Sealing strips for bridge steel expansion joints

An expansion joint and section steel technology, applied in bridges, bridge construction, bridge parts, etc., can solve the problems of displacement deformation performance, poor elastic recovery performance, inability to adapt to the displacement deformation of bridge expansion joints, etc., to achieve low material density and improve labor efficiency. , the effect of simple installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

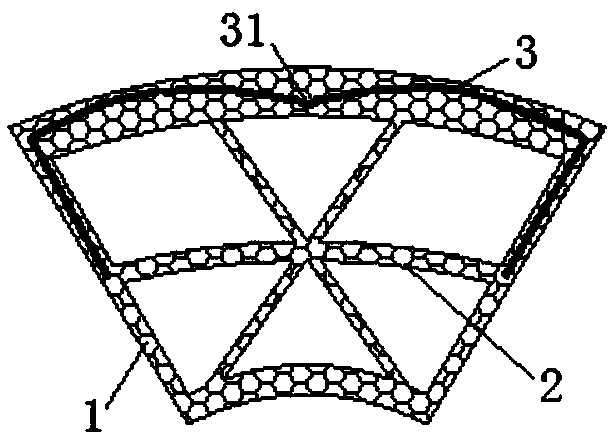

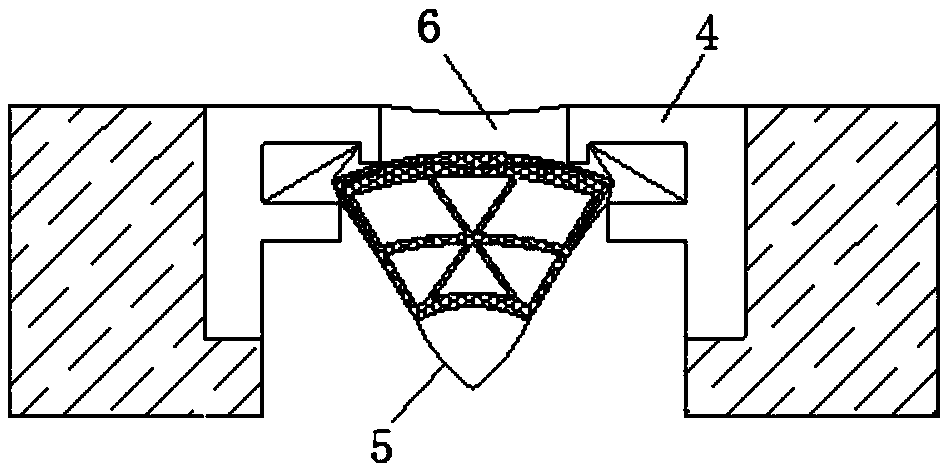

[0027] Referring to the accompanying drawings, a caulking liner is used for the expansion joints of bridge shaped steel. A pair of shaped steel 4 are arranged on both sides of the expansion joint as mirror images of each other to form the shaped steel expansion joints. The inner sides of the shaped steel 4 are provided with grooves with openings facing the expansion joints; The two ends of the strip 5 are respectively embedded in the groove, and the middle of the sealing strip 5 is lower than the two ends, so as to form an upward slot with the shaped steel 4 on both sides; it is characterized in that:

[0028] The caulking strip is used to be arranged in the slot, and the caulking strip has elasticity; the caulking strip includes a body 1, the body 1 has a hollow inner cavity, and the inner cavity is provided with a The skeleton 2 supporting the body, and the skeleton 2 has elasticity;

[0029] The top surface of the body 1 is a convex arc surface; and an elastic layer 3 is sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com