Nylon-coated thermoplastic elastomer

A thermoplastic elastomer and coating technology, which is applied in the field of nylon coated thermoplastic elastomer, can solve the problems of general coating performance, general shock absorption effect, sticky hands, etc., and achieve improved hand feeling, shock absorption performance and good shape recovery ability , good toughness and hand feeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The composite adhesion enhancer is formed by mixing the main agent and the synergistic auxiliary agent according to a weight ratio of 1:5, and the main agent comprises the following steps:

[0025] Step S1. Add 1,5-pentanediamine to absolute ethanol, stir at a constant speed for 15 minutes, then add sebacic acid, continue to stir and react for 36 hours, slowly crystallize during the reaction, filter and wash with suction, collect crystals, and store at 65°C Vacuum drying to obtain an intermediate, controlling the molar ratio of 1,5-pentanediamine and sebacic acid to be 1:1;

[0026] Step S2: Add hexamethylenediamine adipate and intermediates into a reaction kettle equipped with deionized water, stir at a constant speed and add caprolactam, pass in nitrogen to exhaust the air, heat up to 240°C, and maintain the pressure in the reaction kettle at 1.6 MPa, keep warm and react for 2 hours to prepare the main agent, control the molar ratio of hexamethylene adipate and caprol...

Embodiment 2

[0031] The composite adhesion enhancer is formed by mixing the main agent and the synergistic auxiliary agent according to a weight ratio of 1:5, and the main agent comprises the following steps:

[0032] Step S1: Add 1,5-pentanediamine to absolute ethanol, stir at a constant speed for 15 minutes, then add sebacic acid, continue to stir and react for 36 hours, slowly crystallize during the reaction, filter and wash with suction, collect crystals, and store at 65°C Vacuum drying to obtain an intermediate, controlling the molar ratio of 1,5-pentanediamine and sebacic acid to be 1:1;

[0033]Step S2: Add hexamethylenediamine adipate and intermediates into a reaction kettle equipped with deionized water, stir at a constant speed and add caprolactam, pass in nitrogen to exhaust the air, heat up to 240°C, and maintain the pressure in the reaction kettle at 1.6 MPa, keep warm and react for 2 hours to prepare the main agent, control the molar ratio of hexamethylene adipate and caprola...

Embodiment 3

[0038] The composite adhesion enhancer is formed by mixing the main agent and the synergistic auxiliary agent according to a weight ratio of 1:5, and the main agent comprises the following steps:

[0039] Step S1: Add 1,5-pentanediamine to absolute ethanol, stir at a constant speed for 15 minutes, then add sebacic acid, continue to stir and react for 36 hours, slowly crystallize during the reaction, filter and wash with suction, collect crystals, and store at 65°C Vacuum drying to obtain an intermediate, controlling the molar ratio of 1,5-pentanediamine and sebacic acid to be 1:1;

[0040] Step S2: Add hexamethylenediamine adipate and intermediates into a reaction kettle equipped with deionized water, stir at a constant speed and add caprolactam, pass in nitrogen to exhaust the air, heat up to 240°C, and maintain the pressure in the reaction kettle at 1.6 MPa, keep warm and react for 2 hours to prepare the main agent. Control the molar ratio of hexamethylene adipate and caprol...

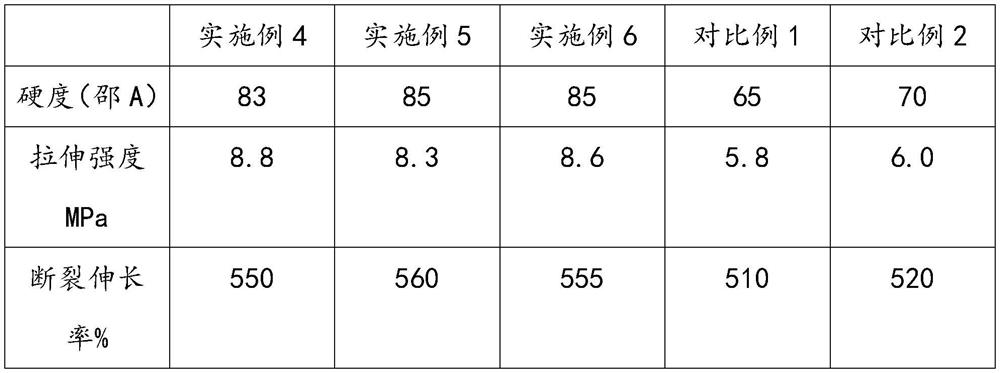

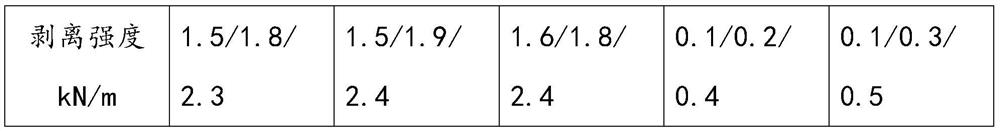

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com