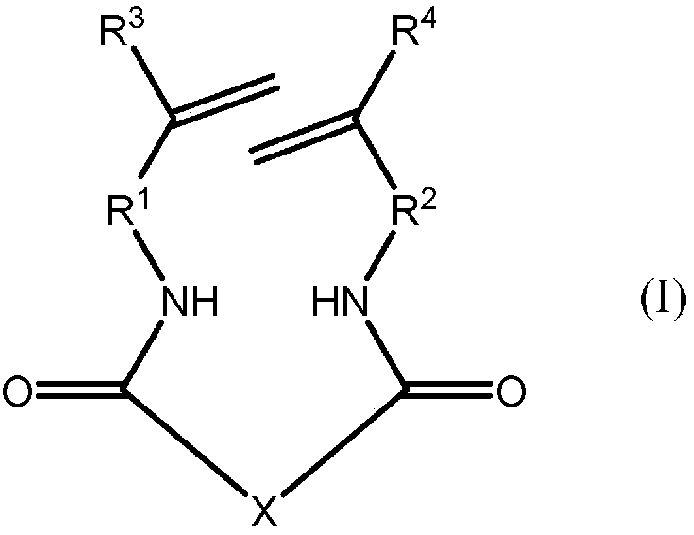

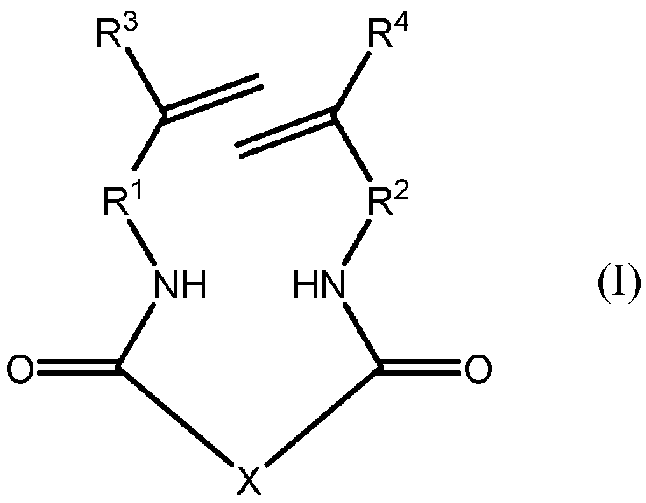

Curable resin composition, composition for molding, resin molded article, and method for producing resin molded article

A technology of curable resins and resin moldings, applied in the field of curable resin compositions, can solve problems such as easy cracking and brittle moldings, achieve high elongation at break, improve shape recovery speed, stress relaxation and water resistance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0142] Hereinafter, an Example is given and this invention is demonstrated further concretely. However, the present invention is not limited to these Examples.

[0143] (curable resin composition)

[0144] 1. Synthesis of Polymers Containing Polyoxyalkylene Chains (Modification Polymers)

[0145] Polymer 1

[0146] After adding diol in the amount (mg) shown in Table 1 to a 20 mL round bottom flask, the inside of the flask was replaced with nitrogen, and the contents were melted at 115°C. 4,4'-Dicyclohexylmethane diisocyanate (262 mg, 1.00 mmol) was added to the molten liquid, and stirred at 115°C for 24 hours under a nitrogen atmosphere to obtain Polymer 1 containing a polyoxypropylene chain.

[0147] A GPC chromatogram of the obtained polymer was obtained at a flow rate of 1 mL / min using DMF (N,N-dimethylformamide) containing 10 mM lithium bromide as an eluent. From the obtained chromatogram, the number average molecular weight Mn of the polymer was determined as a value ...

Synthetic example 1

[0171] Synthesis Example 1: Synthesis of trans-1,2-bis(2-acryloyloxyethylcarbamoyloxy)cyclohexane (BACH)

[0172] Trans-1,2-cyclohexanediol (2.32 g, 20.0 mmol) was placed in a 100 mL two-necked round-bottom flask, and the inside of the flask was replaced with nitrogen. Dichloromethane (40 mL), and dibutyltin dilaurate (11.8 μL, 0.10 mol%: 0.020 mmol) were added thereto. A solution of 2-acryloyloxyethyl isocyanate (5.93 g, 42.0 mmol) in dichloromethane (4 mL) was added dropwise to the reaction solution in the flask from a dropping funnel, and the reaction solution was stirred at 30° C. for 24 hours to carry out reaction. After the reaction was completed, diethyl ether was added to the reaction liquid and washed with saturated brine. After the organic layer was dried over anhydrous magnesium sulfate, the solvent was distilled off under reduced pressure, and a solution containing the target compound was isolated from the residue by silica gel chromatography (elution solvent: ch...

Synthetic example 2

[0174] Synthesis Example 2: Synthesis of PEG-PPG Oligomer 1

[0175] After adding polyethylene glycol (PEG1500, 750 mg, 0.500 mmol, number average molecular weight of 1500) and polypropylene glycol (PPG4000, 2000 mg, 0.500 mmol, number average molecular weight of 4000) into a 20 mL round bottom flask, nitrogen Substitute, allowing the contents to melt at 115°C. 4,4'-Dicyclohexylmethane diisocyanate (262 mg, 1.00 mmol) was added to the molten liquid, and the molten liquid was stirred at 115° C. for 24 hours under a nitrogen atmosphere to obtain PEG-PPG oligomer 1 (containing polyoxygen ethylene chain, and the second polymer of polyoxypropylene chain).

[0176] The weight average molecular weight (Mw) of the obtained oligomer 1 was 9300, and the weight average molecular weight / number average molecular weight (Mw / Mn) of the oligomer 1 was 1.65.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com