Cosmetic puff

a puff and cosmetic technology, applied in the field of cosmetic puffs, can solve the problems of difficult to remove cosmetics sufficiently, damage to the surface material of the puff, and difficult to use the entire puff, etc., and achieve the effects of easy removal, excellent shape restorability, and comfortable feeling on the skin surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0060]A puff using a sponge sheet for its core and a double raschel knitted fabric for the outer side was manufactured according to a normal method. The finished dimensions of the puff were 60 mm in outer diameter, 16 mm in thickness and 8 mm in core thickness, and the ribbon part under which the fingers, etc., were to be guided had a width of 12 mm.

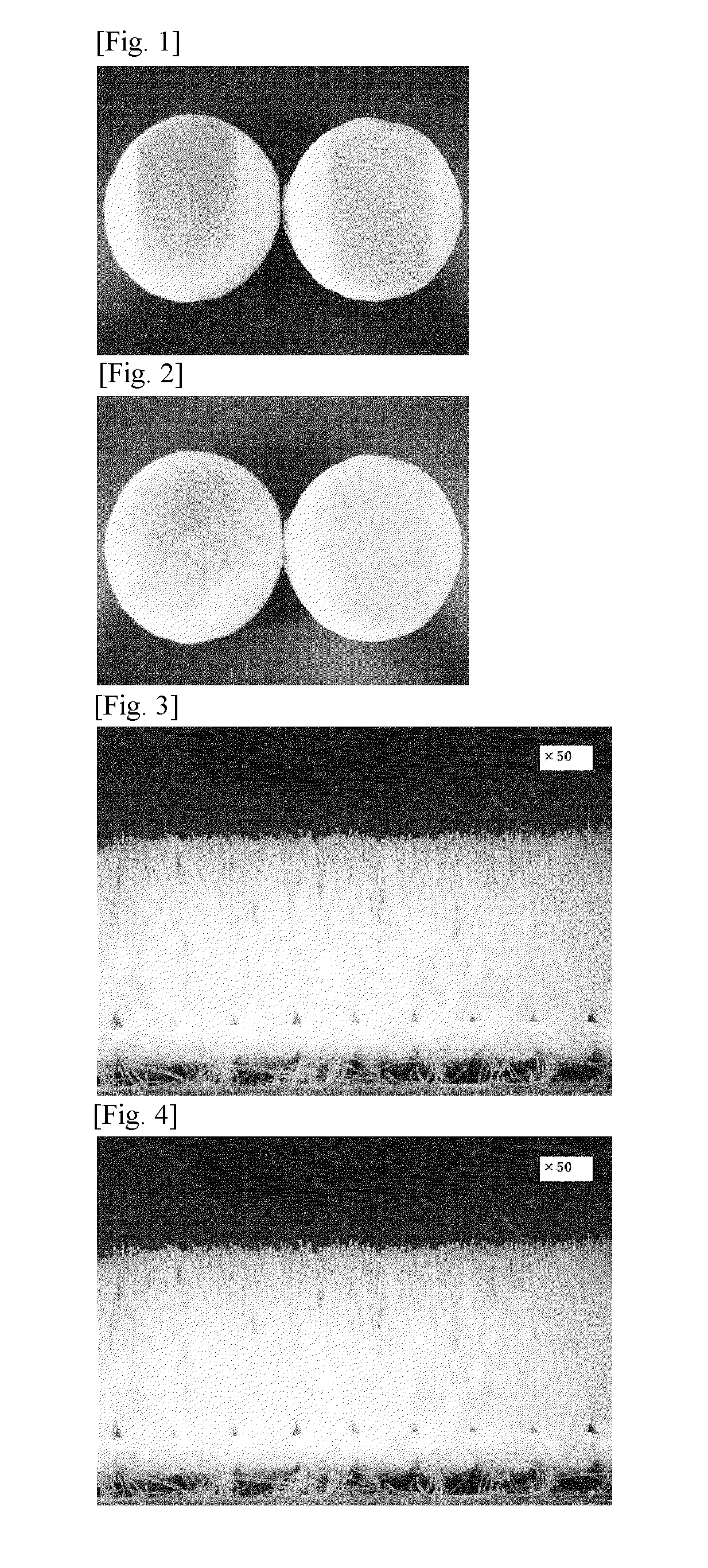

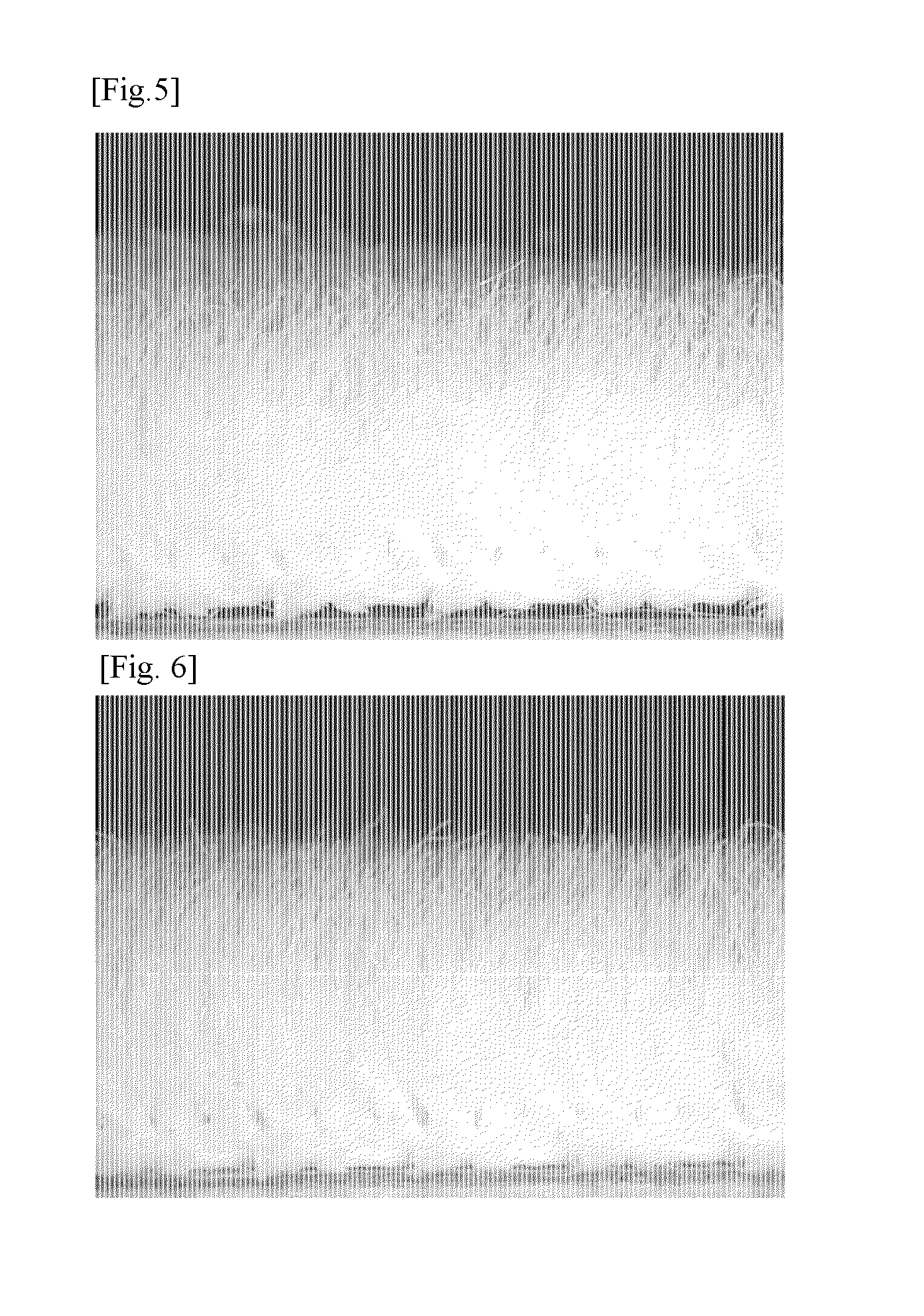

[0061]Additionally, another puff was manufactured in the same manner, except that a tricot knitted fabric was used for the outer side. FIGS. 1 to 6 show the conditions of the respective puffs after a cosmetic had been scraped off and applied to the skin. In FIG. 1, the puff on the left used a tricot knitted fabric, while the puff on the right used a double raschel knitted fabric (the same applies to FIG. 2 hereinafter).

[0062]Using these puffs made of two different knitted fabrics, a powder cosmetic was scraped off by applying an equivalent force. FIG. 1 shows the resulting conditions, and it can be understood that the puff using a double...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com