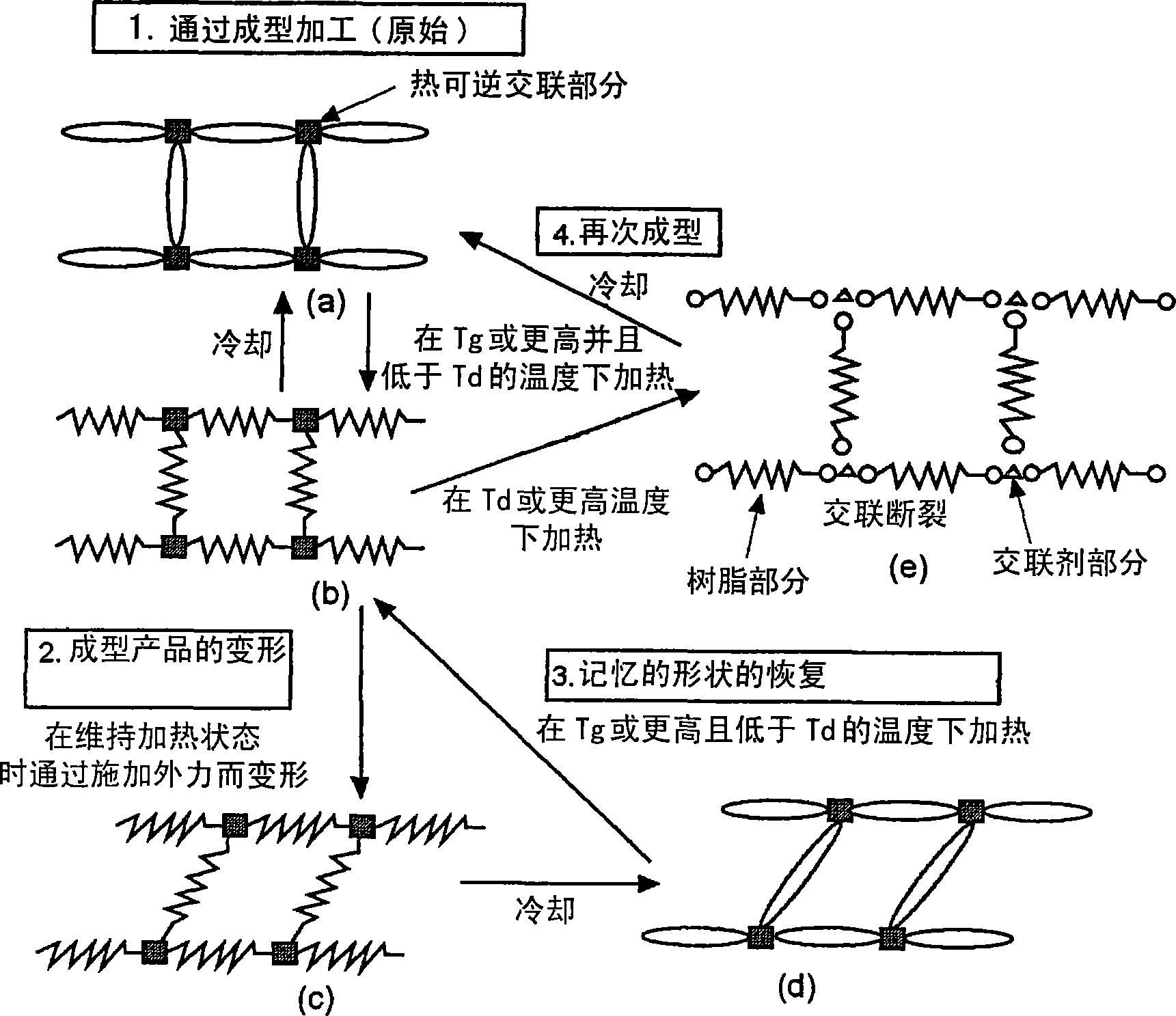

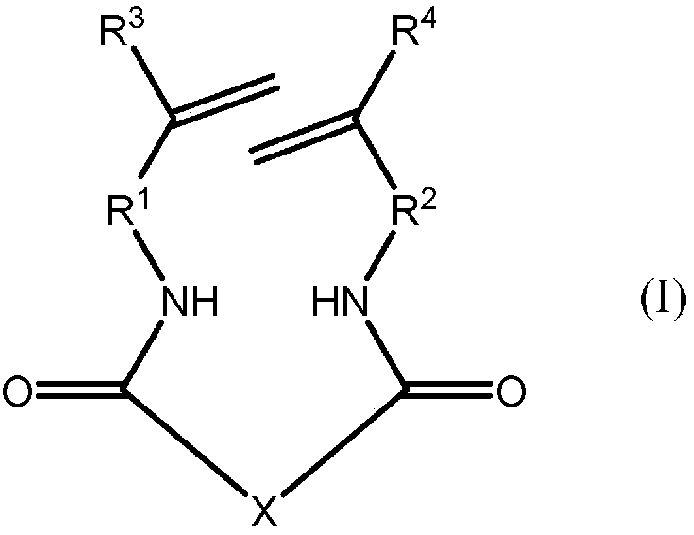

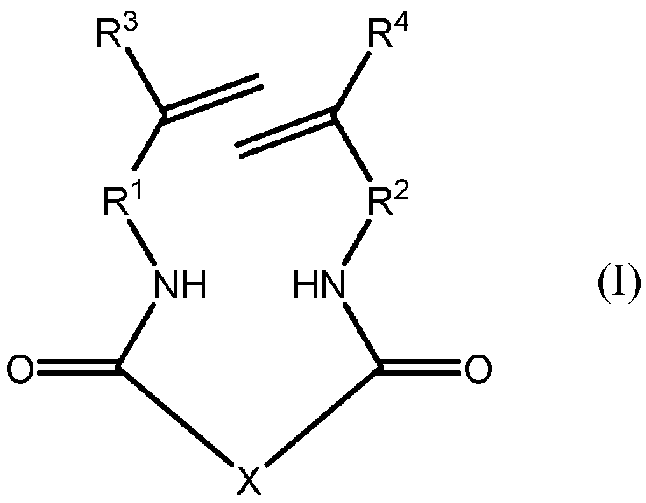

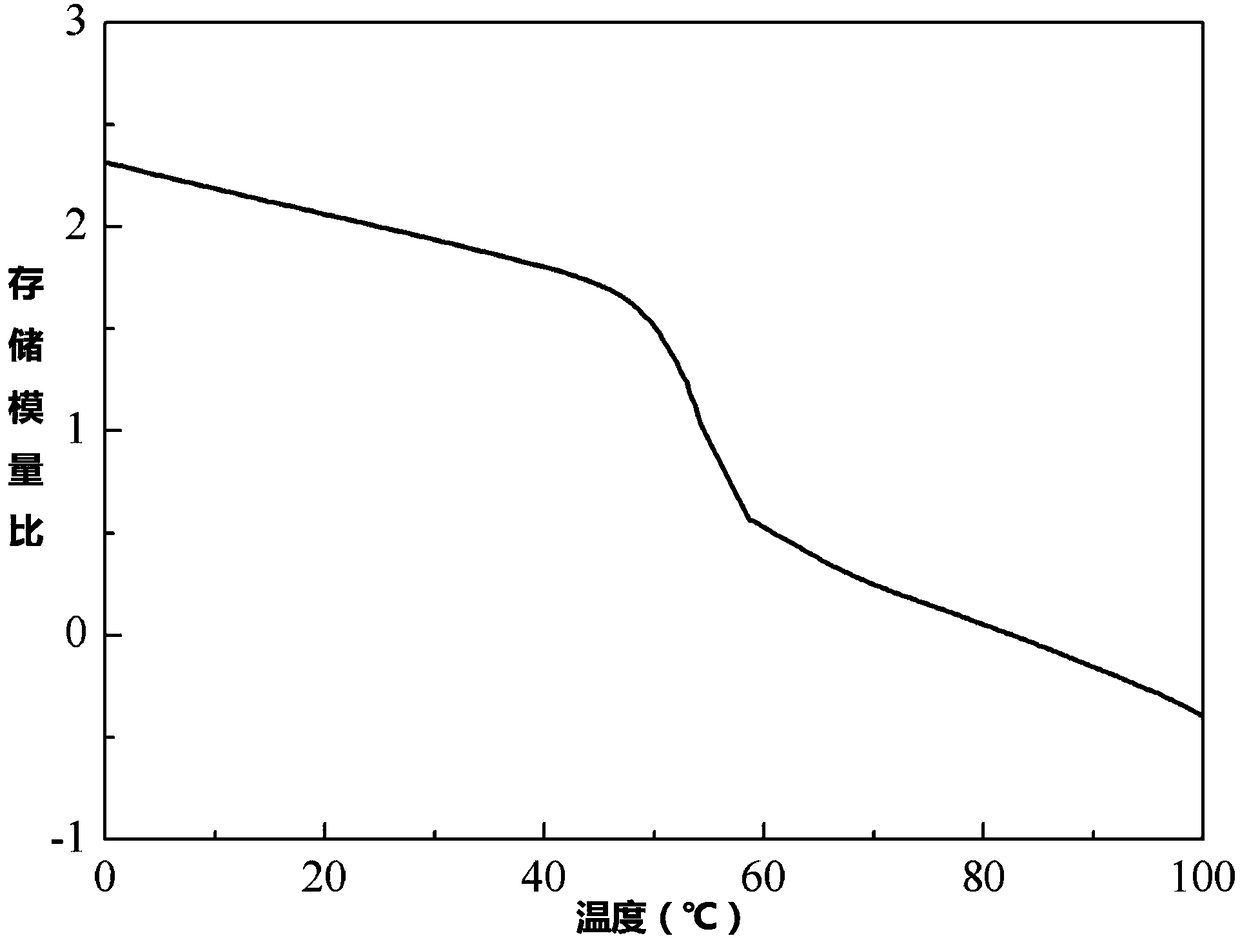

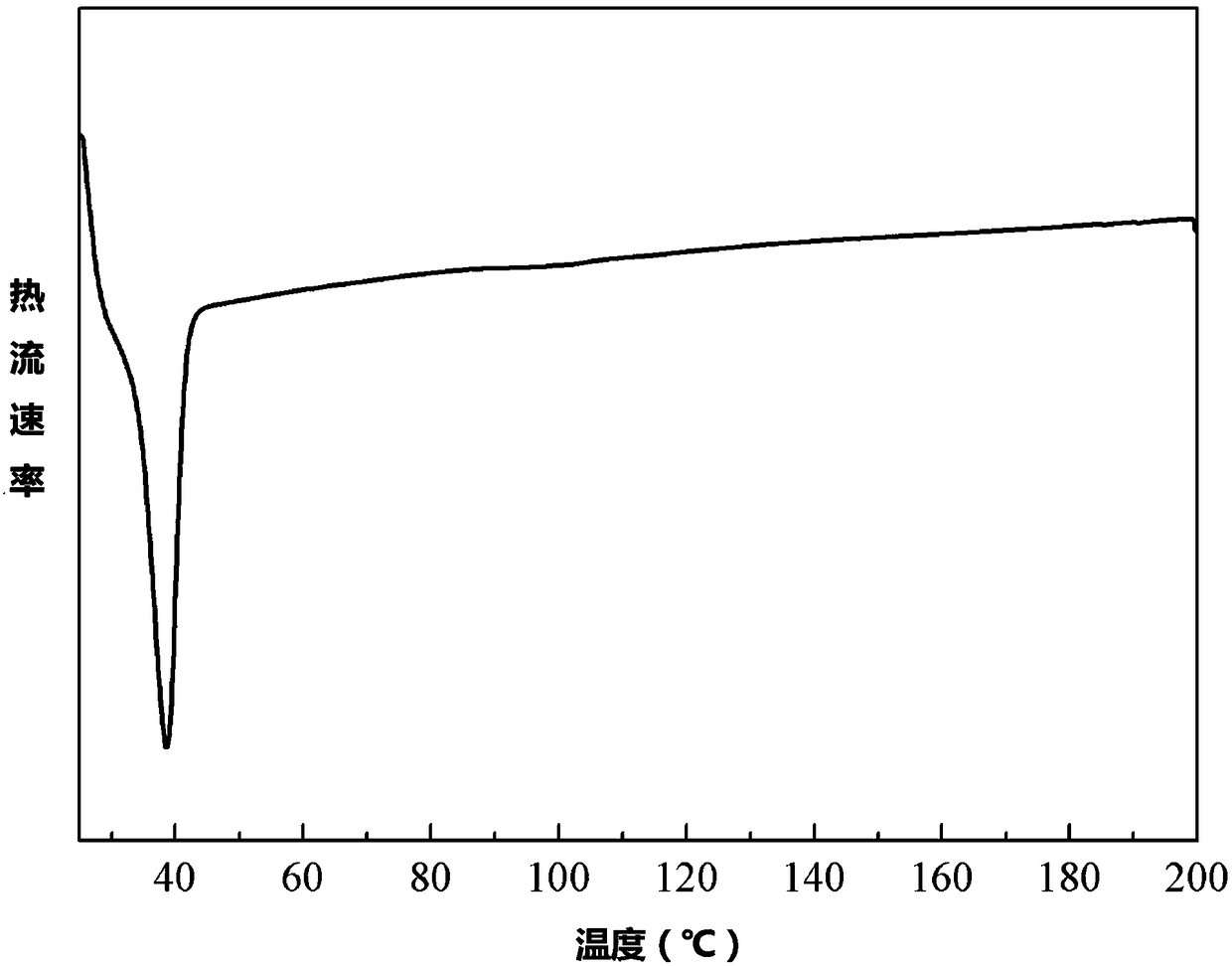

Reshapable shape-memory resin excelling in shape recovery capability and shaped item of the resin having been crosslinked

InactiveCN1894313AExcellent shape recovery performanceEasy to shapeProductsReagentsCross-linkReversible reaction

It is possible to provide a shape-memory molded product having excellent shape-memory properties and recycling efficiency by using a shape-memory resin having a glass transition temperature (Tg) within the range of 40 DEG C. to 200 DEG C. and a dissociation temperature (Td) of a thermo-reversible reaction within the range of 50 DEG C. to 300 DEG C. and satisfying the relationship: Tg+10 DEG C.<=Td, wherein the resin is deformed at a temperature of Tg to less than Td, and cross-linked through a thermo-reversible reaction in which a covalent bond is formed by cooling and dissociated by heating.

Owner:NEC CORP

Shape memory polymers based on semicrystalline thermoplastic polyurethanes bearing nanostructured hard segments

InactiveUS20090253842A1Above the melting point of the POSS domainsAdjustable stiffnessPolymer scienceAdhesive

Thermoplastic polyurethanes having an alternating sequence of hard and soft segments in which a nanostructured polyhedral oligosilsesquioxane diol is used as a chain extender to form a crystalline hard segment constituting SMPs. The polyurethanes are formed by reacting a polyol, a chain extender dihydroxyl-terminated polyhedral oligosilsesquioxane and a diisocyanate. The polyurethanes have multiple applications including for example, implants for human health care, drug delivery matrices, superabsorbant hydrogels, coatings, adhesives, temperature and moisture sensors, etc.

Owner:MATHER PATRICK T +2

Temperature-variable multi-color sponge for powder puff and preparing process thereof

InactiveCN110093027AEasy to operateReduce manufacturing costPackaging toiletriesPackaging cosmeticsWater basedTouch Senses

Temperature-variable multi-color sponge for a powder puff and a preparing process thereof are disclosed in embodiments of the invention, belonging to the technical field of polymer materials. The sponge includes two or more raw materials groups. Each raw material group includes an A component and a B component in a weight ratio of 1.5-2.5:0.8-1.2, wherein the A component includes, by weight, 40-50% of a filler, 1.7-4% of a surfactant, 1-2% of an emulsifier, 0.5-1% of temperature sensing toner powder, and 0.3-1% of water-based color paste, with the balance being water; the B component is a hydrophilic polyurethane prepolymer; and the sponge includes two or more types of temperature sensing toner powder. The sponge enables no dispersion of the toner powder, shows color of the added temperature sensing toner powder, has good physical properties, low smell grade, good environment protection performance, good shape recovery capability and touch sense, and is suitable for cosmetics.

Owner:雅丽日化实业(惠州)有限公司 +1

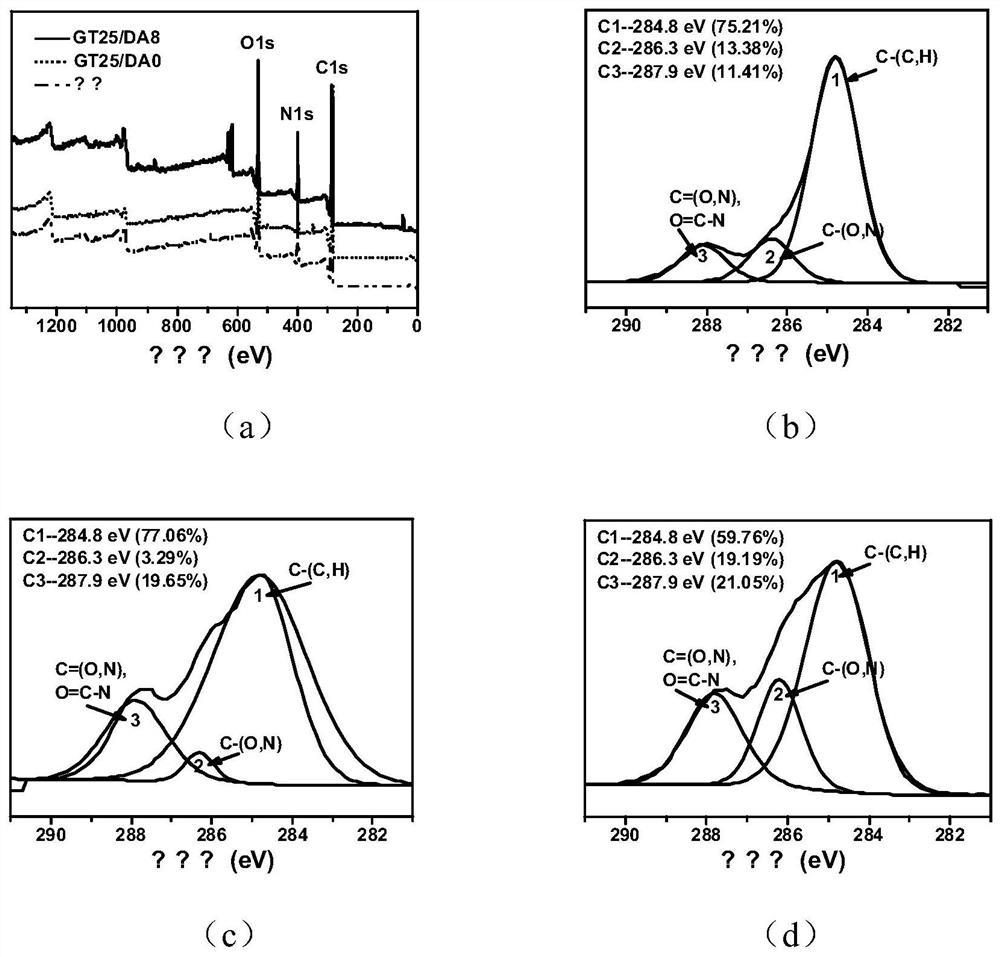

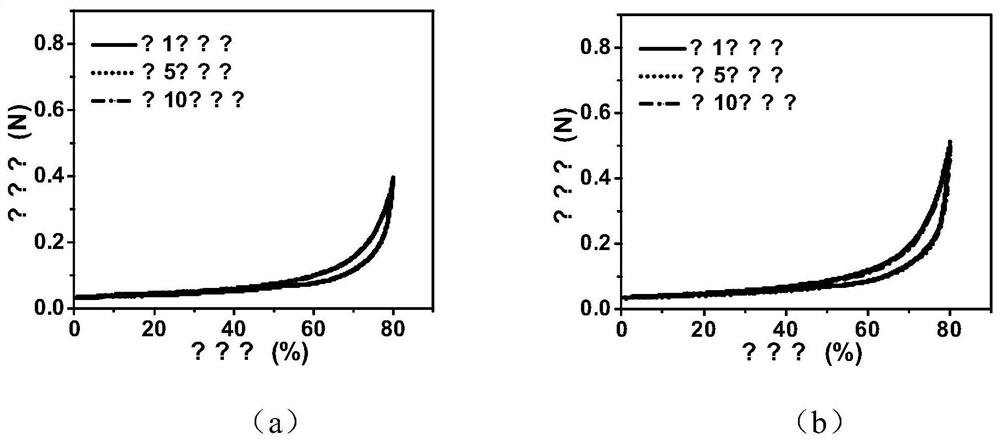

Cryogel for stopping bleeding and carrying anti-cancer drug and preparation method thereof

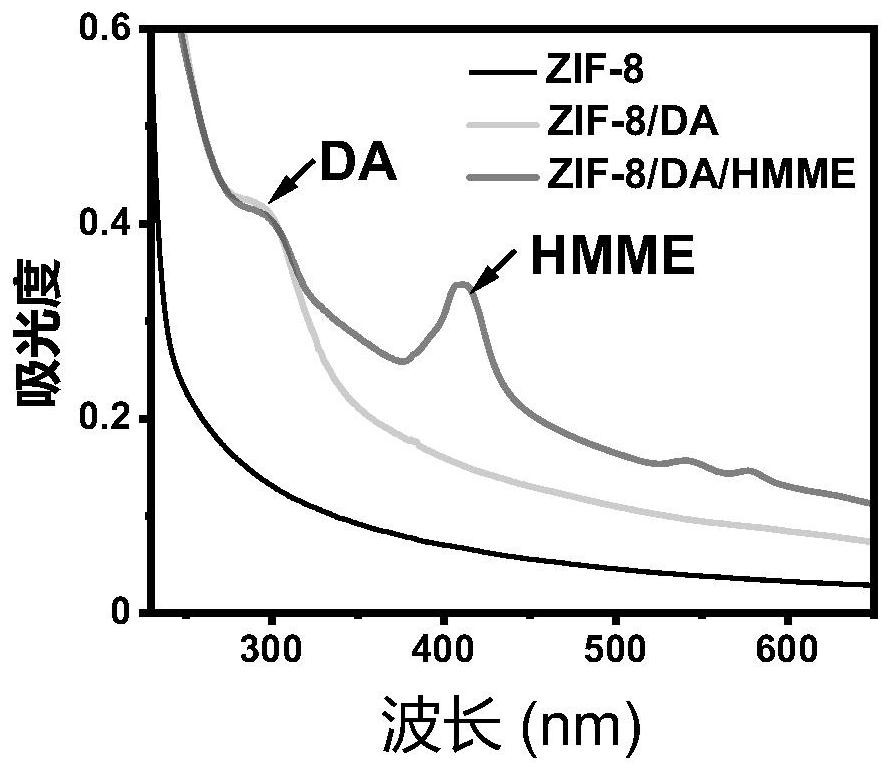

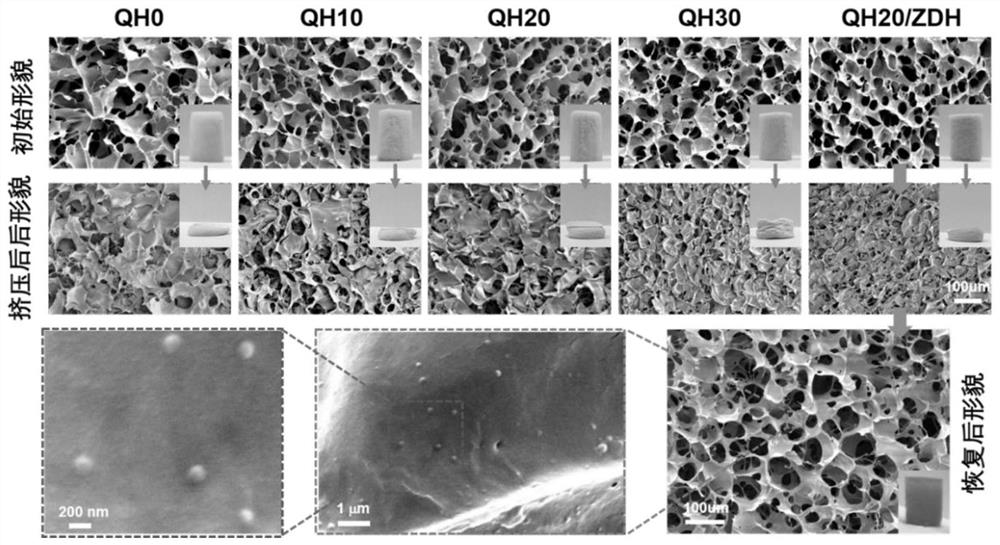

ActiveCN112933286AGood hemostatic effectGood tissue adhesionSurgical adhesivesNanocapsulesDouble bondPolyphenol

The invention discloses a cryogel for stopping bleeding and bearing an anti-cancer drug and a preparation method thereof, the preparation method comprises the following steps: a double bond is modified to a biomacromolecule, a polyphenolic compound is grafted onto the biomacromolecule, and the dopamine molecule and the Zn 2 + ion are coordinated to prepare dopamine-modified ZIF -8; and all the components are respectively prepared into aqueous solutions or dispersion solutions, and then under the action of an initiator, through double-bond polymerization, the multifunctional water / blood triggered shape memory cryogel l is formed at low temperature. According to the preparation method, polysaccharide and other biomacromolecules with good biocompatibility and degradation performance are taken as the basis, the process of chemical grafting of double-bond or polyphenol compounds also has the characteristics of low toxicity and no pollution, the used double-bond functionalized biomacromolecules are simple to prepare, the synthesis technology is mature, and the prepared product has good universality.

Owner:XI AN JIAOTONG UNIV

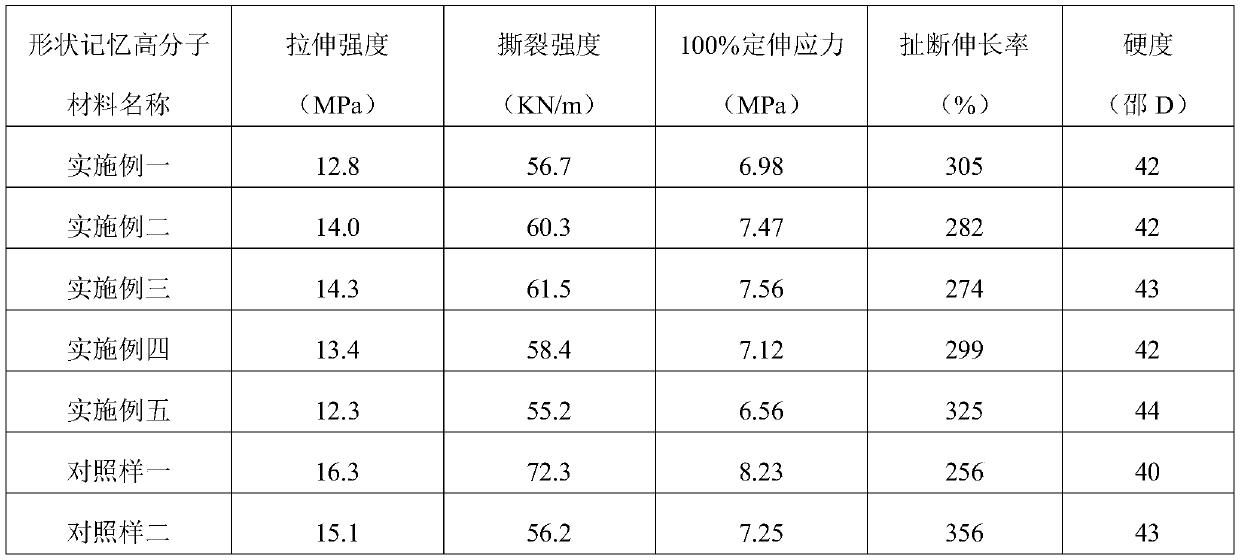

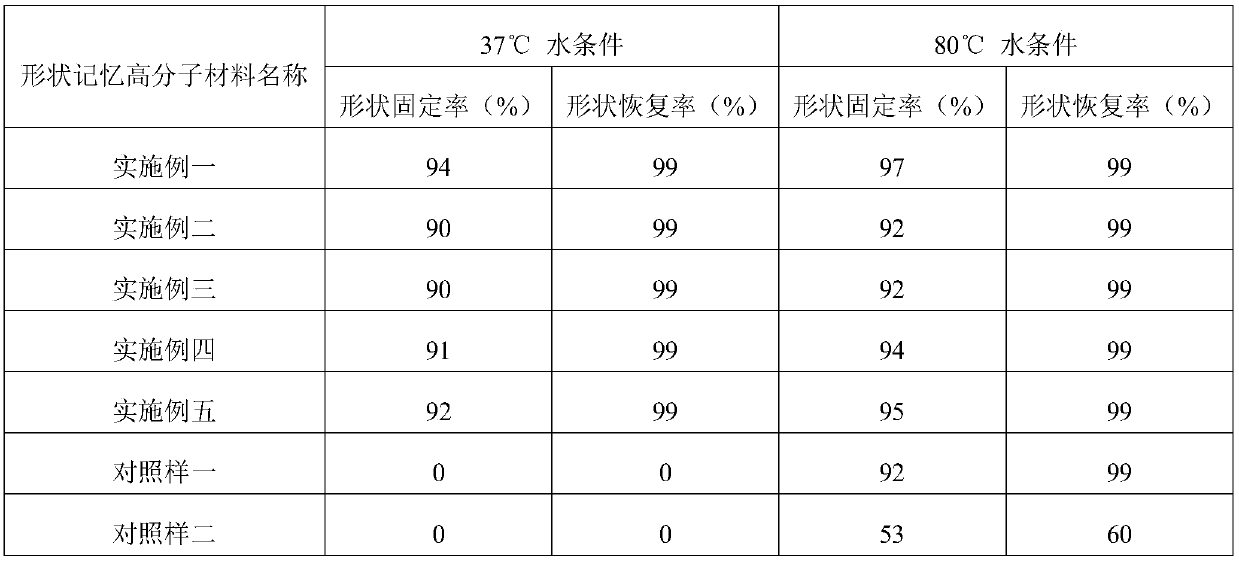

Shape memory high polymer material with eucommia ulmoides rubber and preparation method of shape memory high polymer material

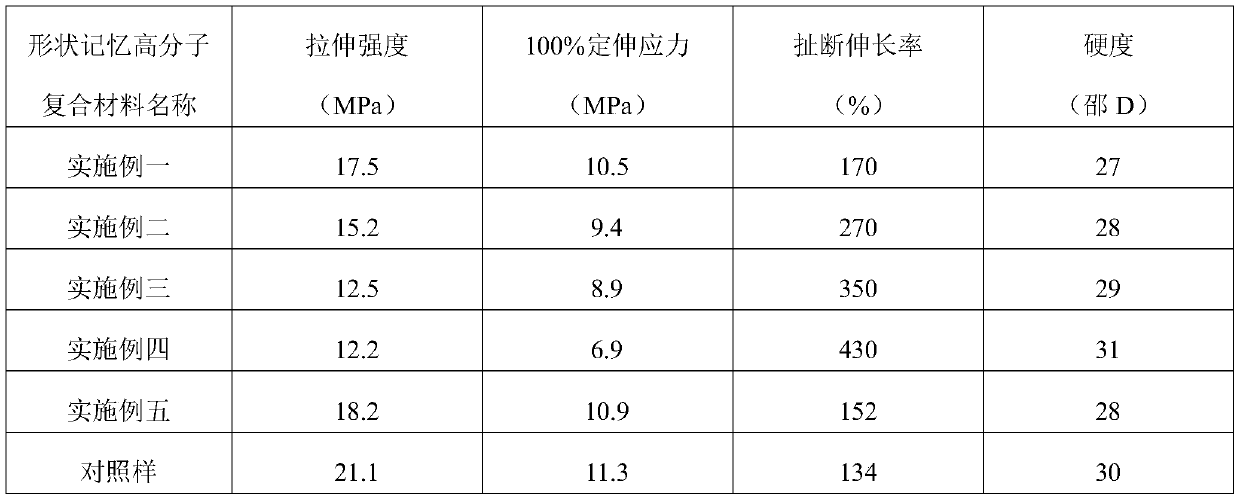

ActiveCN110591188AGood dispersionRetains thermotropic shape memory propertiesPolymer scienceHydroxyethyl cellulose

The invention discloses a shape memory high polymer material with eucommia ulmoides rubber and a preparation method of the shape memory high polymer material. The shape memory high polymer material comprises the following raw materials in parts by weight: 100 parts of eucommia ulmoides rubber, 10-30 parts of a functional filler, 0.5-3 parts of a vulcanizing agent and 0-5 parts of a processing aid,wherein the eucommia ulmoides rubber is carboxyl modified eucommia ulmoides rubber; and the functional filler is one or more of microcrystalline cellulose, hydroxymethyl cellulose, hydroxyethyl cellulose, hydroxypropyl cellulose, starch, water-soluble chitin and gelatin. The invention further discloses the preparation method of the high polymer material. Through a hydroxyl reaction of functionalcarboxyl on the carboxyl modified eucommia ulmoides rubber with the surface of the functional filler, not only is a thermotropic shape memory property of a conventional base material retained, but also the high polymer material has a function of responding to water stimulation, the high polymer material has a property of synergetic response to dual stimulation of water and heat, mechanical properties can be improved, and the application range can be widened.

Owner:QINGDAO UNIV OF SCI & TECH

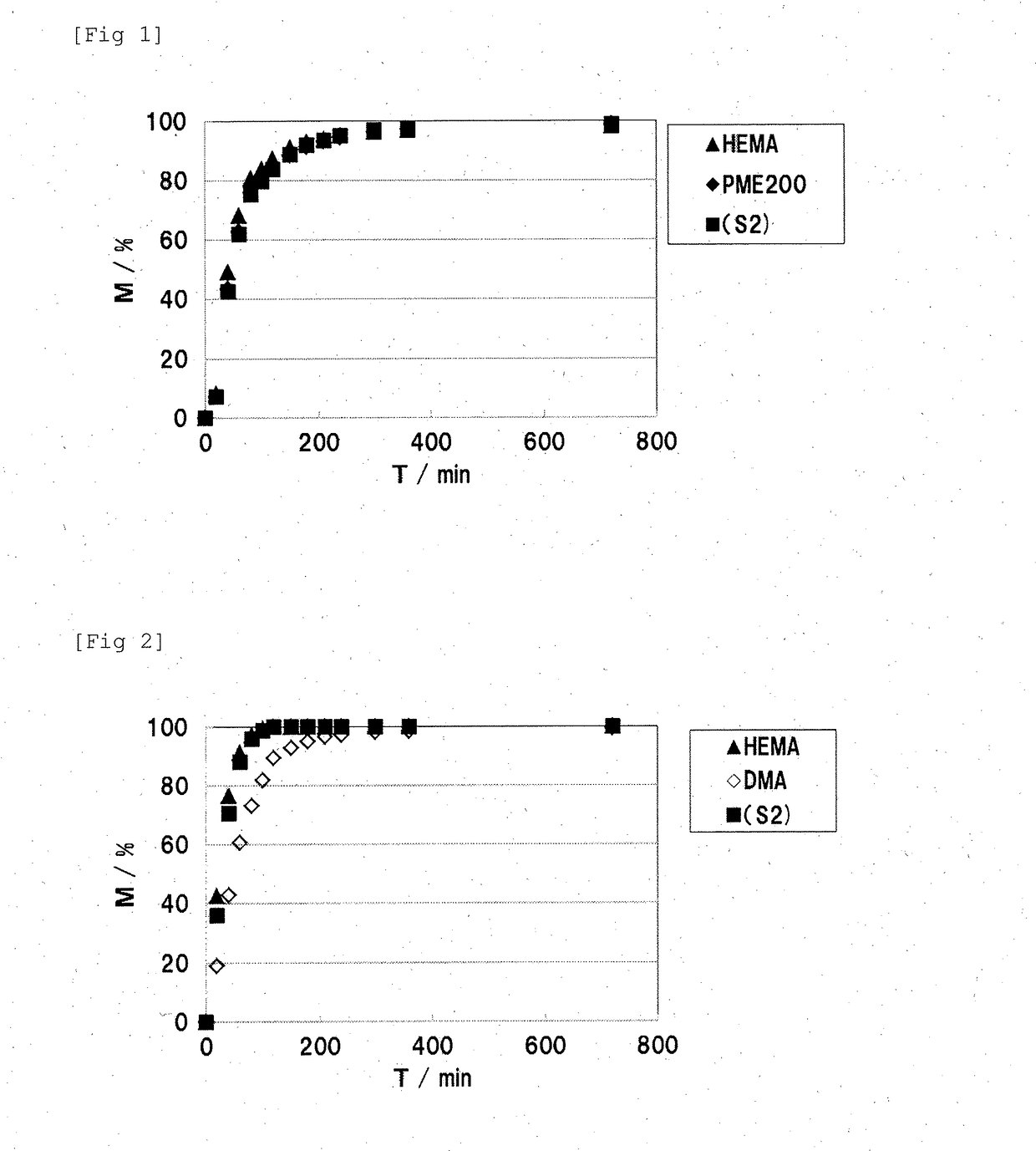

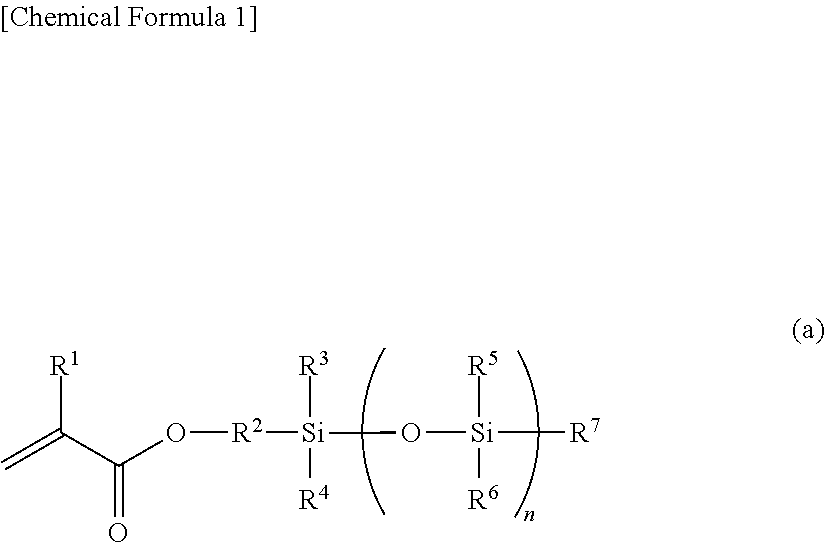

Silicone hydrogel, medical device, lens for eye and contact lens (as amended)

ActiveUS20170204213A1High uniformity of polymerization rateMaintain good propertiesTissue regenerationProsthesisOptical propertyMeth-

In order to provide a silicone hydrogel which has high uniformity in polymerization rates of polymerization components used for copolymerization, excellent mechanical characteristics, excellent optical characteristics and good shape recoverability and in order to also provide various medical devices and ocular lenses having an excellent balance among elasticity, wettability and transparency, the present invention provides a silicone hydrogel which has a repeating unit derived from a monofunctional linear silicone (meth)acrylate and a repeating unit derived from a hydrophilic (meth)acrylate, and wherein the content of the repeating units derived from (meth)acrylates is more than 80% by mass.

Owner:TORAY IND INC

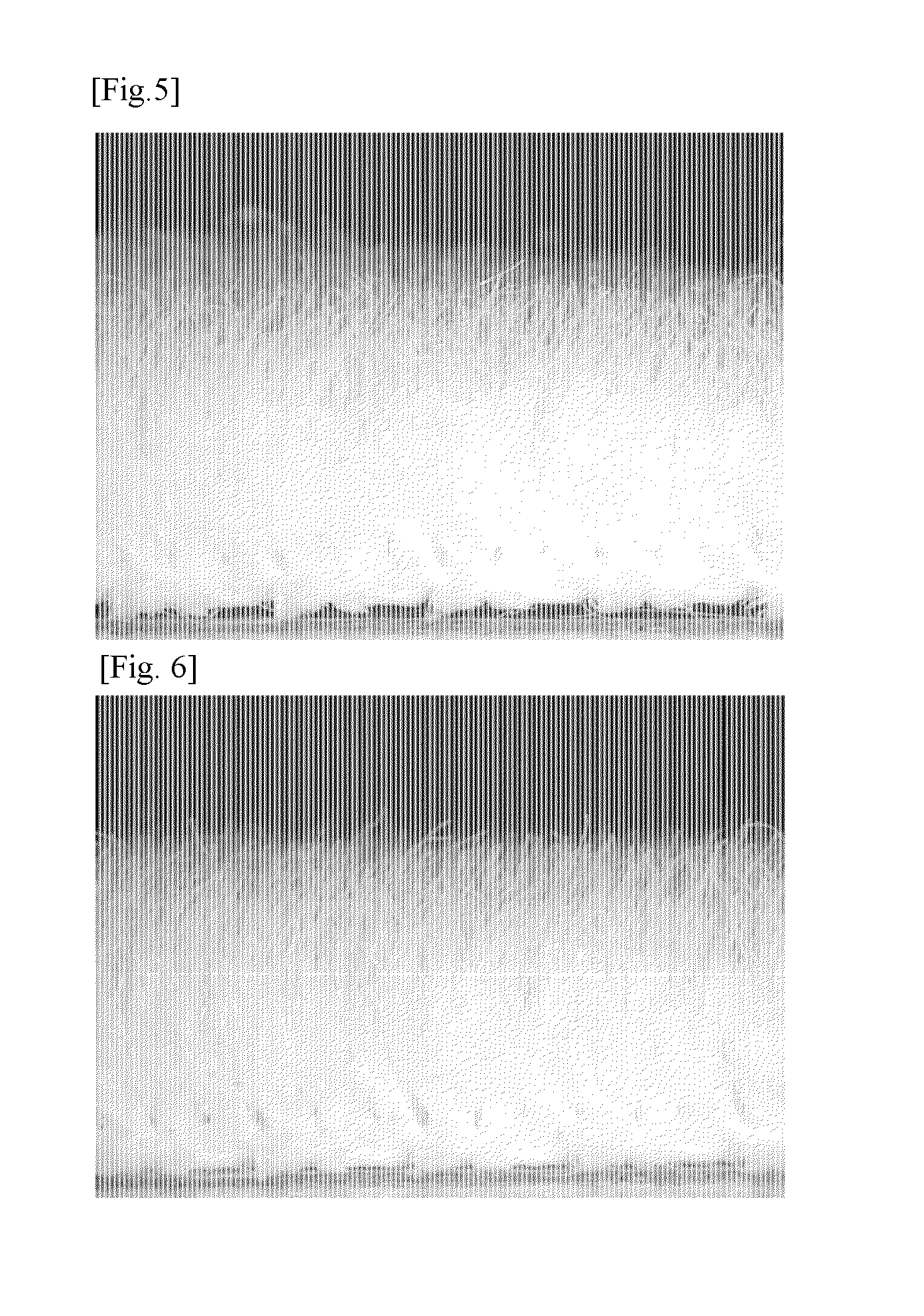

Cosmetic puff

InactiveUS20150173485A1Many applicationsExcellent shape recovery performancePackaging toiletriesPackaging cosmeticsPolytrimethylene terephthalateBiomedical engineering

Provided is a cosmetic puff whose cosmetic application side uses a double raschel knitted fabric knitted from polytrimethylene terephthalate fibers to a 28 gauge, so that the cosmetic puff offers more flexibility and better shape restorability, transfers as much of the scraped-off cosmetic as possible to the skin and consequently maintains a clean puff surface after use, and demonstrates excellent washing resistance, as well.

Owner:KK TAIKI

Biodegradable cryogel dressing as well as preparation method and application thereof

ActiveCN111905144AGood shape fixationExcellent shape recovery performanceAntibacterial agentsAerosol deliveryChemical compoundBiocompatibility

The invention discloses a biodegradable cryogel dressing as well as a preparation method and application thereof, and belongs to the technical field of biomedical materials. Amino compounds are selected as main components, and the selected amino compounds have good biocompatibility and can be degraded in organisms. Therefore, the amidation reaction of amino and carboxyl in the amino compound is catalyzed by EDC hydrochloride and NHS to form a basic network structure of the cryogel. The cryogel dressing is holes communicating with each other in a free state, compared with the cryogel dressing in a shape free state, the cryogel dressing in a shape fixed state is a collapsed and closed hole, but a cryogel dressing sample still keeps an undamaged network structure. The preparation method disclosed by the invention is simple and low in cost, the biodegradable cryogel dressing is easy to carry and biodegradable, and the prepared cryogel dressing can be used for quickly stopping bleeding andhas huge potential in serving as a novel hemostatic for promoting wound healing.

Owner:XI AN JIAOTONG UNIV

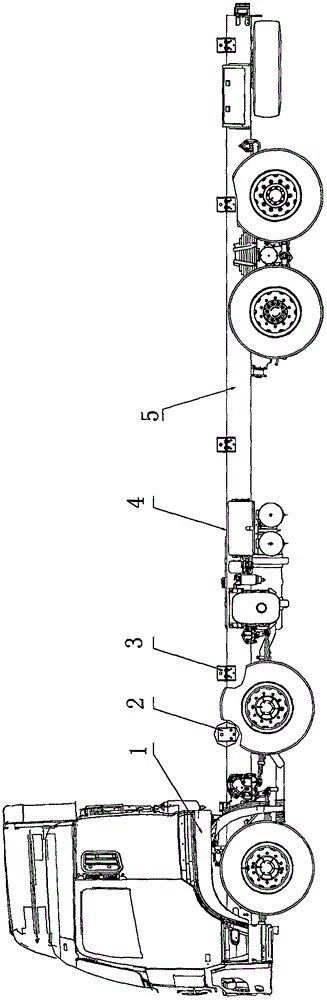

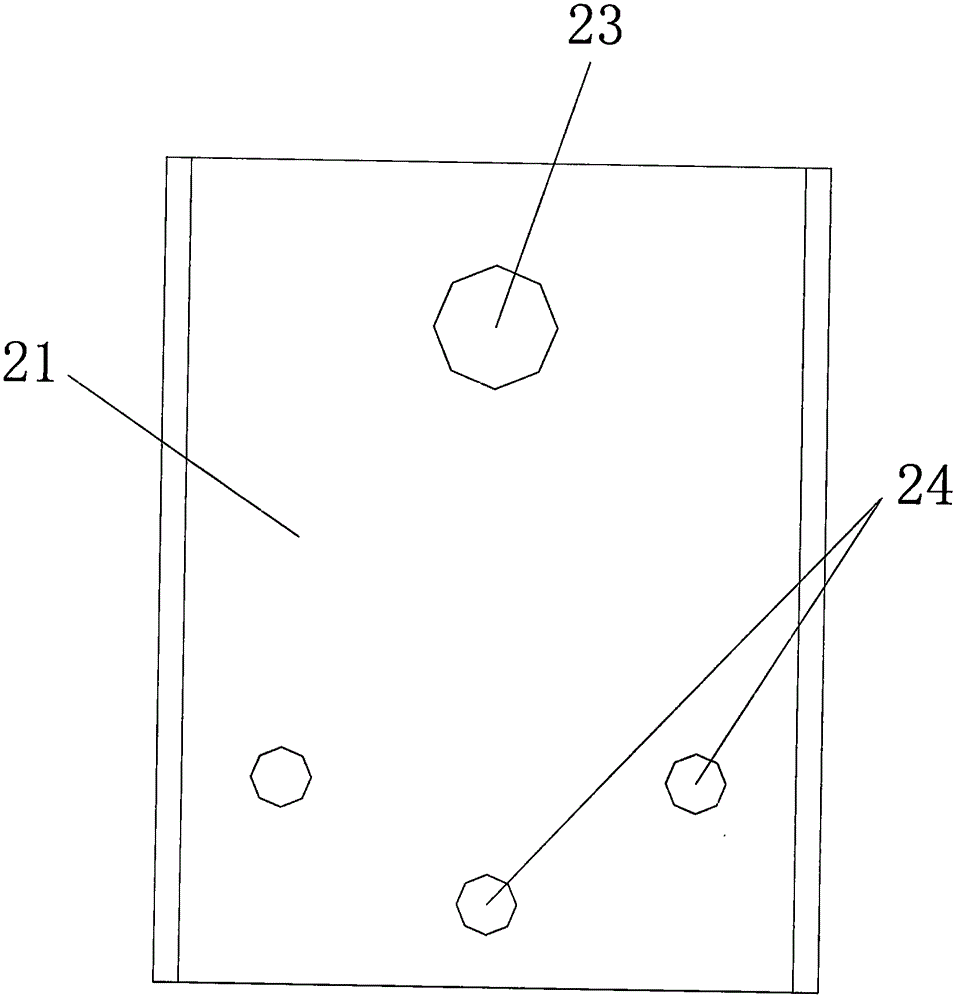

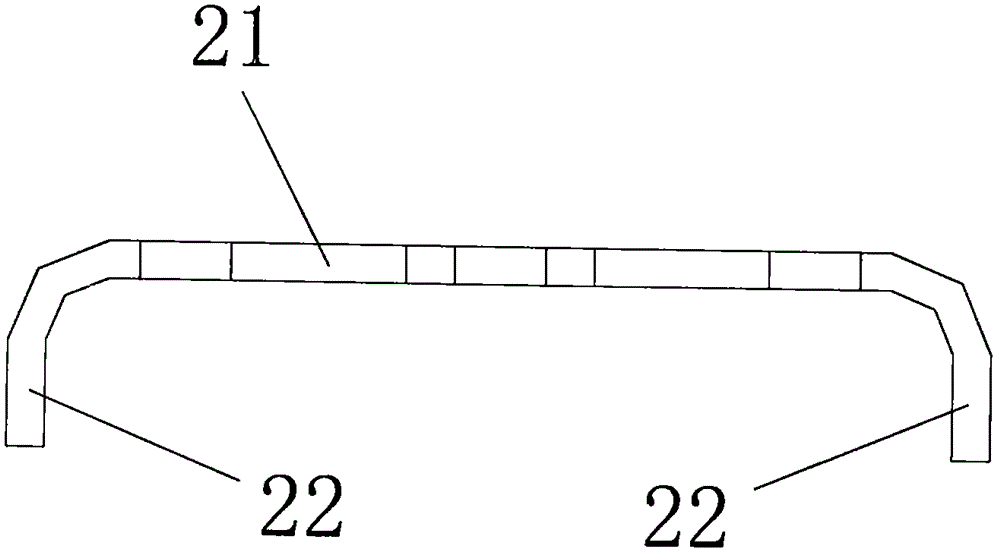

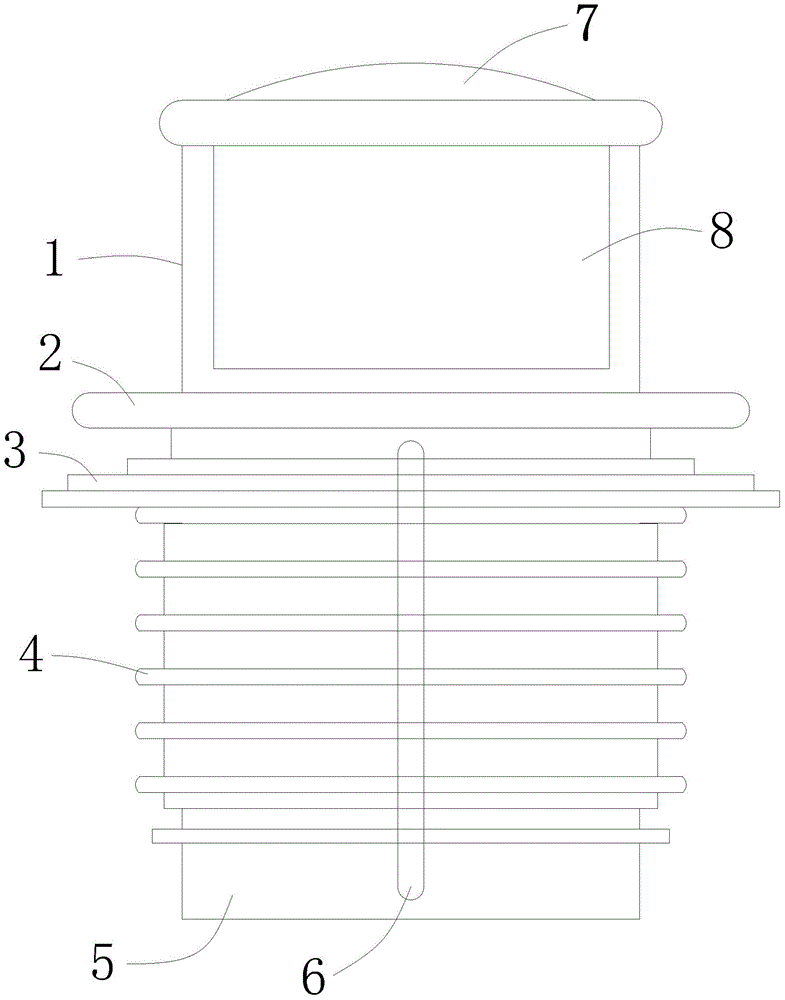

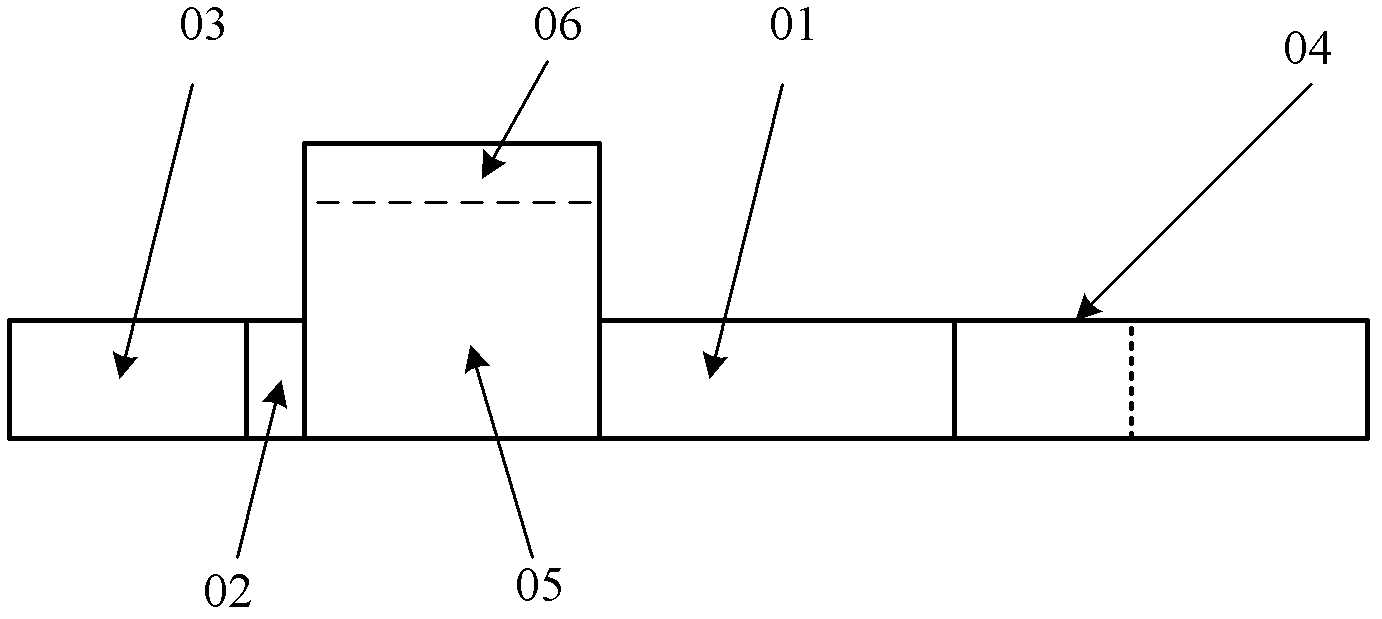

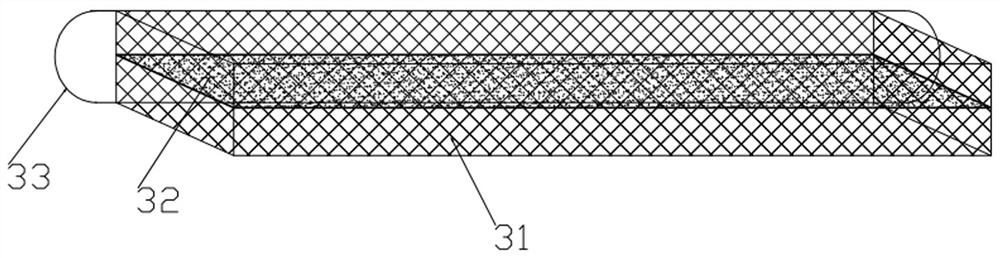

Damping chassis of bulk fodder transport cart

ActiveCN106043093AGuaranteed stabilityExcellent shape recovery performanceTank vehiclesItem transportation vehiclesVehicle frameEngineering

The invention provides a damping chassis of a bulk fodder transport cart. The damping chassis comprises a cart frame and a fodder tank arranged on the cart frame. The damping chassis is characterized in that a set of thrust plates and four sets of tank mounting supporting feet are symmetrically arranged on longitudinal beams on the two sides of the cart frame; the contact face of the upper ends of the longitudinal beams and the fodder tank is provided with flat tape; the flat tape comprises a framework layer; the upper end face of the framework layer is coated with a first resin layer, and the upper end face of the first resin layer is coated with a base cloth layer; and the lower end face of the framework layer is coated with a second resin layer, the lower end face of the second resin layer is coated with a base cloth layer, and the lower end face of the base cloth layer is coated with an adhesive layer. The chassis assembly can be directly used for assembling of the fodder tank, the thrust plates can be used for limiting and keeping the stability of the tank, the flat tape arranged between the tank and the cart frame is of a multi-layer buffer structure, the shape restorability is good, layering and aging are not liable to occur, and the service life is long.

Owner:安徽传旗重科装备制造有限公司

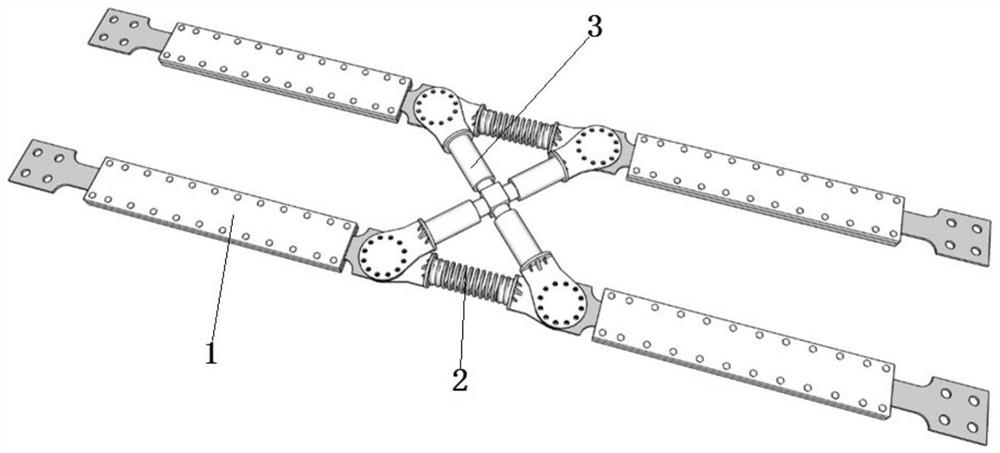

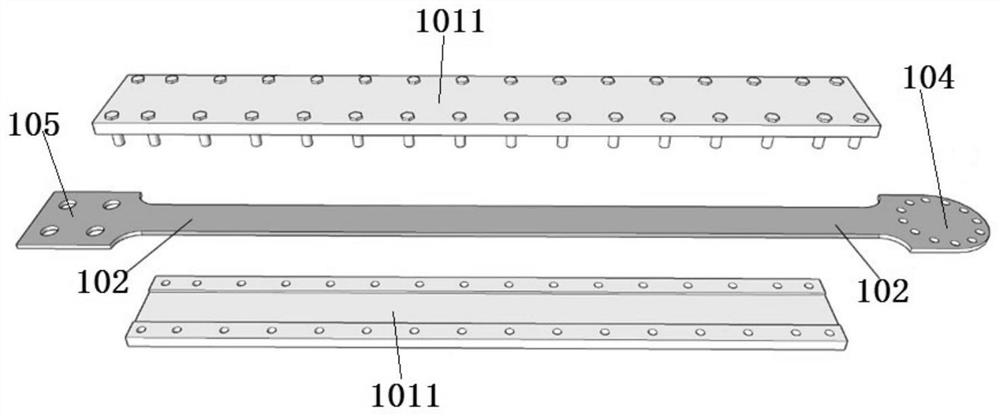

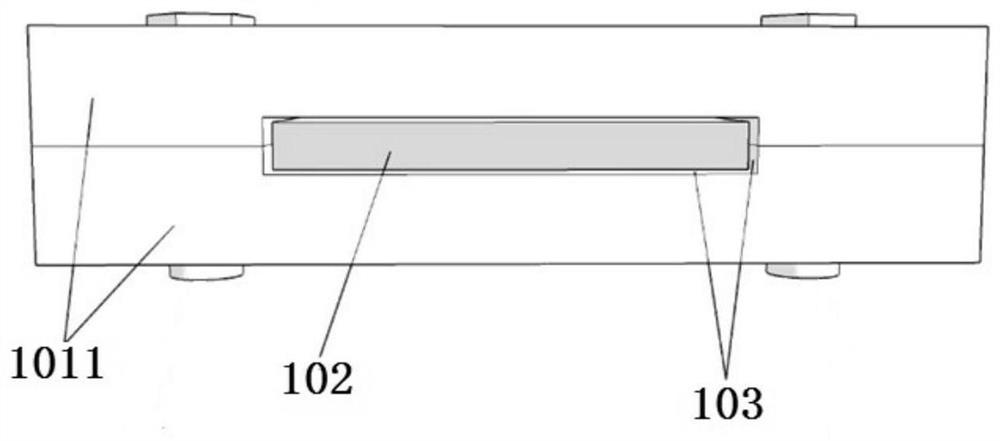

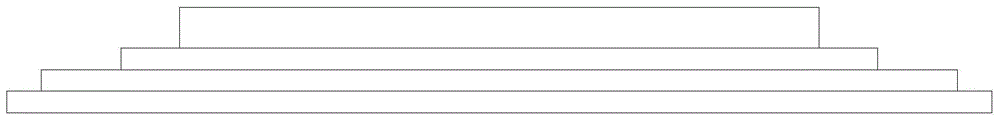

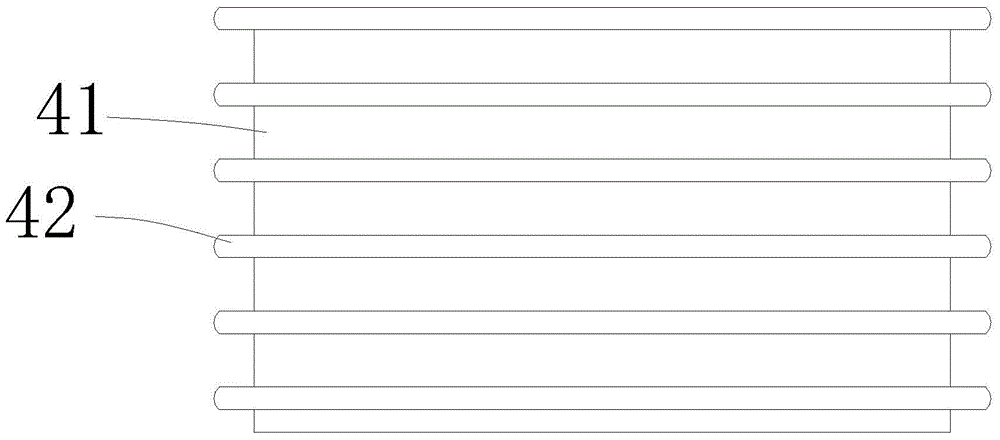

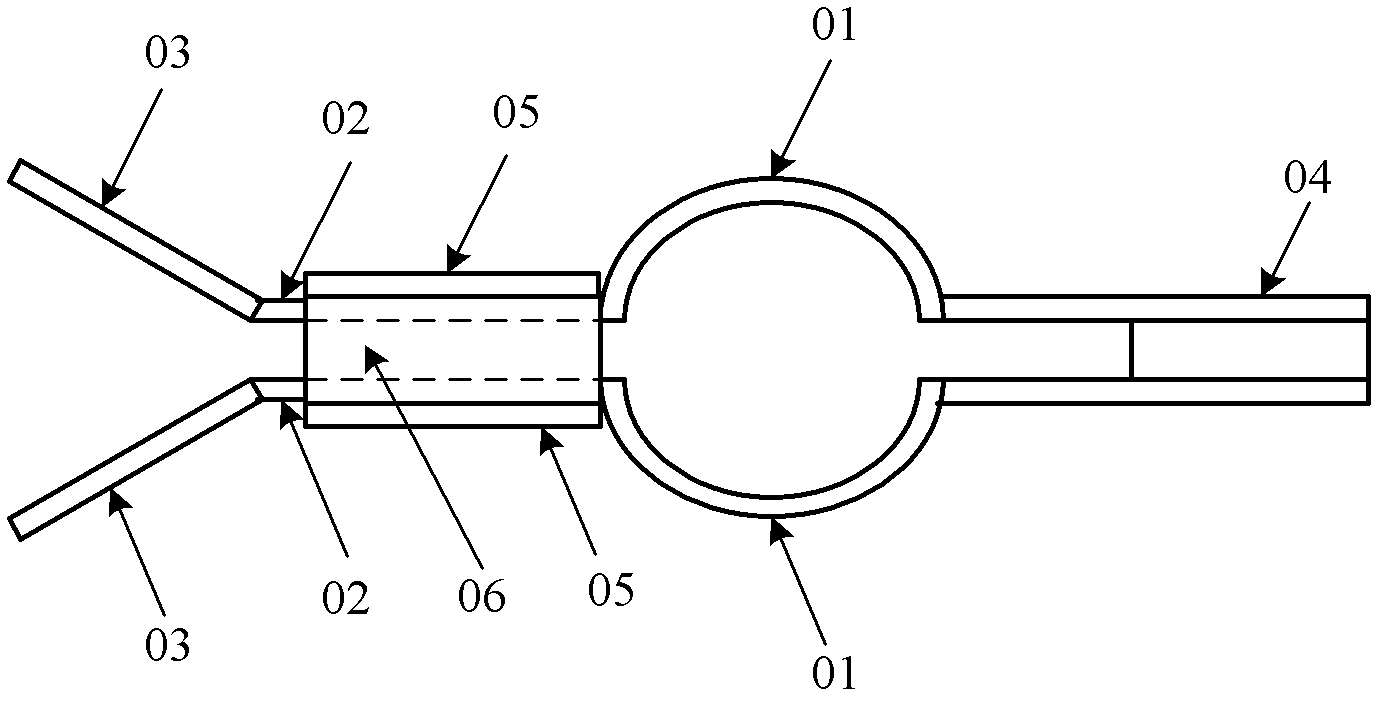

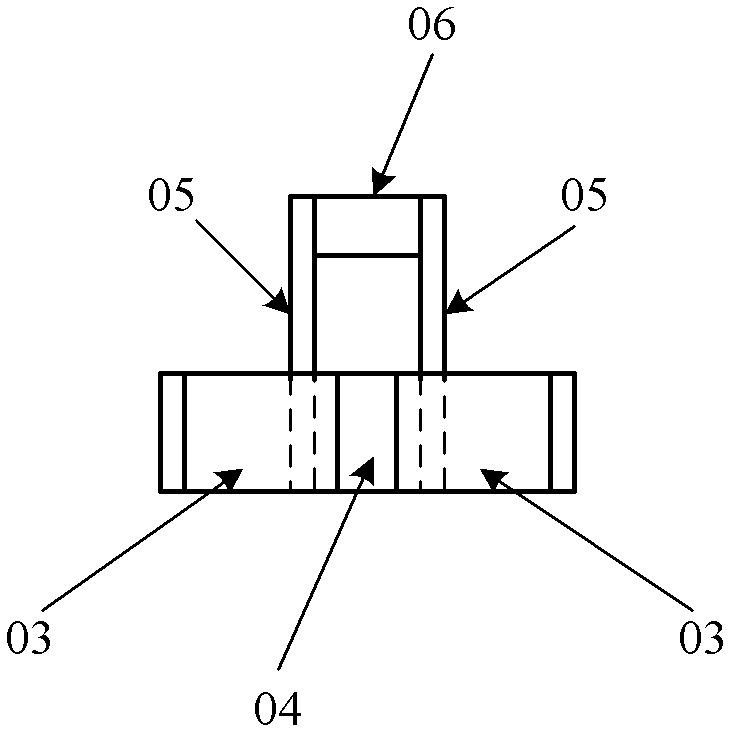

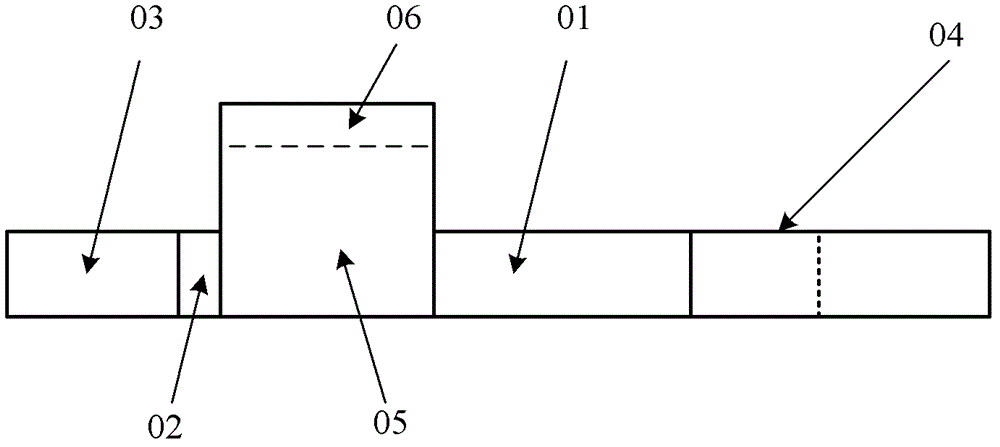

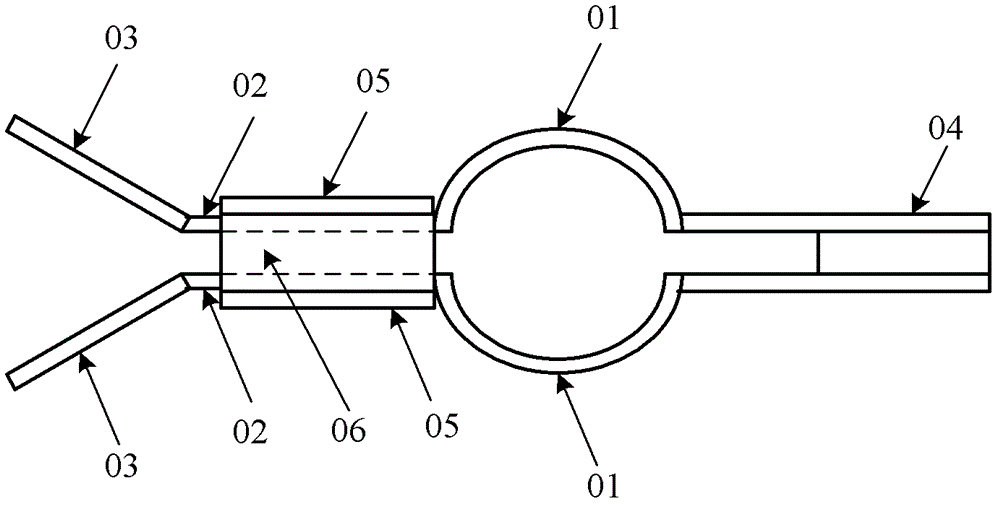

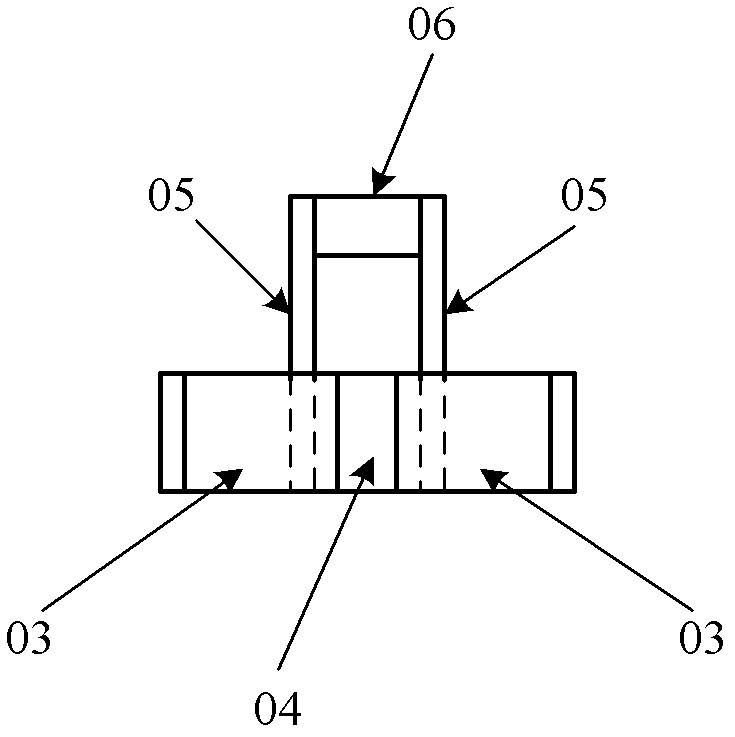

X-shaped connection double-limb buckling-restrained brace

PendingCN112709344AReduce earthquake actionTo achieve the purpose of energy consumption and shock absorptionProtective buildings/sheltersShock proofingEarthquake resistanceArchitectural engineering

The invention discloses an X-shaped connection double-limb buckling-restrained brace, and relates to the technical field of earthquake resistance and disaster prevention of building structures. The X-shaped connection double-limb buckling-restrained brace comprises a buckling-restrained brace member part, a reset connecting piece and an X-shaped connecting piece. According to the X-shaped connection double-limb buckling-restrained brace, four independent buckling-restrained brace members ingeniously form the X-shaped connection double-limb buckling-restrained brace through reset connection and X-shaped connection, the energy dissipation and shock absorption capacity of a single buckling-restrained brace is reserved, and meanwhile, the overall energy dissipation and shock absorption capacity of the buckling-restrained brace is improved through the ingenious design of the reset connection part and the X-shaped connection part; and the buckling-restrained brace has certain self-resetting capacity after the structure is subjected to load action such as earthquake through springs, and the secondary energy dissipation and shock absorption capacity of the buckling-restrained brace is improved.

Owner:CHONGQING UNIV

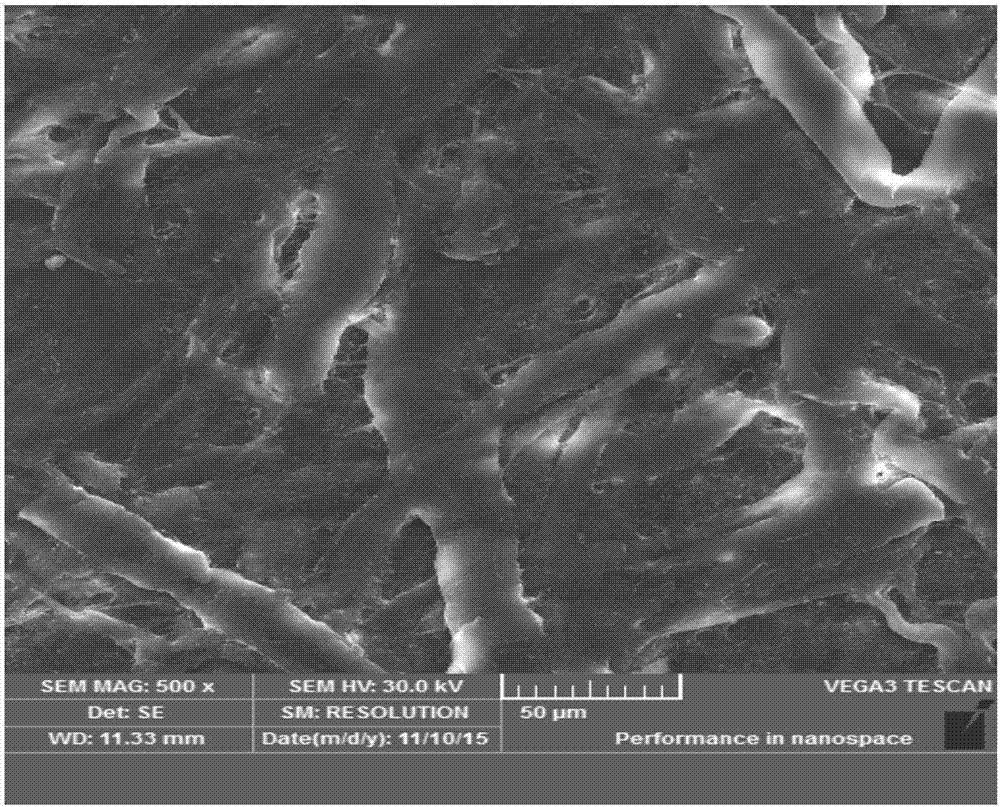

Method for preparing cellulose nanocrystalline sponge material

The invention relates to a method for preparing a cellulose nanocrystalline sponge material. The method comprises the following steps: 1) mixing pretreated biomass cellulose with mixed acid, performing a reaction for 2-10 hours at 50-130 DEG C, after the reaction is completed, performing water washing and centrifugal treatment, and adjusting the pH value of the mixed liquid to be 7 so as to obtain a cellulose nanocrystalline suspension; and 2) pouring the obtained cellulose nanocrystalline suspension into plastic molds of different shapes, and performing freeze-drying, thereby obtaining the cellulose nanocrystalline sponge material of a designed shape. The material is simple and feasible and rapid and efficient in preparation process, is extracted from biomass cellulose, is capable of turning waste into wealth, is green, environmental-friendly and reproducible, and can be degraded in a multifunctional complete biological manner. The obtained cellulose nanocrystalline has the characteristics of an ultra-high length-diameter ratio, a shape of a long nanowire, molecular chain windable self-assembling molding, massive nanocrystalline surface modification groups, an efficient netting effect and the like.

Owner:ZHEJIANG SCI-TECH UNIV

Color-changing upper sealing plate for plastic heat-insulating bottle plug

InactiveCN105694273AImprove anti-agingGood flexibilityThermally-insulated vesselsEpoxyFerric hydroxide

The invention provides a color-changing upper sealing plate for a plastic heat-insulating bottle plug. The upper sealing plate is produced by compounding the raw materials in parts by weight: 45 parts of PVC (polyvinyl chloride), 12 parts of polyester resin, 1.5 parts of epoxy resin, 0.5 part of ferric hydroxide, 1.5 parts of pigment, 2.5 parts of titanium dioxide, 2.5 parts of ultra-fine barium, 1. 2 parts of flatting agent, 0.8 part of brightener, 0.1 part of graphene, 1.2 parts of nano-titanium nitride, 3.5 parts of nanosilicon dioxide, 0.8 part of rare-earth mixture, 0.5 part of phosphotungstic acid, 0.5 part of quartz and 2.5 parts of modified zeolite powder. The upper sealing plate provided by the invention has the characteristic of color changing along with temperature, such that the temperature of a plug body can be judged according to the color change; the raw material components are reasonable in proportion; graphene nanoplatelets are added to promote the coloring performance of a material, such that the material has excellent chemical resistance and weather resistance; the modified zeolite powder is added to ensure that the material is dispersed more easily in a compounding manner; the temperature of the extrusion compounding process is reduced; the upper sealing plate has a natural color, high strength and good cracking resistance.

Owner:蚌埠市万达塑料制品有限公司

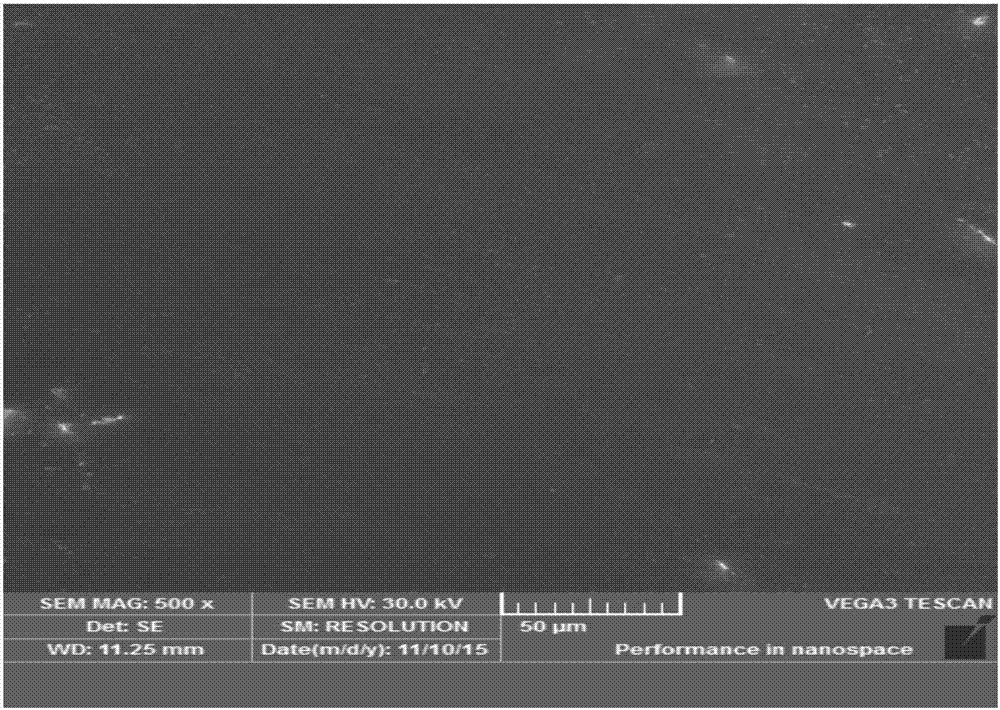

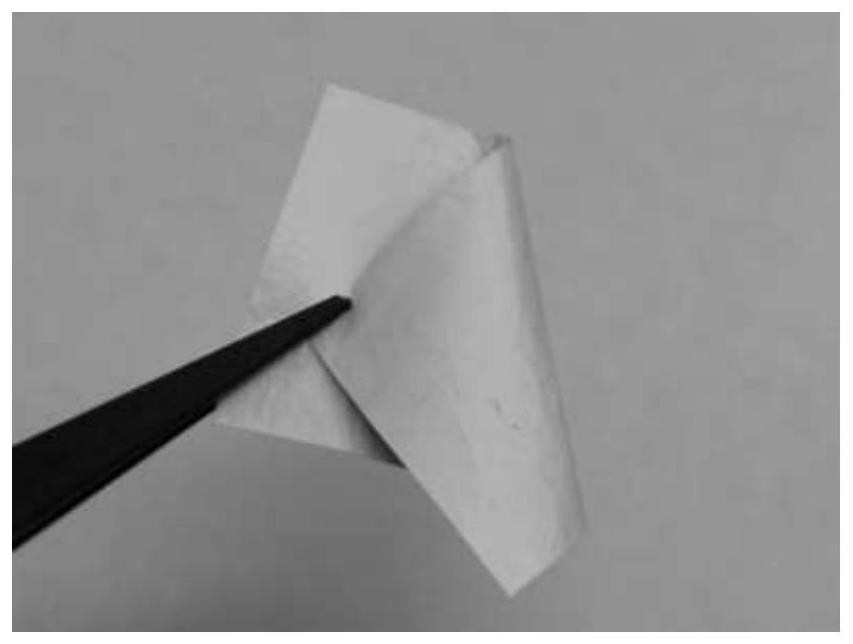

Preparation method of shape memory polyurethane coating solution

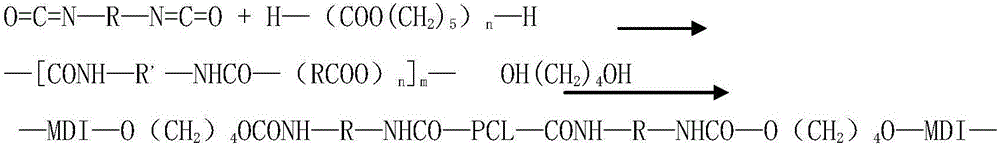

ActiveCN105524289BNo potential toxicityNo toxicityNon-fibrous pulp additionPaper/cardboardGlass transitionPrepolymer

The invention provides a preparation method and application of a shape memory polyurethane film laminating solution, belonging to the field of surface modification of materials. The objective of the invention is to overcome the problem that conventional paper products are prone to generation of creases and wearing during usage. The preparation method for the shape memory polyurethane film laminating solution comprises the following steps: 1, adding dry DMF and MDI into dehydrated PCL and carrying out a reaction at 70 to 80 DEG C so as to obtain a prepolymer; 2, adding 1,4-BDO and DMF into the prepolymer and carrying out a chain extension reaction at 70 to 80 DEG C so as to obtain a linear SMPU solution; 3, coating a glass plate with the linear SMPU solution and carrying out drying so as to obtain shape memory polyurethane; and 4, adding DMF so as to prepare the solution. A paper product is immersed into the shape memory polyurethane solution and then dried so as to obtain a laminated film. When a paper product coated with the film creases, the film is heated to a temperature higher than the glass-transition temperature of the polymer, so the paper product becomes smooth again.

Owner:HARBIN INST OF TECH

Solar cell graphite boat electrode holder and solar cell graphite boat

ActiveCN103137783AAvoid deformationExtended service lifeFinal product manufactureSemiconductor/solid-state device manufacturingGraphiteSolar cell

The invention discloses a solar cell graphite boat electrode holder and a solar cell graphite boat. Steel sheets are respectively arranged on the outer sides of clamping pieces of the electrode holder and the two steel sheets are connected through a welding block to limit the loosening position of the clamping pieces, and due to the fact that the steel sheets are good in elasticity and shape recovering capacity, the steel sheets play a certain role in calibrating the clamping pieces, deformation of the electrode holder is prevented, generation of chromatic aberration pieces caused by the deformation of the electrode holder is avoided, the service life of the electrode holder can be greatly prolonged, and production cost is reduced.

Owner:JETION SOLAR HLDG

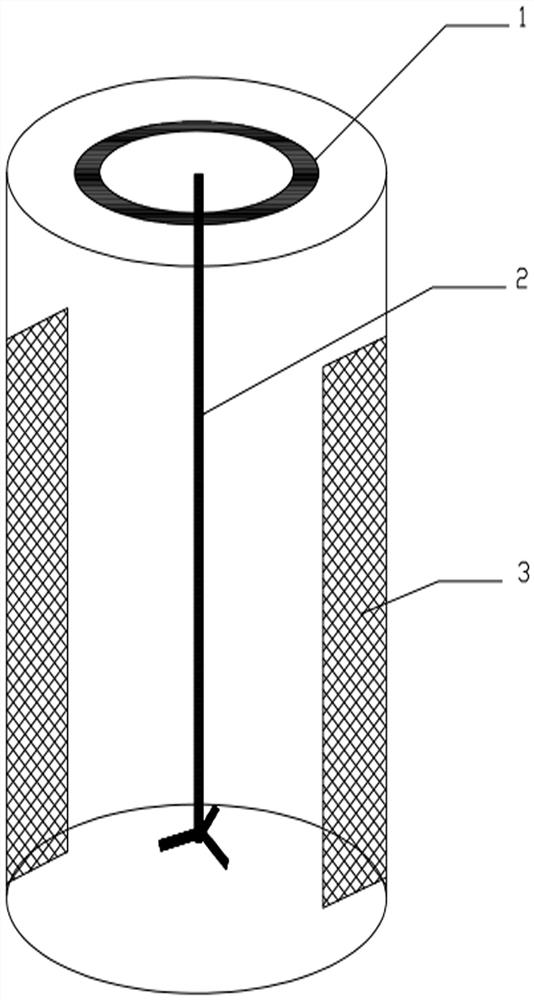

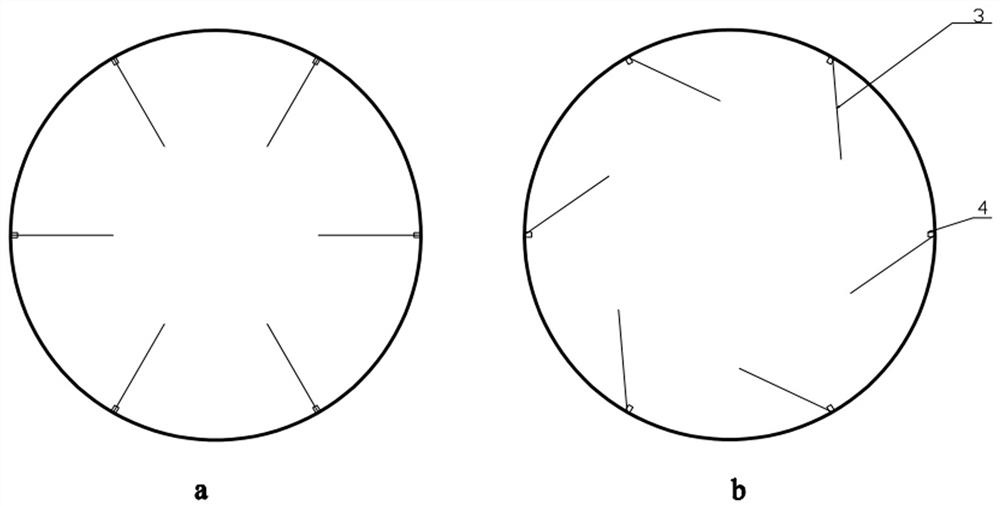

Composite resin aerogel in sewage treatment and application thereof

PendingCN112604669AReduce turbidityReduce chromaWater/sewage treatment by irradiationOther chemical processesCellulosePolymer science

The invention provides a composite resin aerogel, which is obtained by compounding an organic resin prepared from glycidyl methacrylate, divinyl benzene and ethylene glycol dimethacrylate with activated cellulose, then modifying with 3-alpha-furyl acrylic acid, and carrying out circulating freeze drying; or compounding the activated cellulose with organic resin, modifying with 3-alpha-furyl acrylic acid, loading a photocatalyst, and carrying out circulating freeze drying to obtain the product. The invention further provides a specific preparation method of the composite resin aerogel and an application method of the composite resin aerogel in sewage treatment, the process is simple, the effect is excellent, the aerogel is wrapped in the stainless steel grids, so that the contact area between the aerogel and sewage is large enough, the integrity of the aerogel is protected, and the aerogel can be repeatedly used; the composite resin aerogel is high in porosity, large in specific surface area, excellent in shape recovery performance, excellent in heavy metal ion adsorption performance, capable of being resolved and regenerated, capable of being recycled for multiple times and good in application potential.

Owner:张倩茹

Nylon-coated thermoplastic elastomer

The invention relates to a nylon-coated thermoplastic elastomer, which is prepared from the following raw materials in parts by weight: 10 to 20 parts of styrene-ethylene / butylene / styrene-styrene copolymer, 5 to 10 parts of a plasticizer, 10 to 15 parts of a nylon elastomer, 12 to 18 parts of a maleic anhydride graft, 3 to 10 parts of calcium carbonate and 10 to 15 parts of a composite bonding enhancer, the composite bonding enhancer is formed by mixing a main agent and a synergistic aid according to the weight ratio of 1: 5; as a thermoplastic elastomer, the nylon-coated thermoplastic elastomer has good toughness and hand feeling, the copolymer is adopted as a base material, and compared with a common SEBS material, the styrene-ethylene / butylene / styrene-styrene copolymer has damping performance and flowing performance, has better compatibility with a polar material and has better wettability to nylon plastic, and the nylon elastomer is added, and the nylon elastomer a filler can meet the wettability of the material and improve the coating capacity.

Owner:GUANGDONG KEYUE NEW MATERIAL CO LTD

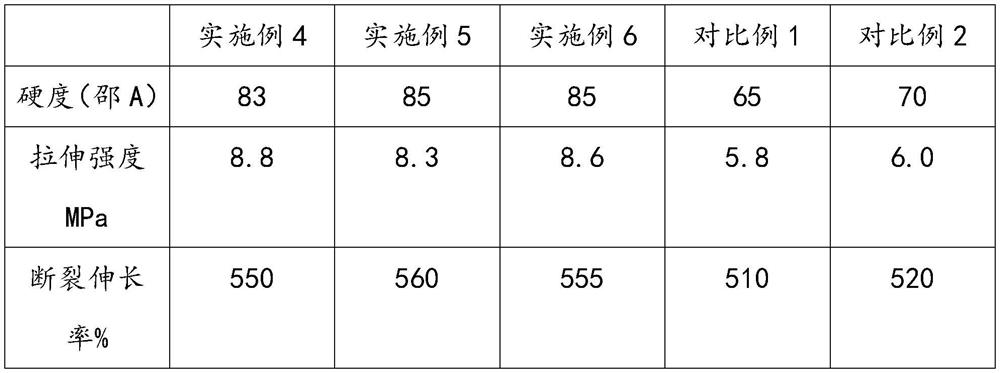

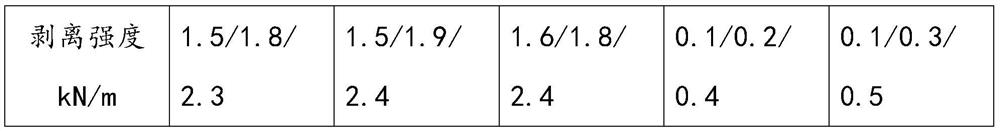

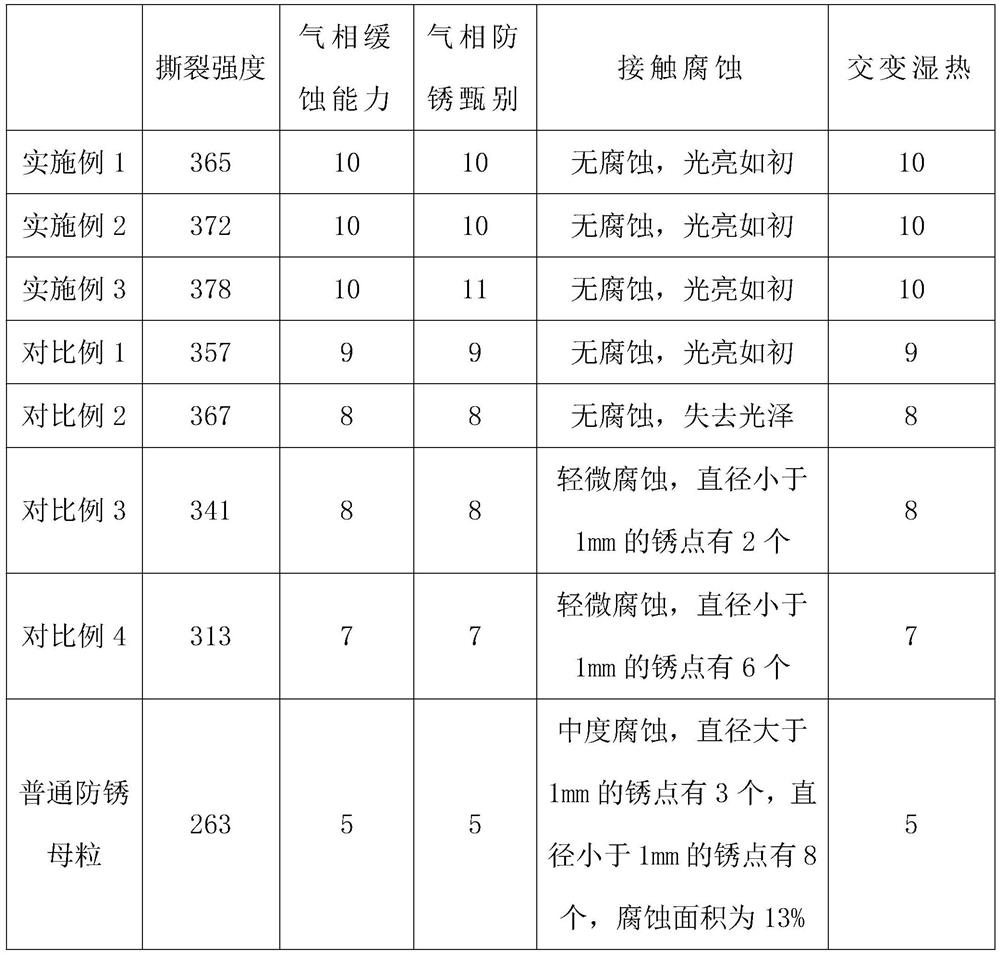

Antirust master batch and preparation process thereof

The invention discloses an antirust master batch and a preparation process thereof. The antirust master batch is prepared from, by weight, 43-57 parts of carrier resin, 31-39 parts of an antirust agent and 12-18 parts of an assistant, wherein the carrier resin is prepared from, by weight, 100 parts of polypropylene, 7-20 parts of polyethylene, 2-15 parts of coumarone resin and 5-10 parts of modified polyurethane. According to the invention, through setting of the components and the proportions, processes and parameters of the components, the prepared antirust master batch has relatively high antirust performance, mechanical strength and mechanical property; the basic performance is provided for the prepared gas-phase antirust film; the tearing damage of the prepared gas-phase antirust filmis avoided; meanwhile, some raw materials do not need to be added for functional compensation, and the prepared antirust master batch further has certain viscosity and sealing performance, so that the prepared gas-phase antirust film can adsorb and get close to metal and metal products, the gaps between the gas-phase antirust film and the metal and metal products are reduced and dried, the effects of isolating air and preventing corrosion are achieved, and the gas-phase antirust master batch is suitable for wide application and popularization.

Owner:CHANGZHOU TIANWANG PLASTIC IND CO LTD

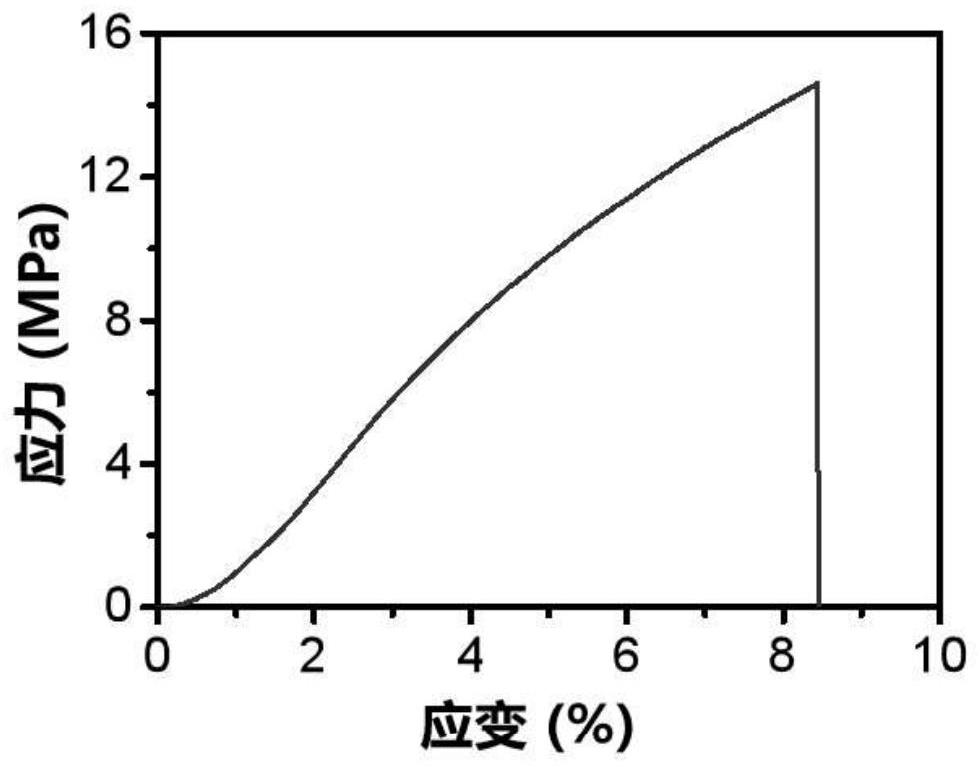

A kind of water stimulus response rubber composite material and preparation method thereof

The invention discloses a water-stimulus-responsive rubber composite material and a preparation method thereof. The present invention comprises the following raw materials in parts by weight: 30-80 parts of nitrile rubber, 20-70 parts of polyethylene oxide, 0.8-1.6 parts of vulcanizing agent, 0-5 parts of processing aids; the present invention also provides the above-mentioned rubber In the preparation method of the composite material, the above raw materials are mixed and vulcanized to obtain the rubber composite material. The present invention adopts traditional rubber polymer materials and functional polymer materials to combine, and through mixing and vulcanization, a kind of rubber composite material with water stimulus response is prepared, which is a new type of stimulus response rubber composite material, which improves The utilization value of the shape memory polymer material is realized. The rubber composite material is uniform in texture, has a cross-linked network structure, and does not have problems such as delamination. The conversion temperature range is always between room temperature and body temperature, and has better shape memory fixation and shape. Recovery performance, widely used in biomedical and other fields.

Owner:QINGDAO UNIV OF SCI & TECH

Preparation method of transparent self-adaptive shape memory polymer anti-wrinkle body film solution

ActiveCN105919833AExtended service lifeExcellent shape recovery performanceCosmetic preparationsToilet preparationsDimethyl formamidePrepolymer

The invention discloses a preparation method of a transparent self-adaptive shape memory polymer anti-wrinkle body film solution. The preparation method comprises the following steps: conducting drying treatment on DMF (dimethyl formamide) by virtue of a molecular sieve (as shown in Description), so that dried DMF is obtained, vacuum dehydrating liquid PCL (polycaprolactone) in a reaction container, then adding the dried DMF and MDI (diphenylmethane diisocyanate) under a condition of argon protection, and conducting reacting under stirring at 70-80 DEG C for 1.5-2.5h, so that a prepolymer is obtained; adding 1,4-BDO (1,4-butanediol) and the dried DMF to the prepolymer, and conducting a chain extension reaction under a condition of 70-80 DEG C, so that a linear SMPU (shape memory polyurethane) solution which contains 13-18% of solids is obtained; uniformly coating a glass plate with the linear SMPU solution, performing drying in an oven at 70-100 DEG C for 12-15h, and conducting placing at room temperature for 22-26h, so that shape memory polyurethane is obtained; and adding the shape memory polyurethane and the dried DMF to a reaction flask, preparing a solution which contains 5-10% by mass of the shape memory polyurethane, and performing magnetic stirring until the polyurethane is completely dissolved, so that the shape memory polymer anti-wrinkle body film solution is obtained.

Owner:HARBIN INST OF TECH

Preparation method of transparent adaptive shape-memory polymer wrinkle-removing film solution

ActiveCN105919833BNo potential toxicityExtended service lifeCosmetic preparationsToilet preparationsPolymer scienceButanediol

Owner:HARBIN INST OF TECH

A shape memory polymer material containing eucommia rubber and its preparation method

ActiveCN110591188BGood dispersionRetains thermotropic shape memory propertiesPolymer scienceHydroxyethyl cellulose

The invention discloses a shape memory polymer material containing eucommia rubber and a preparation method thereof. The invention comprises the following raw materials in parts by weight: 100 parts of Eucommia rubber, 10-30 parts of functional filler, 0.5-3 parts of vulcanizing agent, and 0-5 parts of processing aid; Eucommia rubber is carboxyl-modified Eucommia rubber, and the functional filler is Any one or more of microcrystalline cellulose, hydroxymethyl cellulose, hydroxyethyl cellulose, hydroxypropyl cellulose, starch, water-soluble chitin, and gelatin. The present invention also provides the preparation method of the above polymer material. In the present invention, the functional carboxyl group on the carboxyl-modified eucommia rubber reacts with the hydroxyl group on the surface of the functional filler, which not only can retain the thermally induced shape memory performance of the original matrix material, but also endows the polymer material with a strong resistance to water stimulation. Responsive function, so that the polymer material has the performance of synergistic response to dual stimuli of water and heat, which improves the mechanical properties and expands the scope of application.

Owner:QINGDAO UNIV OF SCI & TECH

Water stimulation response rubber composite material and preparation method thereof

The invention discloses a water stimulation response rubber composite material and a preparation method thereof. The rubber composite material comprises the following raw materials in parts by weight:30-80 parts of nitrile rubber, 20-70 parts of polyethylene oxide, 0.8-1.6 parts of a vulcanizing agent and 0-5 parts of a processing aid. The invention further discloses a preparation method of the rubber composite material. The rubber composite material is prepared from the raw materials through mixing and vulcanization. A conventional rubber high polymer material and a functional high polymer material are compounded to prepare the rubber composite material with water stimulation response through mixing and vulcanization, the rubber composite material is a novel stimulation response rubber composite material, the utilization value of a shape memory high polymer material can be increased, the rubber composite material has a uniform texture, is of a cross-linked network structure, is freeof problems such as delamination, has a transition temperature interval between room temperature and body temperature constantly, has good properties of shape memory fixation and shape recovery, and can be widely applied to fields such as biological medical treatment.

Owner:QINGDAO UNIV OF SCI & TECH

Solar cell graphite boat electrode clip and solar cell graphite boat

ActiveCN103137783BAvoid deformationExtended service lifeFinal product manufactureSemiconductor/solid-state device manufacturingGraphiteSolar cell

The invention discloses a solar cell graphite boat electrode holder and a solar cell graphite boat. Steel sheets are respectively arranged on the outer sides of clamping pieces of the electrode holder and the two steel sheets are connected through a welding block to limit the loosening position of the clamping pieces, and due to the fact that the steel sheets are good in elasticity and shape recovering capacity, the steel sheets play a certain role in calibrating the clamping pieces, deformation of the electrode holder is prevented, generation of chromatic aberration pieces caused by the deformation of the electrode holder is avoided, the service life of the electrode holder can be greatly prolonged, and production cost is reduced.

Owner:JETION SOLAR HLDG

Curable resin composition, composition for molding, resin molded article, and method for producing resin molded article

InactiveUS20180237599A1High elongationExcellent shape recovery performancePolymer chemistryRadical polymerization

Disclosed is a curable resin composition that includes radical polymerizable monomers including a monofunctional radical polymerizable monomer, a linear or branched polymer containing a polyoxyalkylene chain, and a radical polymerization initiator.

Owner:HITACHI CHEM CO LTD

Curable resin composition, composition for molding, resin molded article, and method for producing resin molded article

Owner:RESONAC CORPORATION

Manufacturing method and application of shape-memory polymer leather wrinkle-removing finishing material

ActiveCN105693996BImprove molding abilityImprove covering abilityPolyurea/polyurethane coatingsLeather surface finishingWrinkle skinMolecular sieve

The invention provides shape memory polymer leather anti-wrinkling coating material manufacturing and leather anti-wrinkling application. A manufacturing method includes the steps that DMF is dried through a molecular sieve to obtain dried DMF, liquid PCL is placed in a reaction container for vacuumizing and dehydration, then dried DMF and MDI are added under the argon protection condition, a stirring reaction is conducted for 1.5-2.5 h at the temperature of 70-80 DEG C, and a prepolymer is obtained; 1,4-BDO and the dried DMF are added into the prepolymer obtained in the first step, a chain extension reaction is conducted at the temperature of 70-80 DEG C, and a linear SMPU solution with the solid content being 13-18% is obtained, namely a shape memory polymer leather anti-wrinkling coating material. Leather anti-wrinkling application includes the steps that an SMPU solution is evenly coated on the leather with the clean surface, the leather is placed in an oven at the temperature of 60-90 DEG C to be dried for 10-18 h, the leather is placed at room temperature for 20-28 h, and a leather product coated with the shape memory polymer leather anti-wrinkling coating material is obtained.

Owner:HARBIN INST OF TECH

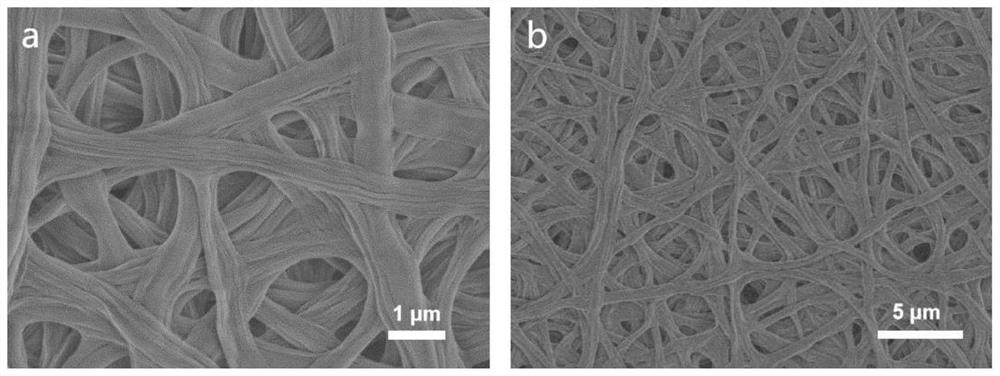

Electrostatic spinning polyimide uniform small-aperture nanofiber membrane as well as preparation method and application thereof

ActiveCN114277509AUniform pore sizeUniform Small ApertureSemi-permeable membranesFilament/thread formingFiberImide

The invention provides an electrostatic spinning polyimide uniform small-aperture nanofiber membrane as well as a preparation method and application thereof, and belongs to the technical field of electrostatic spinning nanofiber membrane materials. The preparation method comprises the following steps: firstly, mixing polyamic acid and polystyrene, carrying out electrostatic spinning, then removing the polystyrene component in the obtained polyamic acid / polystyrene composite nanofiber membrane through heat treatment, and finally obtaining the electrostatic spinning polyimide uniform small-aperture nanofiber membrane. Compared with the conventional electrostatic spinning polyimide nanofiber membrane, the electrostatic spinning polyimide uniform small-aperture nanofiber membrane prepared by the method has the advantages of smaller aperture, more uniform aperture distribution and better mechanical property. The preparation process is simple and easy to operate, and the prepared nanofiber membrane is high in yield, good in comprehensive performance and extremely wide in application range.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com