High-strength self-repair three-network hydrogel preparation method

A hydrogel and self-healing technology, which is applied in the field of preparation of high-strength self-healing hydrogels, can solve the problems of not showing self-healing properties, hydrogels without self-healing properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Step 1: Preparation of polyacrylic acid / agar / polyvinyl alcohol composite solution

[0016] Take 20 parts of deionized water, 1.6 parts of polyvinyl alcohol and 0.3 parts of agar into the reaction kettle, stir at 95°C for 2 hours, then add 4 parts of acrylic acid monomer, chemical crosslinking agent ( N'N-dimethylbisacrylamide) 0.06 part and ferric chloride 0.3 part, after uniform stirring to form a mixed solution, then add 0.1 part of initiator persulfate after deoxygenating the mixed solution, and obtain polyacrylic acid after fully stirring / polyvinyl alcohol / agar composite solution, set aside.

[0017] Step 2: Preparation of polyacrylic acid / agar / polyvinyl alcohol triple network hydrogel

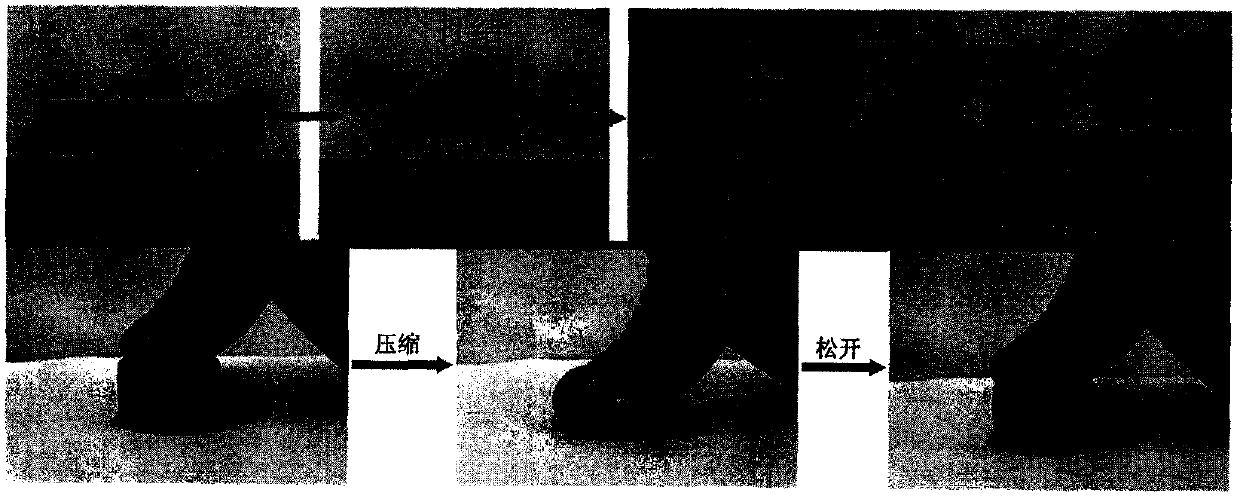

[0018] Take 5 parts of polyacrylic acid / agar / polyvinyl alcohol composite solution, pour it into a mold, and then put the mold at 60°C for 2 hours to form the first layer of polyacrylic acid-Fe 3+ Then put the mold at 5°C to cool for 1 hour to form the second layer of agar netw...

Embodiment 2

[0020] Step 1: Preparation of polyacrylic acid / agar / polyvinyl alcohol composite solution

[0021] Take 20 parts of deionized water, 0.4 parts of polyvinyl alcohol and 0.1 part of agar into the flask, stir at 90°C for 1 hour, then add 1 part of acrylic acid monomer, chemical crosslinking agent (N 0.01 part of 'N-dimethylbisacrylamide) and 0.1 part of ferric chloride, uniformly stirred to form a mixed solution, then added 0.01 part of initiator ammonium persulfate after deoxygenating the mixed solution, and obtained polyacrylic acid / Polyvinyl alcohol / agar compound solution, set aside.

[0022] Step 2: Preparation of polyacrylic acid / agar / polyvinyl alcohol triple network hydrogel

[0023] Take 10 parts of polyacrylic acid / agar / polyvinyl alcohol composite solution, pour it into a mold, put the mold at 70°C and react for 2 hours to form the first layer of polyacrylic acid-Fe 3+ Network, then freeze the mold at -20°C for 3 hours, then thaw for 3 hours to form the second layer of ...

Embodiment 3

[0025] Step 1: Preparation of polyacrylic acid / agar / polyvinyl alcohol composite solution

[0026] Take 10 parts of deionized water, 1.6 parts of polyvinyl alcohol and 0.5 parts of agar into the flask, stir at 85°C for 1.5h, then add 4 parts of acrylic acid monomer, chemical crosslinking agent ( N'N-dimethylbisacrylamide) 0.06 part and ferric chloride 0.4 part, after uniform stirring to form a mixed solution, then add 0.1 part of initiator ammonium persulfate after deoxygenating the mixed solution, and obtain polyacrylic acid after fully stirring / polyvinyl alcohol / agar composite solution, set aside.

[0027] Step 2: Preparation of polyacrylic acid / agar / polyvinyl alcohol triple network hydrogel

[0028] Take 5 parts of polyacrylic acid / agar / polyvinyl alcohol composite solution, pour it into a mold, and then put the mold at 65°C for 1 hour to form the first layer of polyacrylic acid-Fe 3+ Then put the mold at 8°C to cool for 2 hours to form the second layer of agar network,...

PUM

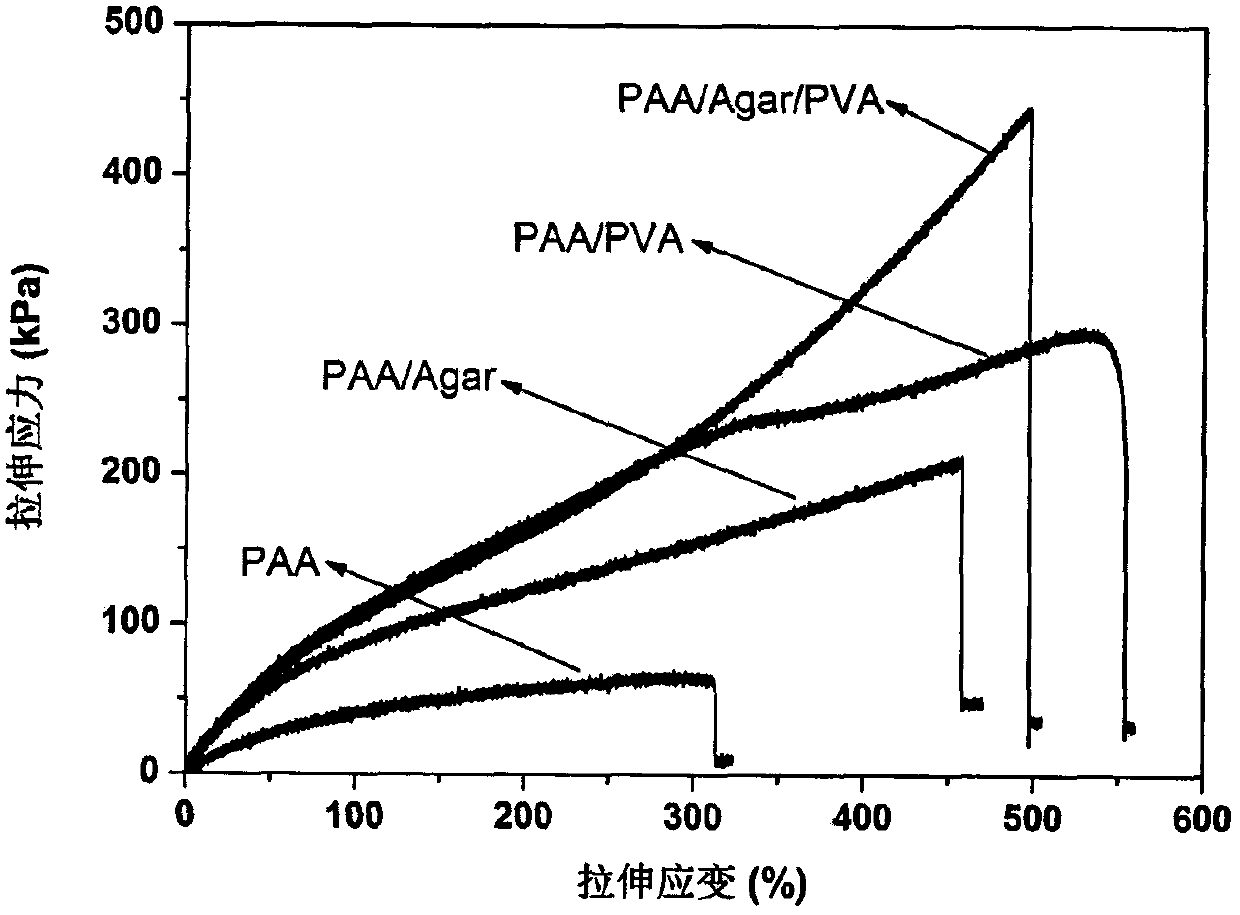

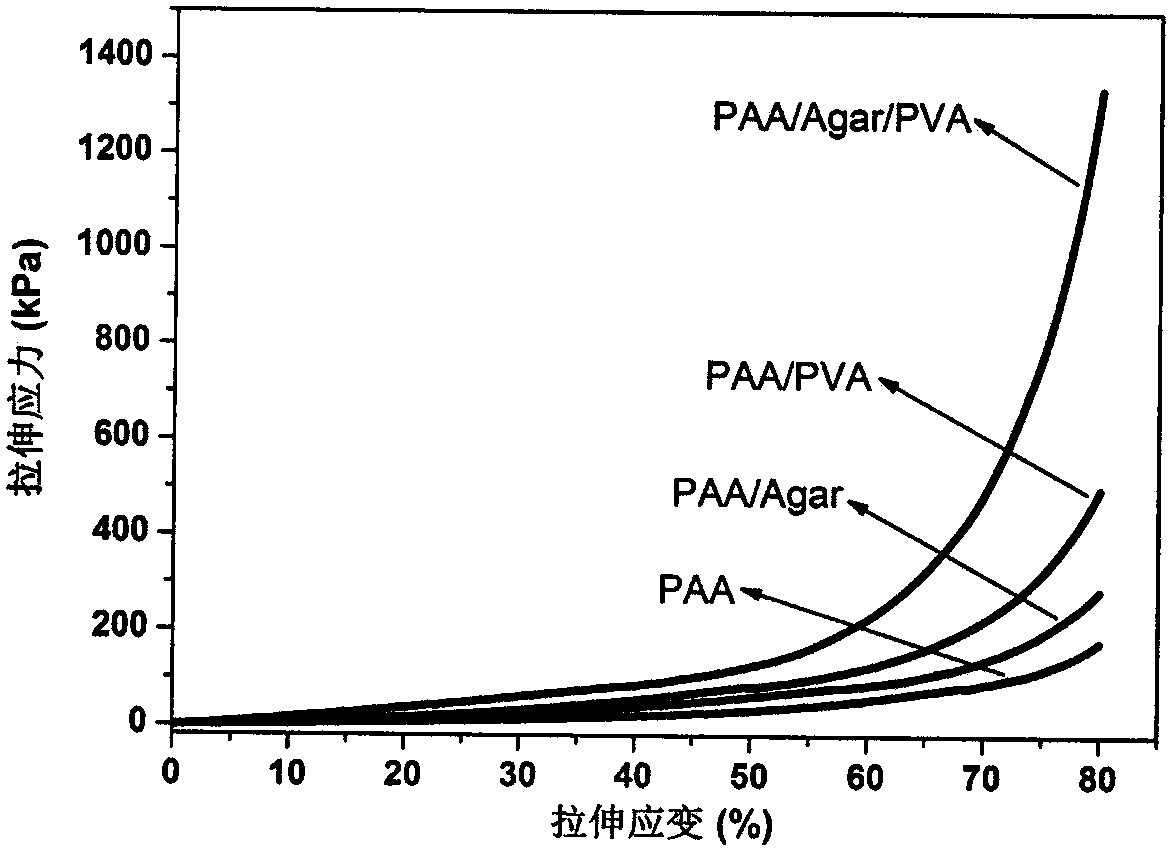

| Property | Measurement | Unit |

|---|---|---|

| tensile stress | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com