X-shaped connection double-limb buckling-restrained brace

A technology of anti-buckling braces and connectors, which is applied in the direction of earthquake resistance, building types, buildings, etc., can solve the problems of buckling-resistant braces’ overall buckling instability and withdrawal, so as to improve the ability of secondary energy consumption and shock absorption, good shape recovery ability, Improve the effect of energy dissipation and shock absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

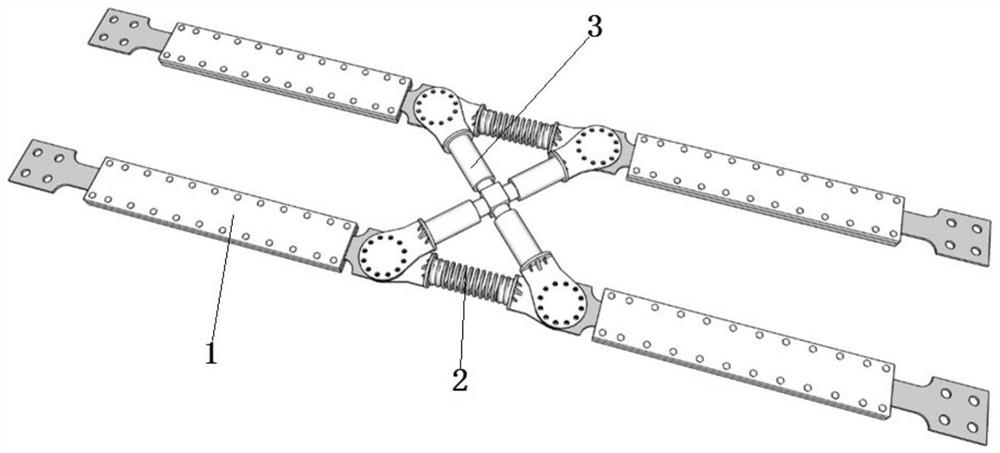

[0041] This embodiment discloses an X-shaped joint anti-buck support for both limbs, which includes an anti-buck support member 1 , a reset connector 2 and an X-shaped connector 3 .

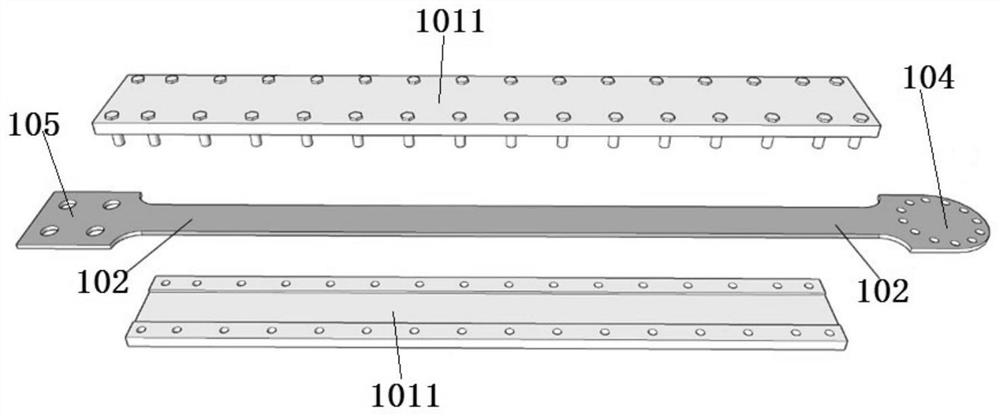

[0042] The anti-buckling support member 1 includes a supporting shell 101 and an energy-dissipating core material 102 , and the material yield value of the energy-dissipating core material 102 is smaller than that of the supporting shell 101 .

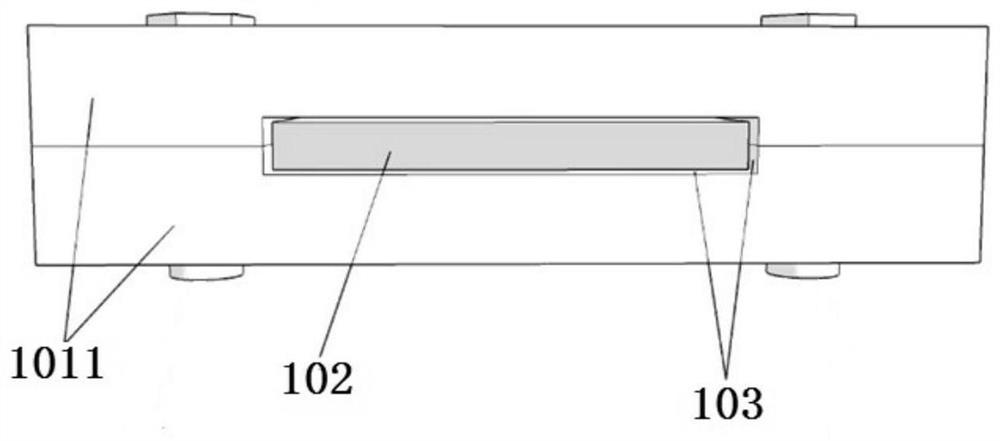

[0043] see figure 2 , the supporting shell 101 is spliced by two constraining plates 1011, and one side of the constraining plate 1011 is provided with a rectangular through-slot running through both ends thereof.

[0044] The slots of the two constraining plates 1011 face each other and are connected by several bolts. The two rectangular through slots are spliced to form a cavity S. The energy-dissipating core material 102 in the shape of a rectangular plate is installed in the two cavities S. The energy-dissipating core material The two ends of 10...

Embodiment 2

[0058] The structure of this embodiment is similar to that of Embodiment 1, the difference is that the structure of the anti-buckling support member 1 is different, specifically, see Figure 7 Or 8, the support shell 101 of this embodiment is a round tube, and the support shell 101 is filled with fillers 106 to form a cavity S with an in-line cross section, and the energy-dissipating core material 102 with a in-line cross-section is installed in the cavity S, Two ends of the energy dissipation core material 102 protrude from the supporting shell 101 . The two protruding ends of the energy dissipation core material 102 are integrally formed with a joint I 104 and a joint II 105 .

[0059] see Figure 8 , a filling material 103 is arranged between the energy dissipation core material 102 and the filling 106 .

Embodiment 3

[0061] The structure of this embodiment is similar to that of Embodiment 2, the difference is that the cross-sectional shape of the cavity S is different, specifically, see Figure 9 , the supporting shell 101 of this embodiment is filled with fillers 106 to form a cavity S with a cross-shaped cross-section, and the energy-dissipating core material 102 with a cross-shaped cross-section is installed in the cavity S. Extend the support case 101 . The two protruding ends of the energy dissipation core material 102 are integrally formed with a joint I 104 and a joint II 105 .

[0062] see Figure 9 , a filling material 103 is arranged between the energy dissipation core material 102 and the filling 106 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com