Shape memory high polymer material with eucommia ulmoides rubber and preparation method of shape memory high polymer material

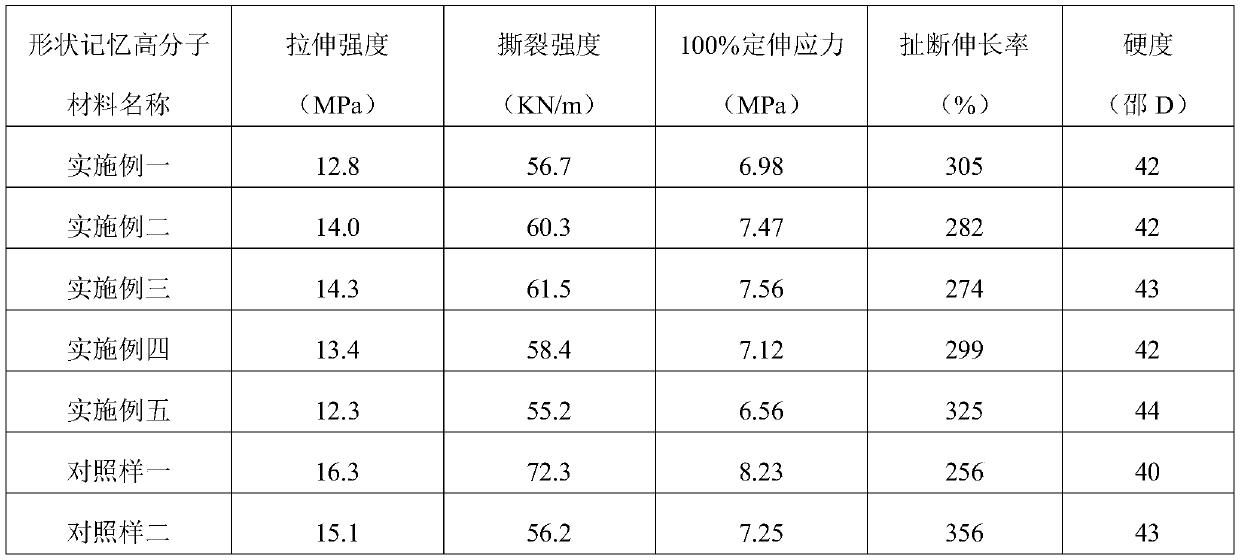

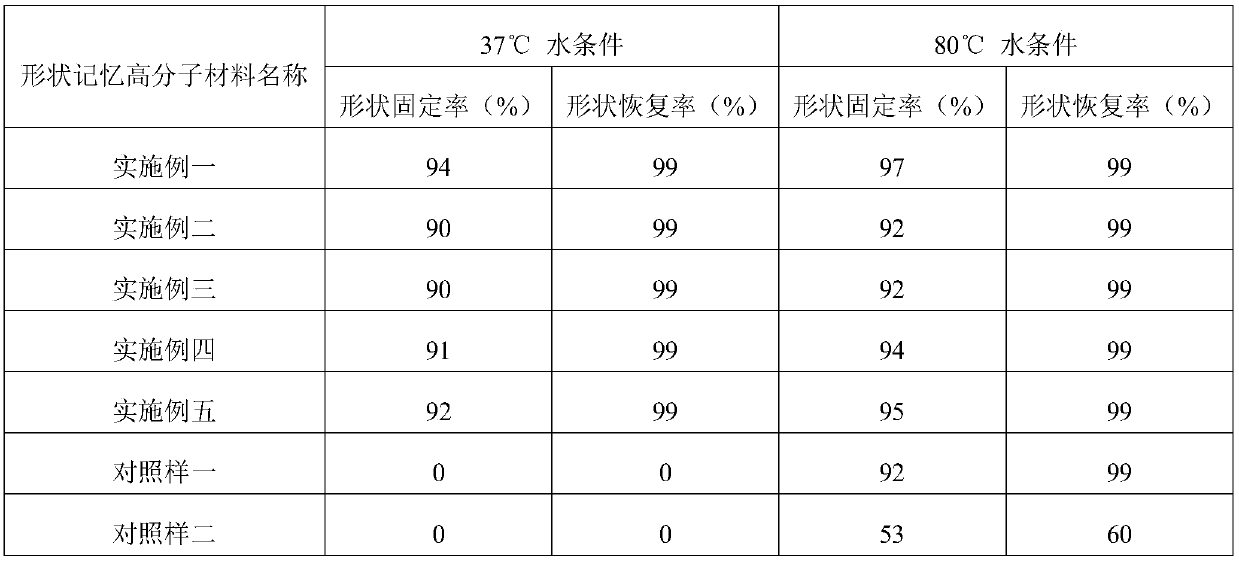

A technology of polymer materials and eucommia rubber, which is applied in the field of shape memory polymer materials containing eucommia rubber and its preparation, can solve the problems of complex preparation methods, high cost, and large environmental pollution, so as to expand the scope of application and enhance sports ability , Improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A preparation method of a shape-memory polymer material containing eucommia rubber of the present invention comprises the following steps:

[0028] Mixing process, in the double-roller mill, adjust the roller temperature to 90-130°C, add Eucommia rubber, wrap the roller; after it is completely wrapped evenly, add functional fillers, and mix; after mixing evenly, add Processing aid, thin pass 3-5 times left and right; add vulcanizing agent, thin pass 3-5 times left and right; adjust the roller distance to 1-3mm, and unload the film; park for 18-24h, re-melt, thin pass 3-5 times; The roller distance is adjusted to 1-3mm, and the film is lowered;

[0029] Vulcanization process, the vulcanization temperature is 150-160°C, and the vulcanization time is 20-30min to obtain polymer materials.

[0030] Preferably, in the mixing process, the wrapping time is 4-10 minutes.

[0031] Further, in the mixing process, the mixing time is 4-10 minutes.

[0032] Specifically, in the mi...

Embodiment 1

[0034] A preparation method of a shape-memory polymer material containing eucommia rubber of the present invention comprises the following steps:

[0035] 1) Weigh the following raw materials in parts by weight in turn: 100 parts of carboxy-modified Eucommia rubber (EUG-COOH), 30 parts of microcrystalline cellulose (MCC), 0.5 parts of vulcanizing agent DCP, 5 parts of processing aids, including 2 parts of antioxidant MB and 3 parts of compatibilizer;

[0036] 2) Mixing process. In the double-roller mill, adjust the roll temperature to 90°C, add EUG-COOH, and cover the rolls; after it is completely covered with rolls, add functional filler—MCC, and mix; After uniformity, add processing aids - compatibilizer polycyclooctene and anti-aging agent MB, thin pass 3 times left and right; add vulcanizing agent - dicumyl peroxide (DCP), thin pass 3 times left and right; adjust roller When the gap is 1.7mm, the next film is parked for 24 hours, re-smelting, thin pass 5 times; the roller...

Embodiment 2

[0039] A preparation method of a shape-memory polymer material containing eucommia rubber of the present invention comprises the following steps:

[0040] 1) Weigh the following raw materials in order by weight: 100 parts of carboxy-modified eucommia rubber (EUG-COOH), 10 parts of hydroxyethyl cellulose, 1.0 parts of vulcanizing agent-sulfur, 1 part of processing aid, including 1 part of anti-aging agent MB, the modification ratio of carboxyl-modified Eucommia rubber is 1%, that is, the carboxyl content in the carboxyl-modified Eucommia rubber is 1%;

[0041] 2) Mixing process. In the double-roller mill, adjust the roll temperature to 130°C, add carboxy-modified Eucommia rubber, wrap the roll, and wrap the roll for 4 minutes; after it is completely wrapped evenly, add functional fillers— -Hydroxyethyl cellulose, mixing, mixing time is 4min; after mixing evenly, add processing aid - anti-aging agent MB, and pass 5 times left and right; add vulcanizing agent - sulfur, pass 5 tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com